Solar energy drying shed

A solar drying and drying technology, used in drying solid materials, local stirring dryers, dryers for static materials, etc., can solve the problems of destroying the active ingredients of drying materials, being susceptible to pollution, flue gas pollution, etc., and maintaining active ingredients. , the drying effect is obvious, the effect of less fixed investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

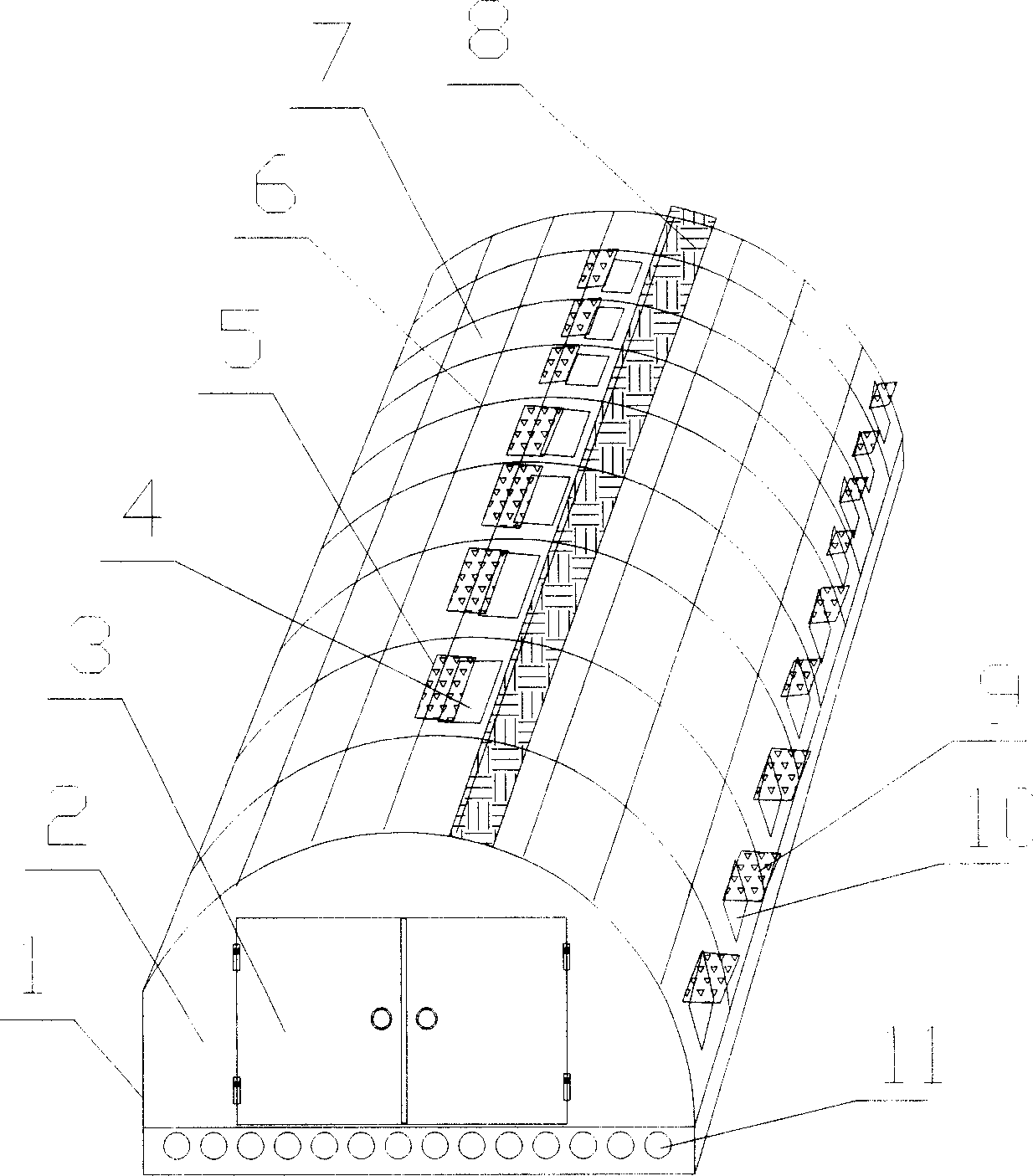

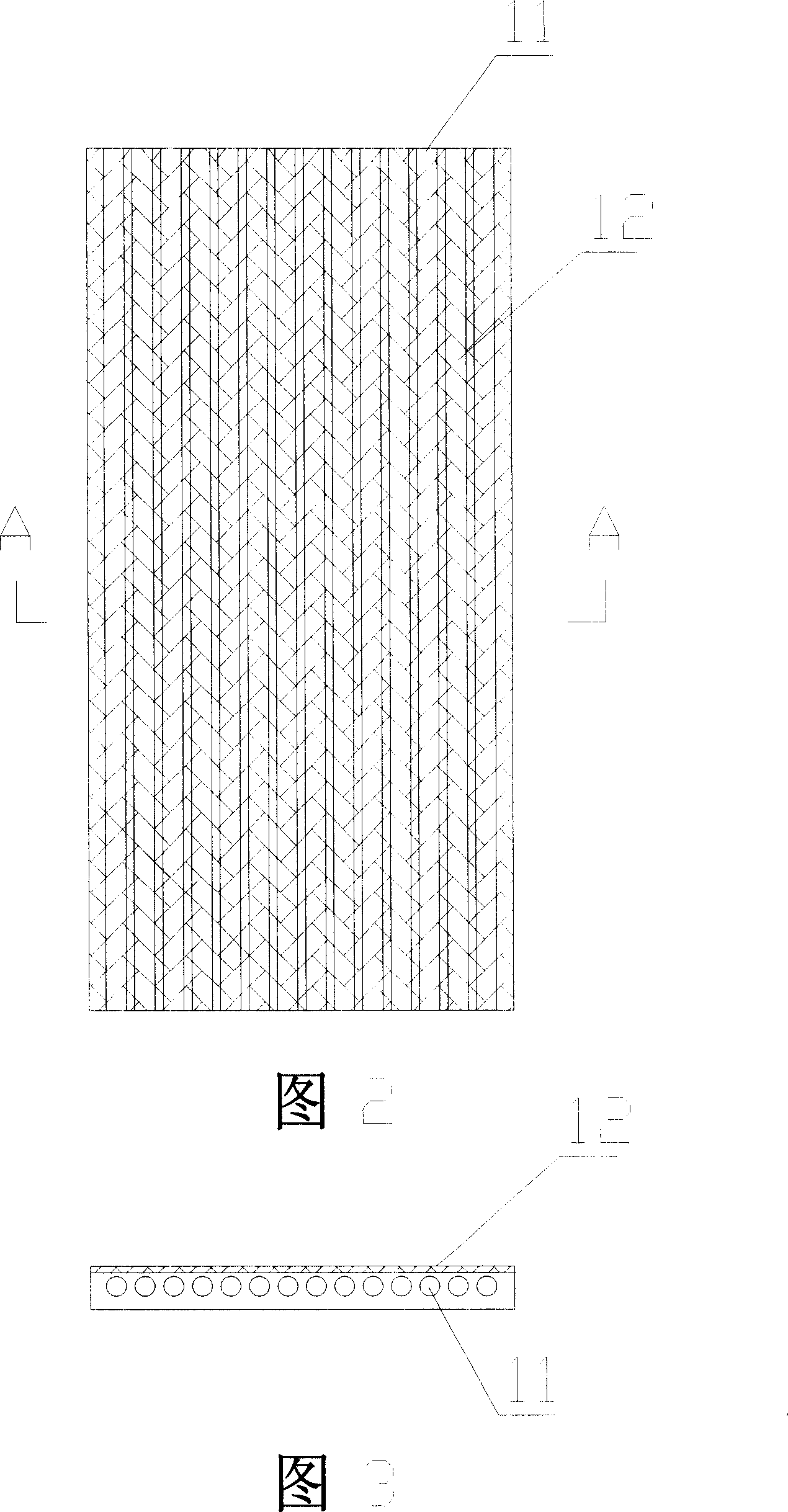

[0023] Refer to attached figure 1 , Figure 2 and Figure 3.

[0024] A solar drying shed comprises a wall body 1, a shed wall 2 and a shed roof. The length of the solar drying shed is 40m, the width of the shed is 20m, and the height of the shed is 4m. The roof is composed of a steel pipe skeleton 6 and a light-transmitting thermal insulation plastic film 7. There is an air outlet 4 above the roof, and a windshield cover 5 is installed above the air outlet 4. There are air inlets 10 on the lower side of the drying shed. 10 is equipped with weatherproof cover 9. Below the other side of the roof is a body of wall 1, which has an air inlet hole, and 6 columns of the steel pipe skeleton of the roof are fixed on the body of wall. There are shed walls 2 at both ends, and the shed walls 2 are provided with doors 3, which can be used for loading and unloading and turning over materials, vehicles and equipment to enter and exit. The roof light-transmitting thermal insulation plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com