Plane-cabin energy-collected cutting apparatus

A cutting device and aircraft cabin technology, applied in the field of explosive cutting, to achieve the effect of convenient use, simple assembly and strong cutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

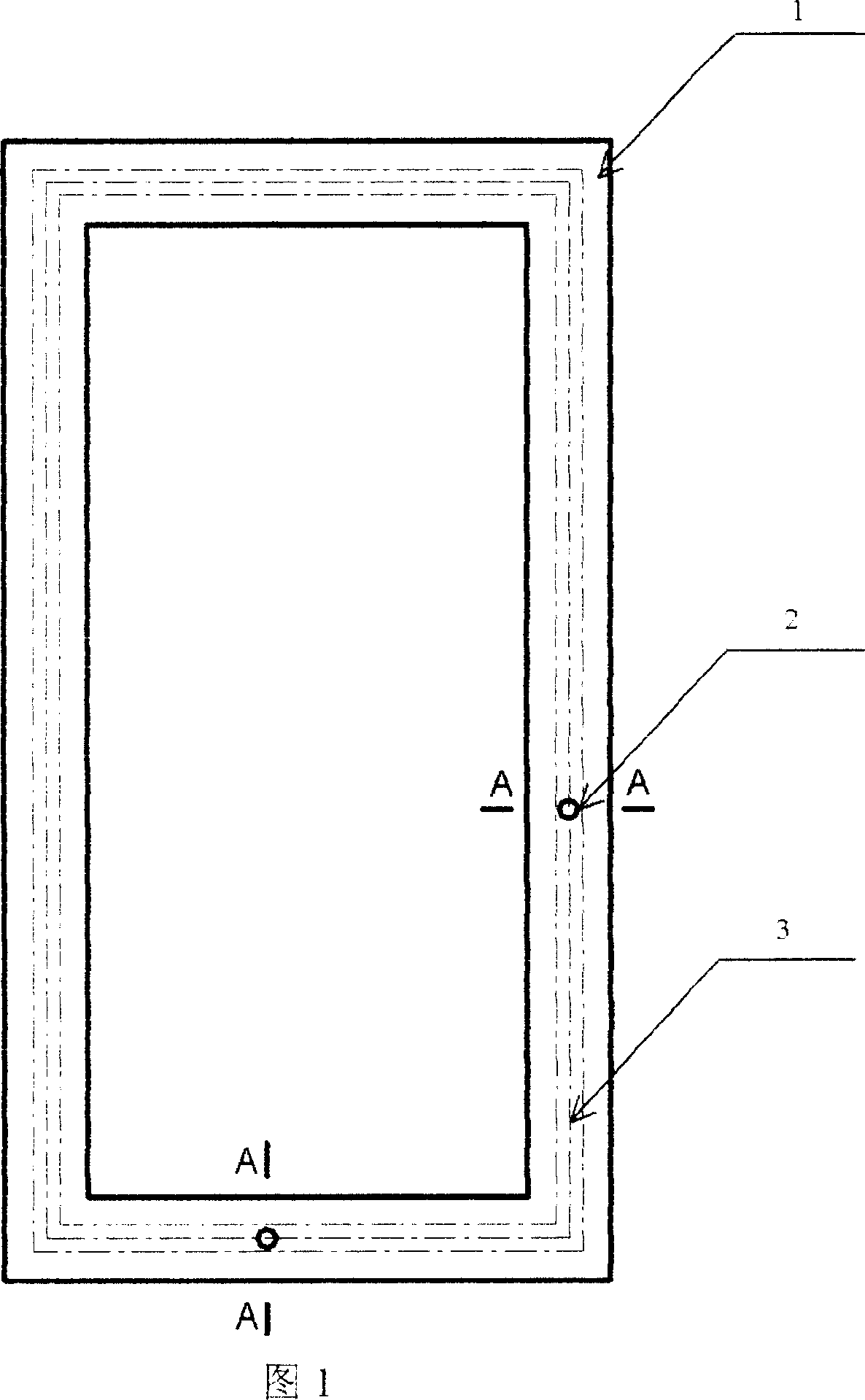

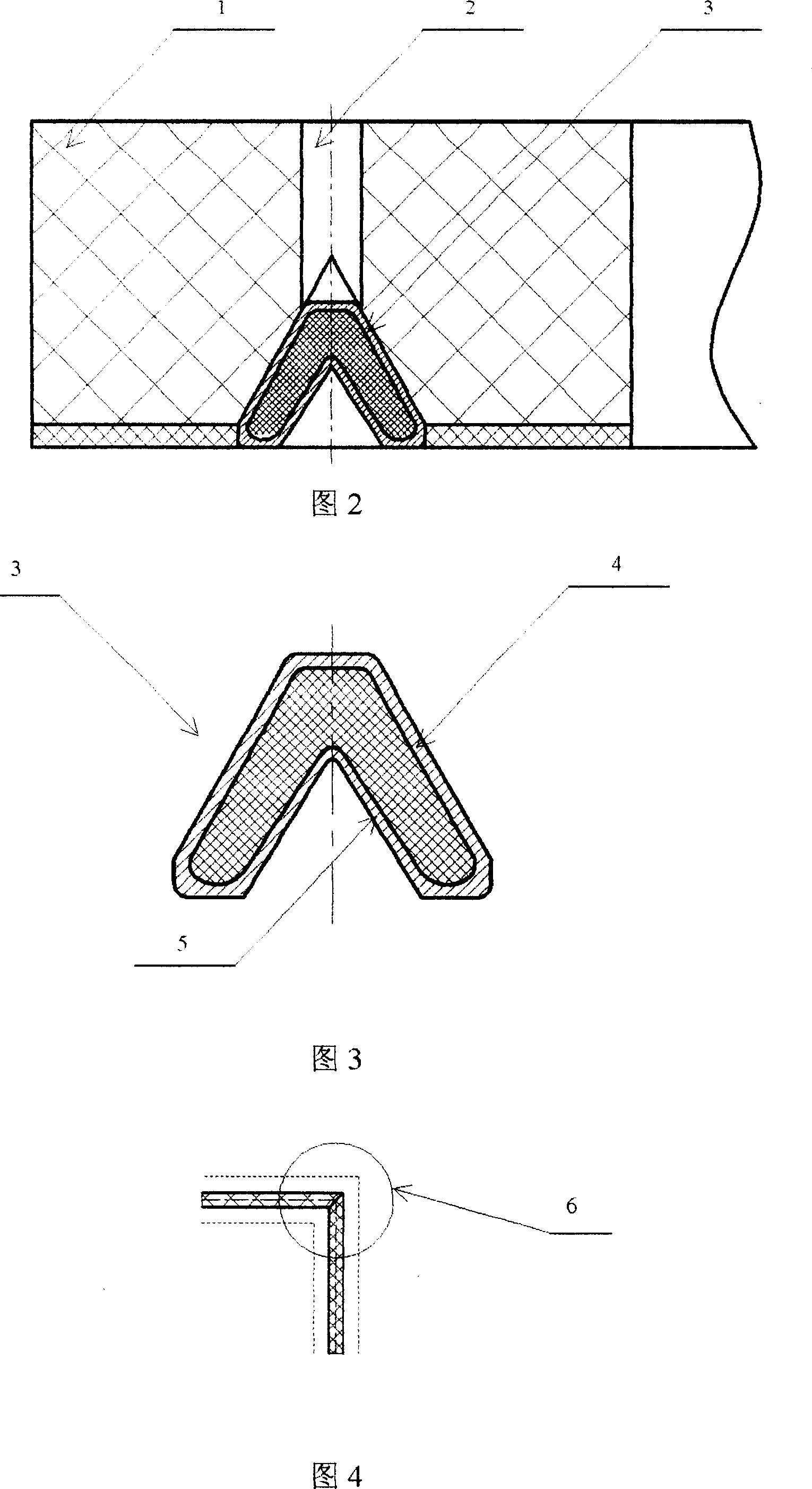

[0017] 1. The present invention is implemented with reference to Figures 1, 2, 3, and 4

[0018] 1.1 Preparation of shaped cutting cord

[0019] First, according to the model and structure of the shaped cutting cord 3, design and manufacture different models of molds; then put the mold into the hydraulic drawing machine, and load the explosive into the shell 4 of the shaped cutting cord 3 according to the technological requirements. 4 is a lead-antimony alloy tube containing 1% antimony; then put the metal tube filled with explosives into a "rolling drawing machine" and repeatedly rolling and drawing until the taper of the drug-shaped cover 4 meets the requirements of energy-converging cutting Cable 3.

[0020] 1.2 Preparation of protective cover

[0021] First, select the polyethylene foam sheet of the specified thickness and standard specifications, and cut the rectangular protective cover 1 outline blank with a high-speed band saw according to the size requirements of the drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com