Industrial extraction and separation method of ganoderma spore polysaccharide and separation device

A technique for the separation of Ganoderma lucidum spores, which is applied in the field of industrial extraction and separation of Ganoderma lucidum spore polysaccharides, can solve the problems of difficult filtration and separation of solid and liquid, low industrial production efficiency, achieve fast separation speed, maintain aromatic flavor, and avoid fermentation and rancidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

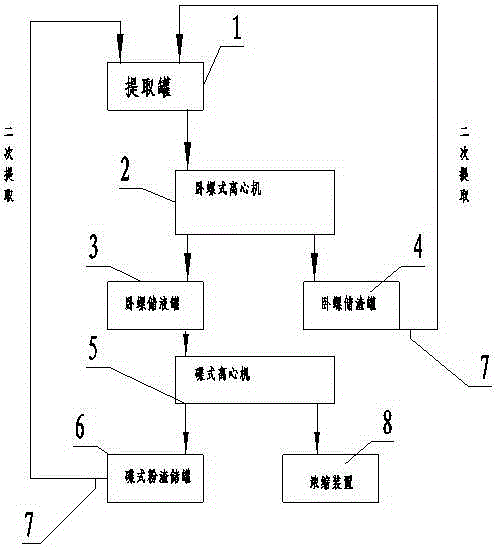

[0034] Industrial extraction and separation of Ganoderma lucidum spore polysaccharides using the above device: Weigh 240kg of defatted spore powder and place it in 3.0T extraction tank 1, add 8 times the amount of spore powder to a total of 1.92T, heat to 100 degrees, extract with boiling water, and extract with constant temperature stirring for 2 hours Afterwards, the above-mentioned spore powder water extraction suspension was separated by decanter centrifuge 2 (drum speed 3800r / min, separation factor 2860) to obtain decanter solid phase powder residue and micro-suspended liquid phase, which were stored in decanter Because the speeds of the two centrifuges are different, a horizontal screw storage tank is needed for liquid storage. If the speed of the two can reach the same, they can be directly connected. The micro-suspended liquid phase in the horizontal screw storage tank 3 enters the butterfly centrifuge 5 (rotating drum speed 7600r / min, separation factor 10000), and separ...

Embodiment 2

[0036] Weigh 240kg of defatted spore powder and place it in 3.0T extraction tank 1. Add 10 times the amount of spore powder to 2.4T for boiling water extraction. After 2 hours of constant temperature stirring and extraction, the above-mentioned water extraction suspension of spore powder is passed through decanter in turn The series system of a type centrifuge (rotating drum speed 3800r / min, separation factor 2860), butterfly centrifuge (rotating drum speed 7600r / min, separation factor 10000) cyclically separates the liquid and solid phases. The final concentration is the Ganoderma lucidum spore powder polysaccharide extract (the yield of polysaccharide is 10.2%, and the content is 15.9%). The liquid phase was sampled for experimental analysis. The turbidity of the liquid phase was 107nut, which was relatively clear. The remaining unmentioned parts are the same as the above example.

Embodiment 3

[0038] Weigh 200kg of defatted spore powder and place it in the extraction device, add 12 times the amount of spore powder to 2.4T for boiling water extraction, stir and extract at constant temperature for 2 hours, then pass the above-mentioned spore powder water extraction suspension sequentially through a decanter centrifuge The series system of the machine (rotary drum speed 5000r / min, separation factor 3525), butterfly centrifuge (rotor drum speed 7060r / min, separation factor 11200) cyclically separates the liquid and solid phases. Concentrate to obtain Ganoderma lucidum spore powder polysaccharide extract (the yield of polysaccharide is 10.5%, and the content is 16%). The liquid phase was sampled for experimental analysis, and the turbidity of the liquid phase was 100nut, which was relatively clear. The rest of the undescribed parts are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com