Efficient firework powder drying system

A drying system and fireworks technology, applied in drying, drying machines, drying solid materials, etc., can solve problems such as unfavorable moisture removal, large investment, and surrounding environmental pollution, and achieve long drying time and increased speed and output, and the effect of reducing the hidden danger of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiments of the present invention, and it is clearly described, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0041] The present invention is implemented by the following preferred embodiments, specific characteristics:

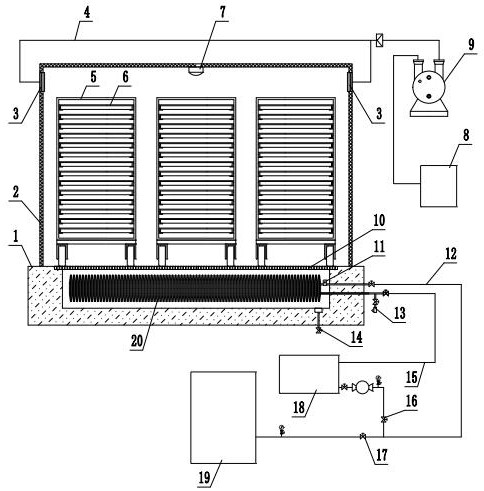

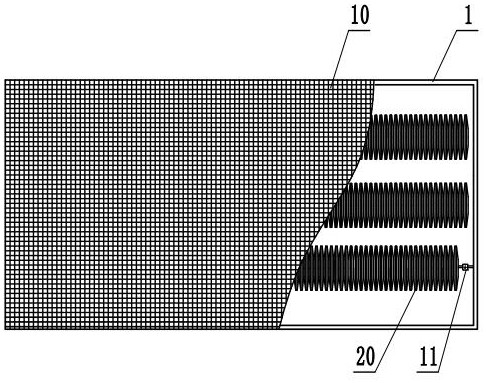

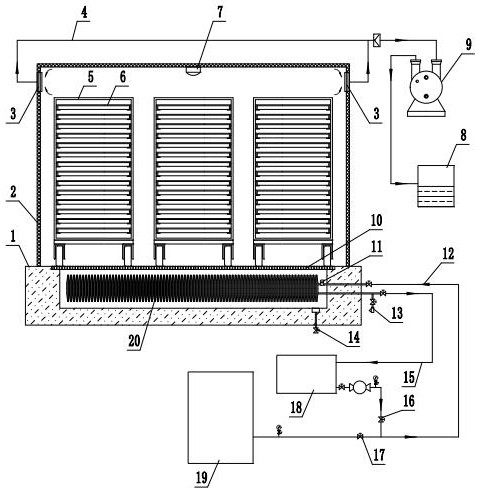

[0042] In an embodiment of the present invention, a highly efficient drying fireworks powder system is characterized in that the dry firework powder system uses an active vacuum dehumidification method, including material drying system, pumping exhaust system, heat dissipation system, The heat source system is fixedly coupled to the outer side position of the material drying system, and the material drying sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com