Methylprednisolone production method and production device

A technology for methylprednisolone and production equipment, which is applied in the directions of drying gas arrangement, steroid, non-progressive dryer, etc., can solve the damage to the shape and structure variation of intermediate products, reduce the production quality of methylprednisolone, and reduce methylprednisolone. Crystallization instability and other problems, to avoid morphological changes, speed up drying, shorten production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

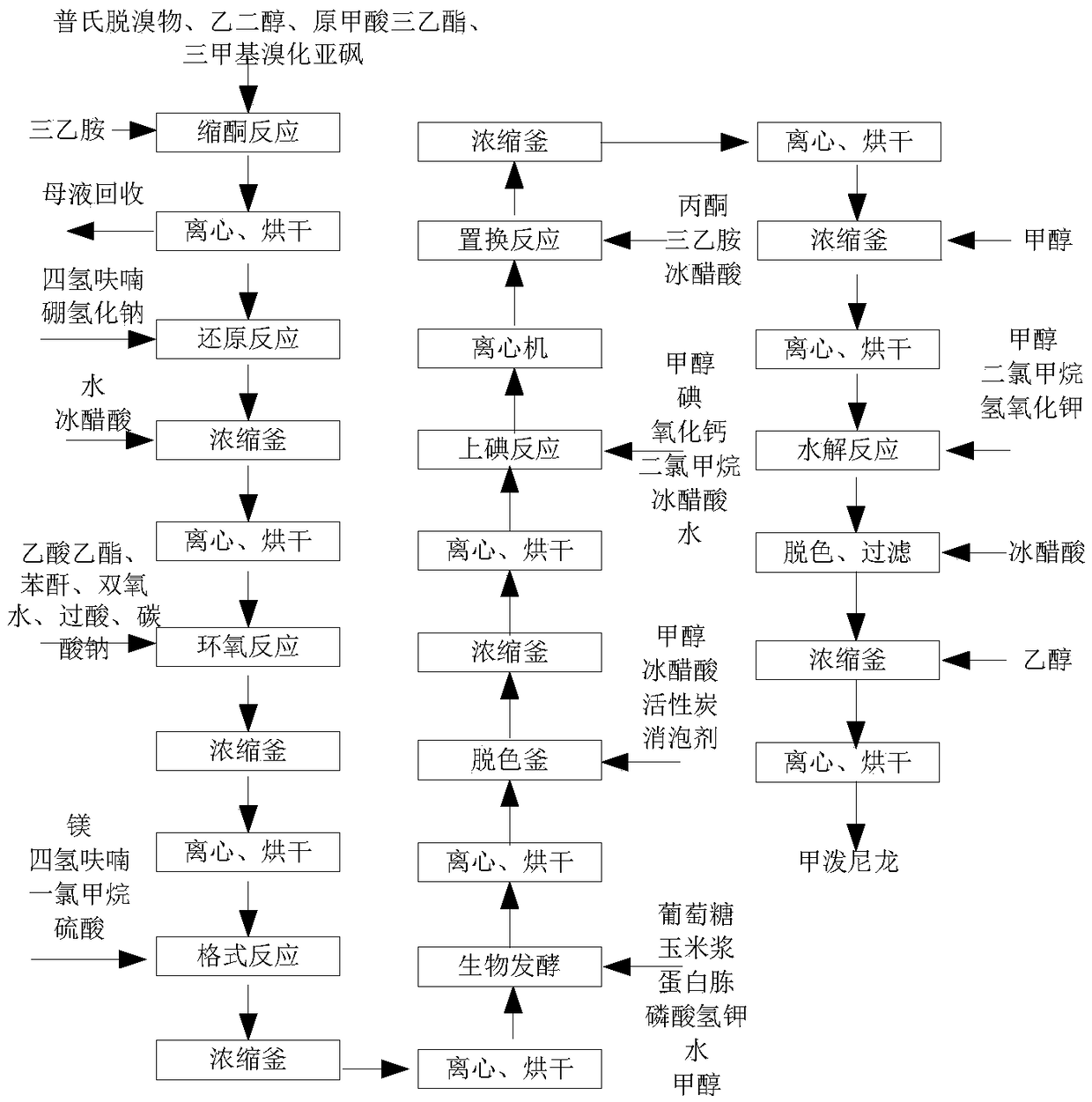

[0075]The process embodiment one of producing methylprednisolone, it comprises following preparation steps:

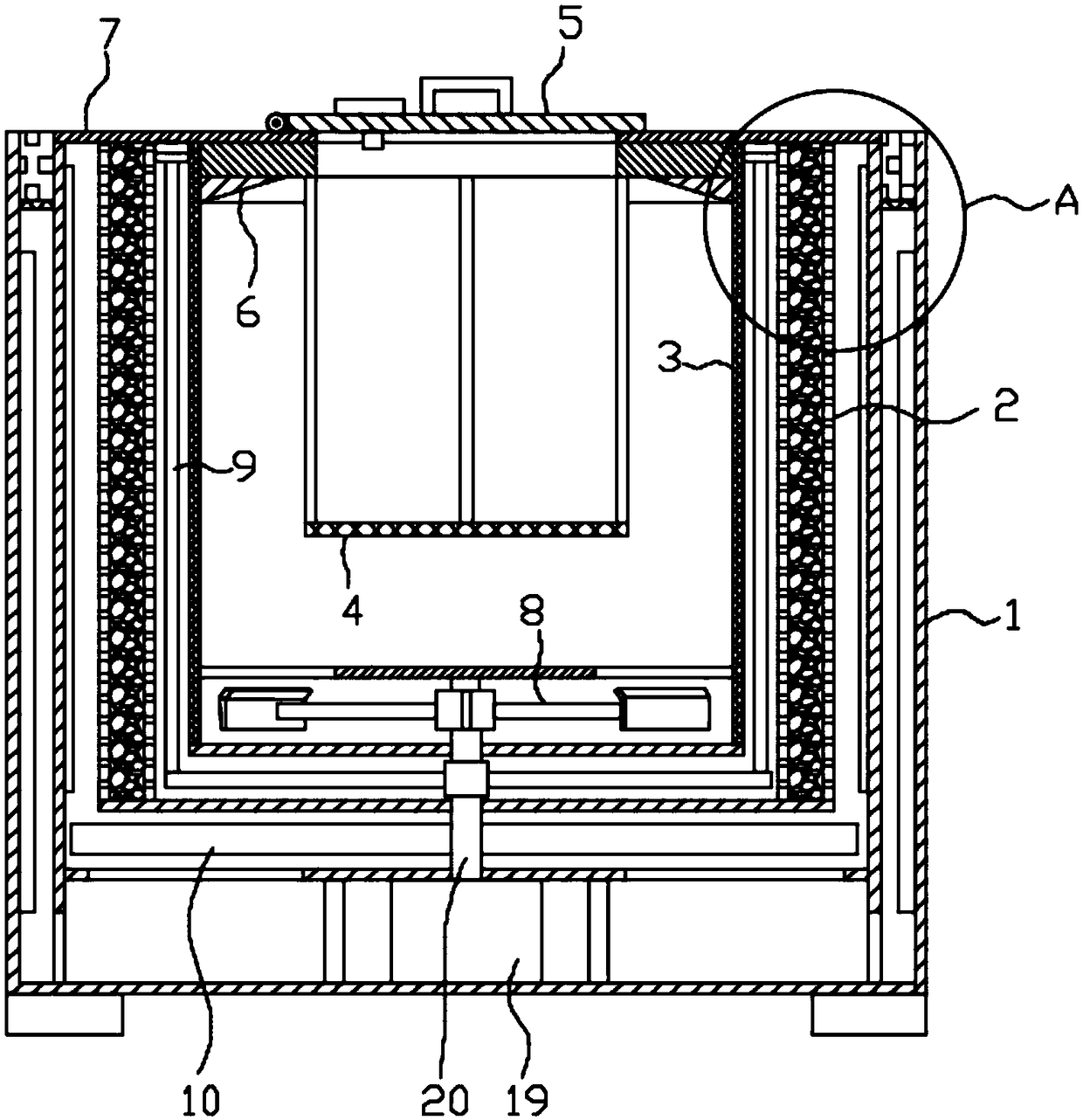

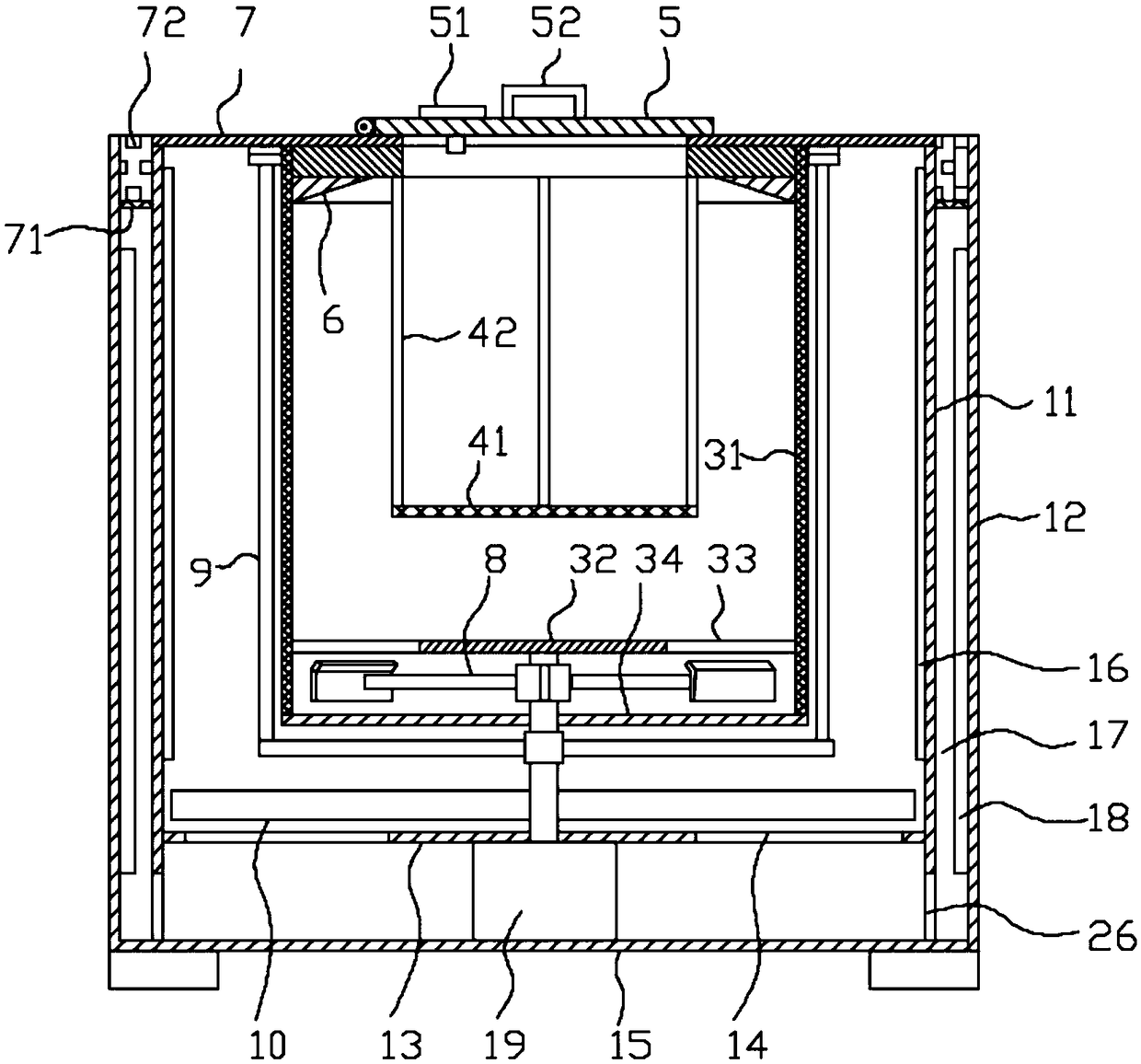

[0076] Ketal reaction: 160 parts of ethylene glycol, 160 parts of triethyl orthoformate, 130 parts of Platts debrominated product, 2 parts of trimethyl sulfoxide bromide were pumped into the reactor, reacted for 5 hours, and triethylamine was added , neutralized to neutral, crystallized, centrifugally dried, put into the drying equipment, start the infrared heating tube 6, irradiate for 5 minutes, control the speed of the motor 19 to 900-1000r / min, and continue to run for 10 minutes to obtain shrinkage Ketones;

[0077] The reaction formula is:

[0078]

[0079] Reduction reaction: pump 800 parts of tetrahydrofuran into the reaction kettle, add 450 parts of the ketal product, 15 parts of sodium borohydride, react for 12 hours, add 6 parts of glacial acetic acid, concentrate and dry tetrahydrofuran under negative pressure, add water for water analysis, centrifuge, ...

Embodiment 2

[0100] The process embodiment two of producing methylprednisolone, it comprises following preparation steps:

[0101] Ketal reaction: pump 200 parts of ethylene glycol, 200 parts of triethyl orthoformate, 170 parts of Platts debrominated product, 4 parts of trimethylsulfoxide bromide into the reactor, react for 7 hours, add triethylamine , neutralized to neutral, crystallized, centrifugally dried, put into the drying equipment, start the infrared heating tube 6, irradiate for 5 minutes, control the speed of the motor 19 to 900-1000r / min, and continue to run for 10 minutes to obtain shrinkage Ketones;

[0102] Reduction reaction: pump 1000 parts of tetrahydrofuran into the reaction kettle, add 550 parts of the ketal product, 20 parts of sodium borohydride, react for 12 to 15 hours, add 10 parts of glacial acetic acid, concentrate and dry tetrahydrofuran under negative pressure, add water for water analysis, After centrifugation and drying, put it into the drying equipment, sta...

Embodiment 3

[0109] The process embodiment three of producing methylprednisolone, it comprises following preparation steps:

[0110] Ketal reaction: pump 180 parts of ethylene glycol, 180 parts of triethyl orthoformate into the reactor, add 150 parts of Platts debrominated product, 3 parts of trimethylsulfoxide bromide, control the temperature at 32-35 °C, and react After 6 hours, add triethylamine, neutralize until the pH is 8, drop to 5-10°C, crystallize for 1 hour, spin dry by centrifugation, put it into the drying equipment, start the infrared heating tube 6, irradiate for 5 minutes, control The rotating speed of the motor 19 is 900-1000r / min, and it runs continuously for 10 minutes to obtain the ketal product;

[0111] Reduction reaction: pump 900 parts of tetrahydrofuran into the reaction kettle, add 516 parts of the ketal product, 18 parts of sodium borohydride, heat up to 65-68°C for reflux reaction for 12-15 hours, point the board to confirm that the raw materials have been reacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com