Aluminum-based in-situ composite material formed based on laser 3D printing and preparation method of aluminum-based in-situ composite material

An in-situ composite material and 3D printing technology, which is applied in the direction of additive processing, process efficiency improvement, energy efficiency improvement, etc., can solve the problems that the mechanical properties such as strength and wear resistance of aluminum alloy cannot be effectively improved, and achieve excellent Comprehensive mechanical properties, improvement of overall mechanical properties, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The invention is a method for preparing an aluminum-based in-situ composite material based on laser 3D printing, including:

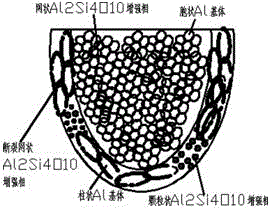

[0048] Equipped with raw materials, Al-Si-Mg alloy powder with a mass fraction ratio of 4:1 of 99.7% purity and an average particle size of 30um and Al with a purity of 99.5% and an average particle size of 5um 2 o 3 The powder is mixed to obtain a mixture; wherein, the composition and mass percentage of the Al-Si-Mg alloy powder are 7.2% Si, 0.28% Mg, 2 o 3 The role of powder wettability promotes the uniformity of the dispersion of raw materials in the subsequent 3D printing process.

[0049] Ball milling, the mixture is milled by batch ball milling process, the diameter is Φ 8mm Al 2 o 3 The ceramic ball is a ball milling medium, the weight ratio of the ball milling medium to the mixture is 5:1, every 10 minutes of ball milling is air-cooled for 5 minutes, and the particle size of the ball milling until the mixture is 1um; the speed of the ...

Embodiment 2

[0056] The invention is a method for preparing an aluminum-based in-situ composite material based on laser 3D printing, including:

[0057] Equipped with raw materials, Al-Si-Mg alloy powder with a mass fraction ratio of 5:1 of 99.8% purity and an average particle size of 30um and Al with a purity of 99.7% and an average particle size of 5um 2 o 3 The mixture obtained by mixing powders; wherein, the composition and mass percentage of Al-Si-Mg alloy powder are 9.2% Si, 0.48% Mg, <0.1% other impurity elements, and the balance is Al .

[0058] Ball milling, the mixture is milled by batch ball milling process, the diameter is Φ 10mm Al 2 o 3 The ceramic ball is a ball milling medium, the weight ratio of the ball milling medium to the mixture is 10:1, every 30 minutes of ball milling is air-cooled for 10 minutes, and the particle size of the ball milling to the mixture is 10 μm; the speed of the balls of the intermittent ball mill is 400r / min, Ball milling time 9h.

[0059] T...

Embodiment 3

[0064] The invention is a method for preparing an aluminum-based in-situ composite material based on laser 3D printing, including:

[0065] Equipped with raw materials, Al-Si-Mg alloy powder with a mass fraction ratio of 6:1 of 99.7% purity and an average particle size of 30um and Al with a purity of 99.5% and an average particle size of 5um 2 o 3 The mixture obtained by mixing powders; wherein, the composition and mass percentage of Al-Si-Mg alloy powder are 8% Si, 0.29% Mg, <0.1% other impurity elements, and the balance is Al.

[0066] Ball milling, the mixture is milled by batch ball milling process, the diameter is Φ 9mm Al 2 o 3 The ceramic ball is a ball milling medium, the weight ratio of the ball milling medium to the mixture is 8:1, every 20 minutes of ball milling is air-cooled for 8 minutes, and the particle size of the ball milling to the mixture is 8um; the speed of the balls of the intermittent ball mill is 380r / min, Ball milling time 6h.

[0067] The mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com