High-efficiency extraction process for polysaccharide of lotus seeds

An extraction process and polysaccharide technology, applied in the field of high-efficiency extraction process of lotus seed polysaccharides, to achieve the effects of easy operation, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

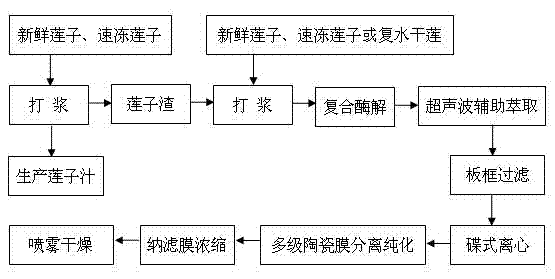

[0033] A high-efficiency extraction process of lotus seed polysaccharide of the present invention, the process flow is shown in figure 1 ,Specific steps are as follows:

[0034] (1) Beat the remaining lotus seed dregs from the production of lotus seed juice with distilled water of 10 times its mass, then pass through a colloid mill with a fineness of 100-120 mesh, and reserve for later use (the lotus seed dregs are provided by Fujian Minjiangyuan Lvtian Industrial Investment and Development Co., Ltd. );

[0035] (2) Add amylase, pectinase and acid cellulase (Zaozhuang Jienuo Bioenzyme Co., Ltd., No. PRO2010113011136) to the lotus seed pulp for hydrolysis, the addition amount is 0.005%, 0.0015%, 0.004%, respectively The hydrolysis temperature is 25°C, and the enzymatic hydrolysis time is 1.5Hr;

[0036] (3) After enzymatic hydrolysis, ultrasonic-assisted extraction is carried out, the ultrasonic power is 350W / kg, and the action time is 6 minutes;

[0037] (4) After ultrason...

Embodiment 2

[0040] A kind of lotus seed polysaccharide high-efficiency extraction process of the present invention, the concrete steps of extraction are:

[0041] (1) Beat the quick-frozen lotus seeds with 15 times the mass of distilled water, and then pass through a colloid mill, with a fineness of 100-120 mesh, for later use (quick-frozen lotus seeds are provided by Fujian Minjiangyuan Lvtian Industrial Investment and Development Co., Ltd.);

[0042](2) Add amylase, pectinase and acid cellulase (Zaozhuang Jienuo Bioenzyme Co., Ltd., No. PRO2010113011136) to the lotus seed pulp for hydrolysis. The hydrolysis temperature is 30°C, and the enzymatic hydrolysis time is 2.0Hr;

[0043] (3) After enzymatic hydrolysis, ultrasonic-assisted extraction is carried out, the ultrasonic power is 400W / kg, and the action time is 8 minutes;

[0044] (4) After ultrasonic-assisted extraction, the extract solution is successively subjected to centrifugation, plate-and-frame filtration and disc centrifugal ...

Embodiment 3

[0047] A kind of lotus seed polysaccharide high-efficiency extraction process of the present invention, the concrete steps of extraction are:

[0048] (1) After soaking and rehydrating the dried lotus, beat it with distilled water 20 times its mass, then pass it through a colloid mill, with a fineness of 100-120 mesh, and reserve it for later use (dried lotus is provided by Fujian Minjiangyuan Lvtian Industrial Investment and Development Co., Ltd.) ;

[0049] (2) Add amylase, pectinase and acid cellulase (Zaozhuang Jienuo Bioenzyme Co., Ltd., No. PRO2010113011136) to lotus seed pulp for hydrolysis, the addition amount is 0.015%, 0.0025%, 0.006%, respectively, enzyme The hydrolysis temperature is 35°C, and the enzymatic hydrolysis time is 2.5Hr;

[0050] (3) After enzymatic hydrolysis, ultrasonic-assisted extraction is carried out, the ultrasonic power is 450W / kg, and the action time is 10 minutes;

[0051] (4) After ultrasonic-assisted extraction, the extract solution is suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com