Yarn cutting machine

A thread cutting machine and yarn technology, applied in textiles and papermaking, textile material cutting, forming non-bundling, etc., can solve the problems of reducing the quality of processed fibers, low work efficiency, and different lengths of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

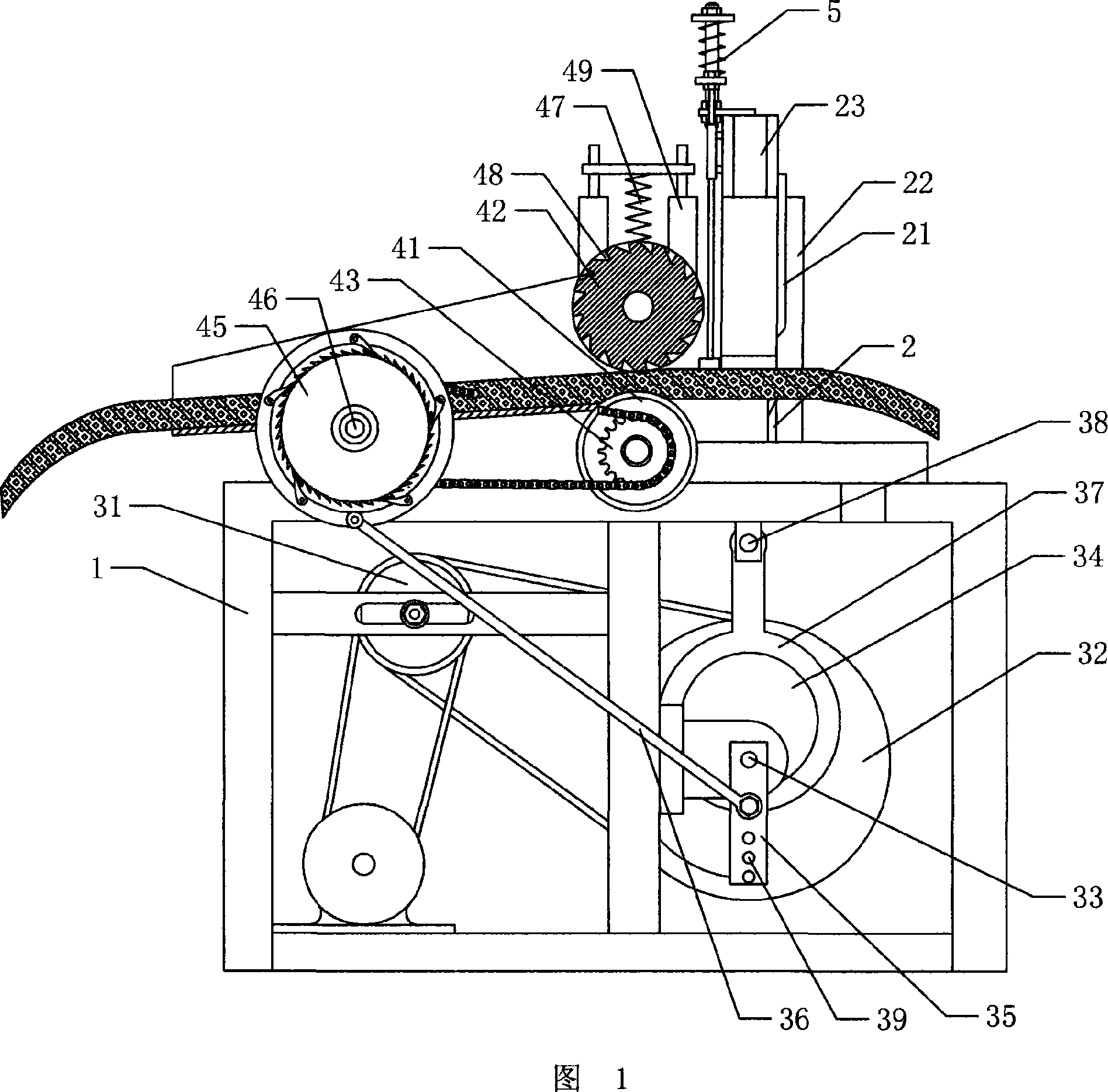

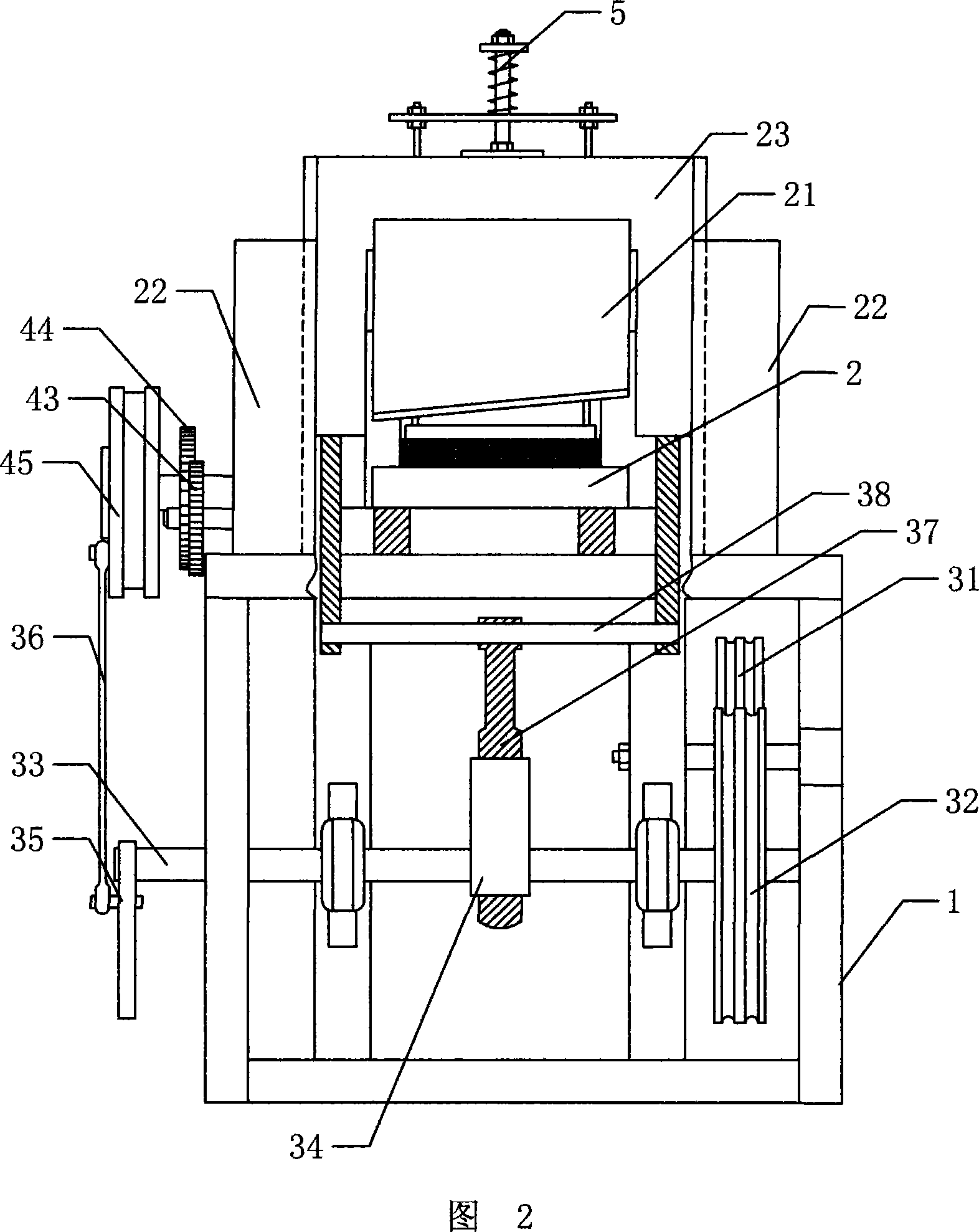

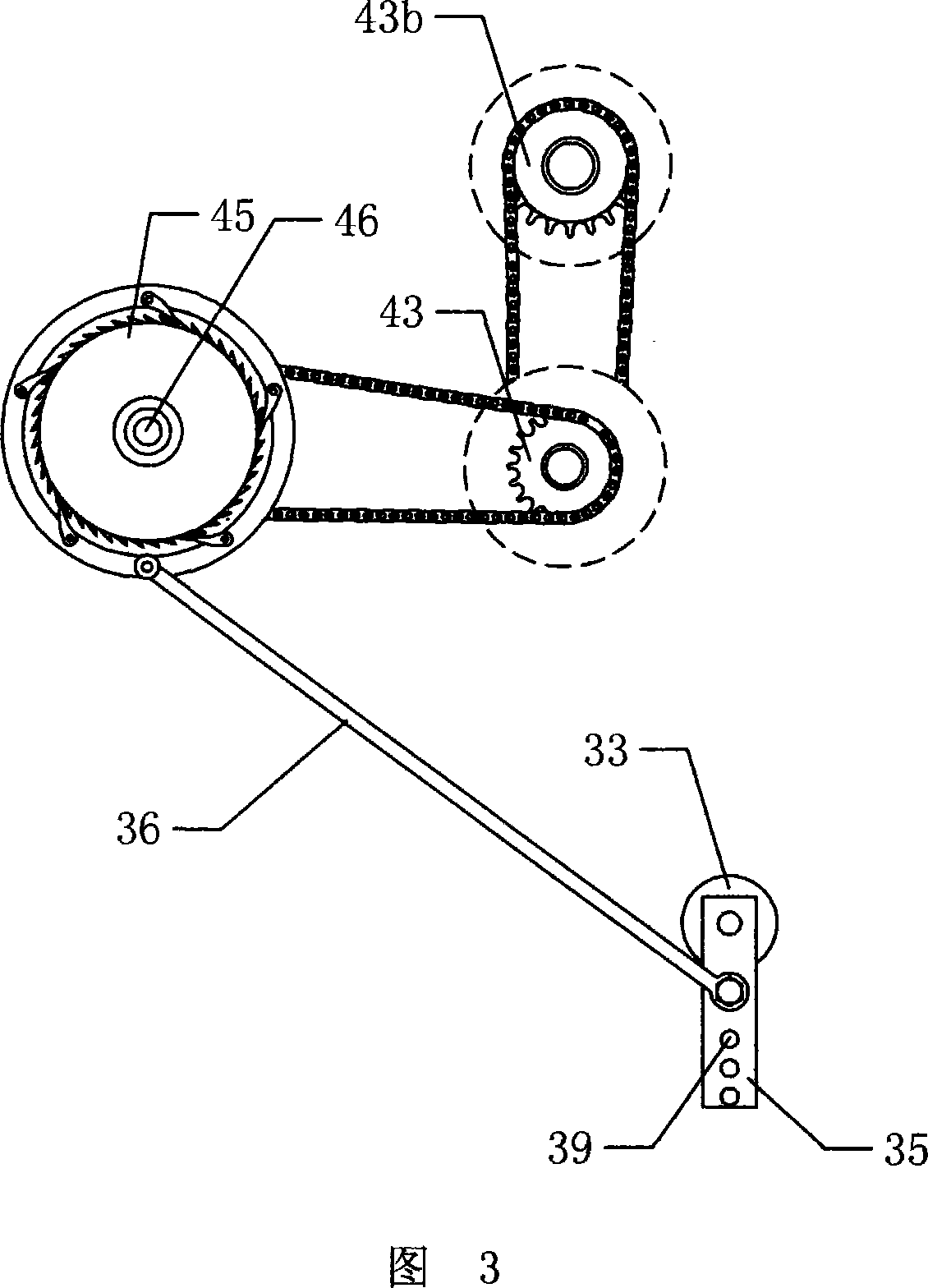

[0019] As shown in Figures 1 and 2, the yarn cutting machine includes a frame 1, a yarn feeding device installed on the frame 1, installed on the frame and positioned at the yarn feeding device The last yarn cutting device is a power device that drives the movement of the yarn feeding device and the yarn cutting device, and the driving device of the yarn feeding device is an intermittent feeding driving device.

[0020] The yarn cutting device includes a fixed knife 2 fixedly installed on the frame 1, a moving knife 21 corresponding to the fixed knife 2, and the moving direction of the moving knife 21 is perpendicular to the yarn feeding device The yarn advance direction, the moving knife 21 is fixedly installed on the knife rest 23, the knife rest 23 is installed on the frame 1 through the moving knife guide rail 22, and the driving device of the moving knife 21 is driven by reciprocating motion. device.

[0021] As shown in Figure 5, the said knife rest 23 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com