Microwave-hot air combined fluidized bed drying experiment device

A combination of drying and experimental device technology, applied in the direction of heating device, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of low dehydration rate and energy utilization rate, influence of product quality uniformity, and difficulty in product quality assurance, etc. Achieve the effect of small equipment occupation, fast drying speed and uniform distribution of electromagnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

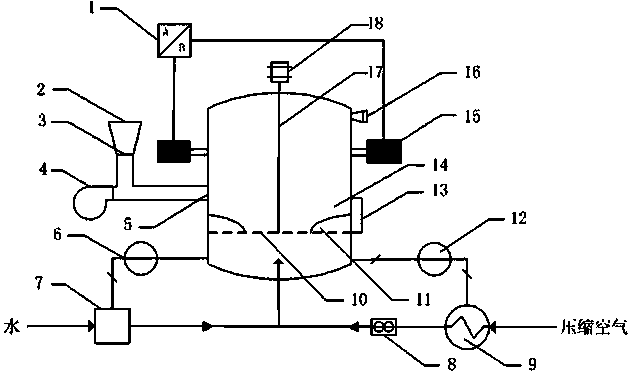

[0024] The present invention is further described below in conjunction with accompanying drawing:

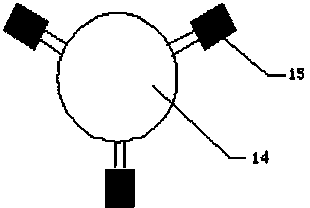

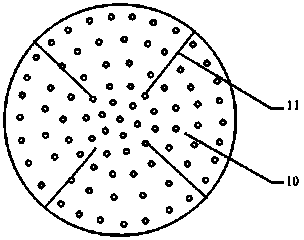

[0025] Such as Figure 1-3 Shown: a microwave fluidized bed hot air combined drying experiment device, including a tower fluidized bed 14, a microwave drying device arranged on the side wall of the tower fluidized bed, and a hot air drying system connected to the bottom of the tower fluidized bed , the middle and lower part of the tower fluidized bed is equipped with a loading screen 10 with a rotating shaft 18, the diameter of the loading screen is the same as the inner diameter of the tower fluidized bed cavity, and the loading screen 10 is provided with four Partition plates 11 distributed radially in cross symmetry (see image 3 ); the upper end of the rotating shaft 17 is connected with the motor 18; the side wall of the tower fluidized bed is respectively provided with a feed port 5 and a discharge port 13; the microwave drying device is composed of a microwave generator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com