Organic additive for electrolytic manganese production and preparation method thereof

An organic additive, electrolytic manganese technology, which is applied in the direction of photographic technology, instruments, photographic auxiliary technology, etc., can solve the problems of not finding high-efficiency selenium-free electrolytic manganese additives, high selenium content, and high price, and achieves less species and low impurity content. , the effect of high manganese content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

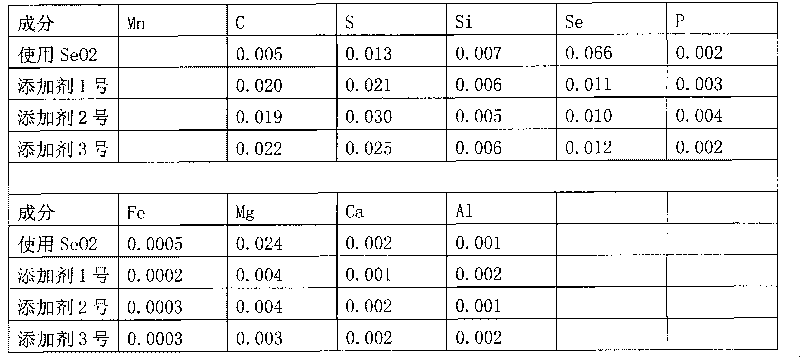

[0027] An organic additive used in the production of electrolytic manganese, the weight percentage of each raw material is shown in Table 1.

[0028] Table 1

[0029] components

name

Weight (g)

% by weight %

Remark

Non-ionic

1

1

Molecular weight 25 million

Acetate

Ammonium acetate

2

2

Analytical pure

Auxiliary

7

7

Analytical pure

water

90

90

[0030] Above-mentioned a kind of preparation method for the organic additive of electrolytic manganese production, it comprises the steps:

[0031] 1), raw material selection: select each raw material according to Table 1;

[0032] 2) First, add polyacrylamide and water into the reaction tank, and stir for 30 minutes at 40°C; then add additives potassium phosphate and ammonium acetate, stir for 3 hours, and cool to room temperature; After the amide swells completely, stir...

Embodiment 2

[0037] An organic additive used in the production of electrolytic manganese, the weight percentage of each raw material is shown in Table 3.

[0038] table 3

[0039] components

name

Weight (g)

% by weight %

Remark

polyacrylamide

Non-ionic

2

2

Molecular weight 16 million

Acetate

Sodium acetate

4

4

Analytical pure

Auxiliary

5

5

Analytical pure

[0040] components

name

Weight (g)

% by weight %

Remark

water

89

89

[0041] Above-mentioned a kind of preparation method for the organic additive of electrolytic manganese production, it comprises the steps:

[0042] 1), raw material selection: select each raw material according to table 3;

[0043] 2) First, add polyacrylamide and water into the reaction tank, and stir for 40 minutes at 42°C; then add additives such as ammonium phosphate and sodium acetate, st...

Embodiment 3

[0048] An organic additive used in the production of electrolytic manganese, the weight percentage of each raw material is shown in Table 5.

[0049] table 5

[0050] components

name

Weight (g)

% by weight %

Remark

polyacrylamide

Non-ionic

2

2

Molecular weight 8 million

Acetate

calcium acetate

5

5

Analytical pure

Auxiliary

10

10

Analytical pure

water

83

83

[0051] Above-mentioned a kind of preparation method for the organic additive of electrolytic manganese production, it comprises the steps:

[0052] 1), raw material selection: select each raw material according to Table 5;

[0053] 2) First, add polyacrylamide and water into the reaction tank, and stir for 60 minutes at 45°C; then add additives such as ammonium phosphate and calcium acetate, stir for 3 hours, and cool to room temperature; After the amide swelling is complete, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com