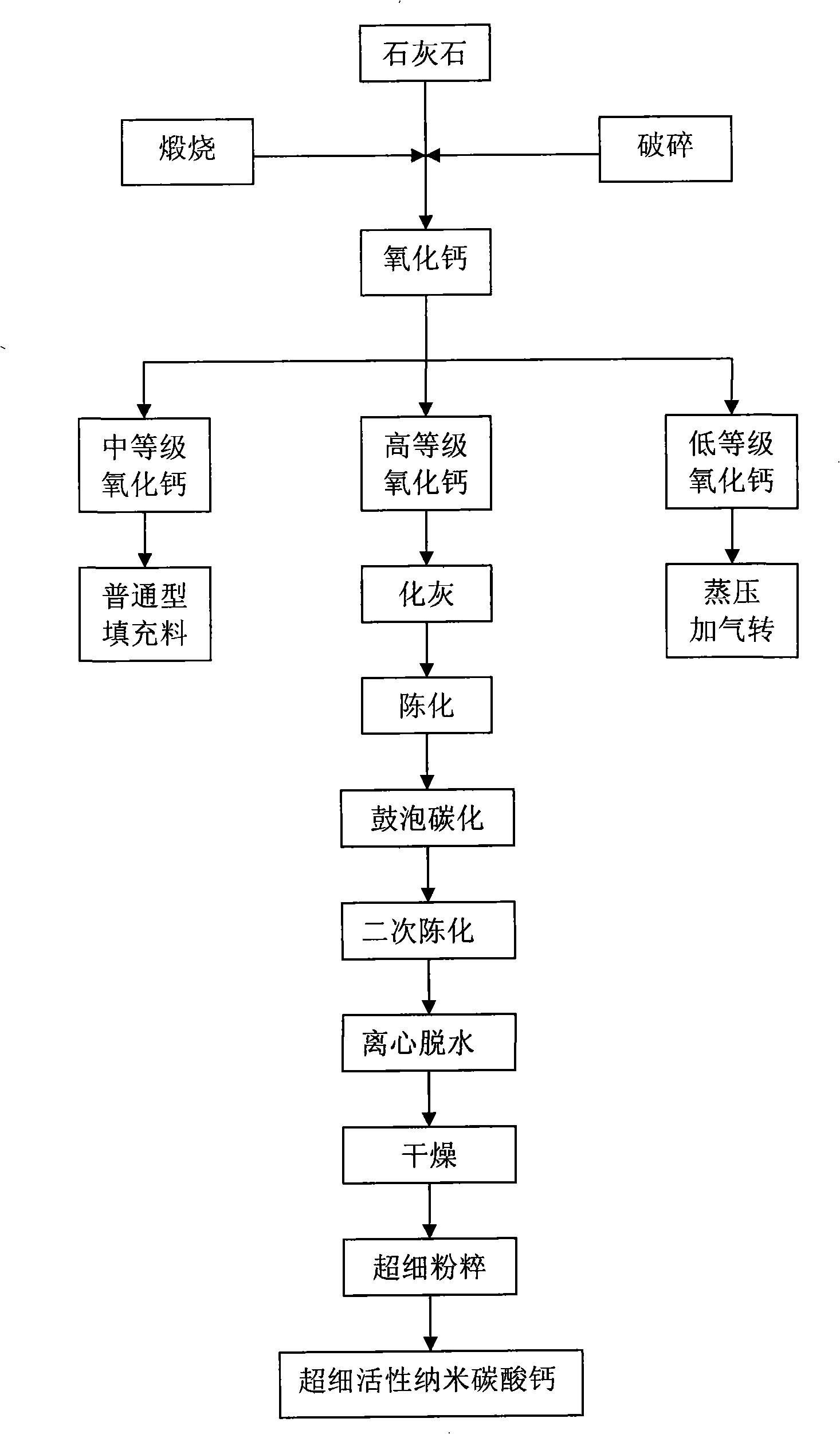

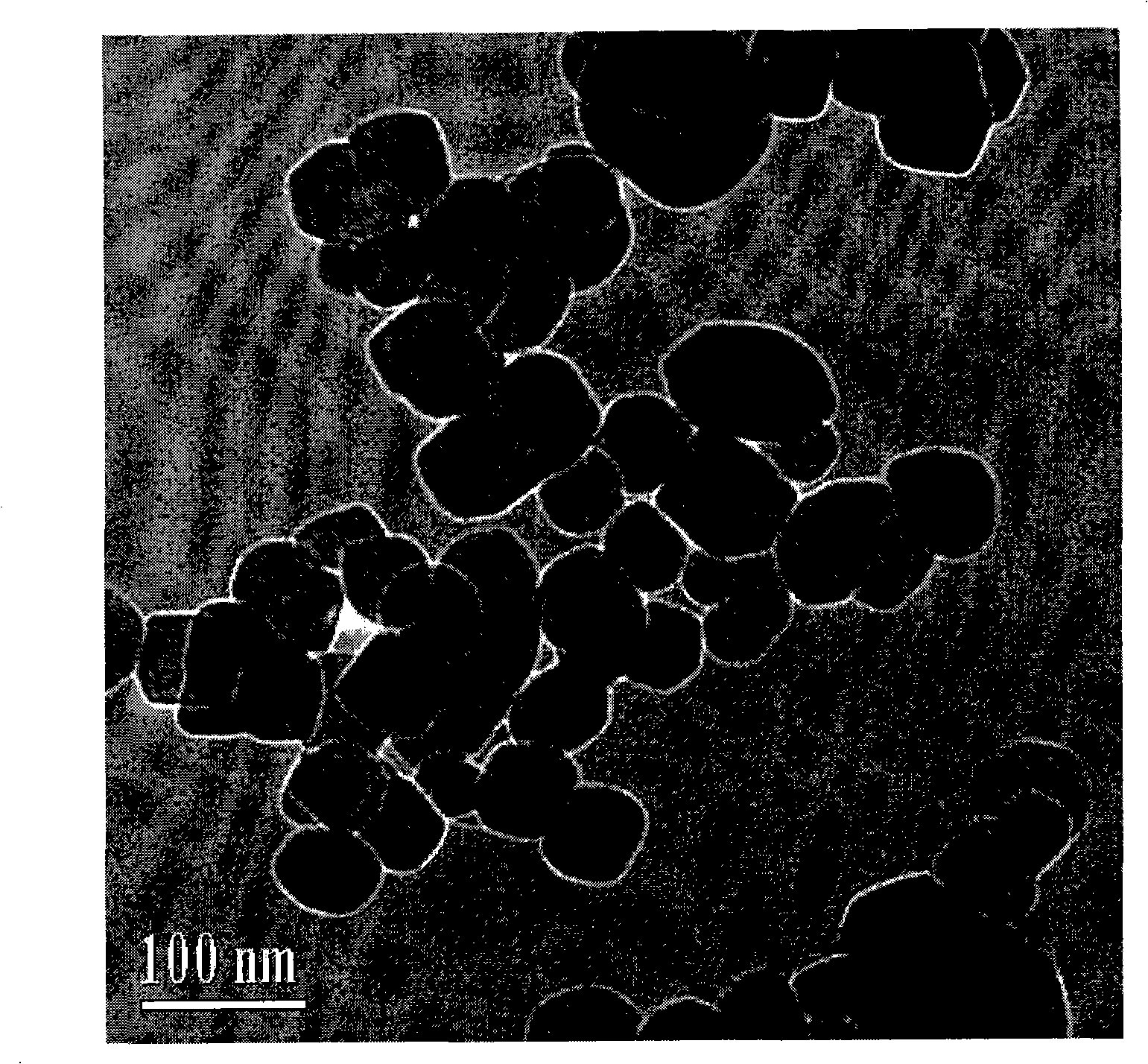

Method for preparing ultra-fine active nano-calcium carbonate with low-ore grade limestone wet-process activation

A low-grade limestone and nano-calcium carbonate technology, applied in the direction of calcium carbonate/strontium/barium, can solve the problems of surfactant loss and energy consumption, and achieve the effect of improving production efficiency and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The limestone is crushed by the jaw crusher to a size of 40-80mm, and then conveyed to the distribution hopper of the shaft kiln by the conveyor belt. The shaft kiln is calcined with a dry pulverized coal injection burner. During calcination, control the coal fire calcination temperature of the jet burner to keep at 1050°C, fire at a constant temperature, calcine for 6 hours, and spray under positive pressure.

[0030]The calcined lime is sieved, and high-quality lime is selected to enter the ash machine for ash. The temperature of the ashing water is controlled at 60°C, and the dosage is 6 times of the mass of lime. The primary slurry contains part of the coarse residue, and the solubility of calcium hydroxide is 13-15Be°. The method of hydrocyclone separation and vibrating sieving is used to remove undigested burnt lime, silicon dioxide, magnesium oxide and other impurities to obtain the refined slurry.

[0031] The prepared fine pulp is kept warm and aged by using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com