Greenhouse-heat collector-type solar sludge drying system and method

A solar drying and heat collector technology, applied in dewatering/drying/concentrating sludge treatment, energy and wastewater treatment, etc., can solve the problems of large temperature difference between day and night, slow drying speed, leakage of heat transfer oil, etc., to achieve low operating costs, Simple operation and obvious energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

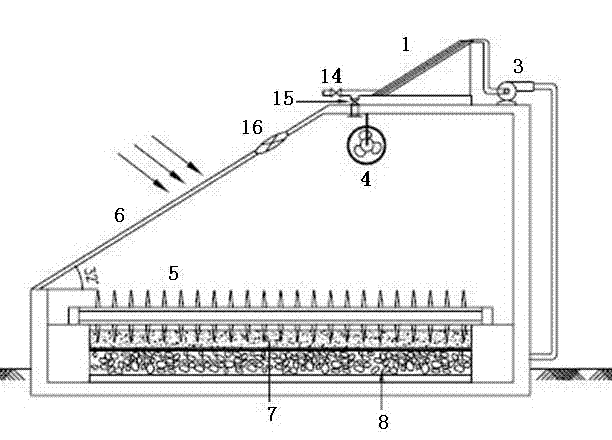

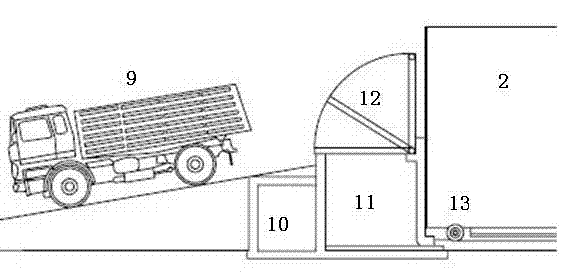

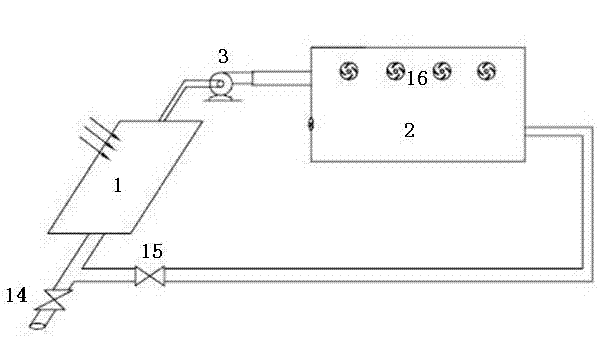

[0027] The present invention will be described in detail below with reference to the accompanying drawings. The greenhouse-heat collector type solar drying sludge system and method of the present invention are mainly composed of solar greenhouse 2, solar air heat collector 1, mud turning equipment 5, ventilation equipment, heat storage layer 8 and pipeline fan 3, etc. .

[0028] Such as figure 1 As shown, the side of the greenhouse is trapezoidal, the inclination angle of the sunny side is 32° (Nanjing area), and the azimuth angle is 10° south by west. Strength thin-walled steel as a load-bearing structure. The solar heat collector adopts a solar flat air heat collector, the arrays are combined and connected in parallel, and the hot air is passed into the greenhouse by using the pipeline fan 3. In order to reduce the floor area, the solar heat collector is placed on the north side of the flat roof of the greenhouse, and its installation direction is in the same direction as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com