Ethylenediamine tetraacetic acid modified diatomite adsorbent as well as preparation method and application thereof to treatment of heavy metal ions in wastewater

A technology of ethylenediaminetetraacetic acid and diatomite, which is applied in the field of water treatment, can solve the problems of refractory biodegradation, severe toxicity or carcinogenicity of heavy metal pollutants, and achieve high adsorption efficiency, convenient raw material acquisition, and strong adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

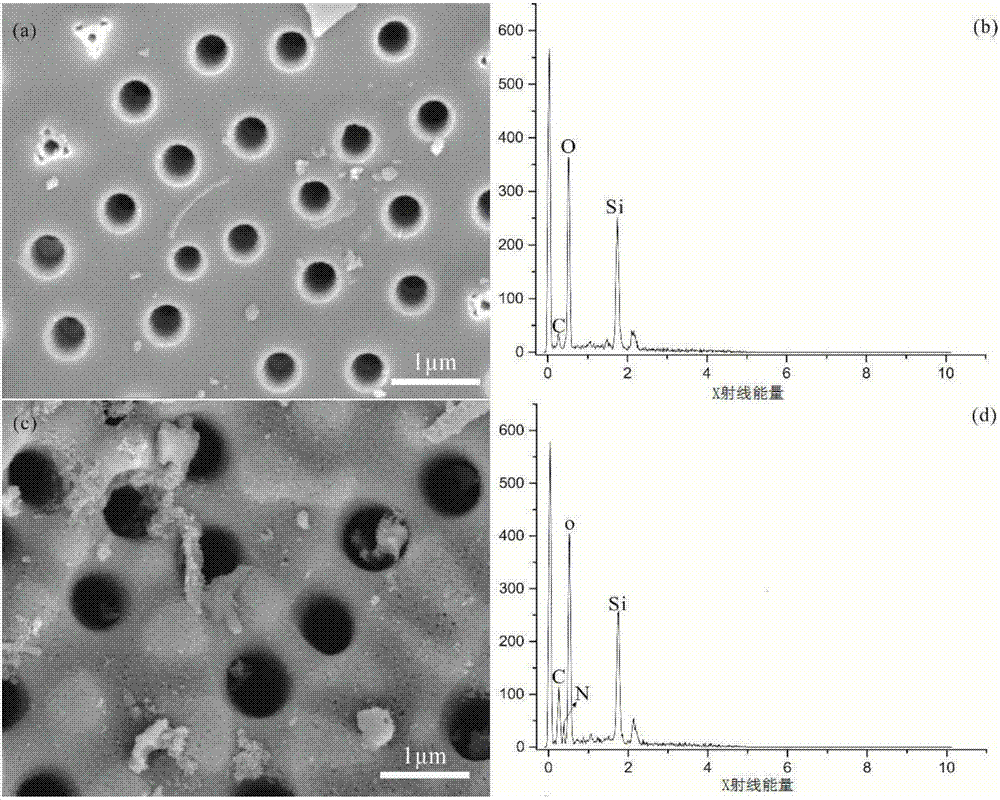

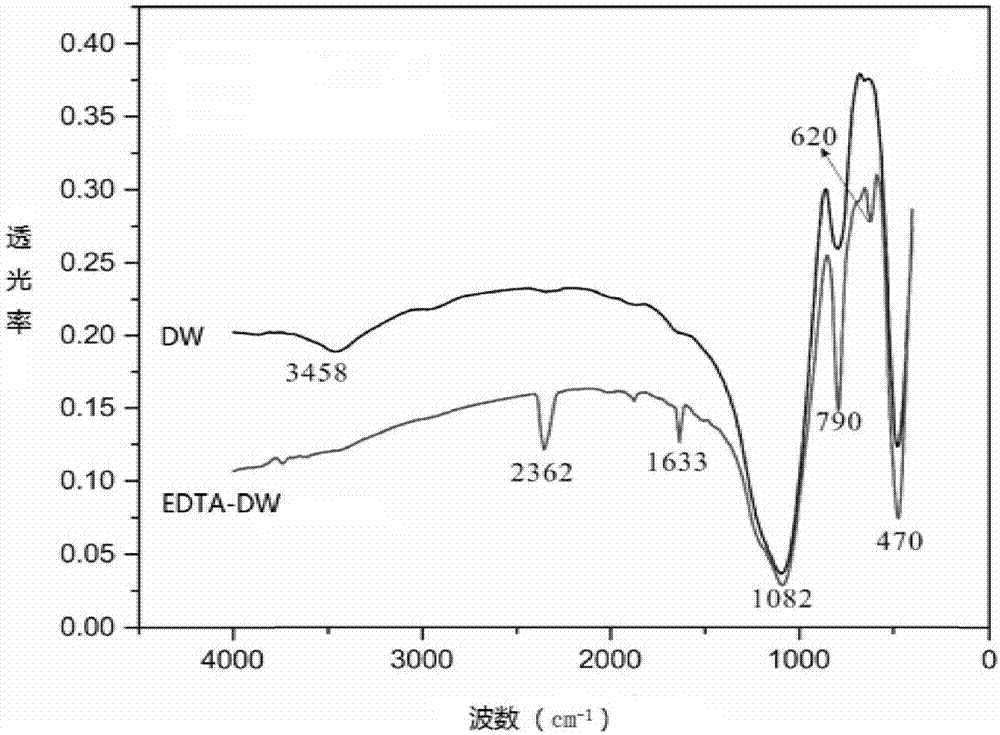

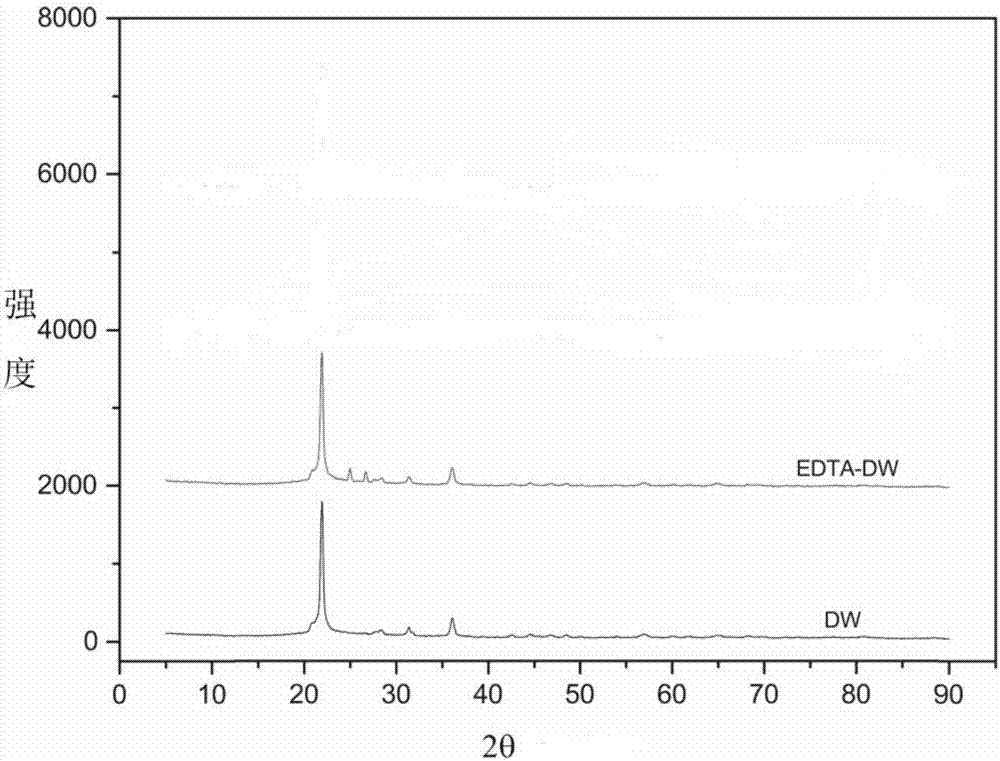

[0019] The preparation method of modified diatomite adsorbent is:

[0020] (1) Pretreatment of waste diatomaceous earth in breweries:

[0021] Soak the waste diatomite from the brewery in 3M NaOH solution, stir for 30 minutes, and centrifuge to obtain the waste diatomite treated with NaOH solution; then soak the waste diatomite treated with NaOH solution in 3M hydrochloric acid solution , after stirring for 30 minutes, centrifuge; then wash with distilled water several times until the washing liquid reaches neutrality. Then bake it in an oven at 120° C. for 12 hours to obtain pretreated waste diatomaceous earth from a brewery.

[0022] (2) Modification of diatomite:

[0023] Get the EDTA of 3.6g urea and 0.7g and put into successively in the flask that fills 30ml ethylene glycol, and add 1.8g through step (1) the brewery waste diatomite powder of pretreatment, under 50 ℃ in magnetic stirrer Stir for 30 minutes. Then the mixture was placed in an autoclave, heated at 200 °C ...

Embodiment 2

[0027] The preparation method of modified diatomite adsorbent is:

[0028] (1) Pretreatment of waste diatomaceous earth in breweries:

[0029] Soak the waste diatomaceous earth from the brewery in 2M NaOH solution, stir for 20 minutes, and centrifuge to obtain the waste diatomite treated with NaOH solution; then soak the waste diatomite treated with NaOH solution in 4M hydrochloric acid solution , after stirring for 20 minutes, centrifuge; then wash with distilled water several times until the washing liquid reaches neutrality. Then bake it in an oven at 120° C. for 12 hours to obtain pretreated waste diatomaceous earth from a brewery.

[0030] (2) Modification of diatomite:

[0031] Get the EDTA of 2.8g urea and 0.7g and put into successively in the flask that fills 30ml ethylene glycol, and add 1.9g through step (1) pretreated brewery waste diatomite powder, under 40 ℃ in the magnetic stirrer Stir for 30 minutes. Then the mixture was placed in an autoclave, heated at 160...

Embodiment 3

[0035] The preparation method of modified diatomite adsorbent is:

[0036] (1) Pretreatment of waste diatomaceous earth in breweries:

[0037] Soak the waste diatomite from the brewery in 4M KOH solution, stir for 20 minutes, and centrifuge to obtain the waste diatomite treated with KOH solution; then soak the waste diatomite treated with KOH solution in 2M hydrochloric acid solution , after stirring for 20 minutes, centrifuge; then wash with distilled water several times until the washing liquid reaches neutrality. Then bake it in an oven at 120° C. for 12 hours to obtain pretreated waste diatomaceous earth from a brewery.

[0038] (2) Modification of diatomite:

[0039] Get the EDTA of 4.2g urea and 0.7g and put into the flask that fills 30ml ethylene glycol successively, and add 1.7g through step (1) pretreated brewery waste diatomite powder, under 60 ℃ in magnetic stirrer Stir for 20 minutes. Then the mixture was placed in an autoclave, heated at 160 °C for 6 h, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com