Rice drying device

A drying device and rice technology, which are applied to drying, drying machines, heating devices and other directions, can solve the problems of uneven particle size of rice grains, inability to control the degree of rice drying, and unsatisfactory rice drying effect, etc. To achieve the effect of easy control, high degree of automation, and uniform drying of rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

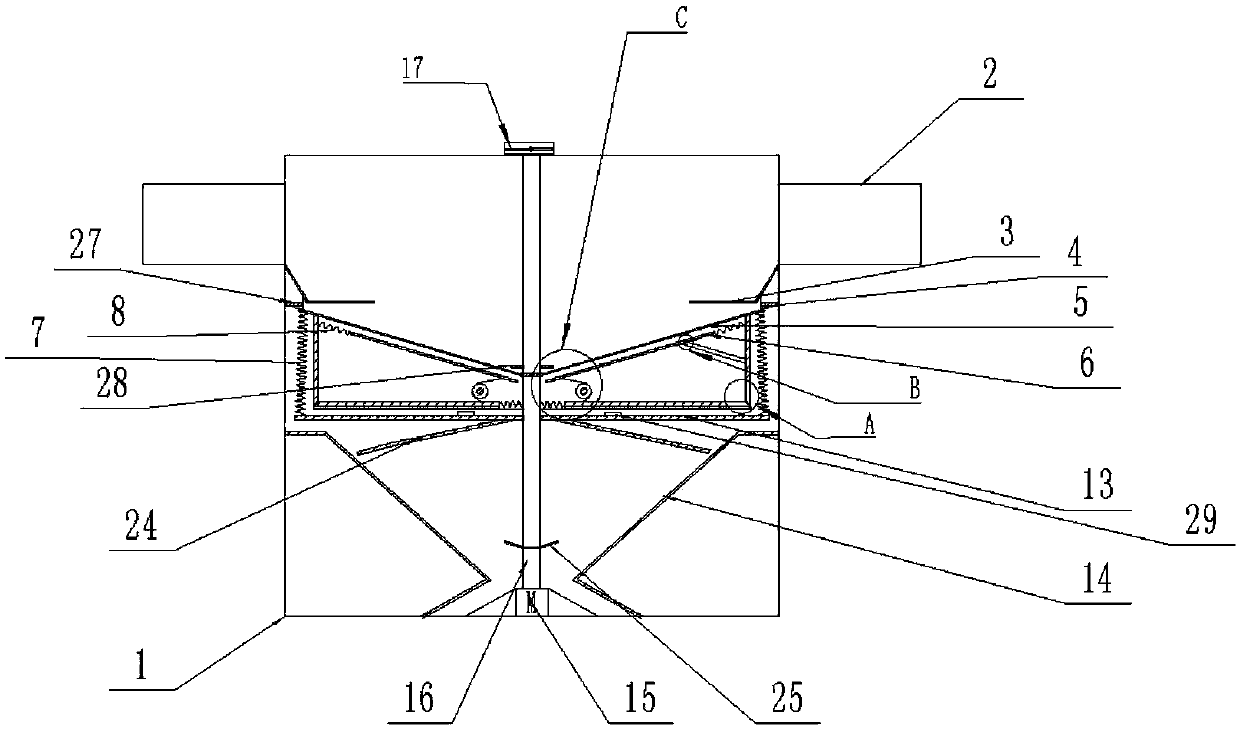

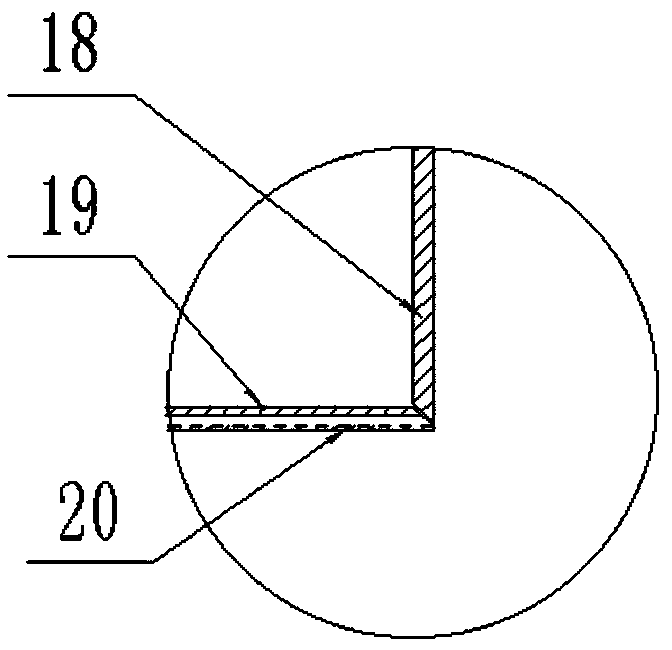

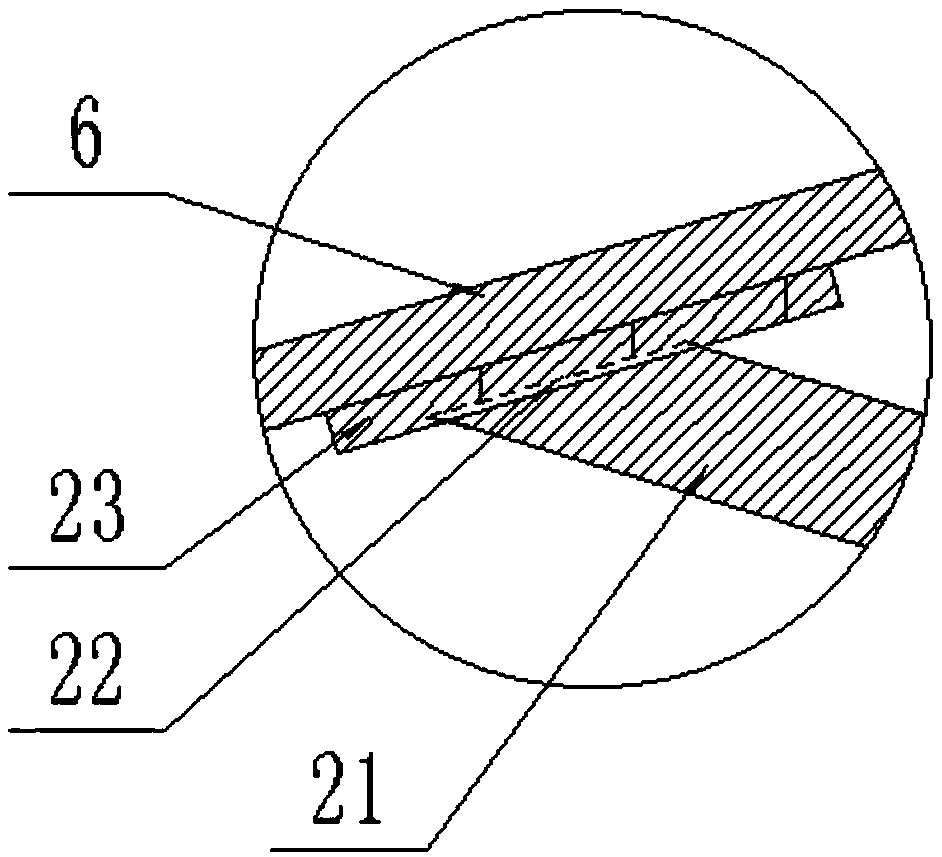

[0027] The orientation words such as "left, right" described in this embodiment only correspond to figure 1 , a rice drying device, such as figure 1 Shown, comprise casing 1, motor 15 and feeding box 2, casing 1 profile is cylindrical, and casing 1 top is provided with two feeding boxes 2 for the entry of rice, feeding box 2 and casing 1 Connected by a pin shaft, the inside of the casing 1 also includes a rotating shaft 16, a first leaking plate 5 and a second leaking plate 6, and a connecting plate 3 is located below the feed box 2, and the connecting plate 3 is fixed and welded on the first leaking plate through a fixed rod 4. On the plate 5, the connecting plate 3 is assembled by a horizontal plate and a vertical plate, and the horizontal plate and the vertical plate are connected by a torsion spring, and the motor 15 connected to the rotating shaft 16 and the negative air compressor 17 are fixedly connected to the casing 1 Below the top, both the second bushing plate 6 an...

Embodiment 2

[0038] Rice drying device, compared with embodiment 1, the difference of this embodiment is: (1) as figure 1 As shown, a slant plate 24 is also installed on the rotating shaft 16 below the first cross bar 13, the plate surface of the slant plate 24 is inclined downward, and the inclination angle with the horizontal plane is set to 20 °, and the slant plate 24 has evenly distributed filter holes , the aperture of the filter hole is smaller than the particle diameter of the rice grain, and the periphery of the inclined plate 24 has a circle of filter holes larger than the rice grain diameter.

[0039] (2) A fan 25 is also installed on the rotating shaft 16, and the fan 25 is located in the middle of the swash plate 24 and the motor 15.

[0040] As an optimization of Example 1, when the rice to be dried is poured into the feeding box 2, since the feeding box 2 is connected by a pin shaft, the rice in the feeding box 2 can be poured with a light touch. Pour into the connecting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com