Wood chip drying device

A drying device and wood chip technology, applied in drying, drying machine, drying gas arrangement, etc., can solve problems such as waste, heat loss, and difficult control of tunnel heat temperature, and achieve low production cost, energy reduction, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

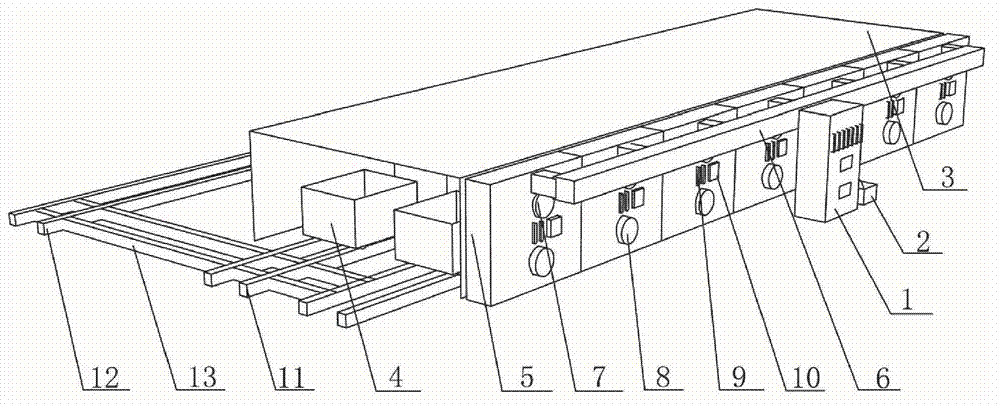

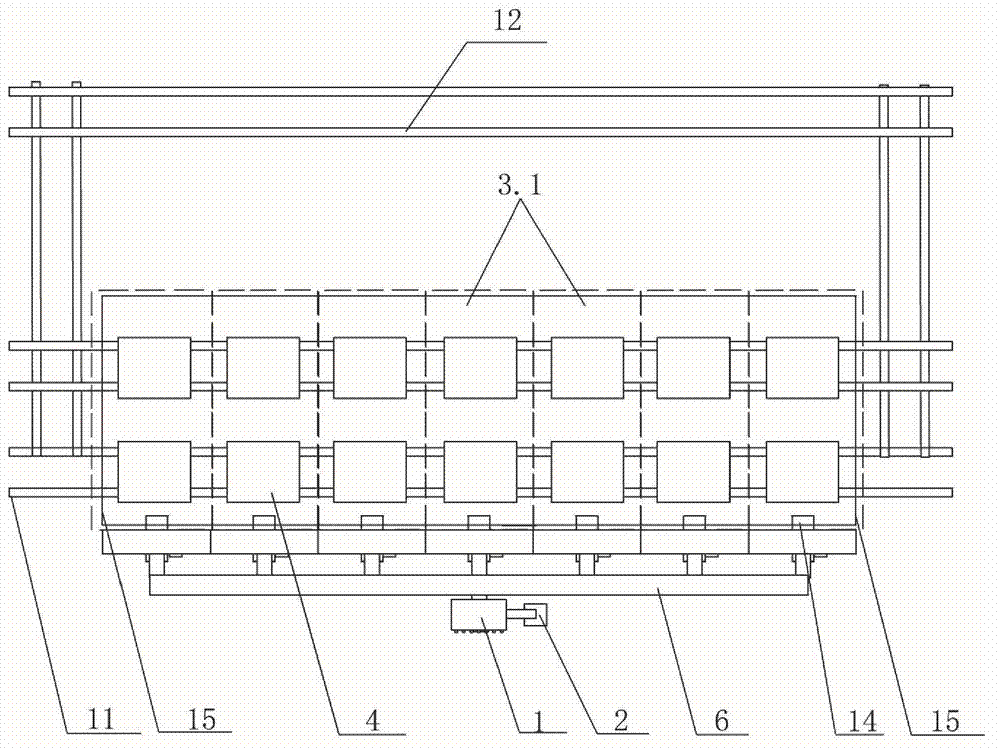

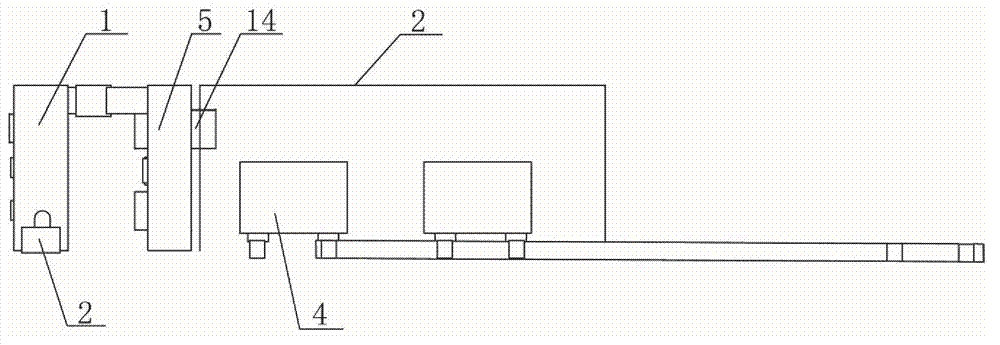

[0027] Such as Figure 1-3 As shown, the wood chip drying device of the present invention includes a combustion furnace 1, a blower 2, a dryer tunnel 3 and a dryer trolley 4, the combustion furnace 1 is connected with the blower 2, and the two ends of the dryer tunnel 3 are provided with furnace doors 15. There are two main rails 11 in the dryer tunnel 3, and the dryer trolley 4 is installed on the main rails 11. There are seven heat exchangers 5 on the side of the dryer tunnel 3, and the combustion furnace 1 is connected to each heat exchanger 5 through a heat pipe 6. The upper and lower parts of the heat exchanger 5 are respectively provided with an exhaust fan 7 and a flow fan 8. The exchanger 5 is connected with the dryer tunnel 3 through the flow air channel 14, wherein, seven heat exchangers 5 divide the corresponding dryer tunnel 3 into seven drying units 3.1, and each drying unit 3.1 is parked with 2 dryer trolleys 4. The side of the dryer tunnel 3 is also provided w...

Embodiment 2

[0030] The difference from Embodiment 1 is that the exhaust fan 7 and the flow fan 8 are replaced by a dual-purpose exhaust fan, and the control system 10 controls the dual-purpose exhaust fan according to the temperature in the dryer tunnel 3 . The forward and reverse rotation of the exhaust fan realizes the effect of blowing and sucking air. The rest of the working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com