Extraction and purification method of bioactive polysaccharides in dendrobium huoshanense

A technology for bioactive polysaccharides and purification methods, applied in the field of purification and extraction of bioactive polysaccharides in Dendrobium Huoshanense, can solve problems such as shortening extraction time, achieve the effects of reducing energy consumption, avoiding organic solvent residues, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

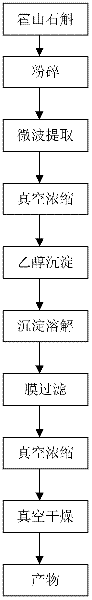

[0031] 1. Microwave extraction: Grind 30 g of Dendrobium Huoshanense into coarse powder, add 600 mL of water to the obtained coarse powder, extract at 2450 MHz frequency, power 500 W, and 60 °C microwave constant temperature for 30 min, extract 4 times, and combine 4 extracts;

[0032] 2. Concentration: Concentrate the extract obtained in step 1 to a relative density of 1.15 (60°C) at a vacuum of -0.07 to -0.08MPa and a temperature of ≤70°C to obtain a concentrate;

[0033] 3. Alcohol precipitation: add 95vt% (volume percentage concentration, the same below) ethanol to the concentrated solution obtained in step 2 to obtain a mixed solution, and the volume percent concentration of ethanol in the mixed solution is 80vt%. 4.3 g of precipitate was obtained by centrifugation under the revolution / minute speed;

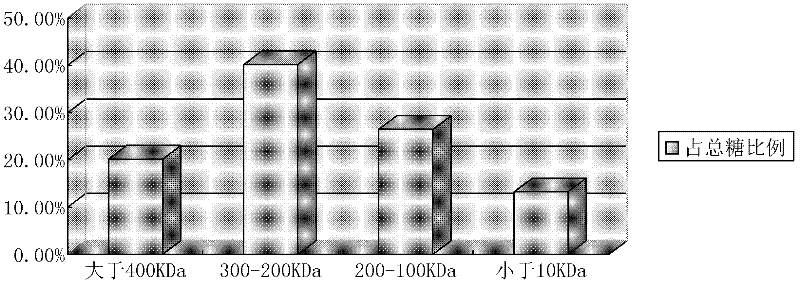

[0034] 4. Membrane filtration: Add 100mL of 60°C water to the precipitate obtained in step 3 to dissolve the precipitate, pass the solution through an ultrafiltration membra...

Embodiment 2

[0041] 1. Microwave extraction: crush 30 g of Dendrobium Huoshanense into a coarse powder, add 450 mL of water to the obtained coarse powder, extract at 2450 MHz frequency, power 560 W, and 80 °C microwave constant temperature for 10 min, extract 4 times, and combine the extracts from 4 times;

[0042] 2. Concentration: Concentrate the extract obtained in step 1 to a relative density of 1.19 (60°C) under the conditions of a vacuum of -0.07 to -0.08MPa and a temperature of ≤70°C to obtain a concentrate;

[0043] 3. Alcohol precipitation: add 95vt% ethanol to the concentrated solution obtained in step 2 to obtain a mixed solution, the volume percent concentration of ethanol in the mixed solution is 80vt%, centrifuge at 4000 rpm after standing for 24 hours to obtain a precipitate 4.6g;

[0044] 4. Membrane filtration: add 10mL of 60°C water to the precipitate obtained in step 3 to dissolve the precipitate, pass the solution through an ultrafiltration membrane with a molecular wei...

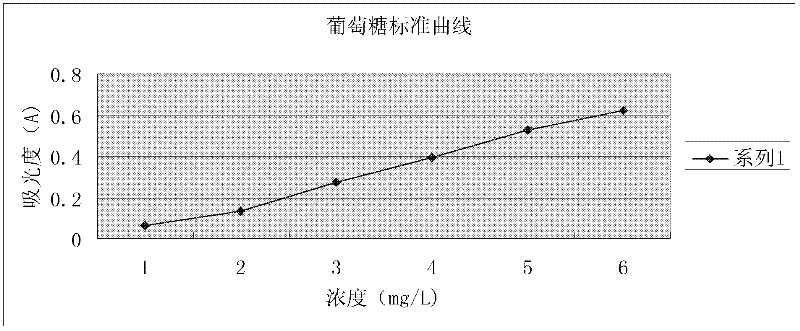

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com