Supersonic skeleton cutting instrument

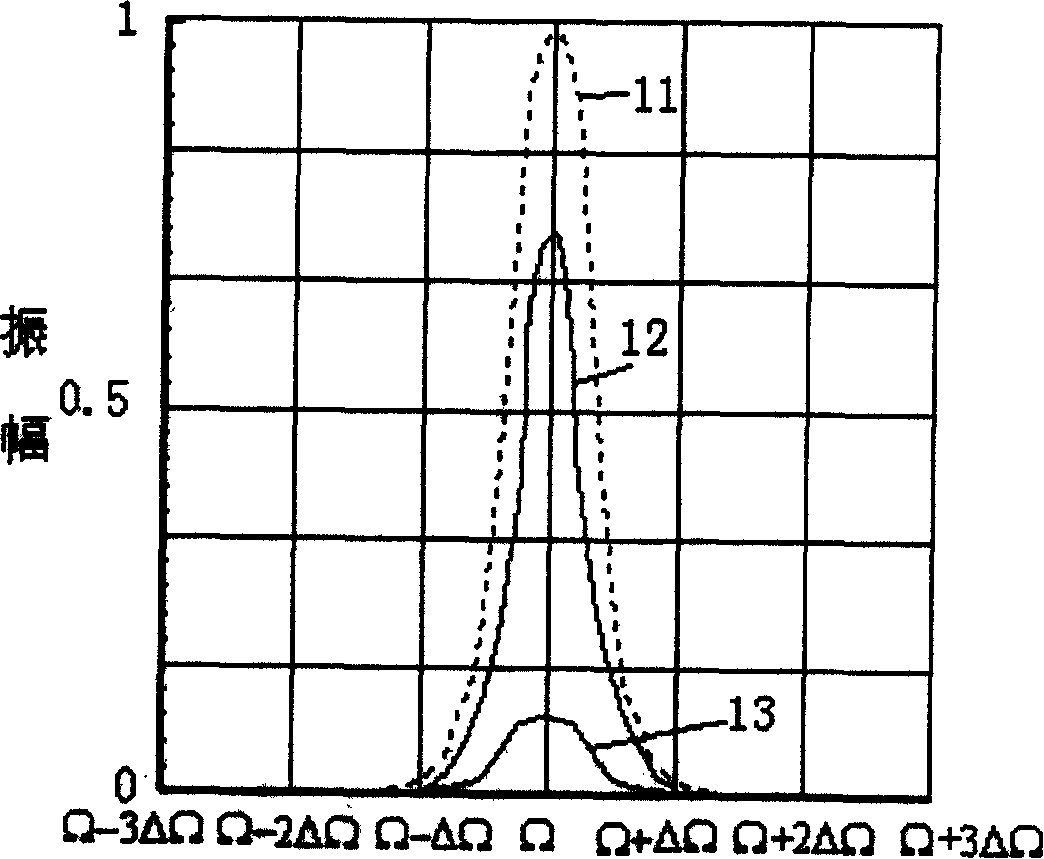

A bone and ultrasound technology, applied in the field of surgical medical devices, can solve problems such as failure to reflect the nature of bone tissue, decrease in output amplitude, and changes in no-load performance, and achieve the effects of fine surgery, smooth chip removal, and strong load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

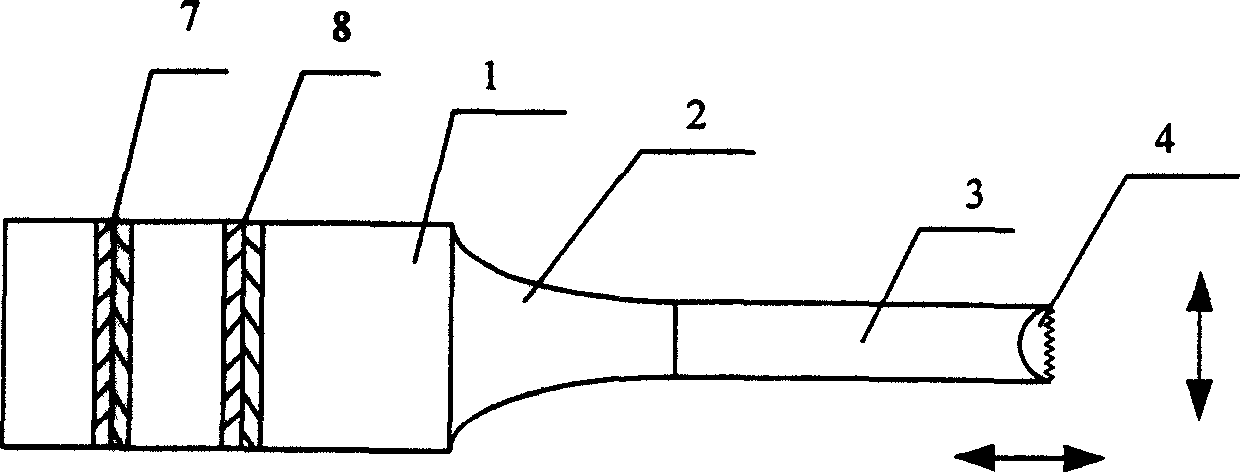

[0027] A kind of ultrasonic bone cutting instrument designed by the present invention is described in detail as follows in conjunction with embodiment and accompanying drawing:

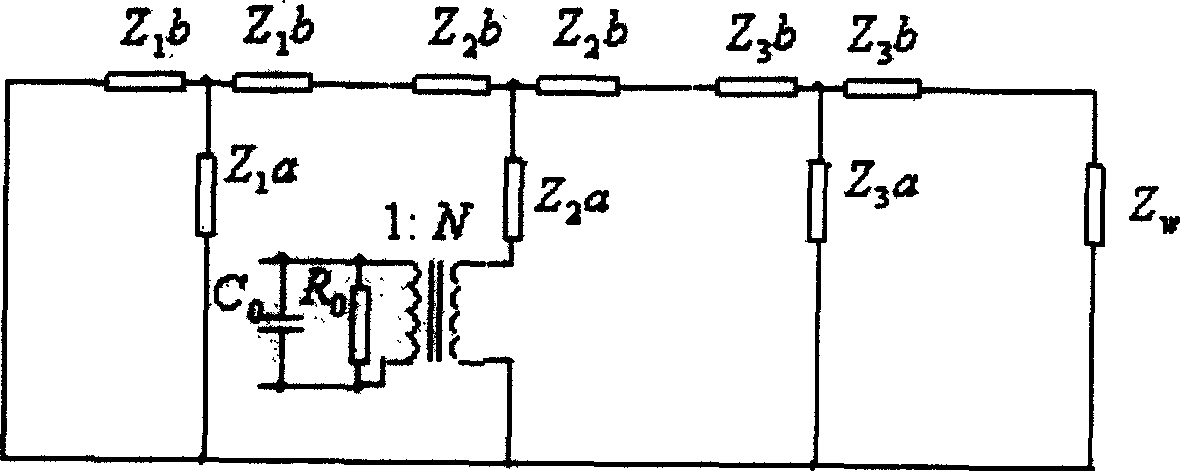

[0028] An embodiment of an ultrasonic bone cutting instrument designed by the present invention mainly includes two parts: a host and a handle. Composite vibration transducer; the transducer is composed of a group of longitudinally polarized piezoelectric sheets and a group of tangentially polarized piezoelectric sheets, and the host is connected to the transducer through cables; this embodiment also includes a cooling The cooling device is connected with the cooling conduit, and the outlet end of the cooling conduit is arranged at the end of the tool to cool it.

[0029] The signal generator and power amplifier of the host in this embodiment can select existing components and parts according to the required frequency.

[0030] Both the longitudinally polarized piezoelectric sheets and the tangential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com