Preparation method of special neutral packaging paperboard for preventing copper product from color change

A packaging cardboard and anti-discoloration technology, which is applied in the field of papermaking technology, can solve the problems of easy corrosion, blackening of copper materials, and formation of color spots, and achieve the effects of uniform humidity, high yield and strong binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

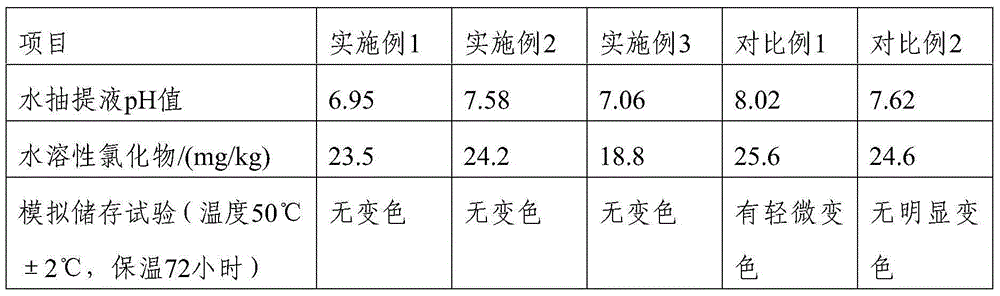

Examples

Embodiment 1

[0036] This embodiment is a production process of neutral packaging cardboard for anti-discoloration of copper materials, which specifically includes the following steps:

[0037] (1) Two kinds of high-quality natural color kraft wood pulps with different characteristics, namely Qingshan pulp and Baoqing pulp, are mixed in a hydropulper in a weight ratio of 7.5:3.5 and pulped, and then put into the rinsing tank after being dehydrated by an inclined sieve; Then use the clean water treated by reverse osmosis (the conductivity of the treated water is 28uS / mm, and the pH value is 8.0) to wash according to certain process requirements to improve the cleanliness of the slurry and reduce the residual drug content in the slurry filtrate. Reduce the residual drug content by about 30% at a time until it falls below 120mg / L, control the slurry concentration to 3.6%, and the pH value to 6.5;

[0038] (2) Slurry is transported to four double-disc refiners connected in series with a pump to...

Embodiment 2

[0043] This embodiment is a production process of neutral packaging cardboard for anti-discoloration of copper materials, which specifically includes the following steps:

[0044](1) Mix two kinds of high-quality natural color kraft wood pulp with different characteristics, that is, Qingshan pulp and Baoqing pulp, in a ratio of 7.5:2.5, and pulp them in a hydropulper, dehydrate them with an inclined screen, put them into the rinsing tank, and then use the reverse The clean water after osmosis treatment (the conductivity of the treated water is 28uS / mm, and the pH value is 5.0) is washed according to certain process requirements to improve the cleanliness of the slurry, reduce the residual drug content in the slurry filtrate, and reduce the residual after each cleaning The drug content is about 30%, until it drops below 110mg / L, the slurry concentration is controlled to 3.8%, and the pH value reaches 7.1;

[0045] (2) then use a pump to transport the paper pulp to four double-d...

Embodiment 3

[0050] This embodiment is a production process of neutral packaging cardboard for anti-discoloration of copper materials, which specifically includes the following steps:

[0051] (1) Two kinds of high-quality natural kraft wood pulp with different characteristics, namely Qingshan pulp and Baoqing pulp, are mixed in a ratio of 7:3 and pulped in a hydropulper, dehydrated by an inclined screen and put into a rinsing tank. Then use the clear water treated by reverse osmosis (the conductivity of the treated water is 30uS / mm, and the pH value is 7.0) to wash according to certain process requirements to improve the cleanliness of the slurry and reduce the residual drug content in the slurry filtrate. Reduce the residual drug content by about 30% at a time until it falls below 120mg / L, control the slurry concentration to 4.0%, and the pH value to 8.0;

[0052] (2) Then use a pump to transport the pulp to four series-connected double-disc refiners for primary refining. The semi-finish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Tensile index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com