Water jet cutting system

A cutting system and water jet technology, applied in abrasive jet machine tools, explosion generating devices, abrasives, etc., can solve the problems of high acceleration and deceleration, increased space occupied, inability to provide, etc., and achieve the effect of reducing pressure and increasing life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

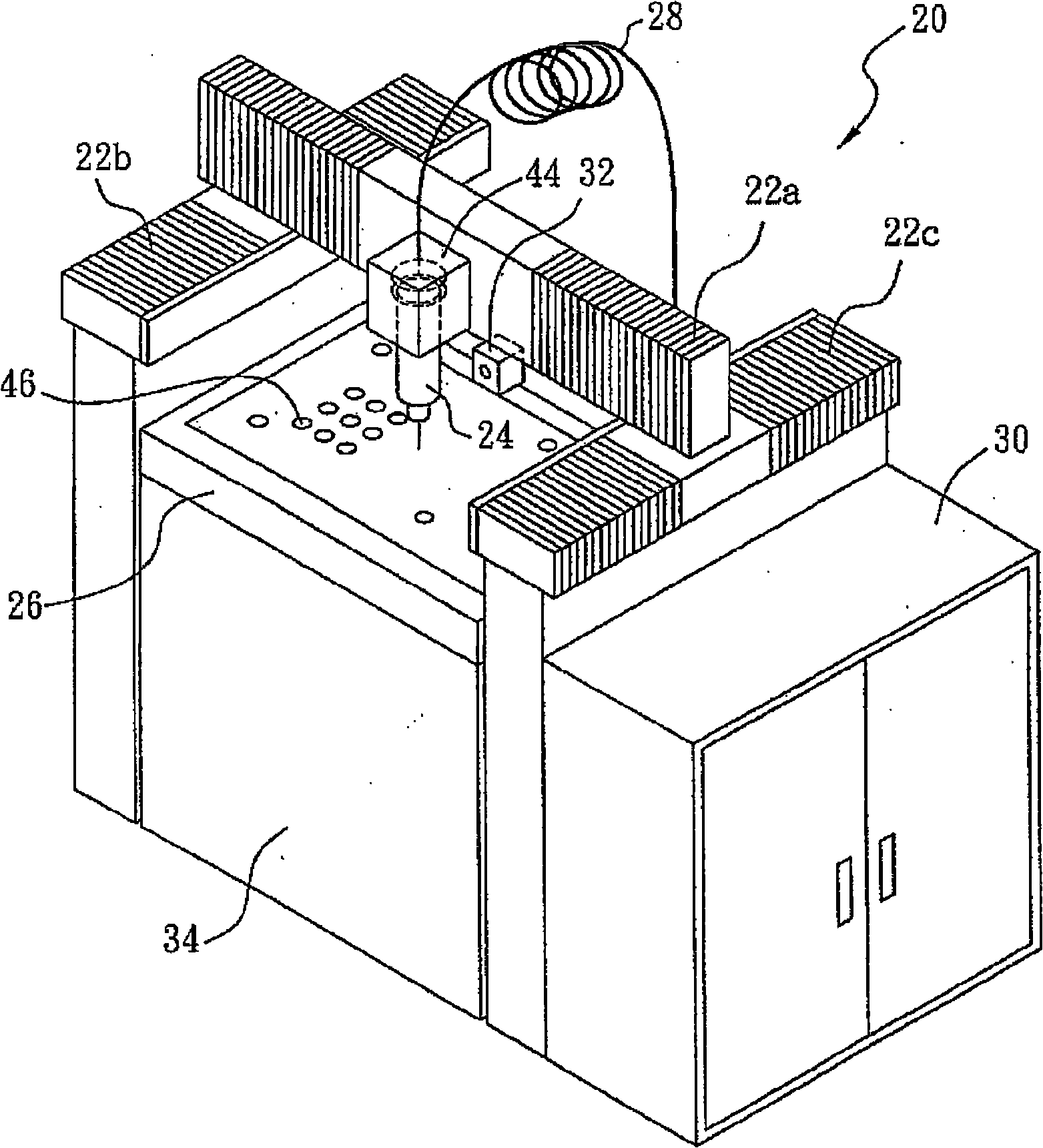

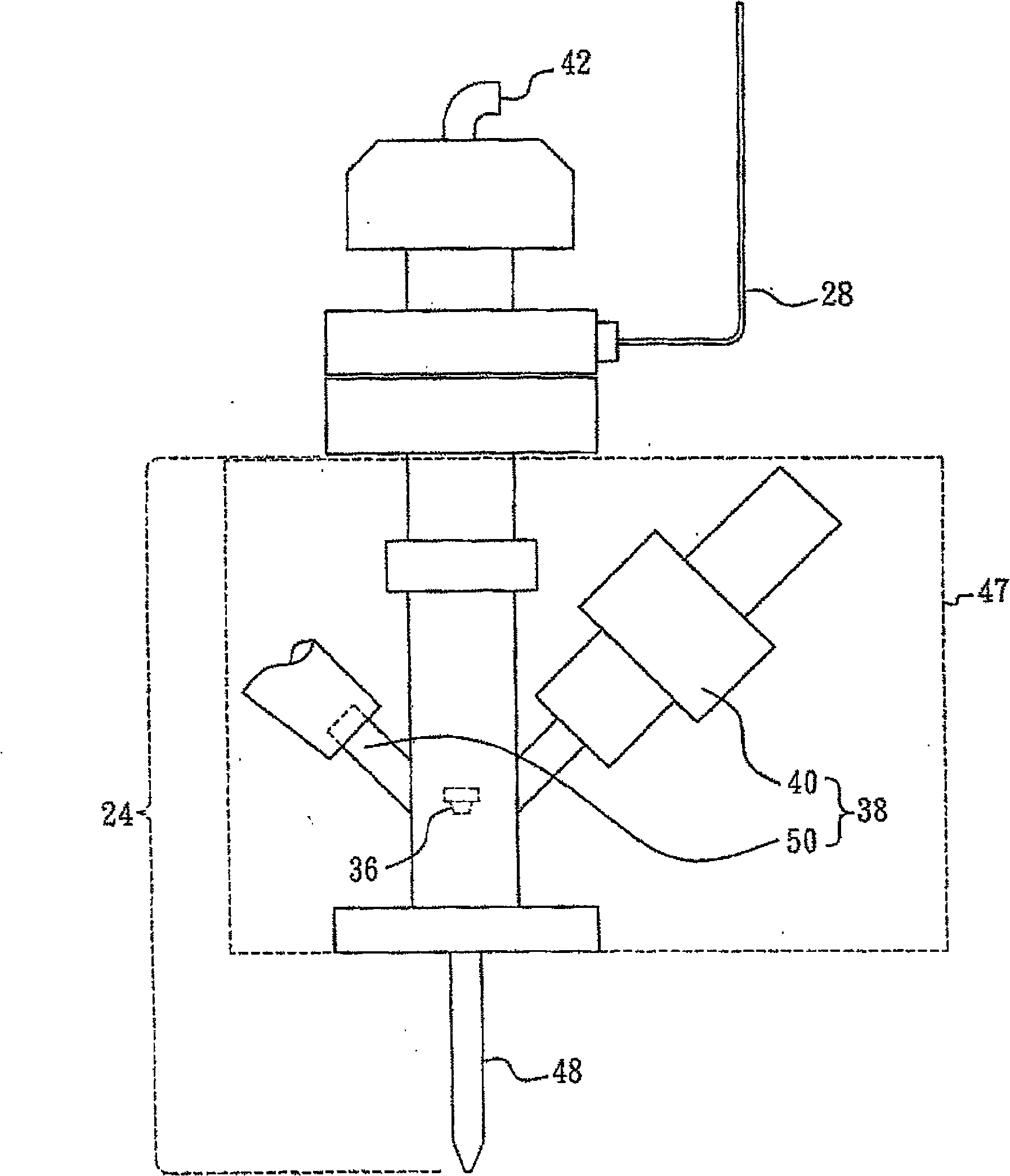

[0019] Such as figure 2 As shown, the water jet cutting system ( 20 ) according to the first embodiment of the present invention includes: a gate type driving device ( 22 ), a high-voltage generating device (not shown) and a cutting device ( 24 ). The water jet cutting system is used to cut semiconductor components, wherein the gate drive device is used to provide driving force in the x-y plane; the high-pressure generating device is used to generate high-pressure water flow; and the cutting device is coupled to the high-voltage A generating device and the door-type driving device are used to cut the semiconductor element by using the high-pressure water flow under the driving of the door-type driving device.

[0020] According to the water jet cutting system (20) of another embodiment of the present invention, because the speed of the high-pressure water flowing through the high-pressure generating device is very fast, the present invention designs the high-pressure pipe (28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com