Hard rock tunneling machine

A technology of hard rock roadheader and cutting part, which is applied in the direction of cutting machinery, slitting machinery, driving device, etc. It can solve the problems of large machine vibration, reduce the working intensity of the operator, and a lot of dust, and achieve high driving power, Effects of protecting physical and mental health and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

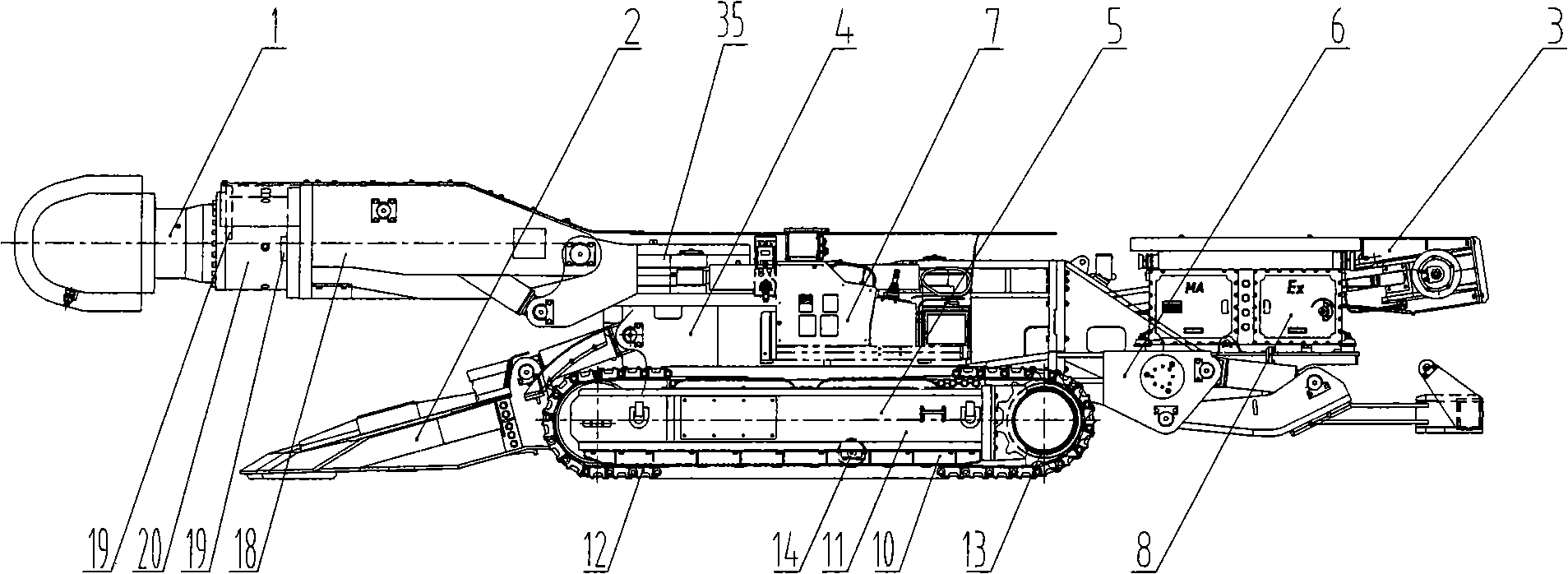

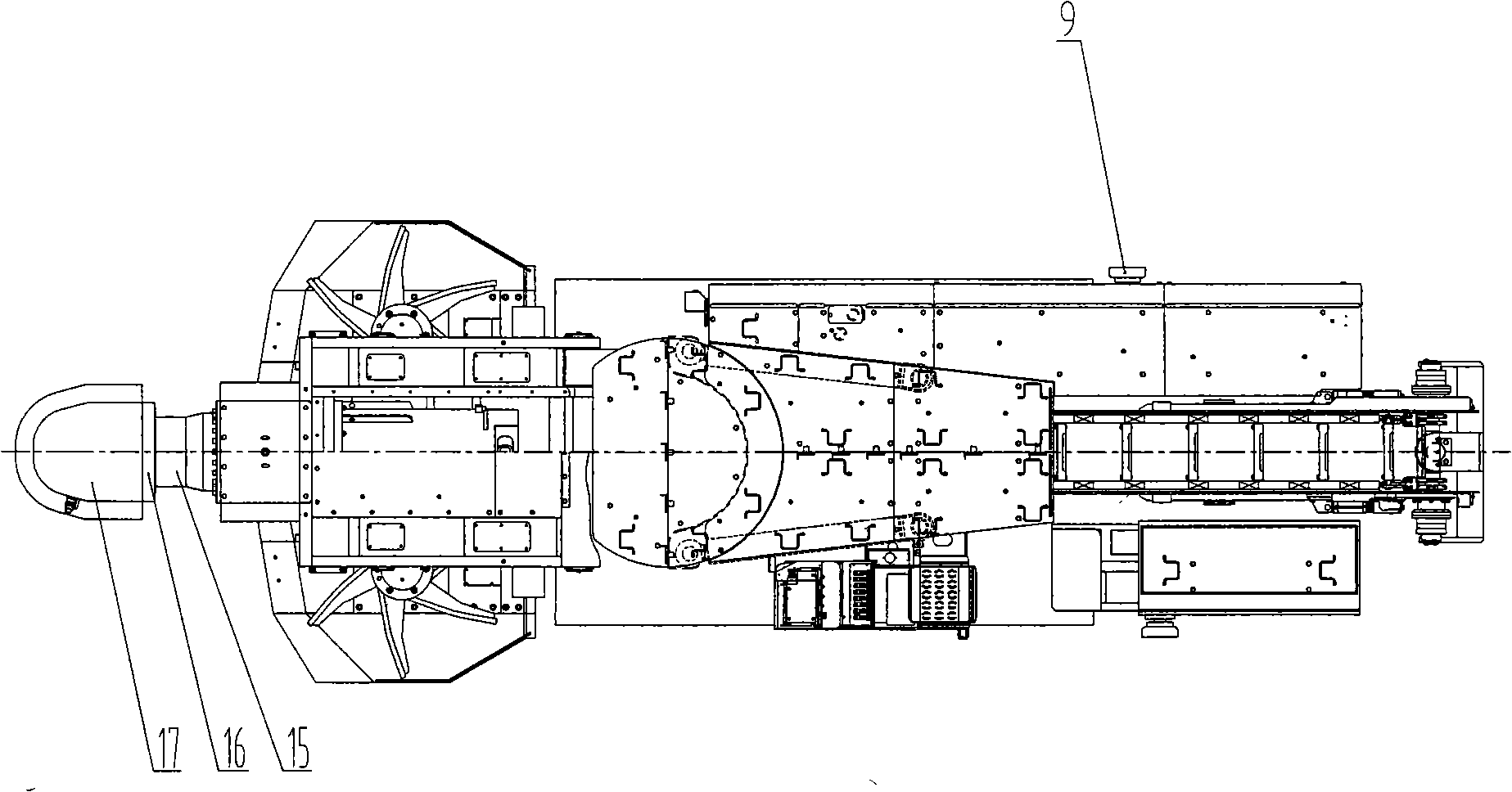

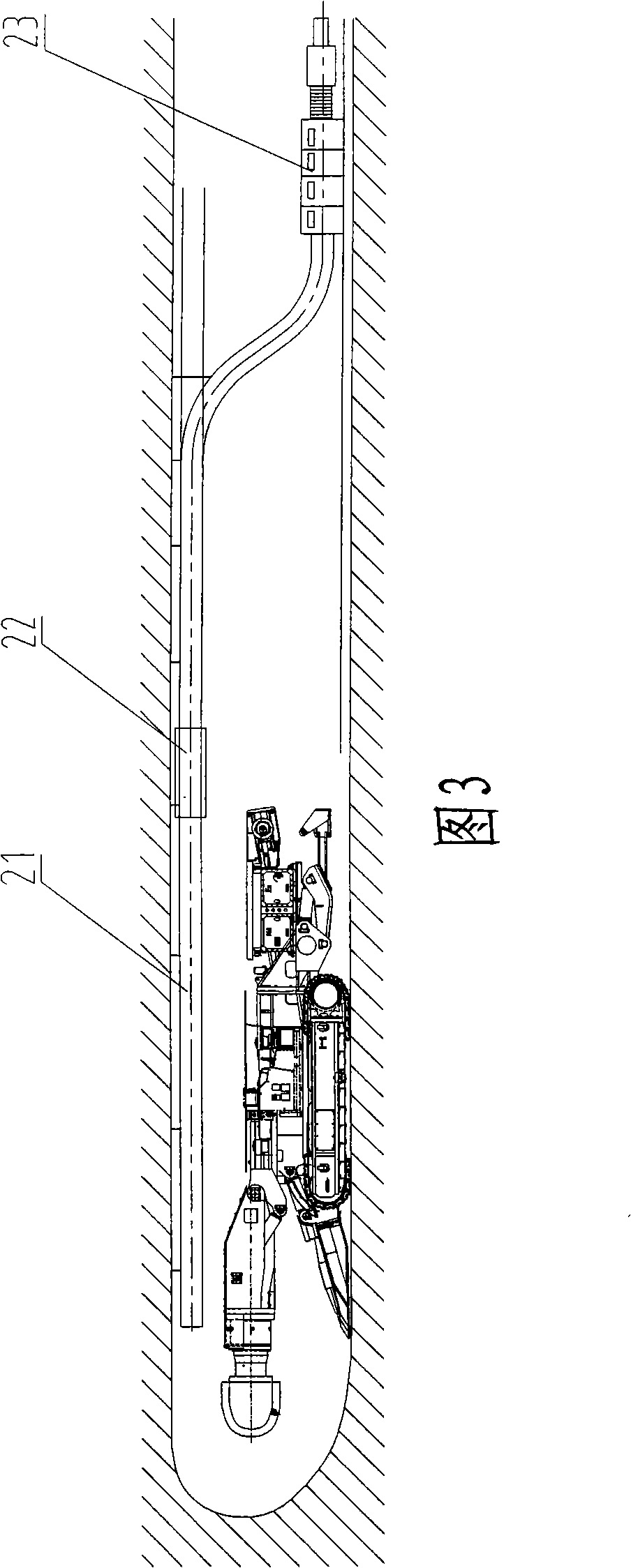

[0038] Such as figure 1 and figure 2As shown, the present invention is a hard rock tunneling machine. The cutting part 1 is installed on the front upper end of the body part 4, the shovel part 2 is installed on the front lower side of the body part 4, the first conveyor 3 is installed in the middle of the body part 4, and the two sides of the body part 4 The bottom is equipped with a running part 5, which includes a guard plate 10, a walking frame 11, a track shoe 12, a driving device 13, a roller 14, etc., and the running part 5 adopts a guard plate 10 which prevents rocks and coal from entering the inner side of the track shoe 12. Closed structure, the guard plate 10 is respectively installed on both sides of the supporting wheels 14 of the traveling frame 11 and on both sides of the driving device 13; Fuel tank, the rear support 6 is installed on the rear side of the main body part 4, the side support device 9 is installed on both sides of the rear support 6, the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com