High-speed restrained cutting experimental device based on split Hopkinson pressure bar loading technology

A Hopkinson pressure bar and experimental device technology, which is applied in the field of high-speed constrained cutting experimental devices, can solve the problems of low cutting speed, ineffective plastic deformation degree, and inability to study the evolution law of material microstructure, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

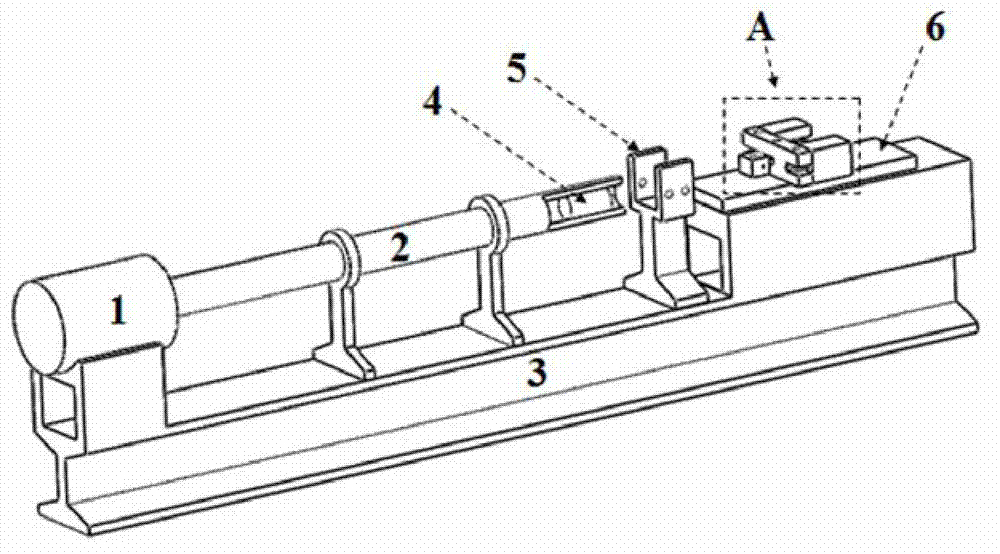

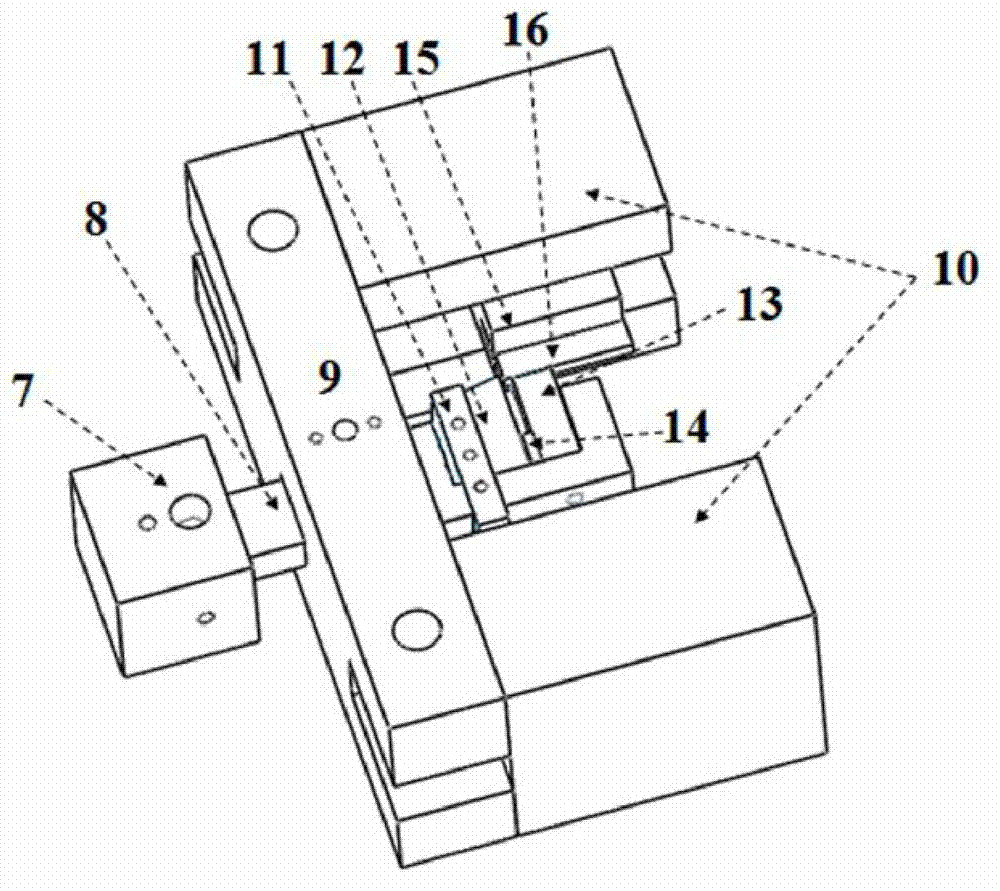

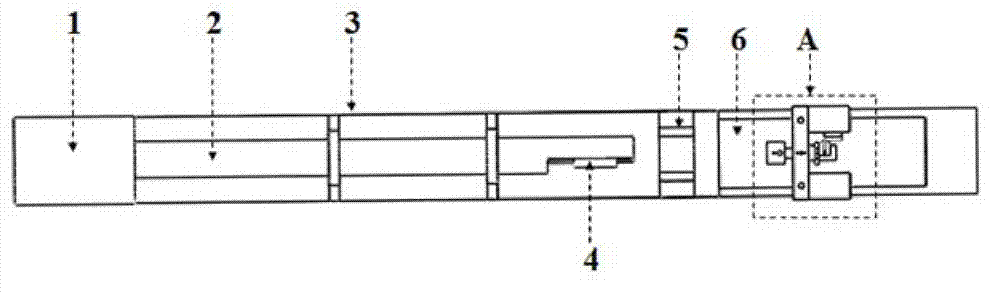

[0038] A high-speed constrained cutting experimental device based on the Hopkinson pressure bar loading technology of the present invention includes: a Hopkinson pressure bar dynamic loading mechanism, a laser speed measuring mechanism, a constrained cutting mechanism, a constrained cutting slideway mechanism, a fixing mechanism and a cutting mechanism. stop agency. The Hopkinson pressure rod dynamic loading mechanism is used to push the bullet to move along the predetermined track at a predetermined speed; the laser speed measuring mechanism is used to measure the movement speed of the bullet before hitting the restrained cutting mechanism; the restrained cutting mechanism is used to perform different processing on the workpiece to be processed Constrained cutting with a degree of plastic deformation; a constrained cutting slideway mechanism, used to give the speed direction of constrained cutting; a fixing mechanism, used to fix the workpiece to be processed; a cutting stop m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com