Wind driven generator blade

A technology for wind turbines and blades, applied in wind turbine components, wind engines, wind power generation, etc., which can solve the problems of carbon fiber elongation, poor impact resistance and fracture toughness, affecting the performance of wind turbine blades, and the infiltration effect of composite materials Poor and other problems, to achieve the effect of improving shear strength, light weight and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

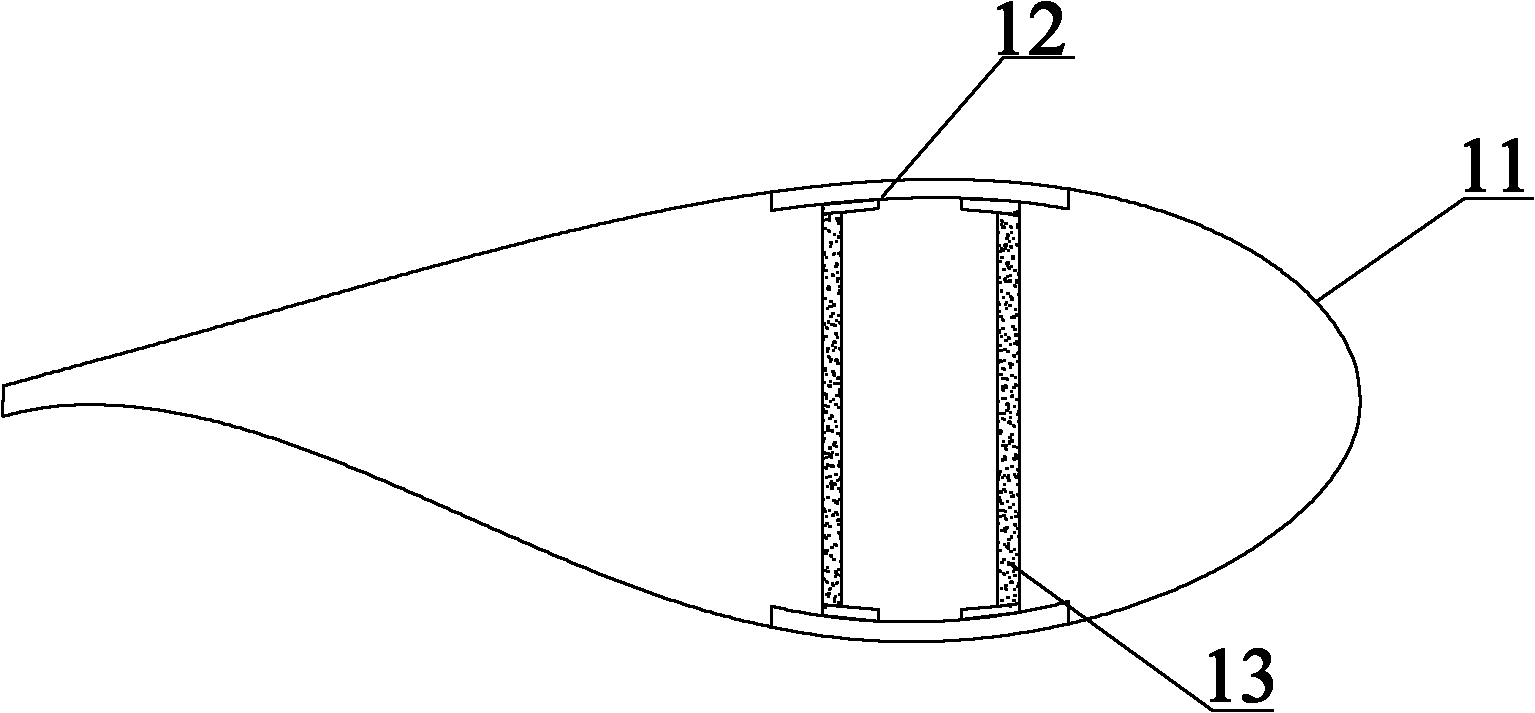

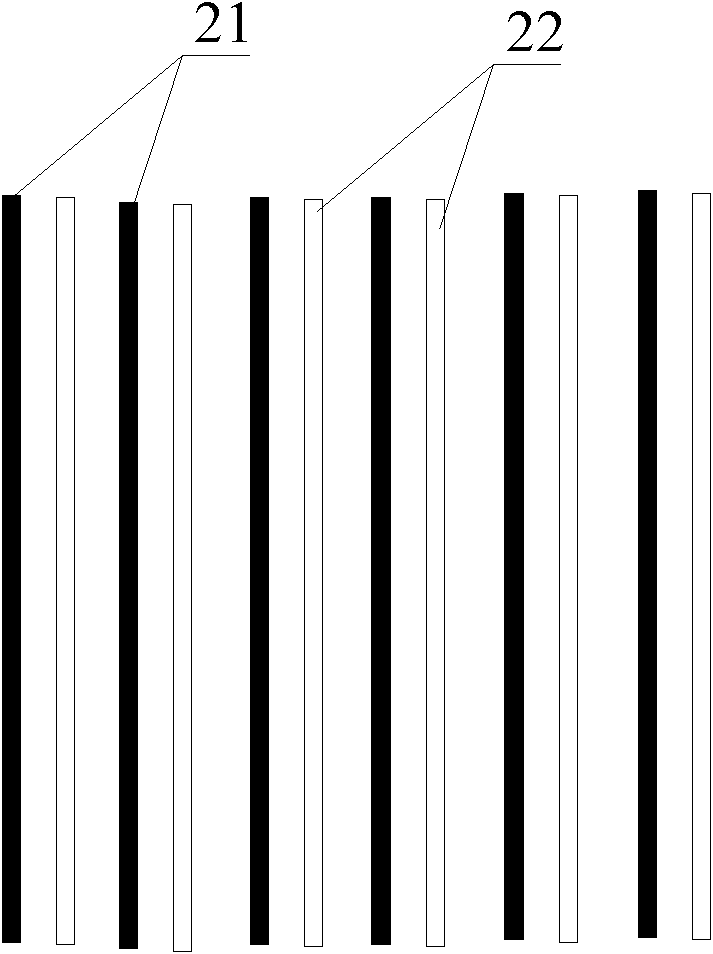

[0043] See figure 2 , carbon fiber 21 and glass fiber 22 are arranged alternately in one direction according to the volume ratio of 1:1, then impregnated with epoxy resin, and after curing, the surface density is 125g / m 2 The weight ratio of total fiber to epoxy resin is 70:30.

[0044] The measured tensile strength of the composite material plate is 2500MPa, the bending strength is 1890MPa, and the shear strength is 51MPa.

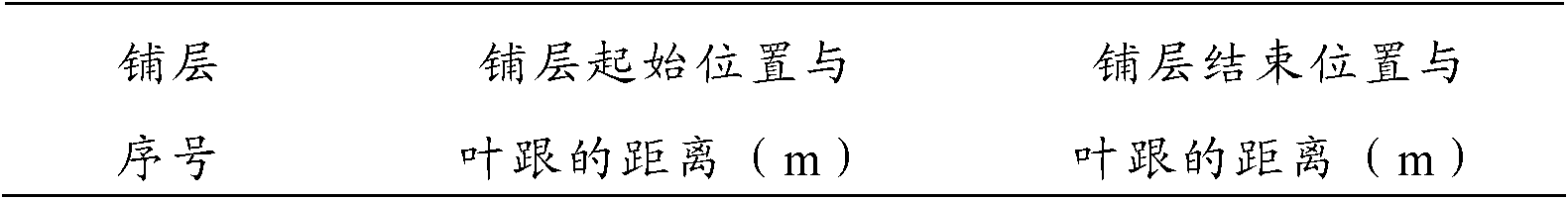

[0045] Take 18 layers of prepreg and lay them up according to the layup sequence in Table 1 and the method of 0°, and then vacuumize and hot-press them on the main beam mold. The forming temperature is 180 °C and the forming pressure is 10 MPa to obtain the main beam.

[0046] Table 1 Lamination method of the main beam of a certain type of blade

[0047]

[0048]

Embodiment 2

[0050] The carbon fiber and the glass fiber are arranged alternately in one direction according to the volume ratio of 2:1, and then impregnated with epoxy resin, and after curing, the surface density is 112g / m 2 The weight ratio of total fiber to epoxy resin is 65:35.

[0051] The measured tensile strength of the composite material plate is 2680MPa, the bending strength is 1780MPa, and the shear strength is 48MPa.

[0052] Take 20 layers of prepregs according to the layup sequence in Table 2 and lay them up in the way of 0° / 90°, and then vacuumize and hot press them on the root end mold of the skin. The molding temperature is 175°C and the molding pressure is 8MPa. Skin.

[0053] Table 2. Root end laying method

[0054]

Embodiment 3

[0056] Arrange carbon fibers and glass fibers alternately in one direction according to the volume ratio of 1:2, then impregnate epoxy resin, and obtain an area density of 135g / m after curing 2 The unidirectional prepreg, the weight ratio of the total amount of fiber and epoxy resin is 68:32.

[0057] The measured tensile strength of the composite material plate is 2350MPa, the bending strength is 1940MPa, and the shear strength is 54MPa.

[0058] Take 18 layers of prepreg and lay them up according to the layup sequence in Table 3 and the method of 0° / 90°, and then vacuumize and hot-press on the web mold. The molding temperature is 165°C and the molding pressure is 9MPa to obtain the web core. The lower layer of material.

[0059] Table 3 Lay-up method of web at the root end

[0060]

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com