Ceramic membrane chemical cleaning system and method

A chemical cleaning and ceramic membrane technology, applied in the field of chemical cleaning ceramic membrane systems, can solve the problems of membrane cleaning liquid secondary treatment, cleaning liquid secondary pollutants, ceramic membrane pollution, etc., to save aeration costs and reduce pollution The effect of mud discharge and no cleaning fluid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

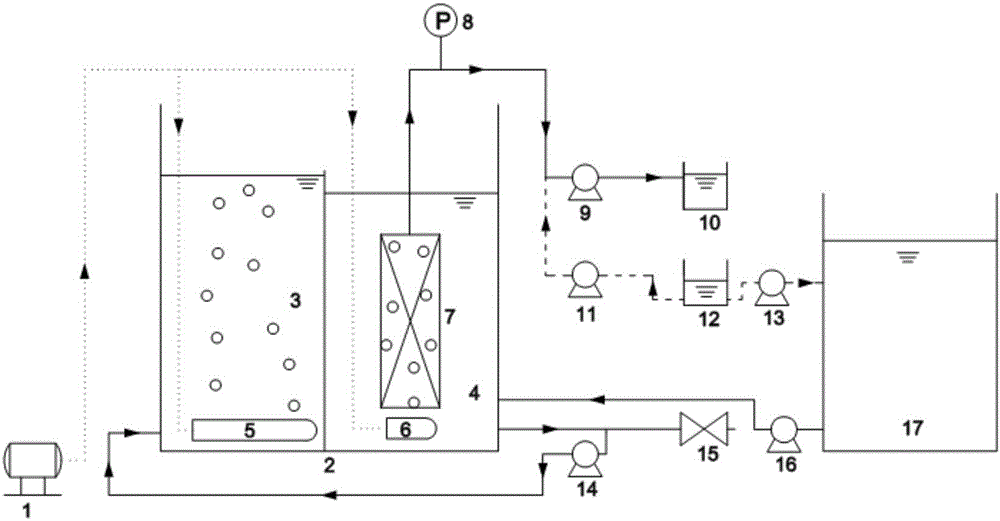

Image

Examples

example 1

[0059] Application of Flat Ceramic Membrane in Sewage Treatment A 2 O process for aerobic biological treatment. Membrane tank sludge concentration MLSS=5g / L, membrane filtration critical flux is 30LMH, start the membrane tank suction system with subcritical flux 20LMH for constant flux stable operation, when the transmembrane pressure difference (TMP) increases to 30- At 35kPa, stop the suction and start the online cleaning system. The results of multiple experiments show that after a certain amount of H 2 o 2 After online cleaning, the recovery rate of the transmembrane pressure difference of the ceramic flat membrane is not less than 93%. The specific test results are shown in Table 1 below.

[0060] Table 1H 2 o 2 On-line cleaning of flat ceramic membrane test results

[0061] Test No. ΔTMP before washing (kPa) After washing ΔTMP(kPa) TMP recovery rate (%) 1 32.6 2.10 93.55 2 31.4 1.66 94.71 3 33.5 1.95 94.17

example 2

[0063] Under the same test conditions, the polluted ceramic diaphragm was subjected to H 2 o 2 Off-line immersion cleaning, the results of multiple tests show that after a certain amount of H 2 o 2 After off-line immersion, the recovery rate of the transmembrane pressure difference of the ceramic flat membrane is not less than 98%. The specific test results are shown in Table 2 below.

[0064] Table 2H 2 o 2 Test effect of off-line immersion cleaning flat ceramic membrane

[0065] Test No. ΔTMP before washing (kPa) After washing ΔTMP(kPa) TMP recovery rate (%) 1 35.4 0.43 98.78 2 34.2 0.40 98.83 3 34.7 0.38 98.90

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com