Dry method for preparing TEM (Transmission Electron Microscope) sample of two-dimensional material

A technology of two-dimensional materials and samples, which is applied in the field of TEM samples of two-dimensional materials by dry method, can solve the problems of sample fold overlap, sample folds, amorphous layer, etc., so as to save the time of removing the transfer medium and ensure non-pollution , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

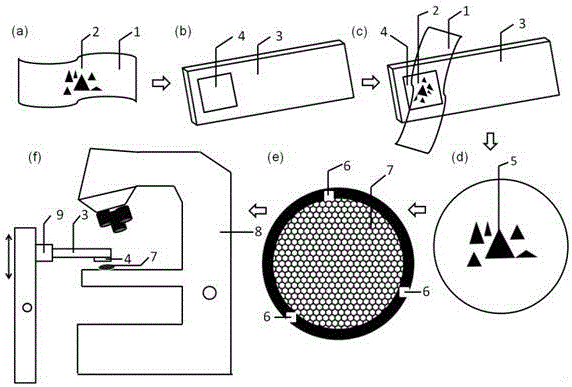

[0031] The two-dimensional material of this embodiment selects molybdenum disulfide block, refer to figure 1 , the specific preparation process is as follows:

[0032] Step 1: Mechanical peeling, using blue film tape 1 to tear off a piece of molybdenum disulfide sheet from the surface of molybdenum disulfide block material with bright surface and less damage, and then glued and separated six times to find that the sample-intensive area 2 on the tape is relatively Dense, and basically no metallic luster, such as figure 1 (a).

[0033] Step 2: Select a clean experimental glass slide 3, wash it with deionized water, and put it in an oven to dry. Use scissors to cut off a square PDMS gel sheet 4 smaller than the width of the slide, hold the gel sheet with tweezers, peel off the protective layer, and stick it carefully on the transparent end of the slide. During the sticking process, the PDMS gel sheet 4 Keep it flat without wrinkles and air bubbles, such as figure 1 (b).

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com