Boiled egg peeling device

A technology for boiling eggs and power devices, which is applied in egg cookers, kitchen utensils, household utensils, etc. It can solve the problems of eggs being easily scratched, achieve the effect of fully automatic peeling of eggshells and improve the efficiency of shelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

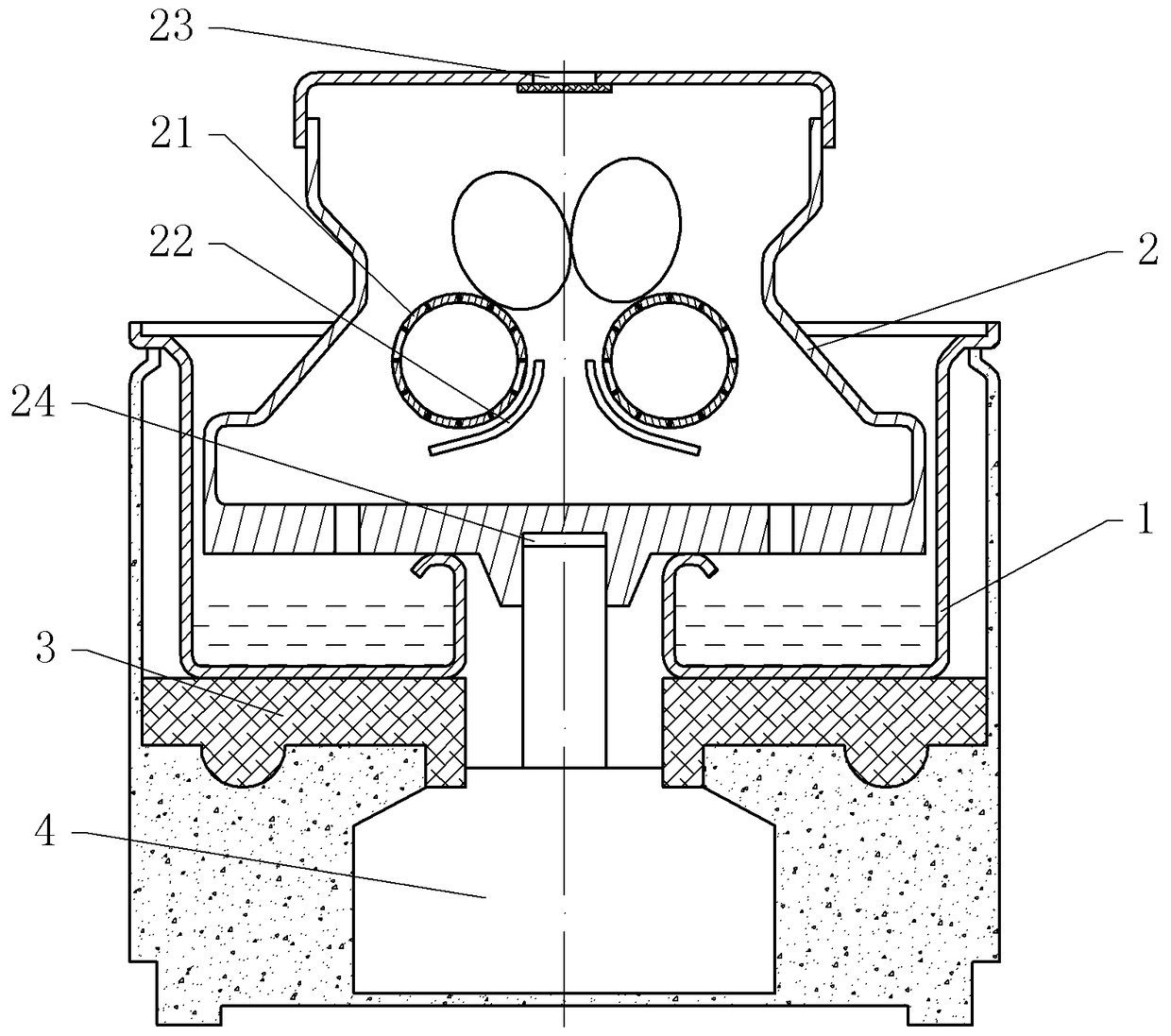

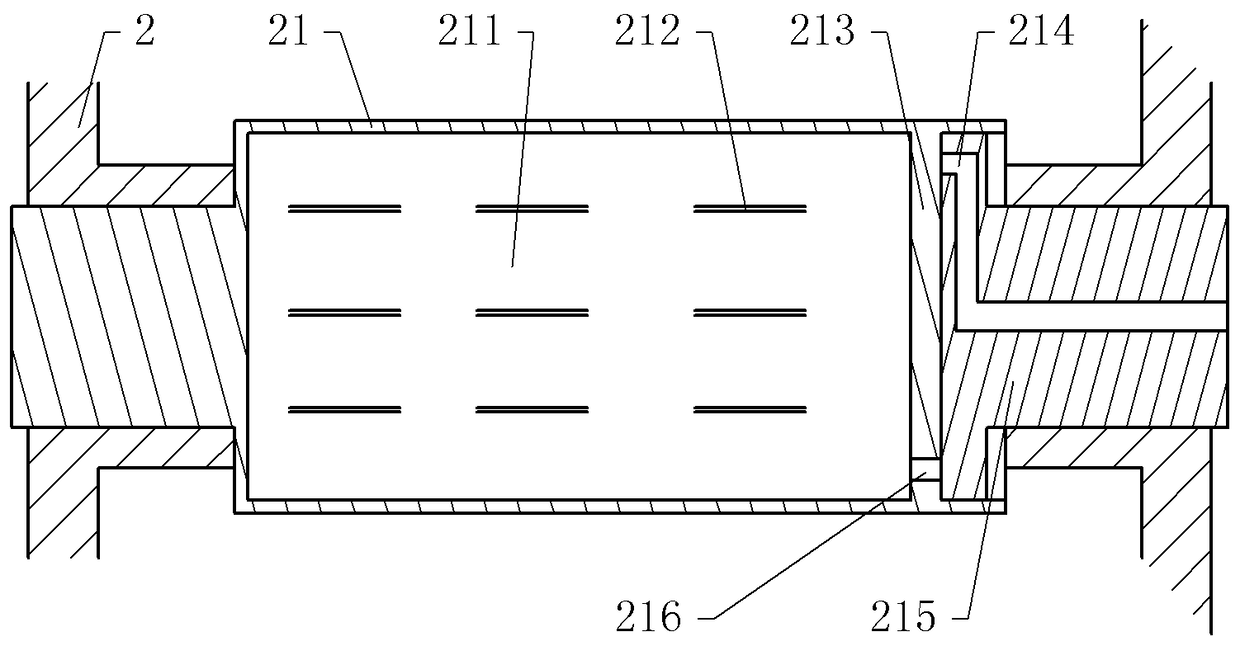

[0024] The reference signs in the drawings of the description include: water container 1, shell cracker 2, shelling shaft 21, arc baffle plate 22, air outlet 23, central axis hole 24, cavity 211, air hole 212, fixed axis 213, air outlet 214, rotation axis 215, air guide hole 216, electric heating plate 3, motor 4.

[0025] The embodiment is basically as figure 1 , figure 2 Shown:

[0026] The boiled egg peeling device of the present embodiment includes a shell breaker 2, and the shell breaker 2 is a cylindrical container, and its bottom surface is provided with a central axis hole 24, which is used to connect with the power unit, and at the same time It is convenient for the shell crusher 2 to be separated from the power device, the power device can drive the shell crusher 2 to rotate, and the power device is a motor 4 that can rotate forward and reverse. The cracker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com