All-weather fluidized bed method grain drier

A technology of grain dryer and fluidized bed method, applied in the direction of dryer, drying solid material, drying gas arrangement, etc., can solve the problems of wind energy loss, small adhesion, difficult to be removed, etc., and achieve a pollution-free service life , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

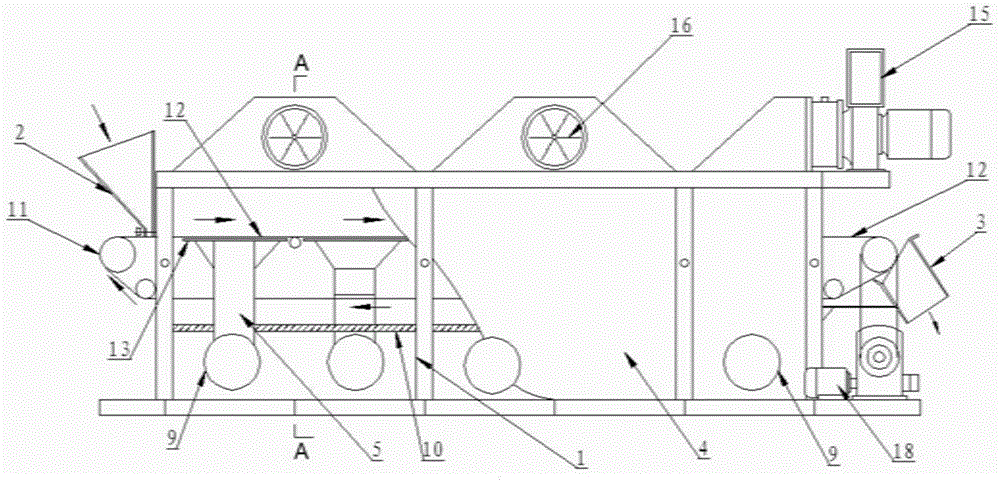

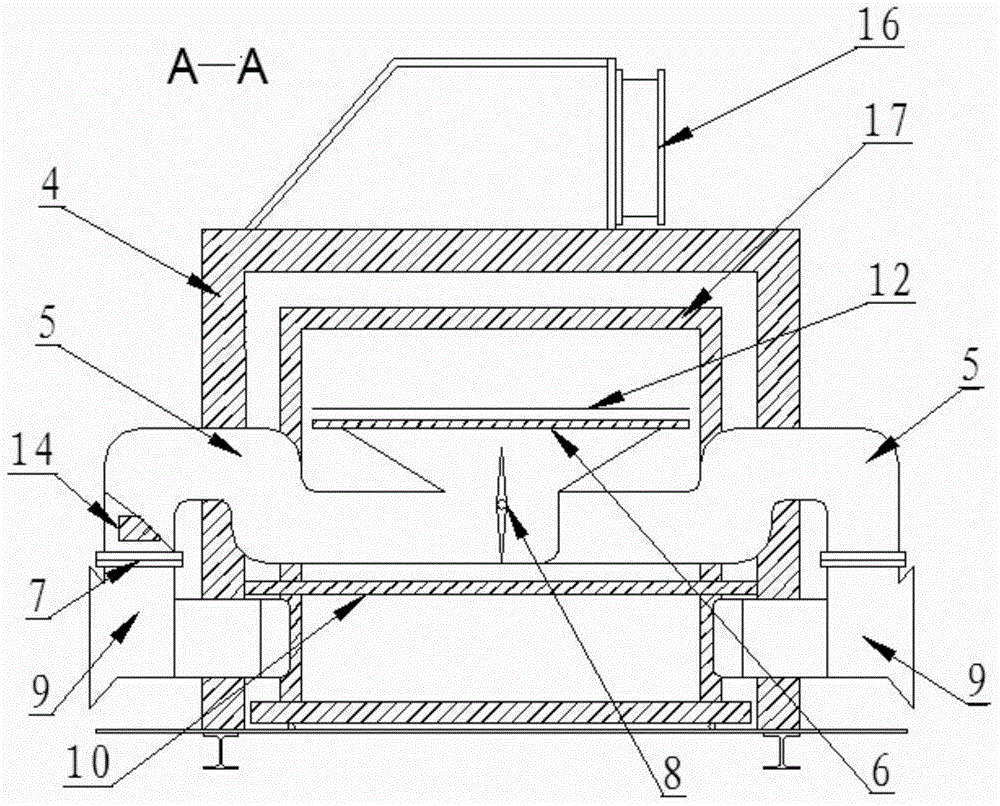

[0040] Such as figure 1 , 2 As shown, the present invention provides an all-weather fluidized bed grain dryer, comprising a support 1, a feed hopper 2 positioned at both ends of the support 1 and a discharge hopper 3, a conveying mechanism between the feed hopper 2 and the discharge hopper 3, Two dehumidification sections, one induced-air dust removal section and a protective cover 4 wrapped outside the dehumidification section and the induced-air dust removal section are placed across the conveying mechanism in sequence;

[0041] The dehumidification section is located at 2 places close to the feed hopper, and the induced wind dust removal mechanism is located at 3 places close to the discharge hopper;

[0042] The dehumidification section includes two blowing mechanisms, two heating mechanisms corresponding to the blowing mechanisms, and a dehumidification mechanism located directly above the dehumidification section. The two blowing mechanisms are respectively placed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com