High voltage auxiliary solar drying device and method

A technology of solar drying and solar energy, applied in chemical instruments and methods, dehydration/drying/concentrated sludge treatment, energy wastewater treatment, etc., can solve the problems of high moisture content of sludge, high treatment cost, difficult transportation, etc., and achieve increased The effect of drying rate, low energy consumption, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

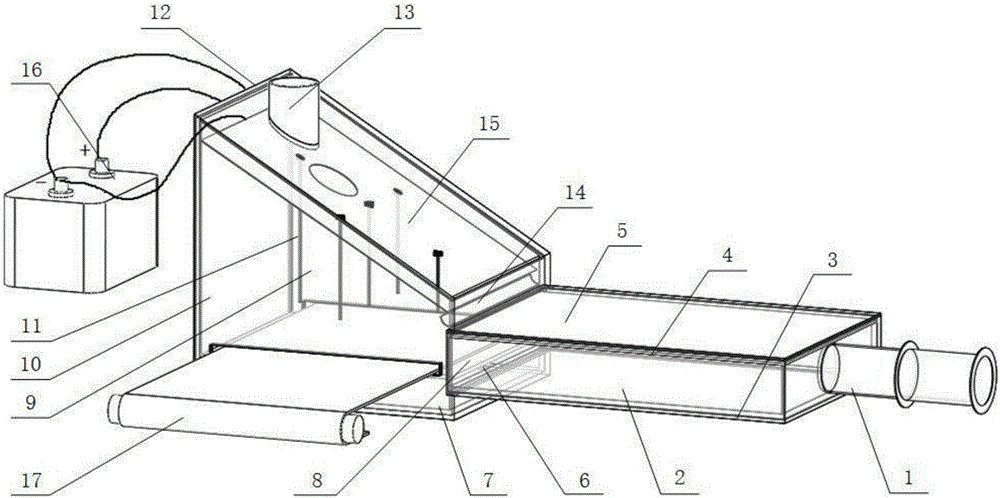

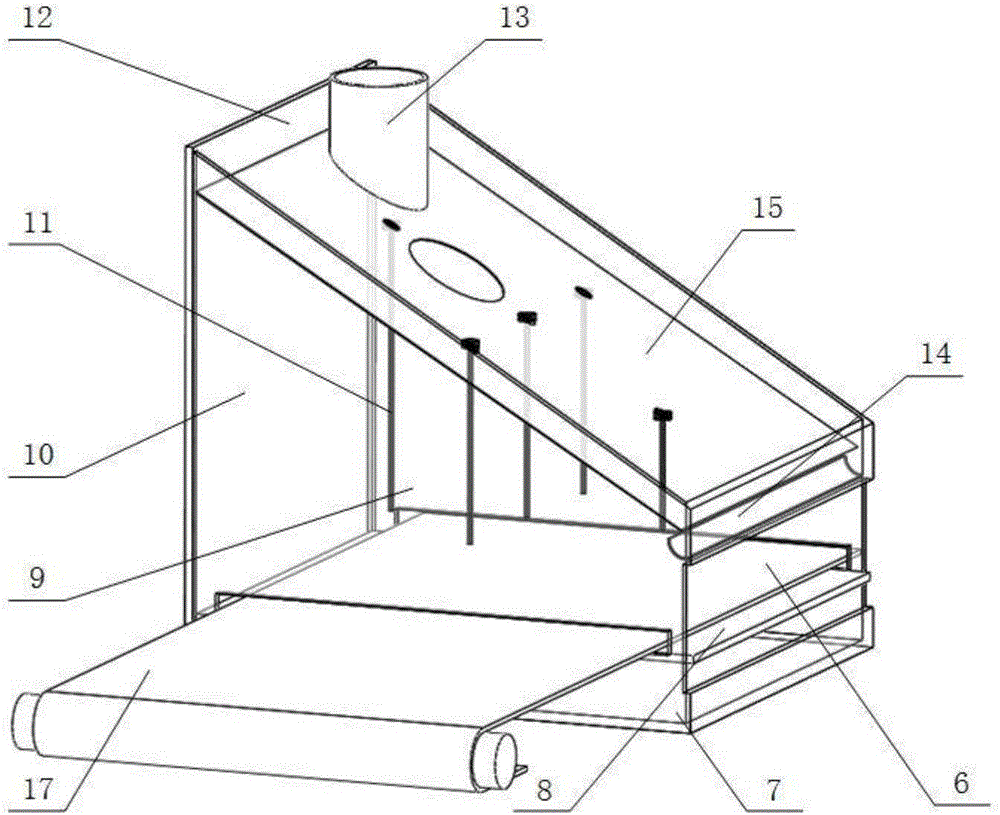

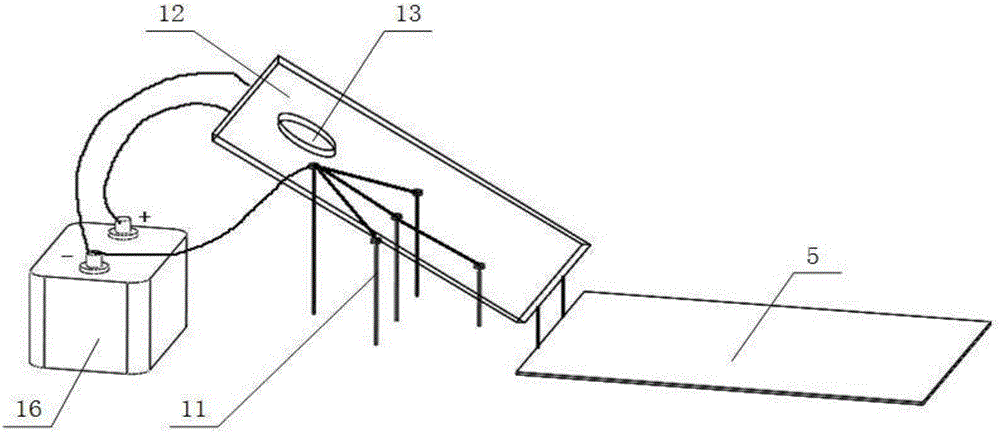

[0028] The design scheme will be fully described below in conjunction with the accompanying drawings.

[0029] like figure 1 and figure 2As shown, a high-voltage electricity-assisted solar drying device includes an air inlet 1, a solar heat collecting chamber 2, a heat collecting chamber insulation layer 3, a heat collecting plate A4, a thin film solar panel A5, an air vent 6, and a drying chamber Insulation layer 7, high-voltage electrode plate 8, solar drying chamber 9, reflector 10, high-voltage electrode needle 11, thin-film solar panel B12, air outlet 13, water tank 14, heat collecting plate B15, battery 16, transmission mechanism 17; The heat chamber 2 is a hollow cavity, and the thermal insulation layer 3 of the heat collection chamber is arranged on the inside, the air inlet 1 is provided on the right side, and the air vent 6 is provided on the left side to communicate with the solar drying chamber 9, and the thin film solar panel A5 and the collection chamber are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com