Puffed glutinous rice purple sweet potato crisp chip and production method thereof

A technology for puffed glutinous rice and a production method, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of high oil content of the product, does not meet the low oil content, and destroys nutrients, and achieves good taste, low production cost, and maintenance. The effect of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Put the sliced purple potato slices into hot water at a certain temperature for pre-cooking, and steam the pre-cooked purple potato slices with hot steam in a steam pot to mash them into puree. In this example, the precooking time, precooking temperature, and cooking time are used as the investigation factors, and the free starch content is used as the investigation index to carry out orthogonal optimization, select three factors and three levels, and use the orthogonal design assistant to design experiments, and the purple sweet potato has been obtained. Optimum treatment conditions for mud. The factors and levels are shown in Table 1.

[0062] The free starch content was determined by the method of Lu Yaochang and Karkalas. Use a graduated cylinder to measure 100mL of hot water at about 65.5°C into a 150mL conical flask with a stopper, immediately pour 200mg of purple sweet potato puree into the bottle, and shake it quickly to avoid agglomeration. Shake intermitte...

Embodiment 2

[0075] Determination of the Best Flavor Formula of Embodiment 2 Purple Potato Chips

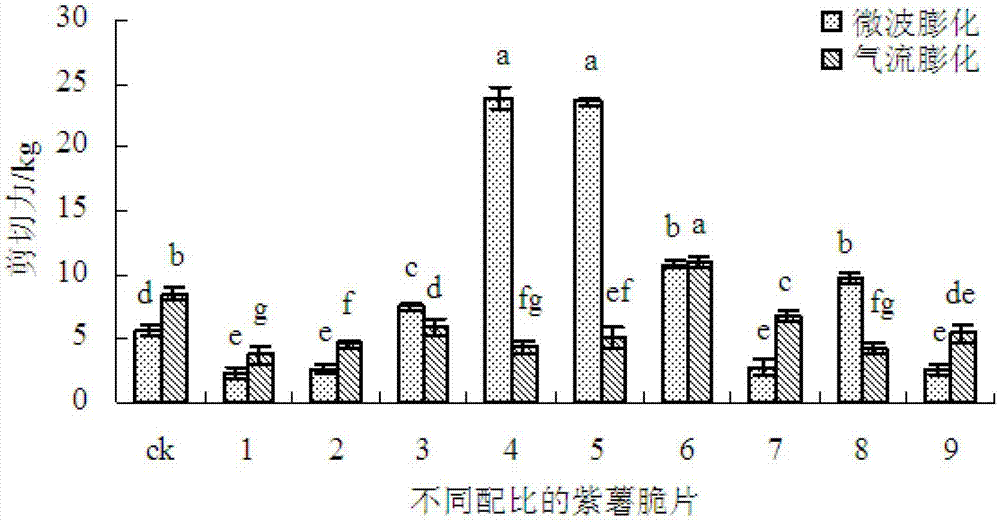

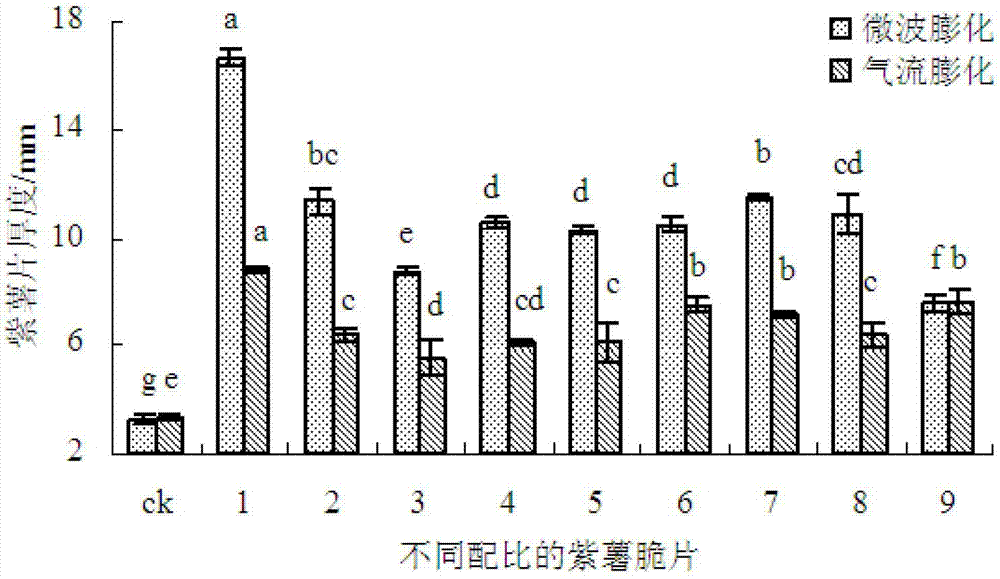

[0076] Orthogonal test (L 9 (3 4 )) Arrange formula design experiments, and use the comprehensive score as the response value (Y). The formula design level of purple sweet potato chips is shown in Table 4. Let the field of purple sweet potato crisps U=(color, puffed thickness, hardness and brittleness, taste, texture), and specify the corresponding weight value X=(0.15, 0.20, 0.25, 0.30, 0.10).

[0077] Table 4 purple potato chips formula L9 (34) orthogonal test factor level table

[0078]

[0079] Changes of hardness, thickness and CIE LAB value of glutinous rice and purple sweet potato chips after air pressure difference puffing and microwave puffing ( Figure 2~Figure 8 ) comparison shows that: for the recombined purple potato chips, the microwave puffing method is better than the air-flow puffing method for the two separate puffing methods, because the microwave puffing method is b...

Embodiment 3

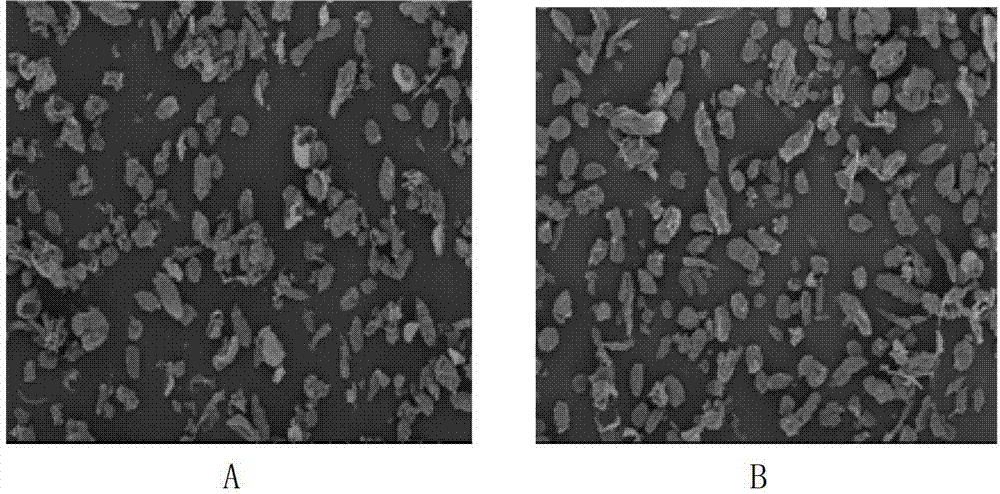

[0096] (1) Select ripe and fresh purple sweet potatoes with large potato pieces, shallow bud eyes, uniform potato flesh color, high dry matter content, low reducing sugar content, low polyphenol oxidase activity, and no obvious symptoms of pests and diseases as raw materials, wash, remove Skin, slice thickness is 5mm, precooking temperature is 70°C, precooking time is 10min, steaming time is 9min, mashed purple sweet potato puree is added 0.12% pulp enzyme at pH value 4.5 and enzymatic at 45°C solution for 2h, the scanning electron microscope photo of the obtained purple sweet potato puree is shown in figure 1 B;

[0097] (2) Cooked potatoes and water are beaten in a homogenizer for 3 minutes according to the mass ratio of 1:1 to obtain mashed potatoes, mashed potatoes, sugar, salt and leavening agent NaHCO 3 Put it into the purple sweet potato puree and mix evenly to make a paste, stir and heat at a stirring speed of 45r / min, heat at 80°C for about 5 minutes, stop until you ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com