Building sealant for house industrialization and preparation method thereof

A sealant and housing technology, applied in the direction of adhesives, adhesive types, polyether adhesives, etc., can solve the problems of poor aging resistance, interface cracking, surface unpaintable, etc., and achieve good displacement resistance and good adhesion Strong, good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

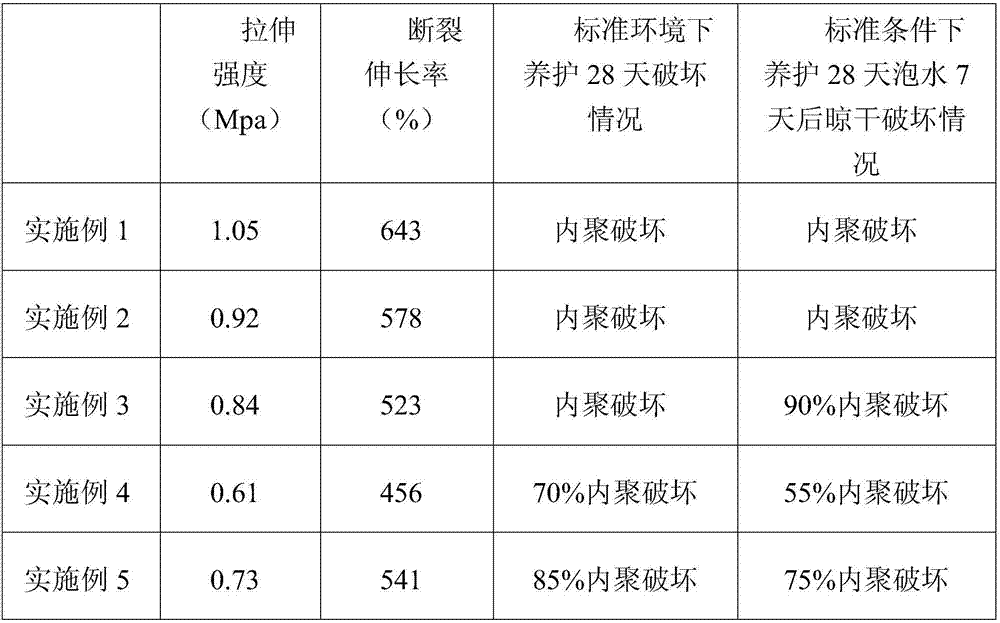

Examples

Embodiment 1

[0025] The building sealant used for the industrialization of this house includes 100 parts of silane-modified polyether resin, 30 parts of plasticizer, 100 parts of nano-calcium carbonate, 1 part of ultraviolet absorber, 3 parts of silane coupling agent, silane 4 parts of crosslinking agent and 1.5 parts of catalyst.

[0026] Furthermore, the silane-modified polyether resin is terminated by siloxane, the main chain is the molecular structure of polyether, the molecular weight is 6000-12000, and the structural formula is: R 1 (R 2 O) 2 SiO((CH2) 3 O) n Si(R 2 O) 2 R 1 , where R 1 and R 2 It is an alkyl group of C1-C2, and n is the number of repeating units in the main chain.

[0027] Furthermore, nano-calcium carbonate is one or more mixtures of nano-scale calcium carbonate, silicon micropowder, and talcum powder kaolin whose surface has been treated with fatty acid or stearic acid.

[0028] Further, the plasticizer is polyethylene glycol with a molecular weight of 2...

Embodiment 2

[0035] The building sealant for residential industrialization includes 100 parts of silane-modified polyether resin, 50 parts of plasticizer, 150 parts of nano calcium carbonate, 1.5 parts of ultraviolet absorber, 4 parts of silane coupling agent, silane 4.5 parts of crosslinking agent and 2 parts of catalyst.

[0036] Further, the plasticizer is polyglycerol with a molecular weight of 5000; the ultraviolet absorber is UV-329; the silane coupling agent is methyltriethoxysilane; the silane crosslinking agent is chloropropyltrimethoxysilane; For stannous octoate.

[0037] The preparation method of the building sealant for housing industrialization of the present embodiment comprises the following steps:

[0038] (1) Take by weighing silane-modified polyether resin, polyglycerol, ultraviolet absorber UV-329 and nano-calcium carbonate respectively by above-mentioned quality component, and add in batches the double planetary power mixer mixing barrel and stir evenly, then Heating...

Embodiment 3

[0043] The building sealant for the industrialization of this house includes 100 parts of silane-modified polyether resin, 60 parts of plasticizer, 200 parts of nano-calcium carbonate, 1.5 parts of ultraviolet absorber, 4.5 parts of silane coupling agent, silane 4 parts of crosslinking agent and 3 parts of catalyst.

[0044] Further, the plasticizer is diisodecyl phthalate; the nano-calcium carbonate is silicon micropowder; the ultraviolet absorber is UV-327; the silane coupling agent is methyltrimethoxysilane; the silane crosslinking agent is N- (β-Aminoethyl)-γ-aminopropyltriethoxysilane; catalyst is dibutyltin dilaurate.

[0045] The preparation method of the building sealant for housing industrialization of the present embodiment comprises the following steps:

[0046] (1) Weigh silane-modified polyether resin, diisodecyl phthalate, ultraviolet absorber UV-327 and silicon micropowder according to the above mass components, and add them to the mixing tank of the double pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com