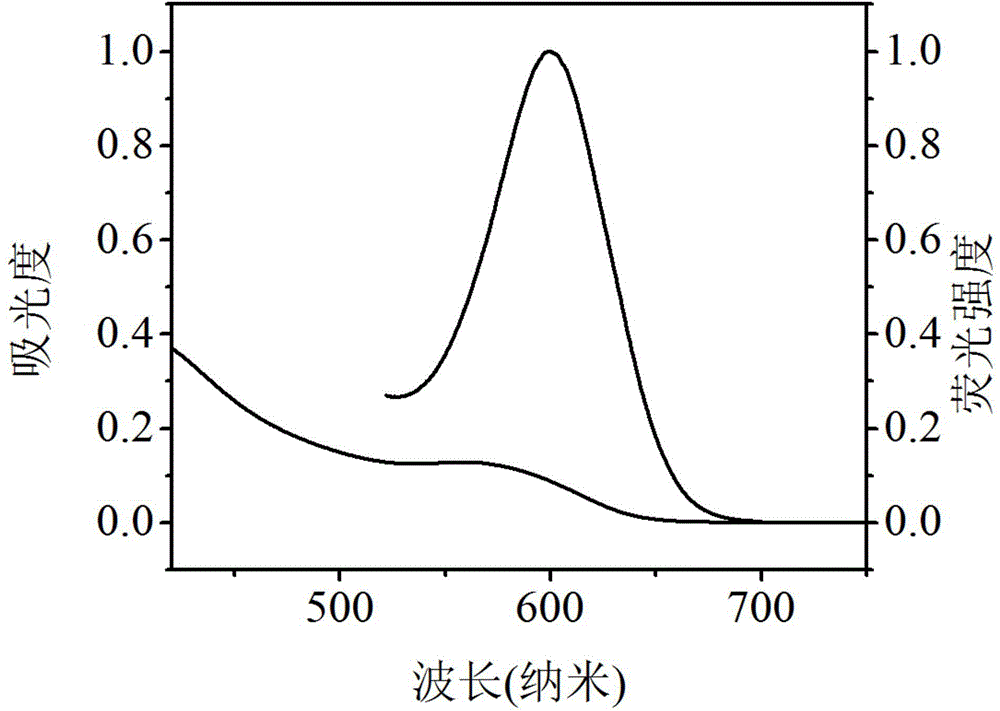

Microwave preparation method of water-soluble Zn-doped Zn:CdTe quantum dots

A water-soluble, quantum dot technology, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve the problem of long time required for quantum dots emitting red fluorescence, poor particle size growth rate and crystallization performance, and poor heating of samples. Uniformity and other issues, to achieve the effects of short heating induction period, prevention of crystal phase formation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of microwave preparation method of water-soluble Zn-doped Zn:CdTe quantum dots comprises the following steps:

[0021] Step 1, put sodium borohydride with a molar ratio of 5.1:1 and tellurium powder with a content of 99.9% in water, the amount of water is 10 parts by mass, and placed in a microwave synthesizer under nitrogen protection, heated to Stir and react at 75°C for 1 minute, then heat to 92°C and stir for 3 minutes to obtain a sodium telluride hydride solution; wherein, the specification of tellurium powder is 120 mesh sieve;

[0022] Step 2, adding cadmium chloride, zinc chloride and modifier water-soluble N-acetyl-L-cysteine solution in the container, wherein Cd 2+ The concentration is 0.12mol / L, Cd 2+ : Zn 2+ The molar ratio of the solution is 1:0.2, and the pH value of the solution is adjusted to 13.1. Under the protection of nitrogen, inject the sodium hydride telluride solution prepared in step 1, and then pass nitrogen gas from the top of the s...

Embodiment 2

[0027] A kind of microwave preparation method of water-soluble Zn-doped Zn:CdTe quantum dots comprises the following steps:

[0028] Step 1. Put sodium borohydride with a molar ratio of 5.1:1 and tellurium powder with a content of 99.9% in water. The amount of water used is 20 parts by mass. Under the protection of nitrogen, place it in a microwave synthesizer and heat it to 70 ℃ for 2 minutes, then heated to 90 ℃ and stirred for 3 minutes to obtain tellurium sodium hydride solution; wherein, the specification of tellurium powder is 120 mesh sieve;

[0029] Step 2, adding cadmium chloride, zinc chloride and modifier water-soluble N-acetyl-L-cysteine solution in the container, wherein Cd 2+ The concentration is 0.12mol / L, Cd 2+ : Zn 2+ The molar ratio of the solution is 1:0.2, and the pH value of the solution is adjusted to 13.1. Under the protection of nitrogen, inject the sodium telluride hydride solution prepared in step 1, and then pass nitrogen gas from the top of the ...

Embodiment 3

[0033] A kind of microwave preparation method of water-soluble Zn-doped Zn:CdTe quantum dots comprises the following steps:

[0034] Step 1, 0.2067g Te powder and 0.3125g NaBH 4 Put it into a container, add 5mL of distilled water, place it in a microwave synthesizer under the protection of nitrogen, heat at 70°C and stir for 2 minutes, then heat to 95°C and stir for 3 minutes to obtain sodium telluride hydride NaHTe solution; among them, The specification of tellurium powder is 150 mesh sieve;

[0035] Step two, 0.8221g CdCl 2 , 0.0982gZnCl 2 and 2.1149g of N-acetyl-L-cysteine were dissolved in 30mL of distilled water, where Cd 2+ The concentration is 0.12mol / L, Cd 2+ : Zn 2+ The molar ratio of the solution is 1:0.2, and the pH value of the solution is adjusted to 13.1. Under the protection of nitrogen, inject the sodium telluride hydride NaHTe solution prepared in step 1, and then pass nitrogen gas from the top to the bottom of the solution for 2 minutes to obtain Zn-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com