Ultraviolet ray light tube stepless power regulating eqiupment

A technology of stepless power adjustment and ultraviolet light, applied in lighting devices, printing, light sources, etc., can solve the problems of non-adjustable power, increased use cost, high energy consumption, etc., to enhance safety and reliability, reduce energy consumption and use The effect of cost and broad market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

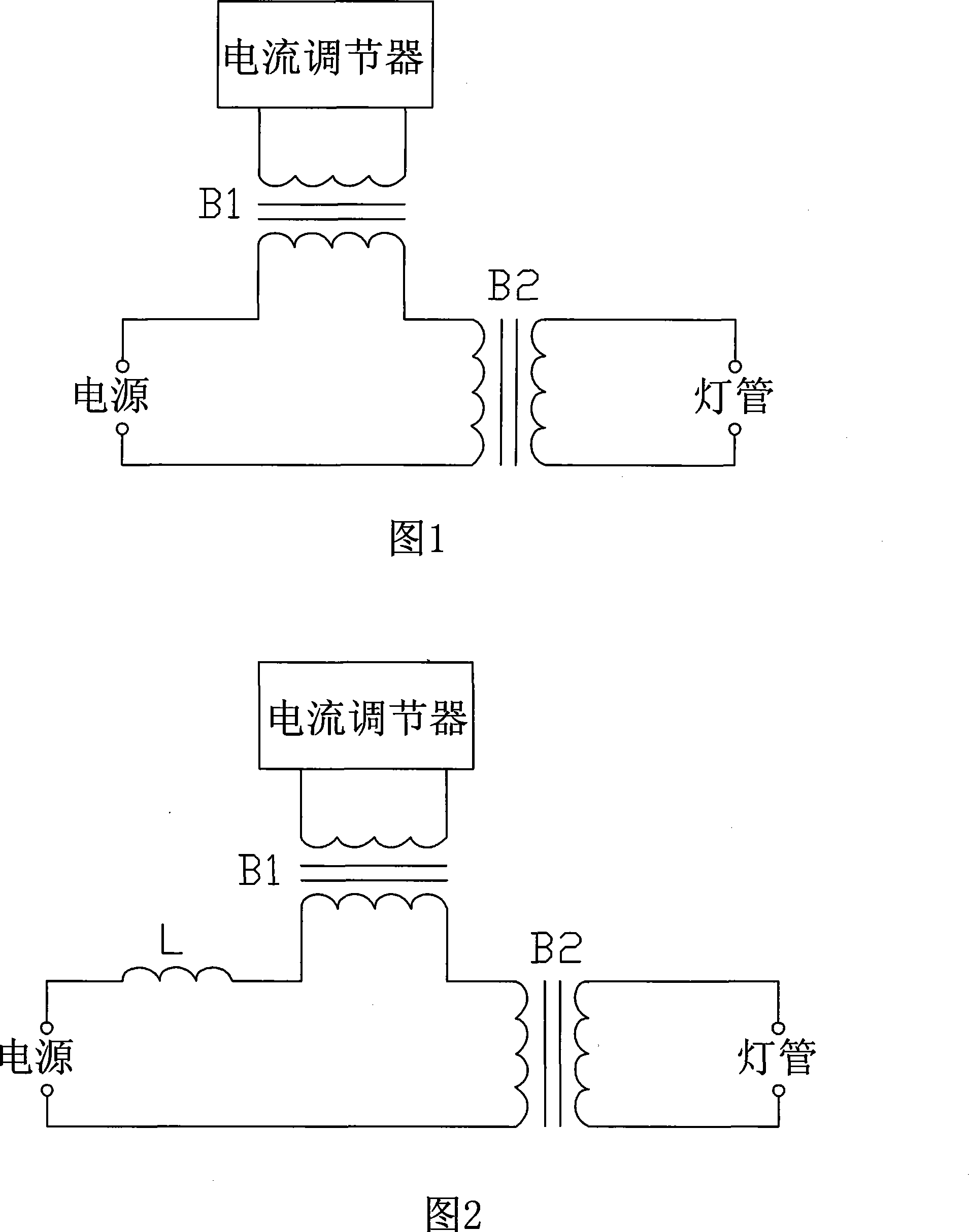

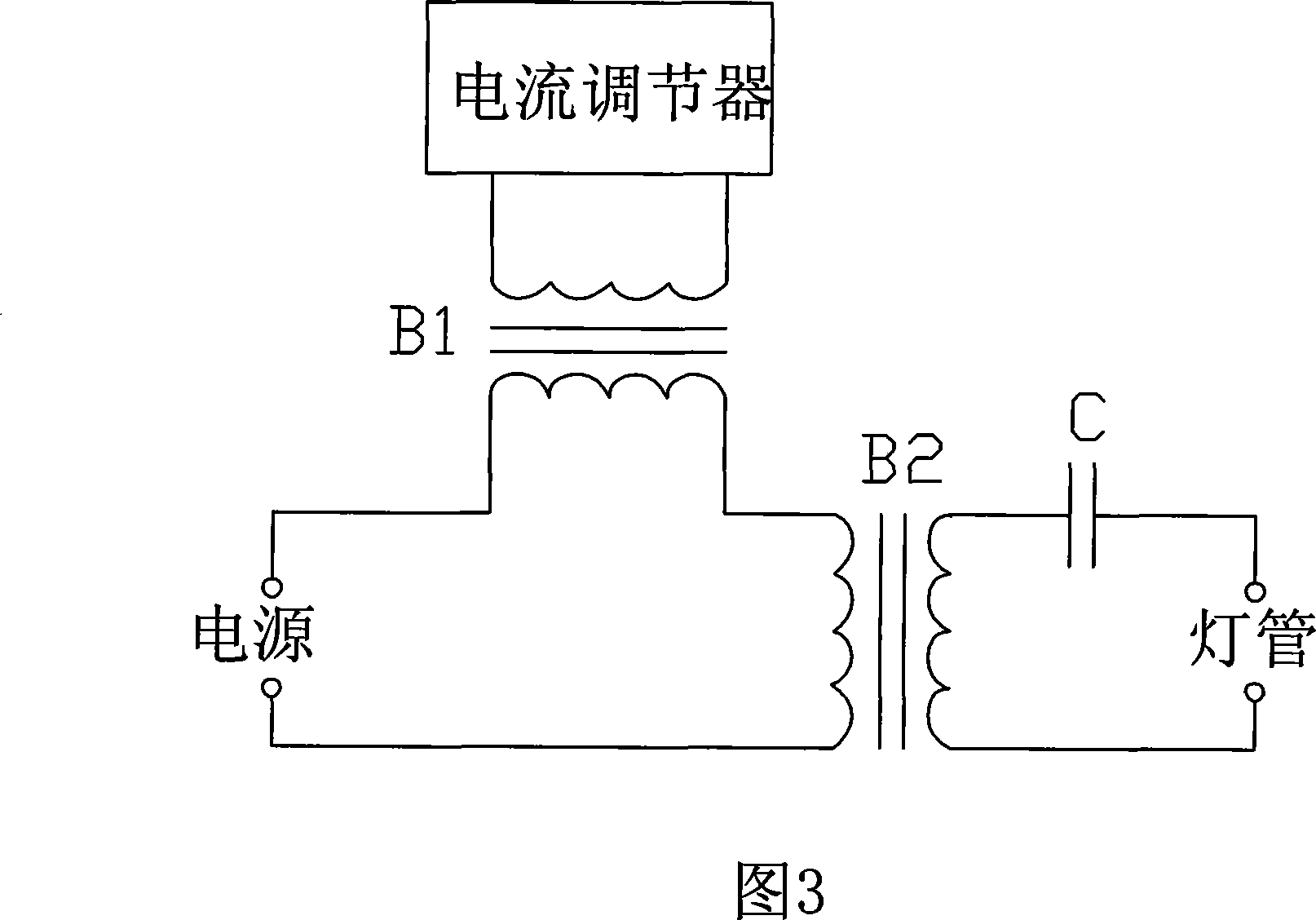

[0012] Referring to Figure 1, a stepless power regulator for ultraviolet lamps includes a step-up transformer B2, the primary side of the step-up transformer B2 is connected to the power supply, the secondary side is connected to the ultraviolet lamp, and the primary side or secondary side of the step-up transformer B2 A voltage regulator is connected for continuously adjusting the output voltage.

[0013] As a further improvement of the present invention, the voltage regulator is connected in series to the primary side of the boost transformer B2; the voltage regulator is a power regulating transformer B1, and the primary side of the power regulating transformer B1 is connected to one side of the boost transformer B2 In series, the secondary side is connected to the current regulator.

[0014] When the ultraviolet lamp is working, the power of the lamp can be determined by the voltage at the output terminal of the step-up transformer B2. Adjust the current of the current reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com