Enclosed infrared heating device for semiconductor chip

A heating device, infrared technology, applied in electric heating device, semiconductor/solid state device manufacturing, ohmic resistance heating and other directions, can solve the problems of low heating efficiency, no cooling of the lamp, affecting the life of the lamp, etc., to achieve good cooling effect, The effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

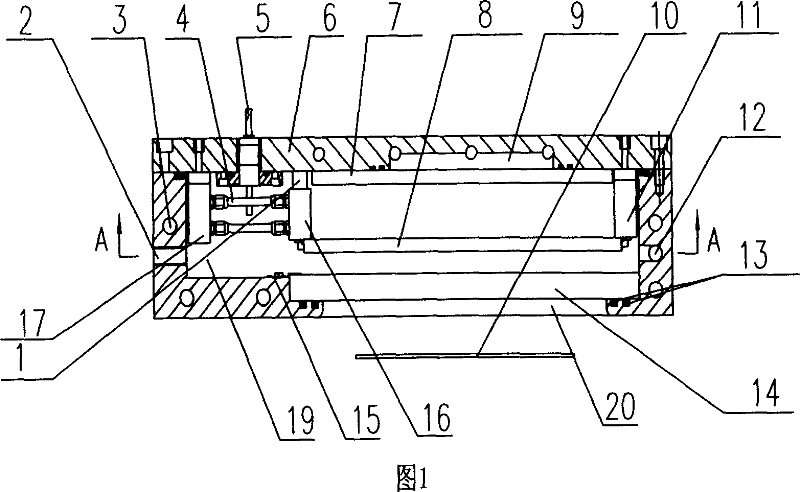

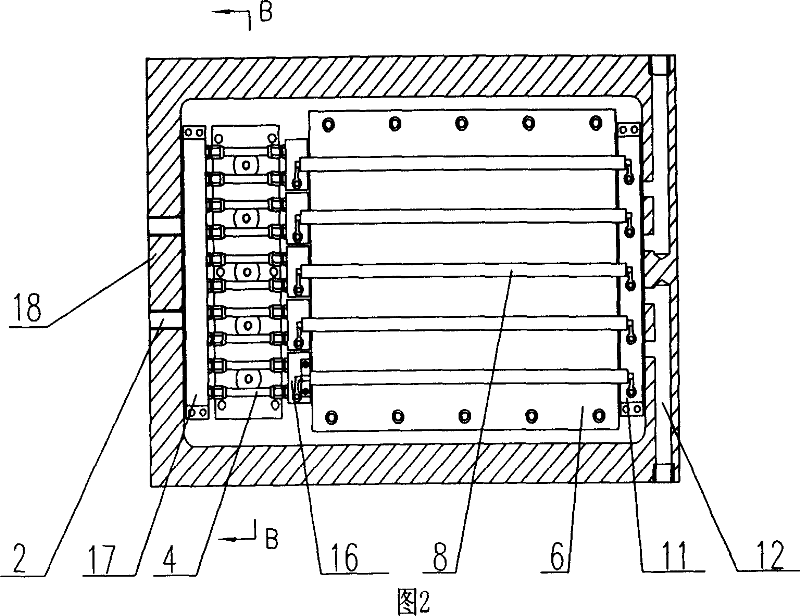

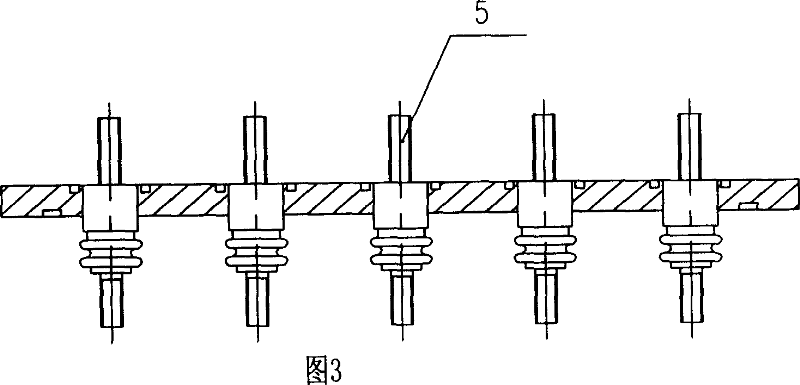

[0024] According to the accompanying drawings and the device of the present invention with the above-mentioned structure, there are five heating lamp tubes 8, five corresponding lamp tube holders 16, the device heating power is 25KW, and the heating temperature is the highest 800°C; the transmission glass 14 shown in Fig. 1 is made of high-purity Quartz glass, a high-temperature-resistant sealing ring 13 is installed between it and the housing 18, and is fixed with a pressing plate 15. The reflecting plate 7 is made of brass plate, and the reflecting surface is plated with gold; Vacuum isolated power supply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com