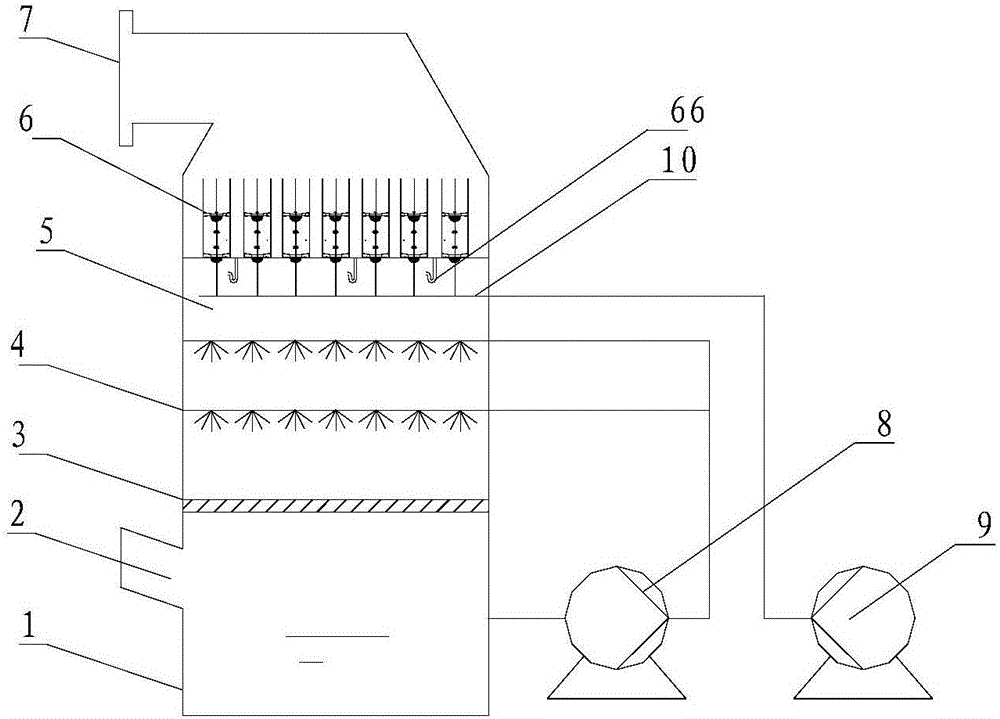

Device and process for coordinative treatment of smoke desulfuration and dedusting

A flue gas and dust technology, which is applied in the dust removal collaborative treatment process and the field of flue gas desulfurization, can solve the problems of low desulfurization efficiency, increased slurry circulation, and easy blockage of the demister, so as to prevent excessive resistance or blockage, Enhance the effect of fog and dust removal and increase the impact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

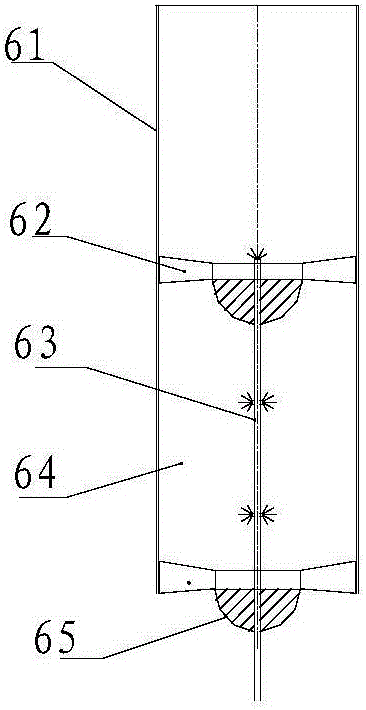

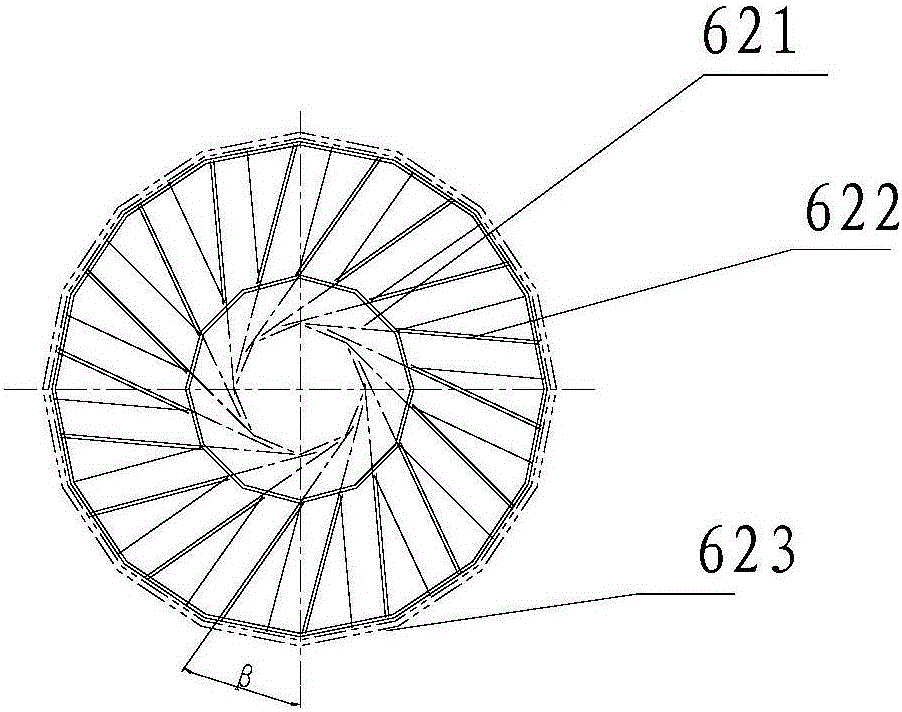

[0062] A sintering plant, 2 sets 260m 2 The new desulfurization project of sintering flue gas adopts this process, and the SO in the inlet flue gas 2 The concentration is 1785mg / m 3 , the dust concentration in the inlet flue gas is 62mg / m 3 , the opening rate of the tray is 35%, the opening diameter is 33mm, the height of the tray baffle is 55mm, the height of the settlement and cooling area is 6.5m, the number of layers of the swirl module is 3 layers, and the distance between two adjacent swirl modules is hollow diversion The inner diameter of the cylinder is 2D, the diameter of the drain hole is 6mm, the diameter of the central blind plate is 0.4 times the inner diameter of the hollow guide cylinder, the horizontal angle of the swirl blade is 35°, and the angle between the upper edge of the swirl blade and the radius is 30°. The atomized average particle size of the nozzle is 30μm, and the liquid-gas ratio of the atomized liquid is 0.06L / Nm 3 , circulating slurry liquid-...

Embodiment 2

[0064] In a thermal power plant, the flue gas desulfurization renovation project of two 135WM units adopts this process, and the SO in the inlet flue gas 2 The concentration is 2239mg / m 3 , the dust concentration in the inlet flue gas is 45mg / m 3 , the opening rate of the tray is 33%, the opening diameter is 30mm, the height of the tray baffle is 60mm, the height of the settlement and cooling area is 6.7m, the number of layers of the swirl module is 3 layers, and the distance between two adjacent swirl modules is hollow diversion The inner diameter of the cylinder is 2.2D, the diameter of the drain hole is 6mm, the diameter of the central blind plate is 0.5 times the inner diameter of the hollow guide cylinder, the horizontal angle of the swirl blade is 30°, and the angle between the upper edge of the swirl blade and the radius is 30° , the average atomized particle size of the nozzle is 38μm, and the liquid-gas ratio of the atomized liquid is 0.08L / Nm 3 , circulating slurry...

Embodiment 3

[0066] A self-provided power plant, a 410t / h boiler flue gas desulfurization renovation project adopts this process, SO in the inlet flue gas 2 The concentration is 1372mg / m 3 , the dust concentration in the inlet flue gas is 50mg / m 3, the opening rate of the tray is 30%, the opening diameter is 35mm, the height of the tray baffle is 60mm, the height of the settlement and cooling area is 6.0m, the number of layers of the swirl module is 2 layers, and the distance between two adjacent swirl modules is hollow diversion The inner diameter of the cylinder is 2.0D, the diameter of the drain hole is 7mm, the diameter of the central blind plate is 0.45 times the inner diameter of the hollow guide cylinder, the horizontal angle of the swirl blade is 30°, and the angle between the upper edge of the swirl blade and the radius is 35° , the atomized average particle size of the nozzle is 33μm, and the liquid-gas ratio of the atomized liquid is 0.08L / Nm 3 , circulating slurry liquid-gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com