Tea leaf drying oven

A drying box and tea technology, which is applied in tea processing before extraction, etc., can solve problems such as poor quality, waste of labor, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

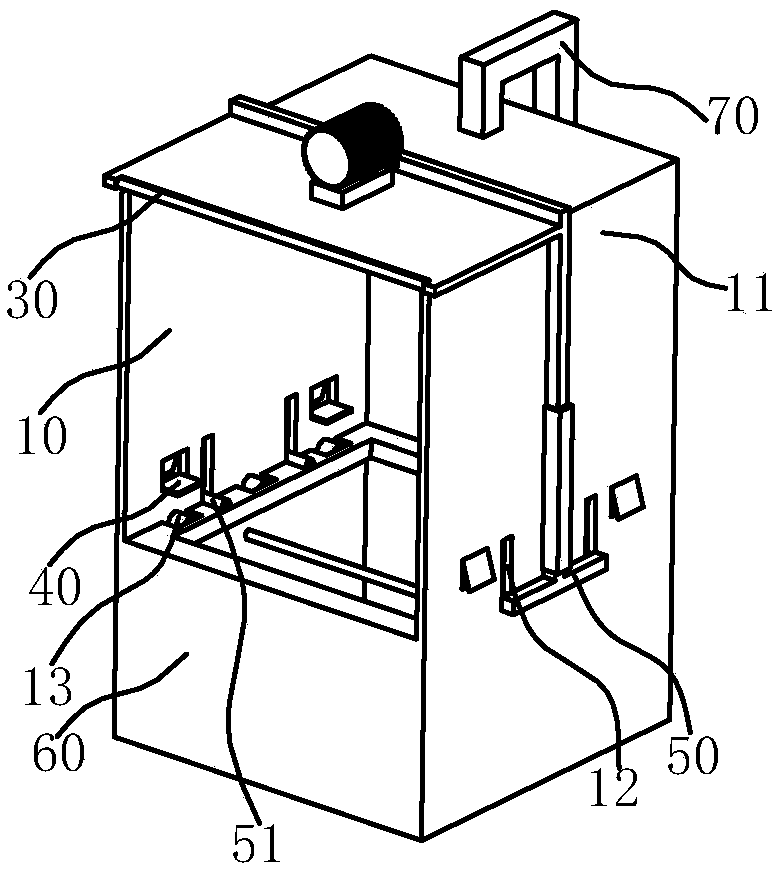

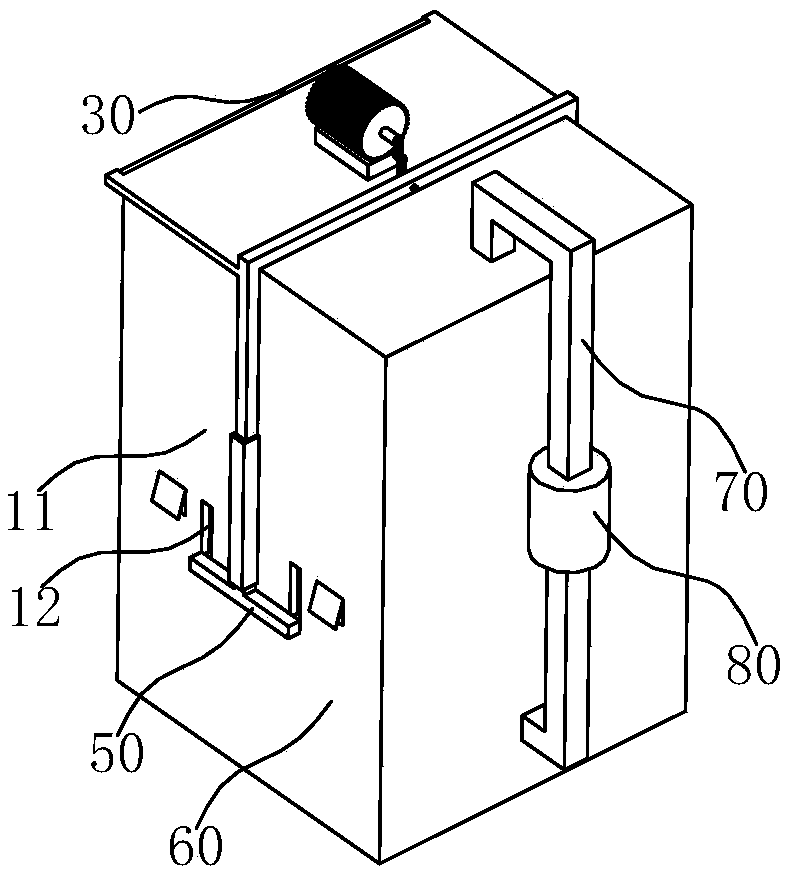

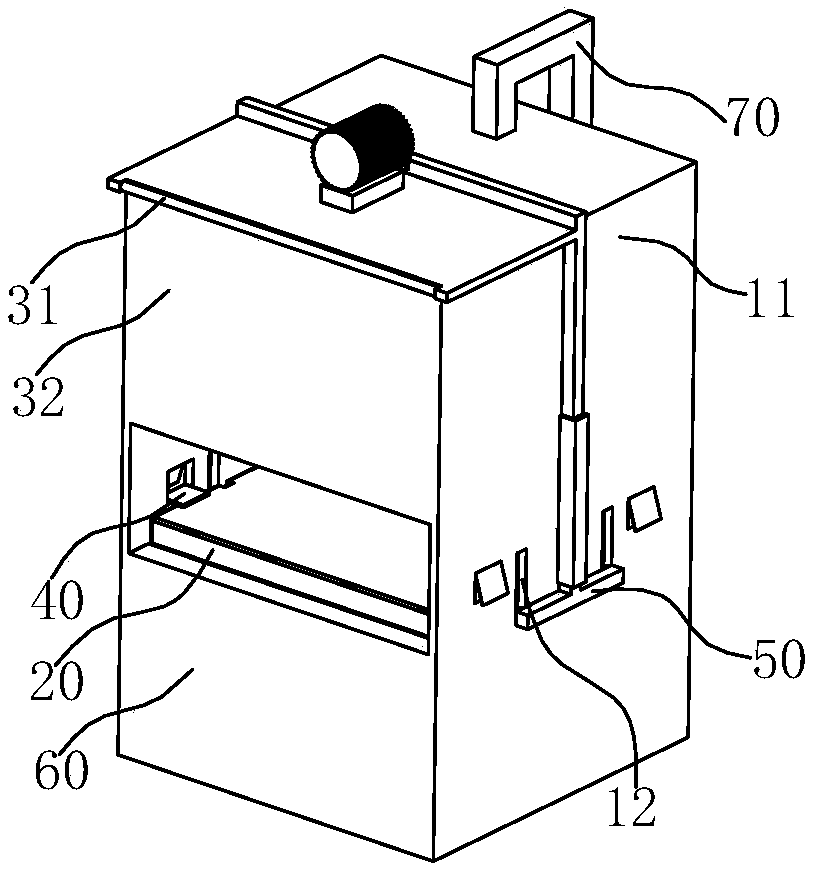

[0010] combined with Figure 1~4 The present invention is further described:

[0011] A tea drying box, comprising an oven 10 for placing a tea drying net 20, the chamber of the oven 10 is connected to a heat source, one side of the oven 10 is open and a curtain 30 is provided at the opening , the oven 10 is provided with a support bracket 40 for supporting the tea drying net 20, there is a space for inserting the tea drying net 20 between the support bracket 40 and the bottom of the oven 10, and the driving unit drives the lifting mechanism 50 to drive and place it on the oven 10. The tea drying net 20 at the bottom is displaced upwards. A curtain 30 is provided to cover the opening of the oven 10 to avoid heat loss, the tea drying net 20 is inserted between the support bracket 40 and the bottom of the oven 10, and the lifting mechanism 50 works to lift the tea drying net 20 onto the support bracket 40, The lifting mechanism 50 returns to continue to lift the next tea dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com