Raw diamond wire saw production system

A production system, stone wire technology, applied in the direction of electrolytic coating, coating, etc., can solve the problems of low cutting efficiency, high environmental protection pressure, agglomeration or accumulation, etc., and achieve the effect of improving production efficiency, strong cutting ability and high cutting ability

Active Publication Date: 2014-07-30

铜陵市力博中小企业服务有限公司

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

2. The muddy cutting fluid needs to be treated and discharged after use, which is easy to cause environmental pollution. During the reprocessing process, the water discharge is very large, and the pressure on environmental protection is great.

3. The cutting process is the material removal mechanism of free abrasive particles, and the cutting efficiency is low;

5. After cutting, the particle size of the waste material and the abrasive is similar, so it is difficult to recycle and reuse

In this way, the diamond can be quickly adsorbed on the surface of the wire. At the same time, due to the conductivity of the diamond surface, during the electrodeposition process, due to the tip effect, the coating on the diamond surface will become very thick, and the thickness of the coating is greater than that of the bare wire surface. , affecting the cutting ability of the wire

2. When the coated diamond is deposited on the surface of the bare wire, due to the problem of electrical conductivity, it is easy to coat the diamond again, which will cause agglomeration or accumulation on the surface and affect the cutting quality

3. The diamond wire production equipment currently used is generally a single wire, and the production efficiency is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

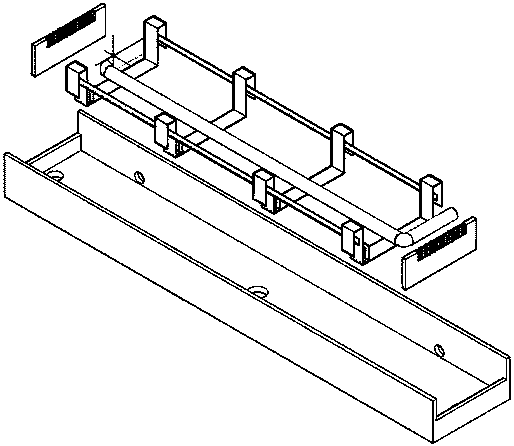

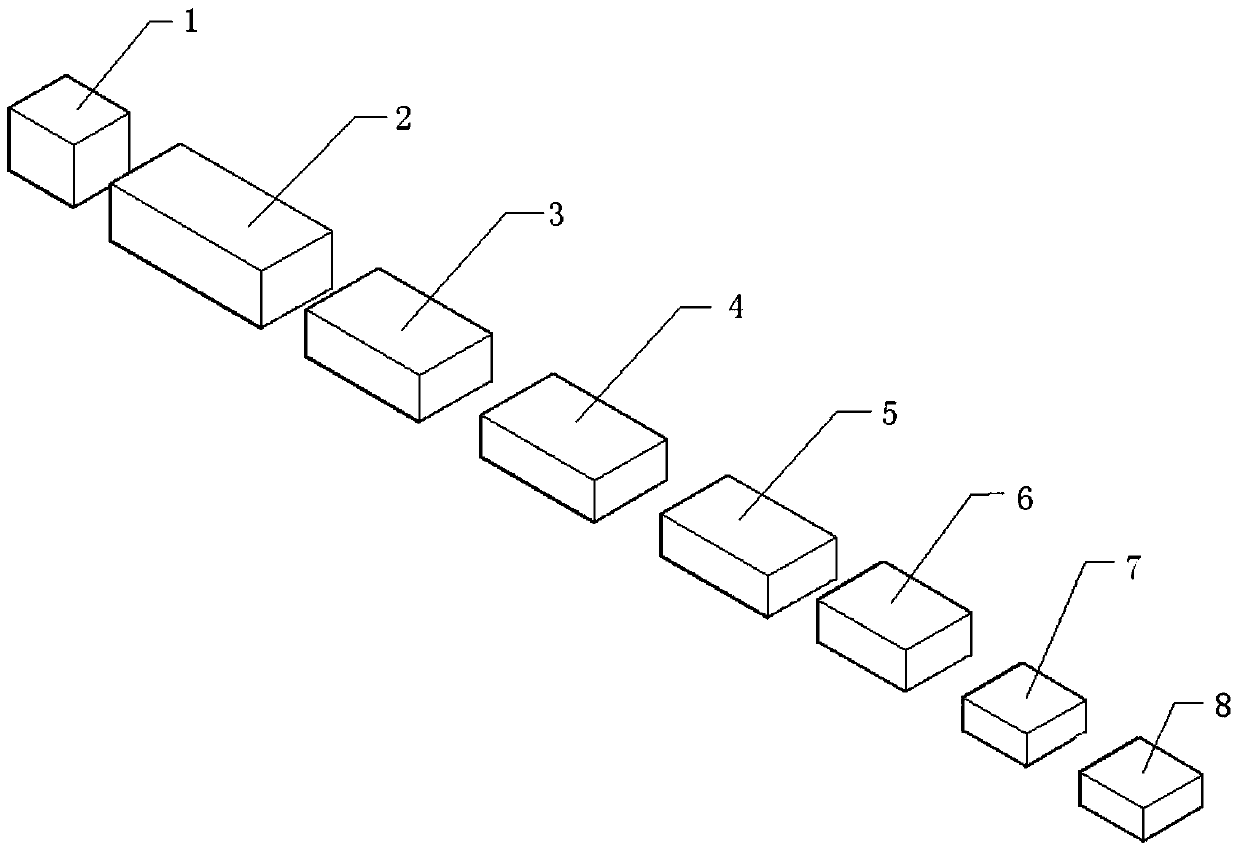

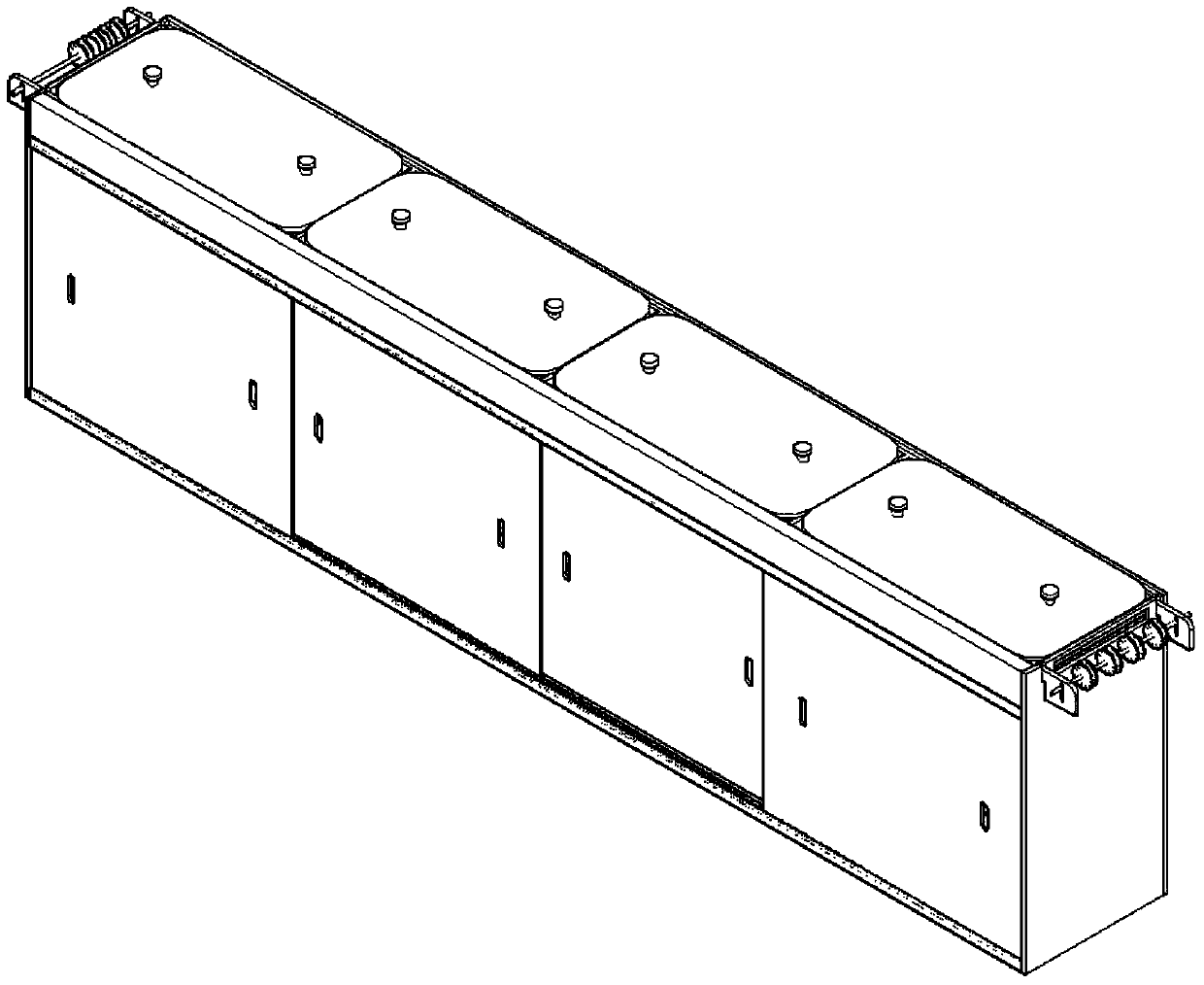

The invention relates to a raw diamond wire saw production system. The raw diamond wire saw production system is characterized by sequentially comprising, from the front to the rear, a wire-pulling device (1), a treatment-before-plating device (2), a pre-plating device (3), a sand-feeding device (4), a curing device (5), a treatment-after-plating device (6), a drying oven (7) and a wire take-up device (8), wherein a sand-feeding groove of the sand-feeding device (4) comprises an upper layer sand-feeding groove (4.1) and a lower layer sand-feeding groove (4.2) which are arranged in the vertical direction, the middle parts of both the upper layer sand-feeding groove (4.1) and the lower layer sand-feeding groove (4.2) are provided with annular sand channels (4.4), sand-feeding wire guide wheels (4.7) are arranged above the front section and rear section of the lower layer sand-feeding groove (4.2), and two sand-feeding pressing rollers (4.6), which are in forward and backward arrangement, are arranged above the sand channels located at the right side of the annular sand channels (4.4). The raw diamond wire saw production system disclosed by the invention has the advantages of high capacity in cutting products, uniform plating of diamond powder and capability in achieving quick mass production.

Description

technical field The invention relates to a bare diamond wire saw production system. Background technique With the rapid development of electronics, new energy and optical industries, the number of manufacturers who cut monocrystalline silicon, sapphire, magnetic materials, ceramic materials, jade, precious metals and other materials into wafers is increasing. The mainstream multi-wire cutting process on the market is "bare steel wire + abrasive slurry". Compared with the previous inner circular saw blades, outer circular blades, and band saws, this cutting method using free abrasives has the advantages of being able to cut large-diameter crystal ingots and cutting multiple wires at the same time, reducing wire loss, etc., but it also has the following obvious shortcomings : 1. Pollution of crystal bar and fat-based grinding fluid in the processing area; 2. The muddy cutting fluid needs to be treated and discharged after use, which is easy to cause environmental pollutio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25D7/06C25D15/00

Inventor 张伟

Owner 铜陵市力博中小企业服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com