Artificial turf and preparing method thereof

A peat and man-made technology, applied in botany equipment and methods, agricultural gas emission reduction, fertilizer mixture, etc., can solve problems that have not been seen yet, and achieve the effect of increasing income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

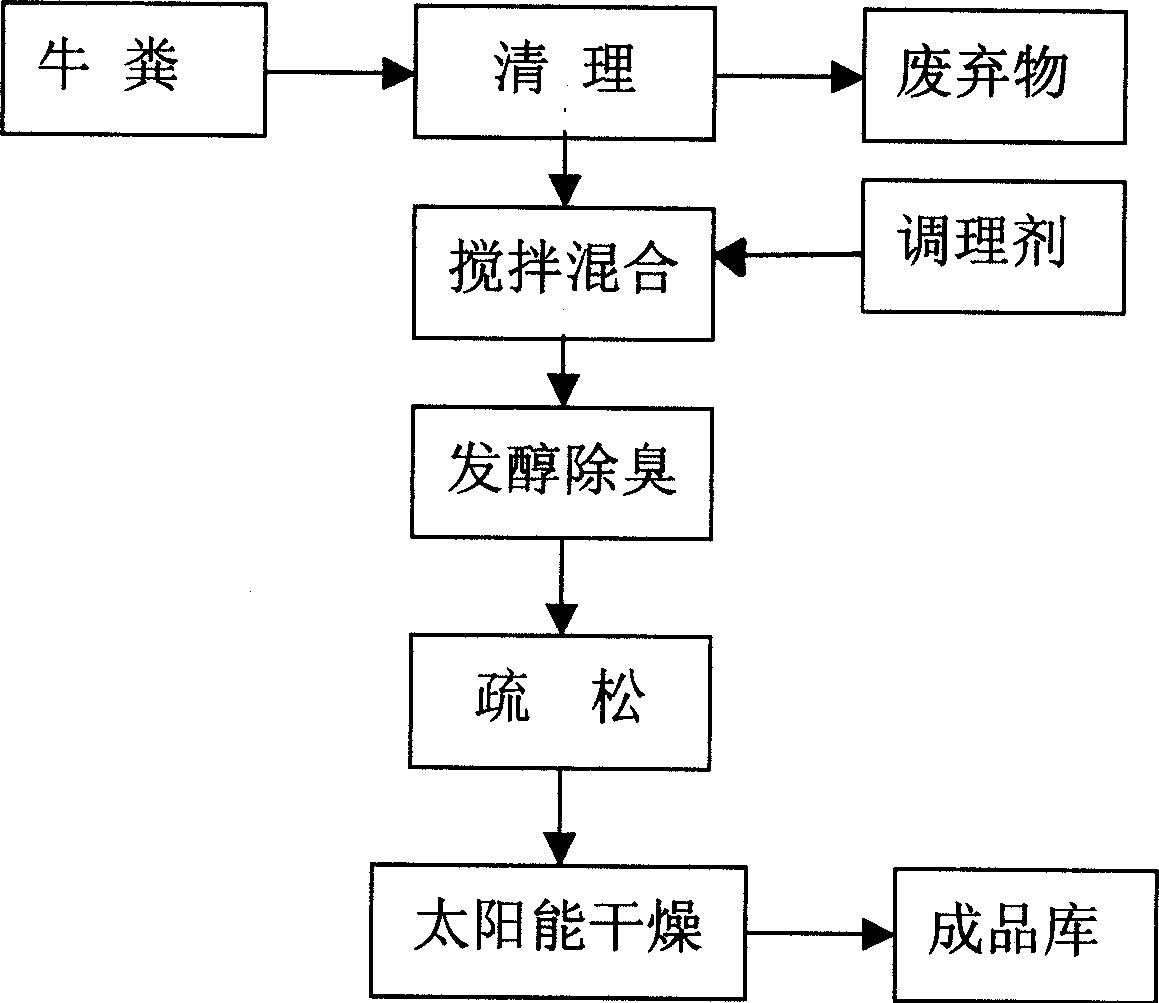

Image

Examples

Embodiment 1

[0027] First of all, clean the cow dung, remove stones, iron wires, iron nails, branches, broken wood and other sundries in the cow dung raw materials, and at the same time properly dry it to reduce the water content of the cow dung to 65%.

[0028] b) Prepare conditioner

[0029] The preparation is carried out according to the volume ratio of cow dung and conditioner, and the straw accounting for 20% of the volume of cow dung, the calcium superphosphate accounting for 0.3% of the volume of cow dung and the raw soil accounting for 1.2% of the volume of cow dung are fully mixed and stirred.

[0030] c) stir to mix

[0031] The cow dung and the conditioner are mixed and stirred evenly by using a special mixing mixer for the organic fertilizer factory.

[0032] d) Fermentation deodorization

[0033] First, 30 ml to 50 ml of biological fertilizer EM stock solution for cow dung mixed with conditioner per cubic meter {biological fertilizer EM stock s...

Embodiment 2

[0041] Repeat Example 1, following difference is arranged: the formula (by cow dung volume ratio) straw of conditioner accounts for 25% of cow dung volume, superphosphate accounts for 0.5% of cow dung volume, raw soil accounts for 25% of cow dung volume 1.5%; during fermentation and deodorization, for each cubic meter of material, the amount of EM stock solution is 50 milliliters, mixed with 10 liters of water. The width of the fermented and deodorized strip pile is 3 meters, and the total pile height is 2 meters. The purpose of fermentation and deodorization can be achieved after 25 days of composting.

Embodiment 3

[0043] Repeat Example 1, following difference is arranged: the prescription (by cow dung volume ratio) flax stalk of conditioning agent accounts for 18% of cow dung volume, superphosphate accounts for 0.5% of cow dung volume, raw soil accounts for 10% of cow dung volume 1.2%. When fermenting and deodorizing, the amount of EM stock solution per cubic meter is 50 milliliters, mixed with 10 liters of water. The pile of fermented and deodorized strips is 2.5 meters wide and 1.8 meters high, and the purpose of fermentation and deodorization can be achieved after 30 days of composting. The plastic greenhouse for drying is 10 meters wide, 2.4 meters high and 40 meters long.

[0044] After the products obtained in Examples 1, 2, and 3 are inspected, the probability and statistics results reach the general physical and chemical property standards of peat charcoal, that is, the pH value is 6.2, and the bulk density is 0.13g / cm 3 , the total porosity is 87%, the large porosity is 9%, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com