Water pump and floating type cutting assembly

A floating, component technology, applied to pump elements, parts of pumping devices for elastic fluids, pumps, etc., can solve problems such as failure to cut off, blockage of water inlets, affecting water intake, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

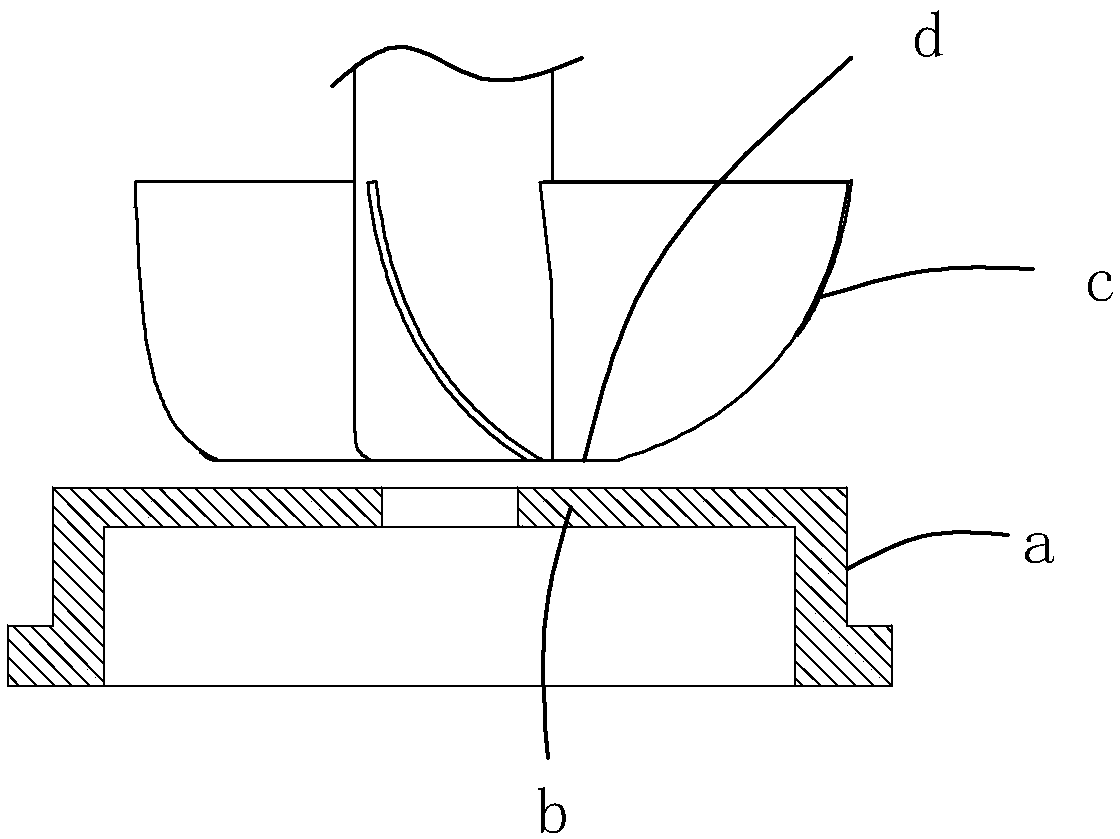

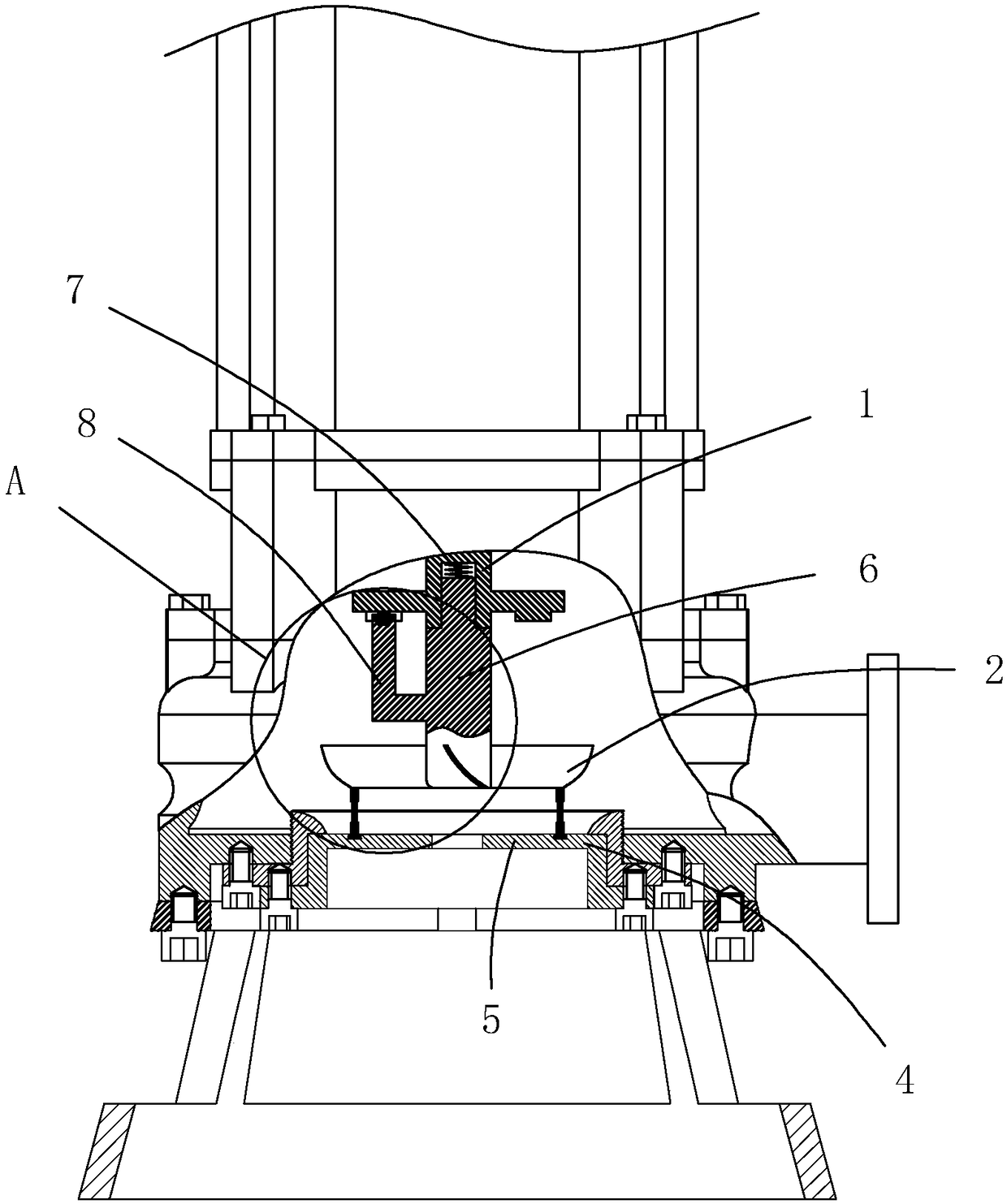

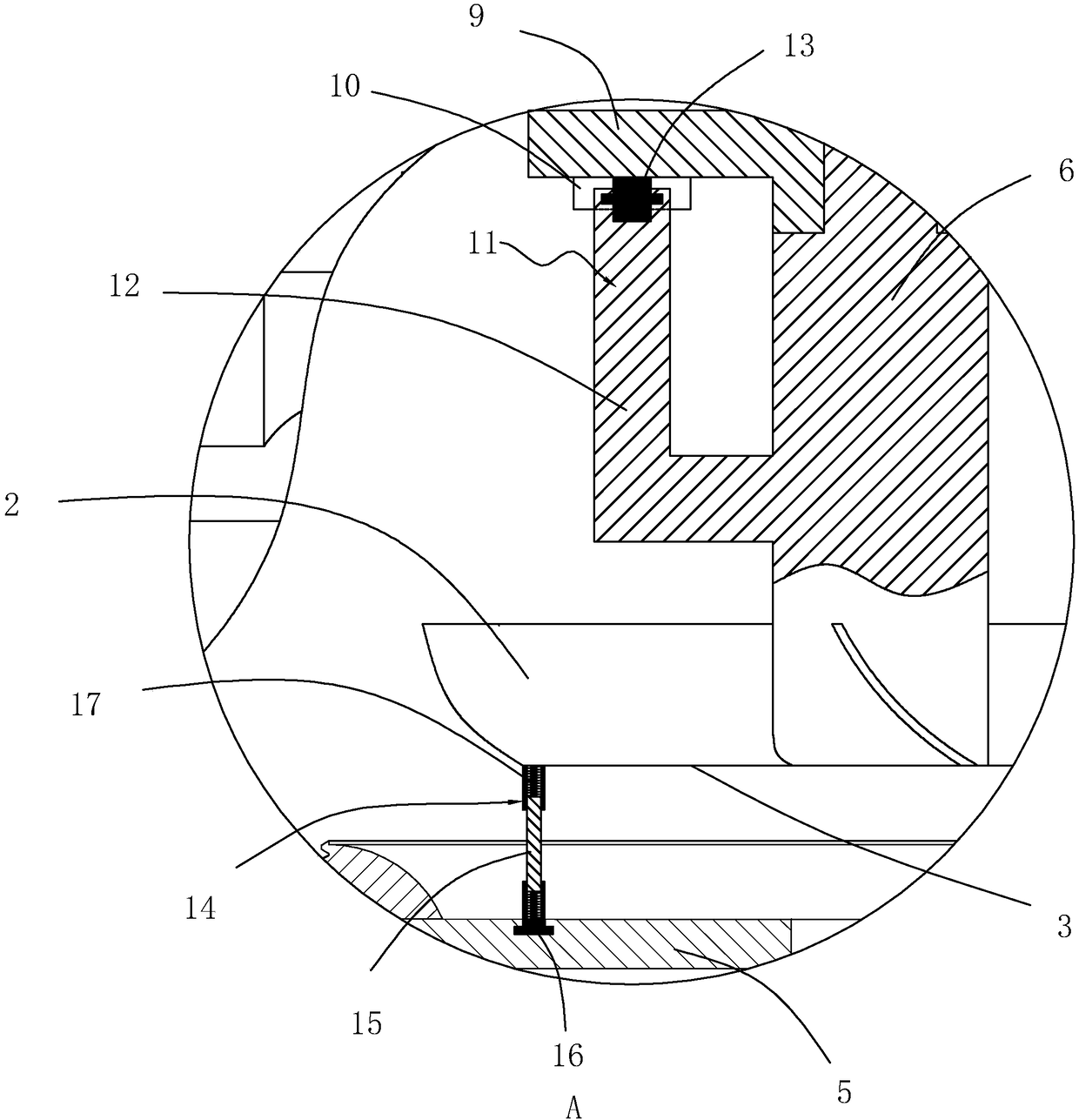

[0033] A floating cutting assembly, including a rotating shaft 1 rotated by a driving source, a cutting blade 2 docked with the end of the rotating shaft 1, and a cutting disc 4. Cutting bars 5 are arranged on the top, and the cutting bars 5 are radially distributed with the middle part of the cutting disc 4 as the center. The cutting blade 2 is provided with a cutting edge 3 near the end of the cutting disc 4. sundries.

[0034] In order to further improve the cutting effect, a movable shaft 6 is provided on the cutting blade 2, and the movable shaft 6 is slidingly sleeved on the end of the rotating shaft 1, and the movable shaft 6 and the rotating shaft 1 are coaxially arranged. A tension spring 7 is connected with the rotating shaft 1, and the tension spring 7 is used to pull the cutting blade 2 to the side away from the cutting disk 4.

[0035] A driving part 8 is provided on the rotating shaft 1, and a transmission part 11 is connected between the driving part 8 and the ...

Embodiment 2

[0042] A water pump includes the floating cutting assembly in the first embodiment, and the floating cutting assembly is installed at the water inlet of the water pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com