Method for treating low-heating value excess sludge

A technology for excess sludge and disposal methods, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve environmental secondary pollution, occupy large land, and affect urban environment Hygiene and other issues, to achieve low energy consumption, reduce the use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

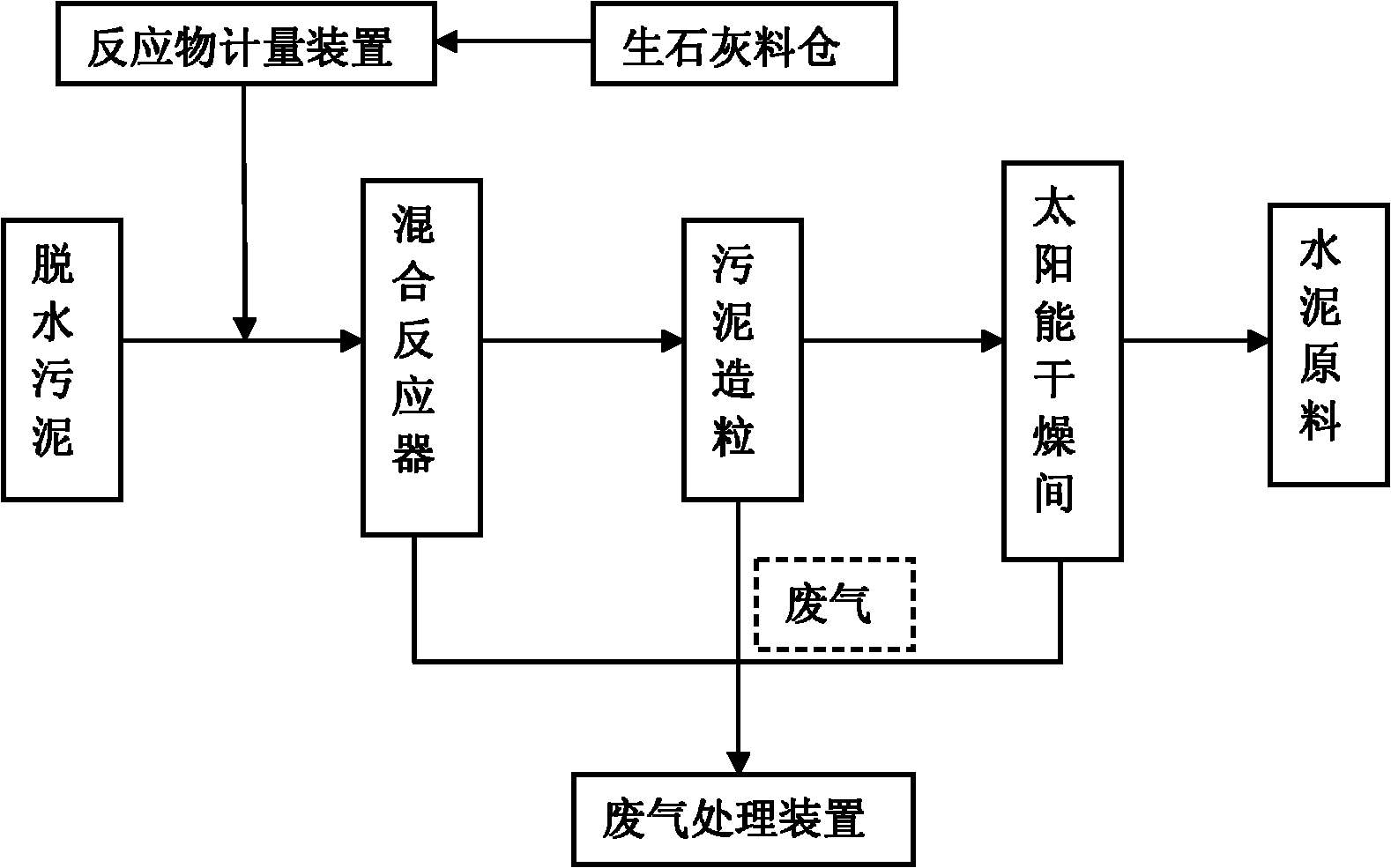

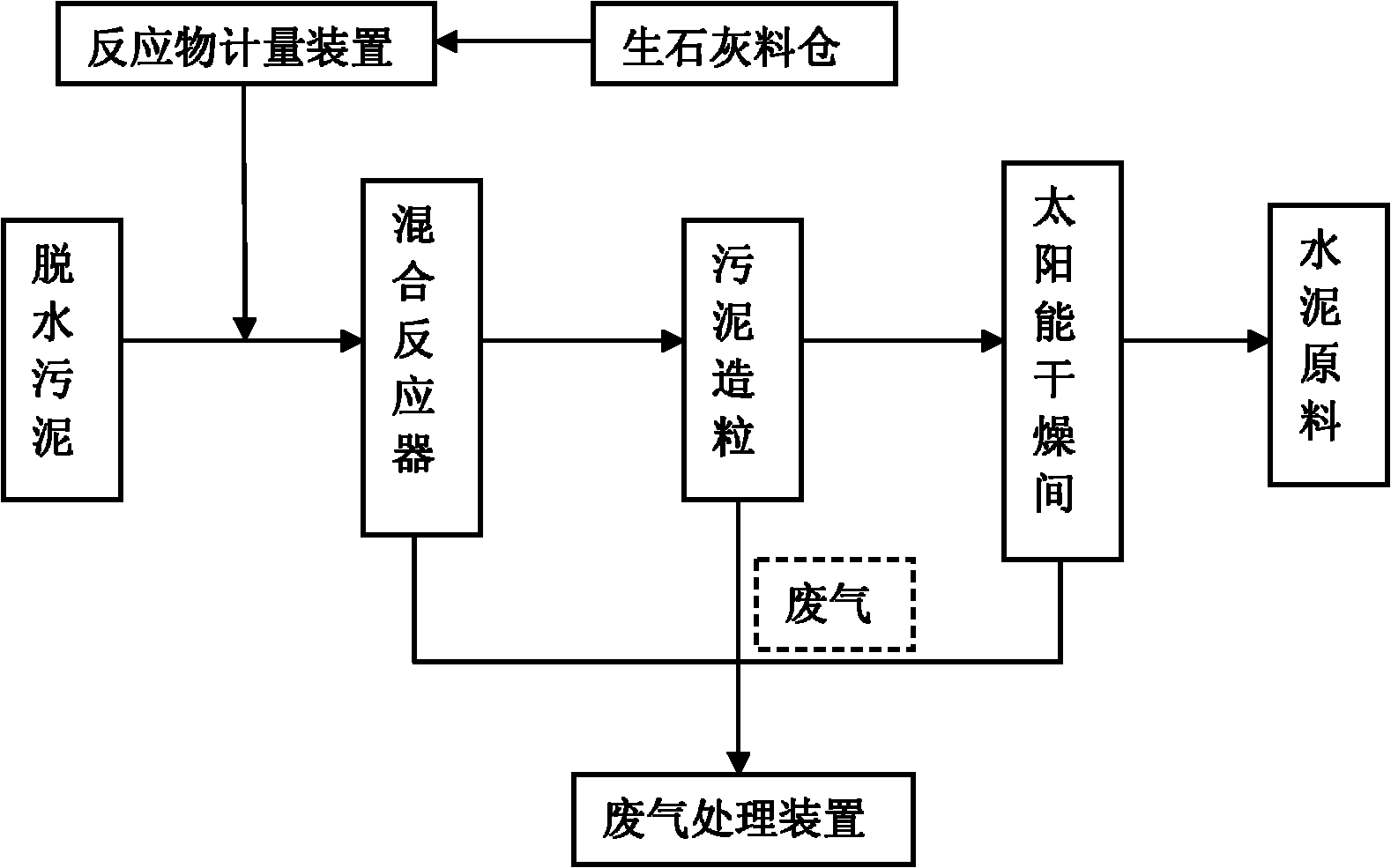

[0021] The moisture content of excess sludge in a sewage treatment plant is 82.3%. According to the mass ratio of quicklime: excess sludge = 0.2:1, the quicklime and excess sludge are transported into the mixing reactor, fully mixed and reacted for 15 minutes, and made into semi-dry The sludge, among which, the generated odor is introduced into the waste gas treatment device for treatment. The semi-dried sludge produced by the mixed reaction is transported into the sludge granulation device, and crushed into sludge particles with a larger specific surface area. The average particle size of the sludge particles is 4.3mm, and the generated odor is introduced into the waste gas treatment device. deal with.

[0022] The outdoor temperature is 33°C during the day and 24°C at night; the temperature in the solar drying room is 56°C during the day and 24°C at night. The sludge particles are laid flat in the solar drying room. During the drying process, the sludge particles are mechan...

Embodiment 2

[0024] The moisture content of excess sludge in a sewage treatment plant is 83.6%. According to the mass ratio of quicklime: excess sludge = 0.4:1, the quicklime and excess sludge are transported into the mixing reactor, fully mixed and reacted for 20 minutes, and made into semi-dry The sludge, among which, the generated odor is introduced into the waste gas treatment device for treatment. The sludge after the mixed reaction is transported into the sludge granulation device, and the sludge particles with a larger specific surface area are produced. The average particle size of the sludge particles is 3.5mm, and the generated odor is introduced into the waste gas treatment device for treatment.

[0025] The outdoor temperature is 35°C during the day and 25°C at night; the temperature in the solar drying room is 60°C during the day and 25°C at night. The sludge particles are laid flat in the solar drying room. During the drying process, the sludge particles are mechanically turn...

Embodiment 3

[0027] The moisture content of the excess sludge in a sewage treatment plant is 83.6%. According to the mass ratio of quicklime: excess sludge = 0.5:1, the quicklime and excess sludge are transported into the mixing reactor, fully mixed and reacted for 20 minutes, and made into semi-dry The sludge, among which, the generated odor is introduced into the waste gas treatment device for treatment. The sludge after the mixed reaction is transported into the sludge granulation device, and the sludge particles with a larger specific surface area are produced. The average particle size of the sludge particles is 2.5mm, and the generated odor is introduced into the waste gas treatment device for treatment.

[0028] The outdoor temperature is 35°C during the day and 25°C at night; the temperature in the solar drying room is 60°C during the day and 25°C at night. The sludge particles are laid flat in the solar drying room. During the drying process, the sludge particles are mechanically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com