Sludge heating and drying device

A technology of heating drying and smelting device, applied in the direction of sludge treatment by temperature control, dewatering/drying/concentrating sludge treatment, etc., can solve problems such as deficiencies, and achieve the effects of reducing waste, easy boiling, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

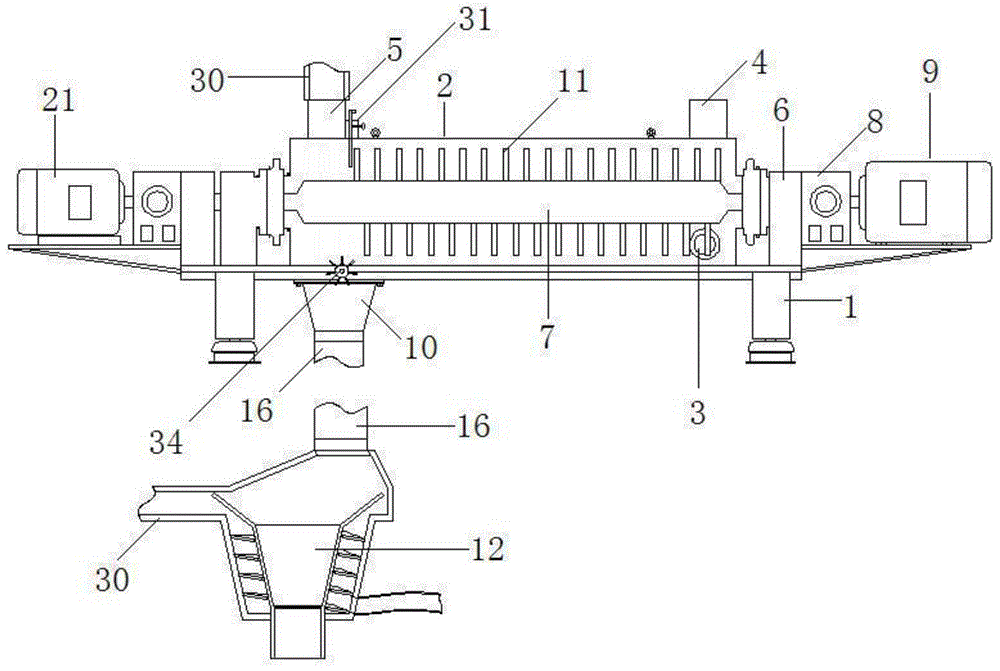

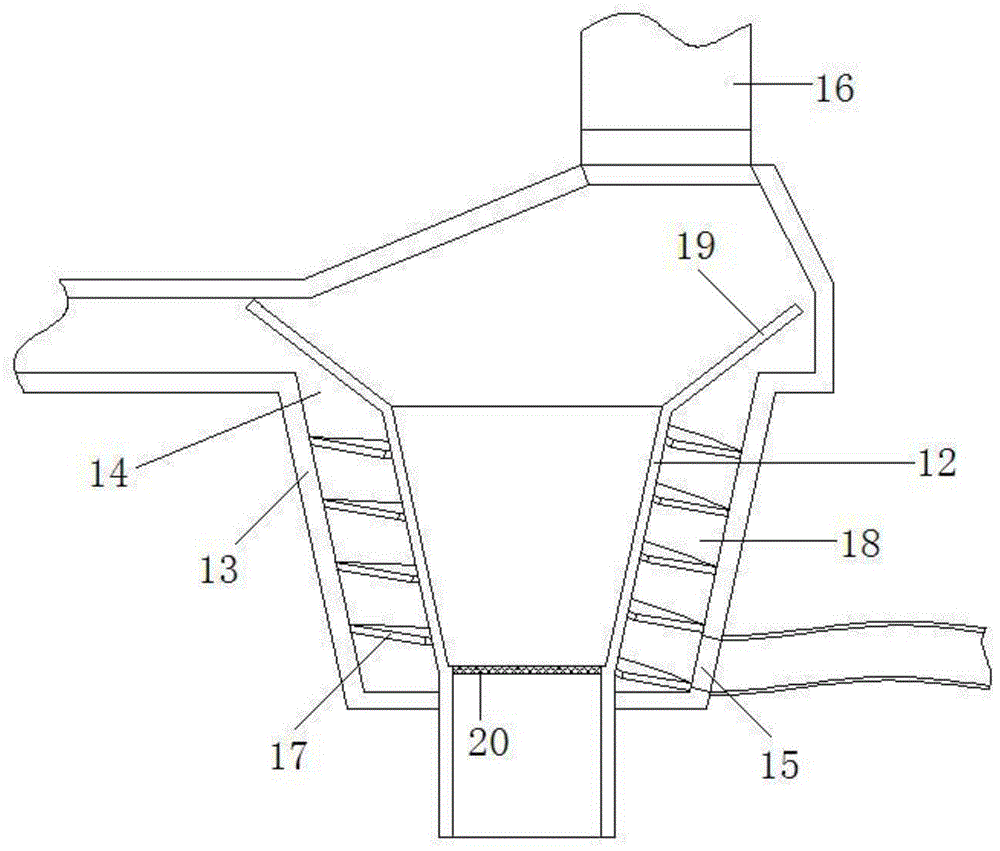

[0023] Embodiment 1: asfigure 1 , figure 2 , Figure 4 , Figure 5 In the shown embodiment, a sludge heating and drying device includes a frame 1, a horizontal drying main cylinder 2, and a dry sludge receiving part. The drying main cylinder is fixed to the frame, and the drying main cylinder There is a sludge feed port 3 on the barrel, and the top of the drying main barrel is provided with a hot flue gas inlet 4 and a wet flue gas outlet 5, and the hot flue gas inlet and the wet flue gas outlet are respectively located near the drying main barrel At the top of both ends, the frame is provided with a bearing seat 6, and the bearing seat is provided with a rotor main shaft 7 matching the bearing seat, and the rotor main shaft is located in the drying main cylinder. The frame is provided with a main shaft drive motor 9 connected to the rotor main shaft through a reducer 8, and a sludge discharge port 10 is provided at the lower part of the drying main cylinder away from the s...

Embodiment 2

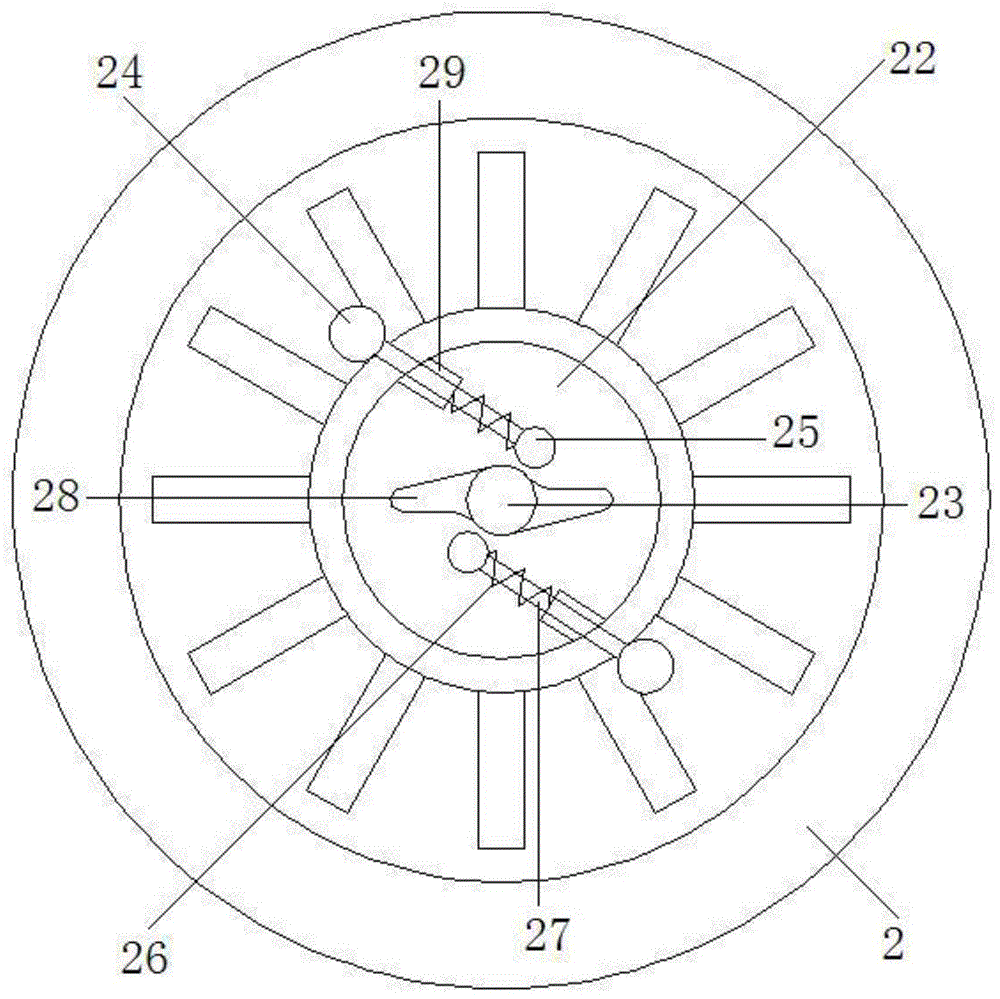

[0025] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as image 3 As shown, the frame is provided with a mud-beating motor 21, and the mud-beating motor is located at the end of the rotor main shaft away from the main shaft drive motor, and the described rotor main shaft is provided with a main shaft inner chamber 22, one of which is connected to the rotor. The coaxial transmission inner shaft 23 of the main shaft extends into the inner cavity of the main shaft. One end of the transmission inner shaft is connected with the output shaft of the mud-beating motor, and the other end is connected with the inner shaft bearing. The rotor main shaft is provided with a plurality of The mud beating device, the mud beating device includes a mud ball 24, a stopper 25, a ball receiving spring 26, a slide bar 27, and a slide hole arranged on the main shaft wall, and the slide bar is slidably matched with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com