Blue-green algae extruding and crushing device

A technology of extrusion crushing and cyanobacteria, which is applied in magnetic separation, solid separation, grain processing, etc., can solve the problems of water absorption discount, difficulty in finished algae cake, and high moisture content of finished algae cake, and achieves convenient production and large promotion and application value. , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

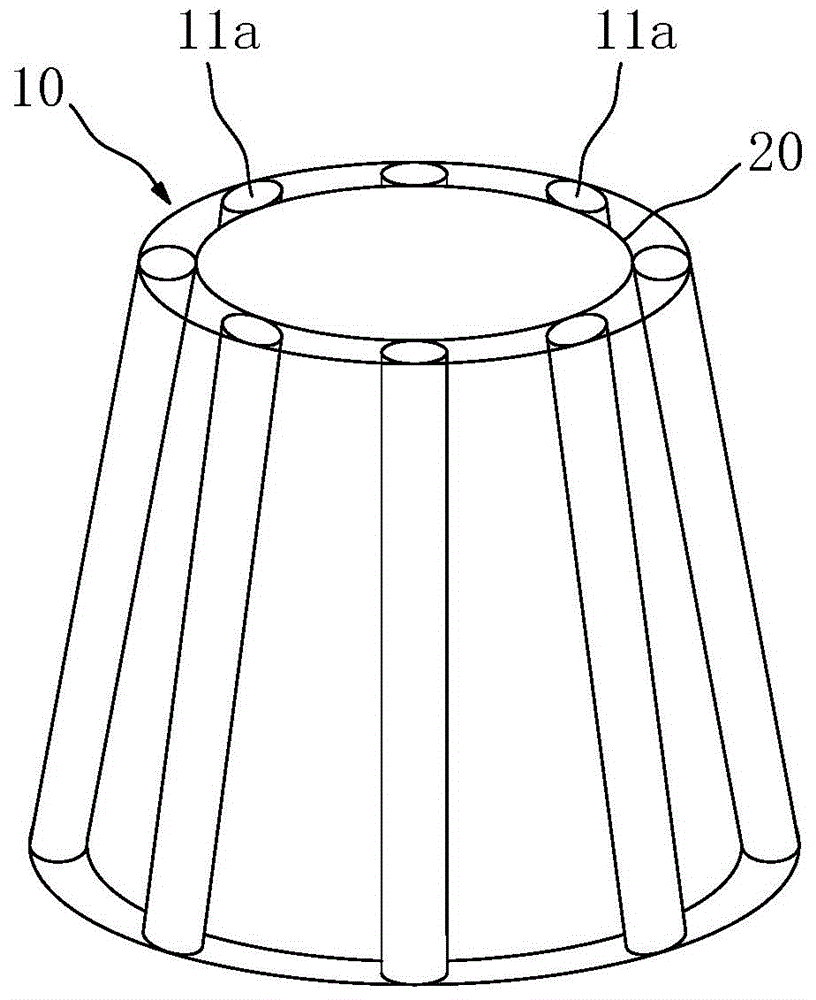

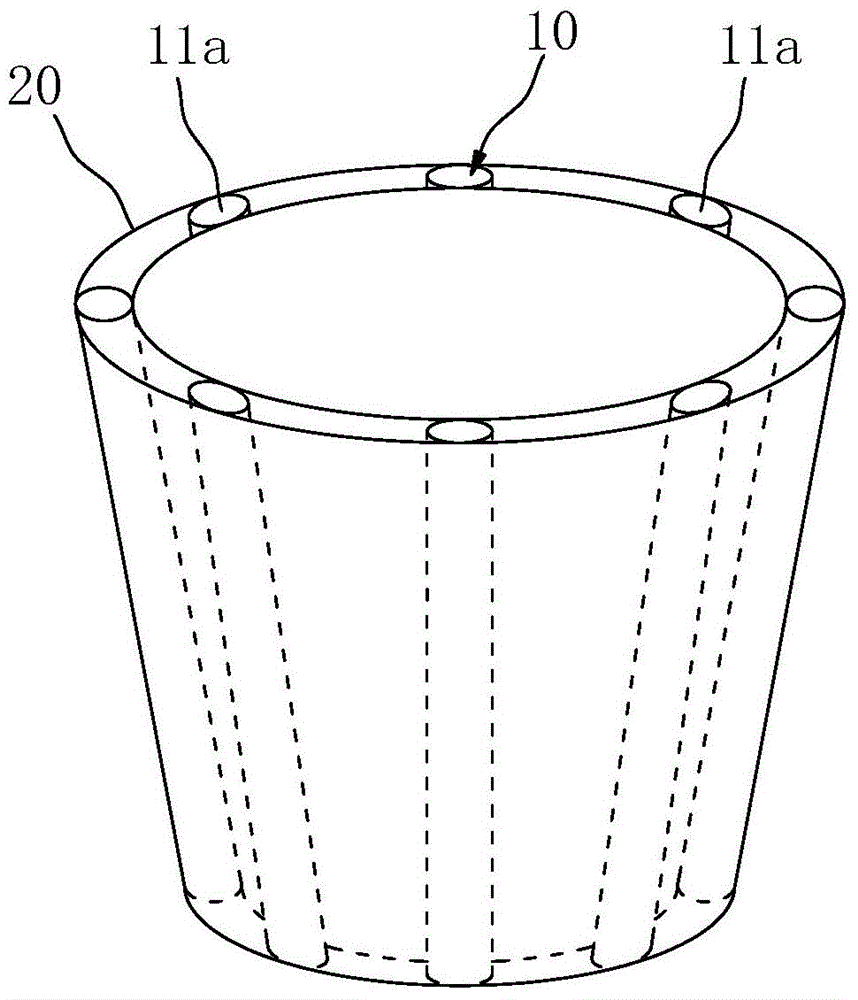

[0037]As shown in Figures 1 and 2, the first extruding member 10 includes a plurality of extruding rods or extruding rollers 11a, and the center of the circle formed by the extruding rods or extruding rollers 11a is connected to the center of the extruding barrel. The center of the circle is on the same center of circle; the second extruding part 20 is a truncated extruding cylinder, the extruding cylinder is vertically arranged, and one end of the extruding cylinder has a large diameter and the other end has a small diameter; the first extrusion A plurality of extruding rods or extruding rollers 11a in the component 10 are attached to the inner peripheral side wall surface / or outer peripheral side wall surface of the extruding cylinder, and the cylinder formed by this plurality of extruding rods or extruding rollers 11a The inside or outside of the extrusion cylinder rotates circularly.

[0038] Such as Figure 1a As shown, the annular structure formed by extrusion rods or ex...

Embodiment 2

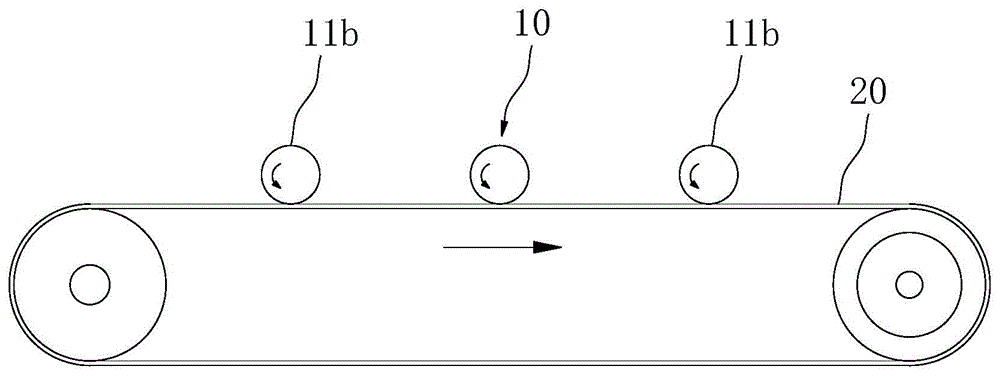

[0043] Such as figure 2 As shown, the first extruding member 10 is set as one or more extruding rods or extruding rollers 11b arranged in parallel, and the contact surface of the second extruding member 20 and the first extruding member 10 is set is flat.

[0044] The second extrusion part 20 in this embodiment is preferably a conveyor belt with a magnetic attraction mechanism, and the contact area between the extrusion roller 11b and the belt surface of the conveyor belt is the extrusion area.

Embodiment 3

[0046] Such as Figure 5 As shown, the first extruding member 10 is configured as an extruding roller 11c, and the outer peripheral surface of the extruding roller 11c is provided with a helical blade 12, and the second extruding member 20 is cylindrical, so The extrusion roller 11c is disposed inside the cylindrical second extrusion member 20 , and the blade edge of the blade 12 on the outer peripheral surface of the extrusion roller 11c is disposed close to the inner wall surface of the second extrusion member 20 .

[0047] Specifically, the second extruding part 20 is a straight cylindrical outer casing, the outer casing has a cylindrical cavity, and the cylindrical cavity constitutes an extrusion chamber of the outer casing for containing the mixed material. The two ends of the extrusion cavity are respectively provided with a feed end and a discharge end communicating with the cavity. A squeeze roller 11c with helical blades 12 is arranged coaxially in the extrusion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com