Chemical industry production drying equipment with poking device

A toggle device and chemical production technology, applied in the direction of drying solid materials, drying gas arrangement, lighting and heating equipment, etc., can solve the problems of heat loss of drying equipment, inability to remove moisture well, reduce work efficiency, etc., and achieve improvement Preliminary drying quality, avoiding heat loss, and improving the effect of drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

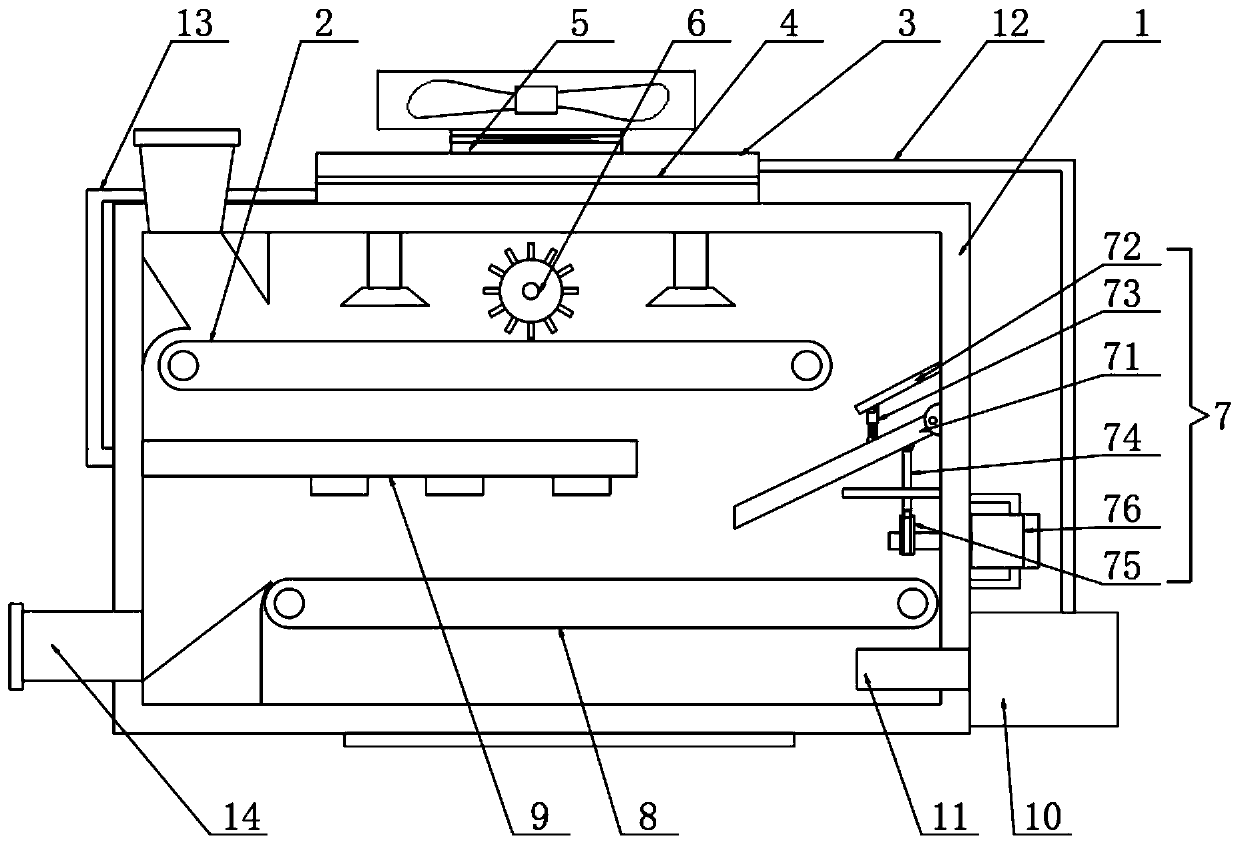

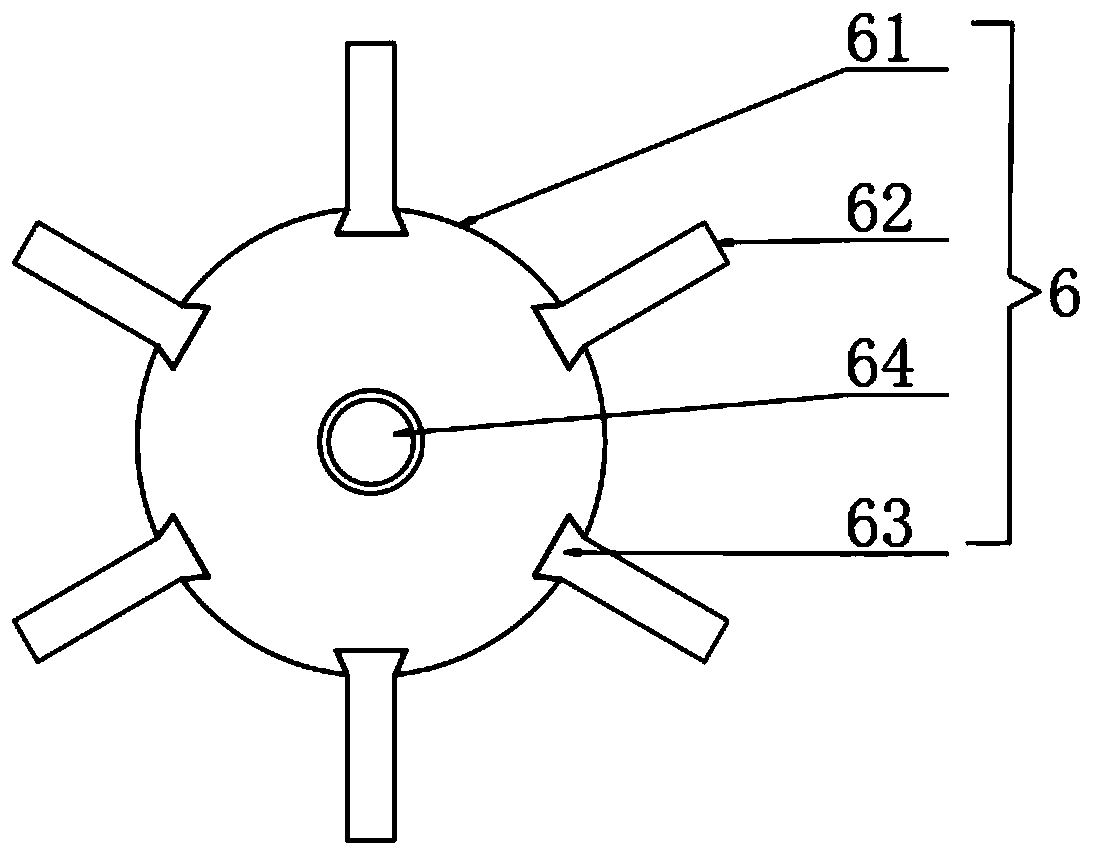

[0023] Example: When in use, put the chemical materials into the hopper, and the materials fall on the top of the horizontal conveyor belt 1,2, start the fan, heating net 4 and the driving motor 64, and the air volume generated by the fan is converted downwards through the heating net 4 into hot air through the air outlet The pipes and nozzles are sprayed against the top of the horizontal conveyor belt 1, and at the same time, part of the hot air is transmitted to the air distribution pipe 9 through the air transfer pipe 13. The nozzles at the bottom are sprayed to the top of the horizontal conveyor belt 2 8. After passing through the first air outlet pipe, the drive motor 64 drives the drum 61 to rotate, and the animal material is turned over by turning the claw 62, and then the second air outlet pipe is performed to complete the preliminary drying work. The material moves to the right through the support plate 72. Slide down onto the shaker plate 71, turn on the drive motor 76...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com