Preparation method of B4C nanosheet and B4C nanosheet

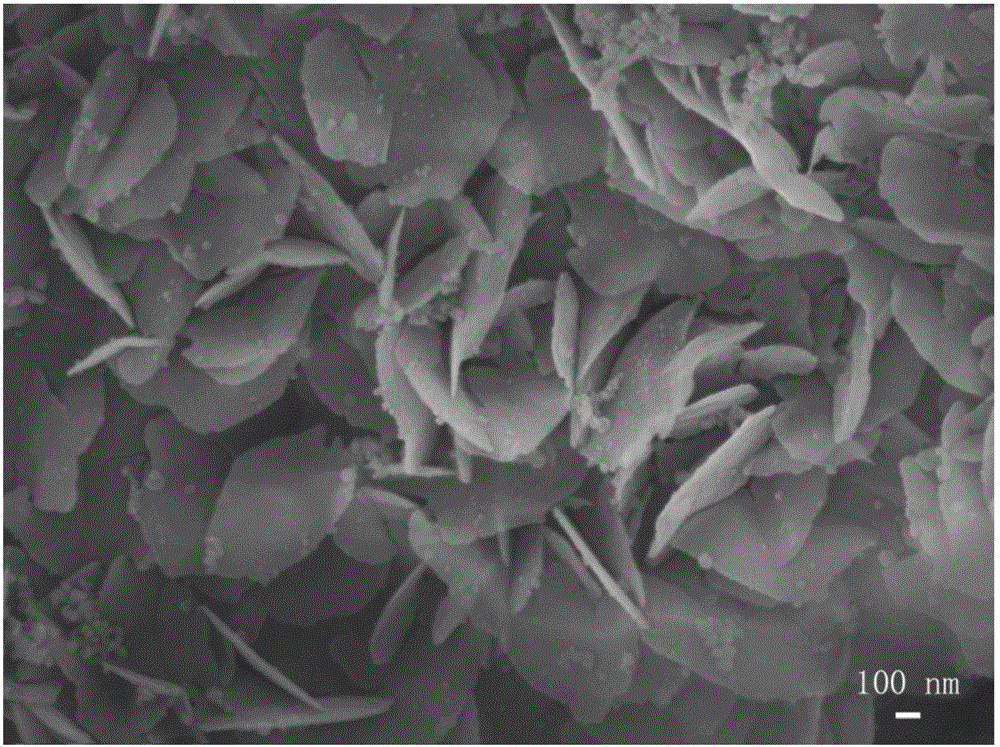

A nanosheet and boric acid technology, applied in nanotechnology and other directions, can solve the problem of inability to form regularly arranged boron carbide nanosheets, and achieve the effects of excellent interface wettability, high yield and purity, and fast reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

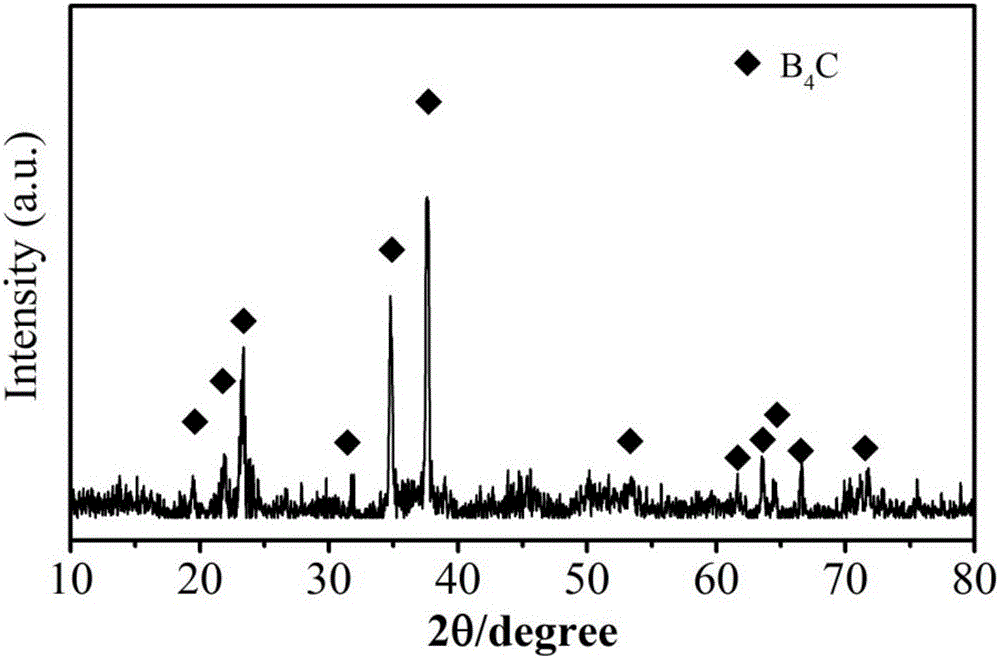

[0040] B of this embodiment 4 The preparation method of C nanosheet includes the following steps:

[0041] 1) According to the mass ratio of 4:1, take 40g of boric acid and 10g of coal powder into the ball mill tank of the planetary ball mill, and add 5g of sodium carbonate (the added mass of sodium carbonate is 10% of the total mass of boric acid and coal powder) and 150ml of ethanol, wet ball milling with a planetary ball mill at a ball-to-battery ratio of 10:1 and a rotating speed of 150r / min for 1h, mix well and dry at 90°C to obtain a mixed powder of boric acid-coated coal powder;

[0042] 2) Pre-press the mixed powder obtained in step 1) into flakes under 5 MPa, and then perform cold isostatic pressing at 150 MPa for 0.5 min to obtain flakes;

[0043] 3) Embed the flakes obtained in step 2) in quartz sand contained in an alumina crucible, and place the crucible together with its contents in the resonant cavity of a multi-mode microwave sintering furnace with a frequency of 2.45...

Embodiment 2

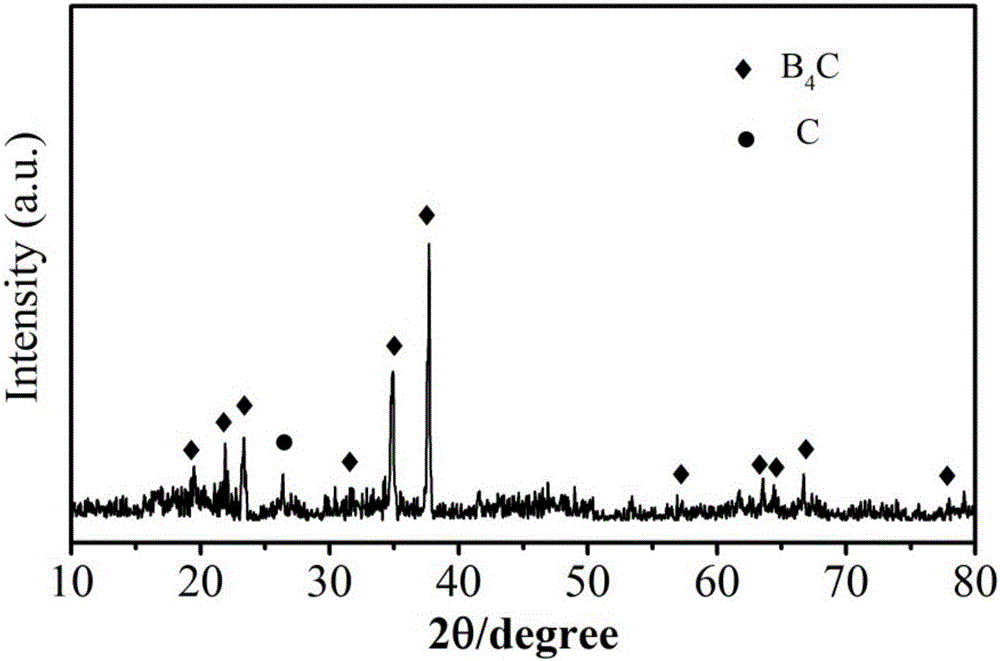

[0047] B of this embodiment 4 The preparation method of C nanosheet includes the following steps:

[0048] 1) According to the mass ratio of 3:1, take 30g of boric acid and 10g of coal powder into the ball mill tank of the planetary ball mill, and add 2g of sodium carbonate (the added mass of sodium carbonate is 5% of the total mass of boric acid and coal powder) and 100ml of ethanol, wet ball milling with a planetary ball mill under the conditions of a ball-to-material ratio of 10:1 and a rotating speed of 150r / min for 2h, mix well and dry at 100°C to obtain a mixed powder of boric acid-coated coal powder;

[0049] 2) Pre-press the mixed powder obtained in step 1) into flakes under 5 MPa, and then subject to 180 MPa cold isostatic pressing for 1 min to obtain flakes;

[0050] 3) Embed the flakes obtained in step 2) in quartz sand contained in an alumina crucible, and place the crucible together with its contents in the resonant cavity of a multi-mode microwave sintering furnace with...

Embodiment 3

[0054] B of this embodiment 4 The preparation method of C nanosheet includes the following steps:

[0055] 1) According to the mass ratio of 3:1, take 30g of boric acid and 10g of coal powder into the ball mill tank of the planetary ball mill, and add 4g of sodium bicarbonate (the added mass of sodium carbonate is 10% of the total mass of boric acid and coal powder) 100ml of ethanol and 100ml of ethanol, use a planetary ball mill at a ball-to-material ratio of 10:1 and a rotating speed of 150r / min to perform wet ball milling for 1.5 hours, mix well and dry at 105°C to obtain a boric acid-coated coal powder mixed powder ;

[0056] 2) Pre-press the mixed powder obtained in step 1) into a sheet shape at 5 MPa, and then subject it to 160 MPa cold isostatic pressing for 0.5 min to obtain a sheet;

[0057] 3) Embed the flakes obtained in step 2) in quartz sand contained in an alumina crucible, and place the crucible together with its contents in the resonant cavity of a multi-mode microwa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com