Boron carbide coated carbon nanotube and preparation method and application thereof

A carbon nanotube and carbon-coated technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of difficult composite materials, difficult dispersion of carbon nanotubes, poor interface bonding ability, etc., to improve mechanical properties. And toughness, improve blindness, the effect of controllable expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

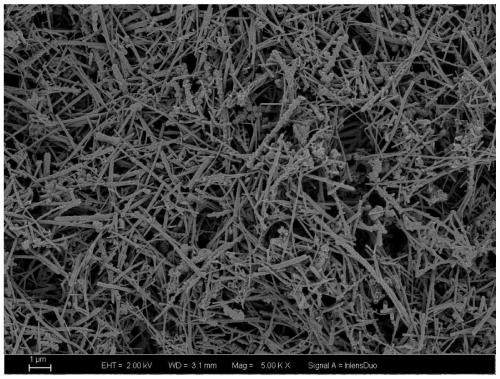

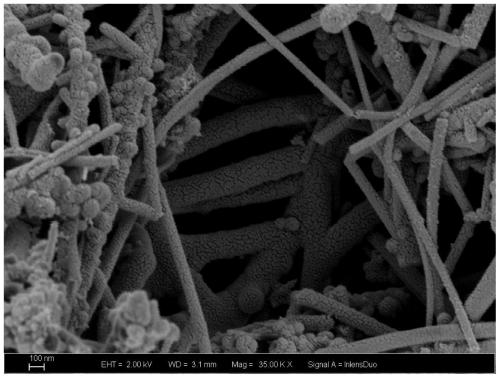

[0028] The embodiment of the present invention relates to a method for preparing boron carbide-coated carbon nanotubes, comprising the following steps:

[0029] S1, put boric acid in a beaker, add trihydroxypropane to it according to the molar ratio of boric acid and trihydroxypropane (1.7-2.4): 1, then mix and stir evenly, heat in a water bath and perform ultrasonic treatment to completely dissolve boric acid in Trihydroxypropane, to obtain a transparent solution A;

[0030] S2, placing the carbon nanotubes in another beaker, adding an ethanol solution dropwise therein, and then ultrasonically treating them after complete soaking to obtain a carbon nanotube slurry B;

[0031] S3, adding the carbon nanotube slurry B prepared in step S2 into the transparent solution A prepared in step S1, mixing evenly and ultrasonically treating, then heating and evaporating ethanol in a water bath while stirring, to obtain carbon nanotubes, boric acid and trihydroxypropane Evenly mixed paste...

Embodiment 1

[0038] This embodiment relates to a method for preparing boron carbide-coated carbon nanotubes, comprising the following steps:

[0039] S1, put 30g of boric acid in a beaker, add 20mL of trihydroxypropane into it, stir evenly with a glass rod, heat it in a water bath to 75°C, and perform ultrasonic treatment on it, the working frequency is 20kHz, the ultrasonic power is 1000W, and the ultrasonic time is 10min. Solution A;

[0040] S2, put 22g of carbon nanotubes in another beaker, and drop ethanol solution into it; after the carbon nanotubes are completely infiltrated, perform ultrasonic treatment, the working frequency is 20kHz, the ultrasonic power is 800W, and the single ultrasonic time is 1min. Ultrasonic again for 2 minutes, a total of 5 times, to obtain carbon nanotube slurry B;

[0041] S3, add the carbon nanotube slurry B into the solution A, continue ultrasonication for 1min, the working frequency is 20kHz, and the ultrasonic power is 1000W, and then at 85°C at a ra...

Embodiment 2

[0046]S1, put 40g of boric acid in a beaker, add 25mL of trihydroxypropane into it, stir evenly with a glass rod, heat it in a water bath to 85°C, and perform ultrasonic treatment on it. The working frequency is 20kHz, the ultrasonic power is 1400W, and the ultrasonic time is about 5min. Transparent solution A;

[0047] S2, put 22g of carbon nanotubes in another beaker, and drop ethanol solution into it; after the carbon nanotubes are completely infiltrated, perform ultrasonic treatment on them, the working frequency is 20kHz, the ultrasonic power is 800W, and the single ultrasonic time is 2min, the interval Ultrasonic again for 2 minutes, a total of 10 times, to obtain carbon nanotube slurry B;

[0048] S3, add the carbon nanotube slurry B into the solution A, continue ultrasonication for 2min, the working frequency is 20kHz, the ultrasonic power is 1000W, and then at 75°C at a rate of 400r / min, the water bath is heated to evaporate ethanol to obtain carbon nanotubes, Paste ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com