System for drying sludge by solar energy

A solar energy drying and sludge technology, applied in drying, dryer, heating device and other directions, can solve the problems of high overall cost and large energy, and achieve the effect of saving equipment investment, reducing energy consumption and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Referring to the accompanying drawings, the present invention will be described in detail below in conjunction with embodiments.

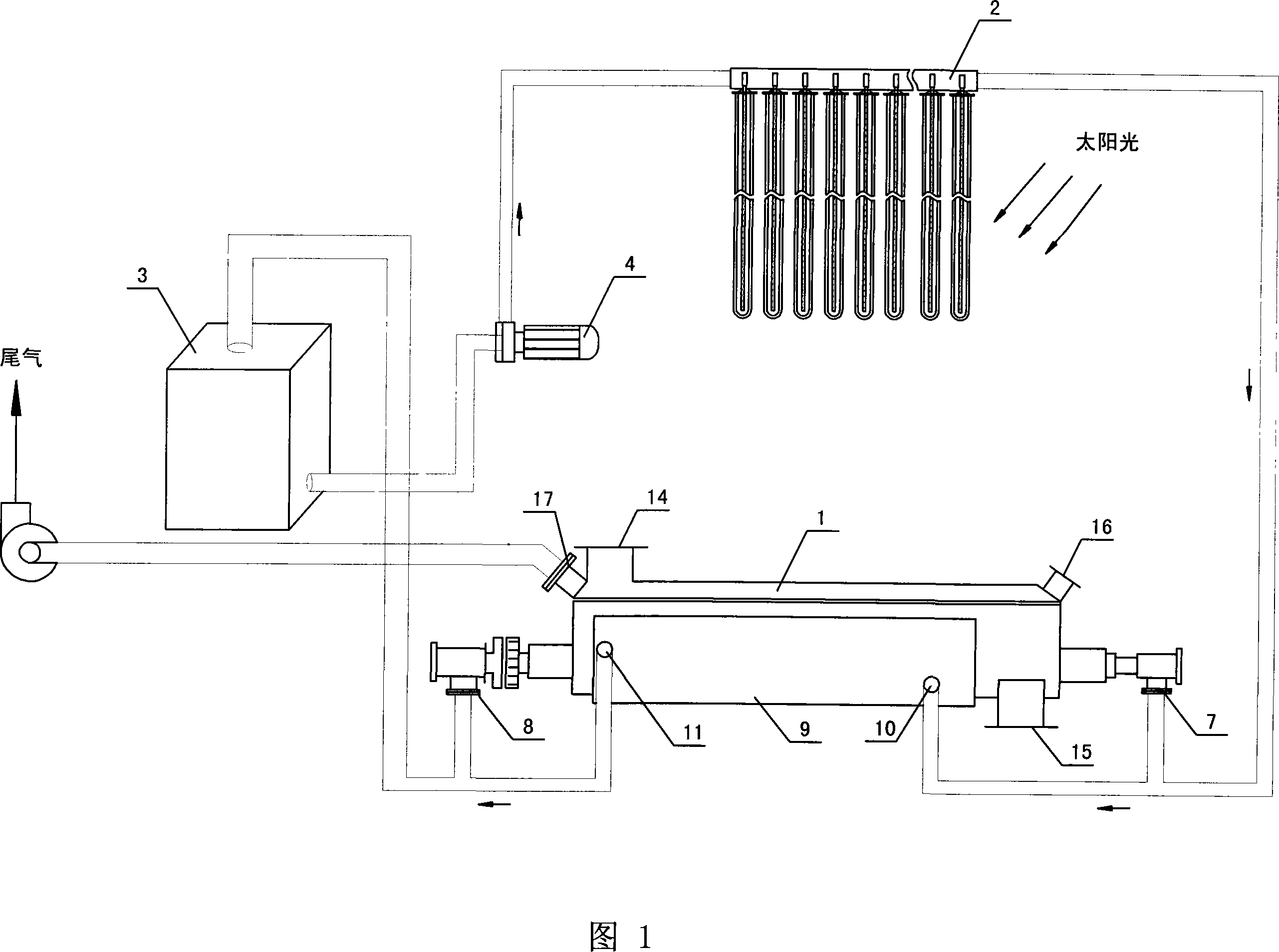

[0028] The entire solar drying system is mainly composed of a spiral rotary sludge drying molding machine 1, a solar collector 2, a heat transfer oil tank 3 and a heat transfer oil pump 4.

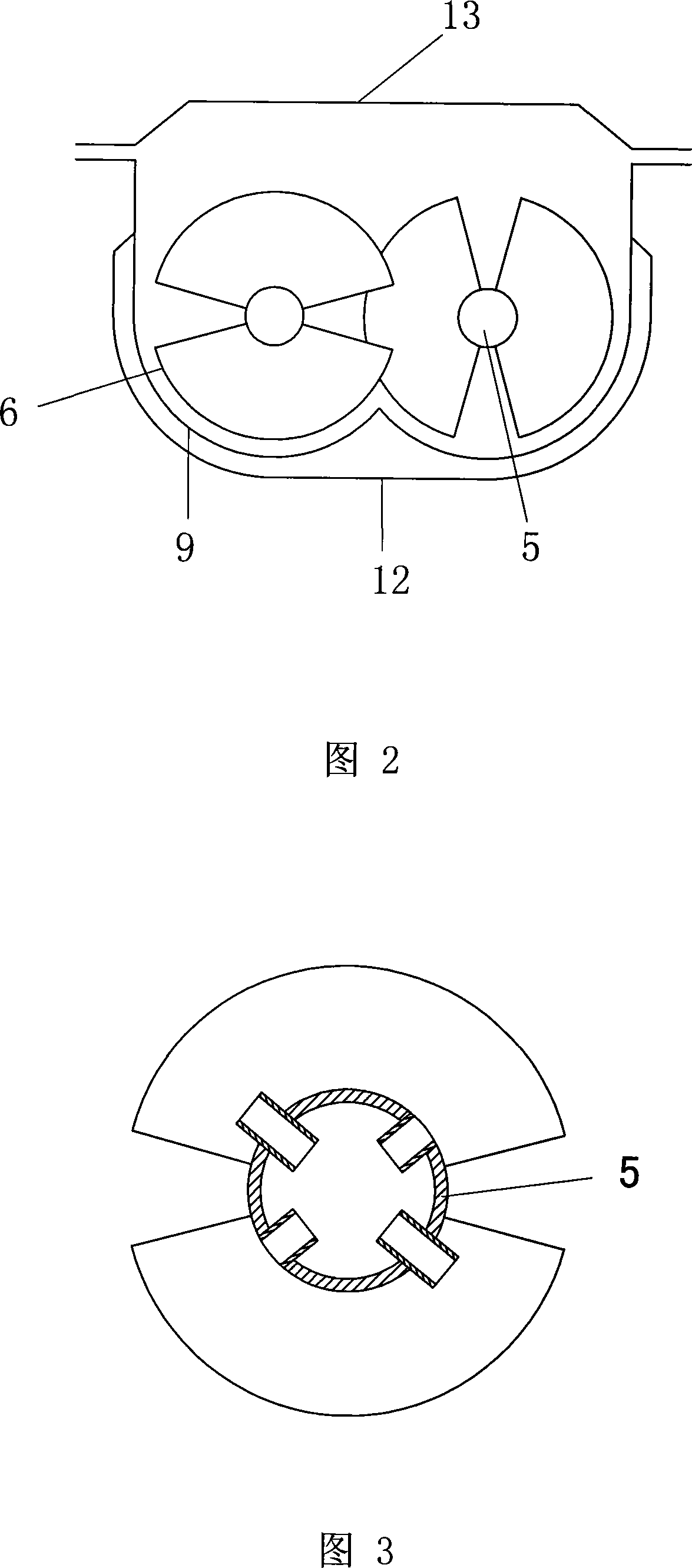

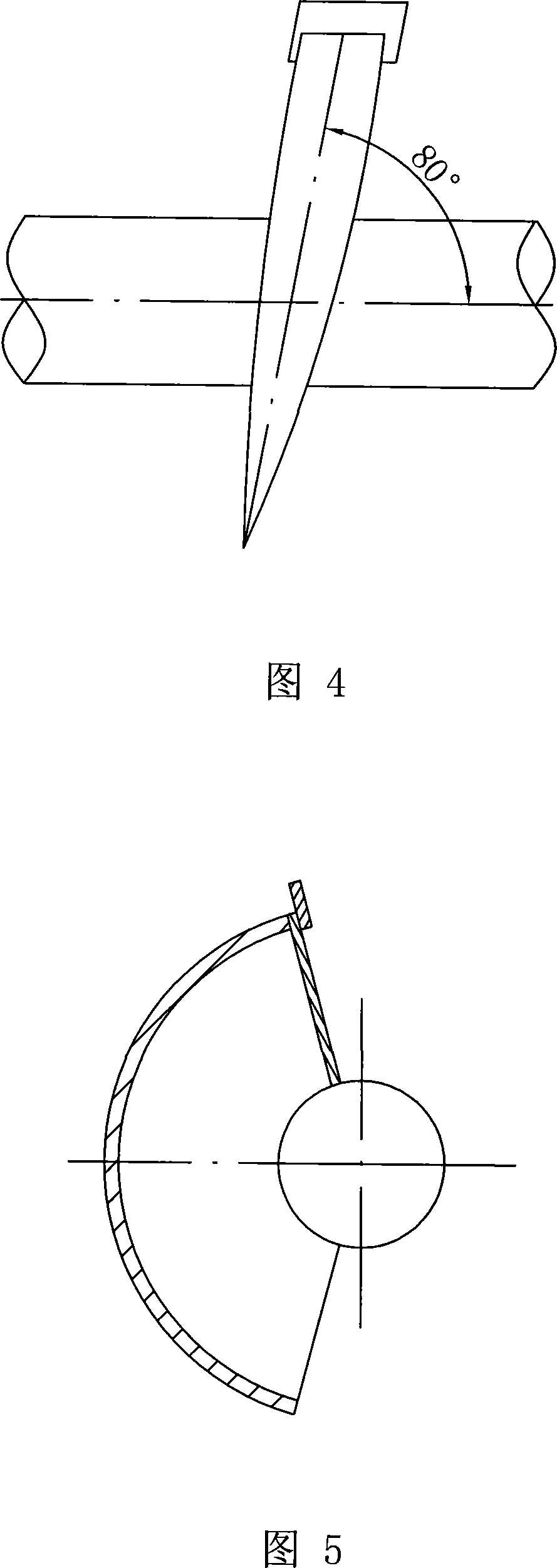

[0029] The spiral rotary sludge drying molding machine 1 includes a shell, and two hollow thermal shafts 5 connected to the transmission mechanism are installed inside the body, and several hollow wedge-shaped paddles 6 are arranged on the hollow thermal shaft 5, and the wedge-shaped paddles 6 are connected with the hollow thermal shafts. The shaft 5 is internally connected, and of course the propeller blades can also be selected as propeller blades.

[0030] The two ends of the hollow thermal shaft 5 are respectively connected to the heat transfer oil inlet 7 and the heat transfer oil outlet 8, and the jacket 9 is arranged on the shell, and the heat tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com