Aluminum alloy electrode material and preparation method and application of aluminum alloy electrode material

A technology of aluminum alloy electrodes and aluminum alloy ingots, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems that cannot meet the technical requirements of power supplies, hinder the application of alkaline aluminum-air batteries, and pollute the environment, and achieve corrosion rates Reduced, low price, uniform corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present application also provides a preparation method of the aluminum alloy electrode material, comprising the following steps:

[0033] After the Al ingot is melted, Mg, Sn, Ga and Al-RE are added, and ultrasonic vibration is performed, and then it is left to stand and cooled to obtain an aluminum alloy ingot;

[0034] The obtained aluminum alloy ingot is solid solution treated, then quenched, and then rolled to obtain an aluminum alloy electrode material.

[0035] The present application provides a method for preparing an aluminum alloy electrode material, which includes: smelting-solution treatment-quenching treatment-rolling, and finally an aluminum alloy electrode material is obtained.

[0036]According to the present invention, the smelting process is first carried out, that is, after the Al ingot is melted, Mg, Sn, Ga and Al-RE are added, ultrasonic vibration is carried out, and the aluminum alloy ingot is obtained after standing still and cooling. In the a...

Embodiment 1

[0045] Based on an aluminum ingot with a purity of 99.9%, the composition ratio of the selected aluminum alloy anode is: magnesium: 2.6wt%, tin: 0.7wt%, gallium: 0.03wt%, RE (specifically Al-20%Ce): 0.04 wt%, aluminum: balance.

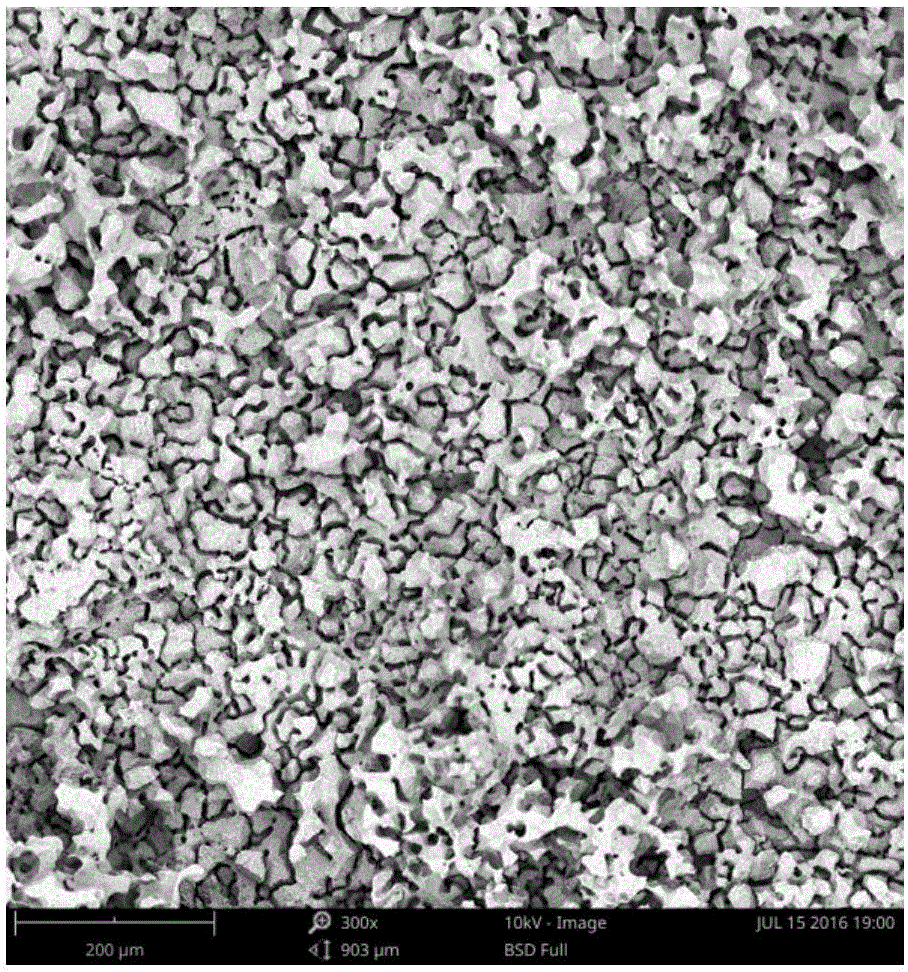

[0046] Put the measured aluminum ingot in a graphite crucible, under the protection of an inert gas, wait until the furnace temperature rises to 735°C to completely melt the aluminum, stir and remove slag, then add other alloy elements wrapped in aluminum foil; import 800W power Ultrasonic vibration, the introduction time is 90s, then stand still for 10min, pour into graphite ark to cool naturally; place the cast aluminum ingot in a resistance furnace at 490°C for solid solution treatment for 4h, and quickly place it in cold water for quenching treatment; The ingot is rolled at 190°C into an aluminum alloy sheet with a thickness of 2mm, and cut into 1cm of the working area 2 Polish the electrodes with 400#, 600#, 800#, 1000#, 2000# sandpaper respecti...

Embodiment 2

[0050] Based on an aluminum ingot with a purity of 99.9%, the composition ratio of the aluminum alloy anode is selected as follows: magnesium: 0.1wt%, tin: 0.05wt%, gallium: 0.01wt%, RE (specifically Al-20%Ce): 0.02 wt%, aluminum: balance.

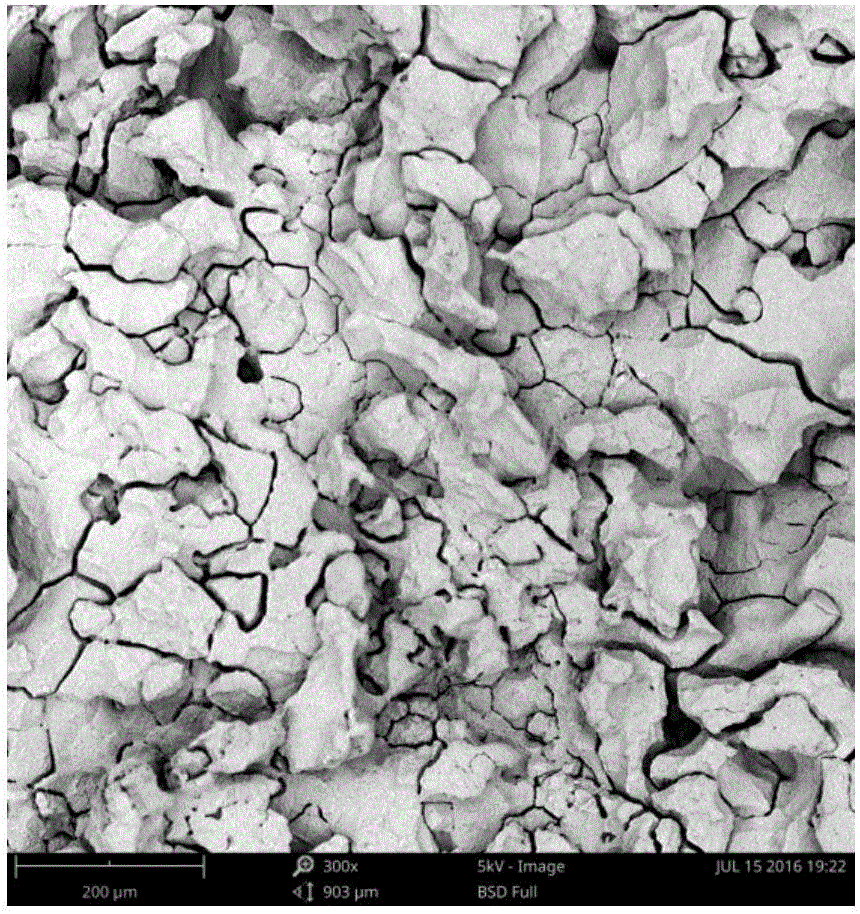

[0051] Put the measured aluminum ingot in a graphite crucible, under the protection of an inert gas, wait until the furnace temperature rises to 700°C to completely melt the aluminum, stir and remove slag, then add other alloy elements wrapped in aluminum foil; import a 500W power Ultrasonic vibration, the introduction time is 60s, then stand still for 10min, pour into graphite ark to cool naturally; place the cast aluminum ingot in a resistance furnace at 450°C for solid solution treatment for 3h, and quickly place it in cold water for quenching treatment; The ingot is rolled at 150°C into an aluminum alloy sheet with a thickness of 2mm, and cut into 1cm of the working area 2 Polish the electrodes with 400#, 600#, 800#, 1000#, 2000# sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com