Cooperative treating method of kitchen waste and sludge of sewage plant

A kitchen waste and co-processing technology, applied in the direction of biological sludge treatment, sludge treatment, sludge treatment, etc., can solve the problems of secondary air pollution, inappropriate treatment process, poor biochemical performance, etc., and achieve reduction Construction and operation costs, ensuring subsequent resource utilization, and facilitating biogas slurry treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

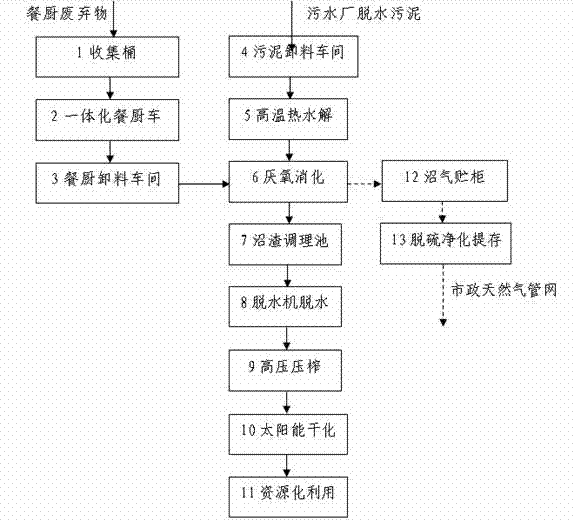

[0026] The method for synergistic treatment of kitchen waste and sewage plant sludge of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0027] In order to realize the treatment of kitchen waste and remaining domestic sludge, the present invention adopts "source pretreatment of kitchen waste + high-temperature thermal hydrolysis of sludge in conjunction with anaerobic digestion + dehydration of biogas residue dehydrator, direct pressing of high-pressure filter press + Solar energy drying” technology, centering on the source pretreatment of kitchen waste, synergistic anaerobic digestion effect, sludge dehydration, drying, biogas residue resource utilization, etc., developed a joint complementary anaerobic digestion of kitchen waste and sludge, Treatment and reuse technology, as shown in the figure, the collaborative treatment method of kitchen waste and sewage plant sludge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com