Process for electroplating diamond wire adopting bare powder coating

A diamond wire and process technology, which is applied in the field of bare powder sanding electroplating diamond wire process, can solve the problems of weakening cutting force and increasing the outer diameter of steel wire, and achieve the effects of reduced material loss, stable wire diameter, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] figure 2 SEM image of the surface of the coated sand electroplated diamond wire;

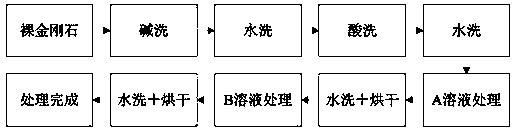

[0044] image 3 Process flow chart of bare sand electroplating diamond wire;

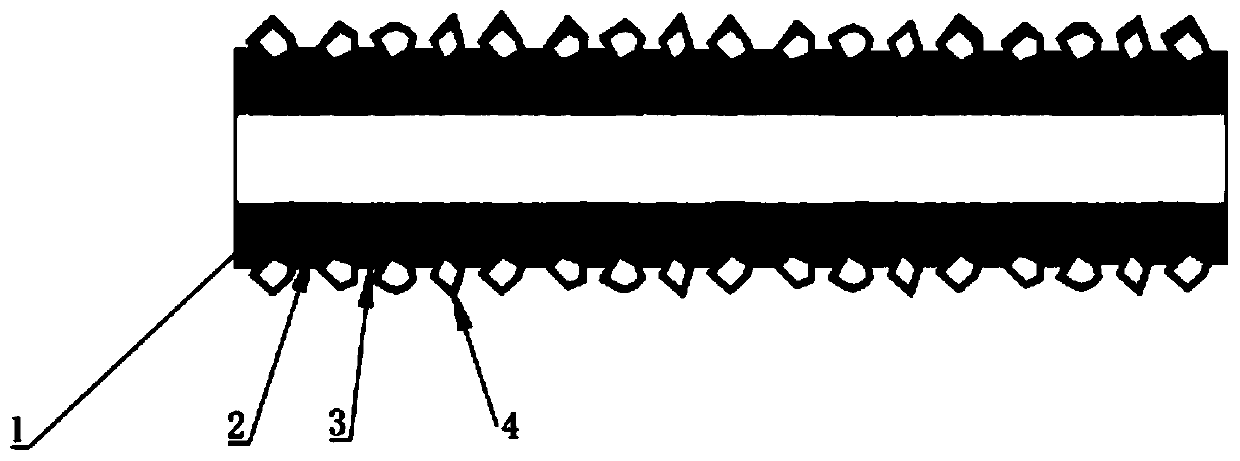

[0045] Figure 4.1 Schematic diagram of the side structure of diamond wire electroplated for bare sand;

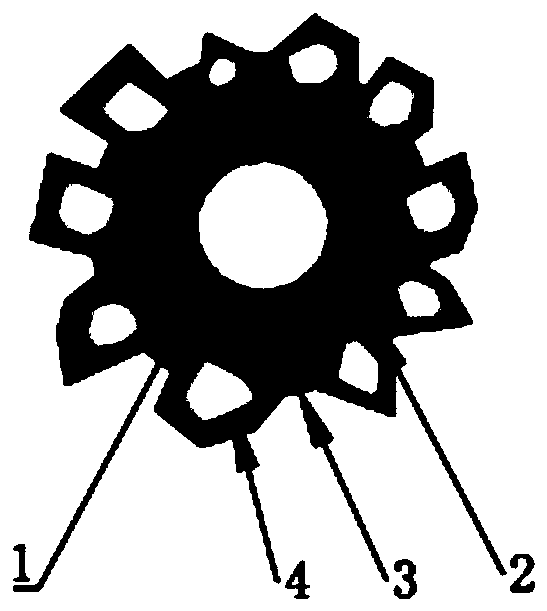

[0046] Figure 4.2 Schematic diagram of the cross-section of electroplating diamond wire for bare sand;

[0047] Figure 5 SEM image of the surface of bare sand electroplated diamond wire.

[0048] With the method of the present invention, use 65um steel wire to cooperate the diamond of D50=8.5um to produce electroplated diamond wire, the production process is as follows:

[0049] (1) Surface treatment of diamond 5: select diamond powder with D50=8.5,

[0050] a) Use NaOH solution with a concentration of 40±5g / L and a temperature of 50°C to clean the diamond powder for 10 minutes, and then wash it with water;

[0051] b) Use a sulfamic acid solution with a concentration of 40±5g / L to clean the ...

Embodiment 2

[0061] Example 2: The difference from Example 1 is that the core wire is a steel wire with a diameter of 55um, and the particle size of the diamond powder used is D50=8.0μm. Other steps are the same as in Example 1, and the finished product electroplated diamond wire has a specification of 68±3 μm.

Embodiment 3

[0062] Embodiment 3: The difference from Embodiment 1 is that the core wire is a steel wire with a diameter of 170 μm, and the particle size of the diamond powder used is D50=35 μm. The other steps are the same as in Example 1, and the specification of the obtained finished electroplated diamond wire is 250±10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com