Organic additive for production of electrolytic manganese and preparation method thereof

An organic additive and electrolytic manganese technology, which is applied in photographic technology, instruments, photographic auxiliary processes, etc., can solve the problem of not finding high-efficiency selenium-free electrolytic manganese additives, etc., and achieve the effects of stable properties, not easy to delaminate, and stable production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

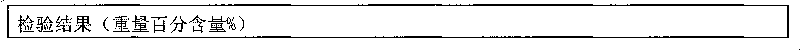

[0026] For the organic additives used in the production of electrolytic manganese, see Table 1 for the percentage by weight of each raw material.

[0027] Table 1

[0028] components

name

Weight (g)

% by weight %

Remark

organic sulfide

2-Aminodiphenylsulfide

4

4

Surfactant

7

7

Analytical pure

polyethylene glycol

polyethylene glycol

15

15

Molecular weight 6000

water

74

74

[0029] The above-mentioned preparation method for the organic additive of electrolytic manganese production, it comprises the steps:

[0030] 1), raw material selection: select each raw material according to Table 1;

[0031] 2) Add organic sulfides and surfactants to the reaction tank first, and add water with 50% of the total weight of water, and stir for 40 minutes at 75° C. until the organic sulfides are dissolved to obtain solution A; polyethylene ...

Embodiment 2

[0036] For the organic additives used in electrolytic manganese production, the weight percentage of each raw material is shown in Table 3.

[0037] table 3

[0038] components

name

Weight (g)

% by weight

Remark

organic sulfide

3

3

Surfactant

8

8

Analytical pure

[0039] components

name

Weight (g)

% by weight

Remark

20

20

Molecular weight 4000

water

69

69

[0040] The above-mentioned preparation method for the organic additive of electrolytic manganese production, it comprises the steps:

[0041] 1), raw material selection: select each raw material according to Table 1;

[0042] 2) Add organic sulfides and surfactants to the reaction tank first, and add water with 50% of the total weight of water, and stir for 50 minutes at 75° C. un...

Embodiment 3

[0060] An organic additive for electrolytic manganese production, which is prepared from organic sulfides, surfactants, polyethylene glycol and water raw materials, and the weight percentages of each raw material are: organic sulfides 2%, surfactants 6%, Polyethylene glycol 15%, water 77%.

[0061] The organic sulfide is diphenyl disulfide; the surfactant is anionic surfactant (sodium lauryl sulfate); the molecular weight of the polyethylene glycol is 2000; the water is tap water.

[0062] The above-mentioned preparation method for the organic additive of electrolytic manganese production, it comprises the steps:

[0063] 1) Select each raw material according to the above proportioning ratio, and set aside;

[0064] 2) Add organic sulfide and surfactant to the reaction tank first, and add water with 40% of the total weight of water, and stir for 30 minutes at 70° C. until the organic sulfide is dissolved to obtain solution A; polyethylene glycol Dissolve in the remaining wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com