A high-strength wood-plastic tray

A high-strength, wood-plastic technology, applied in the field of plastic products production, can solve the problems of agricultural ecological balance destruction, waste of resources, pollution of the environment, etc., and achieve the effect of enhanced binding force, increased strength, and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

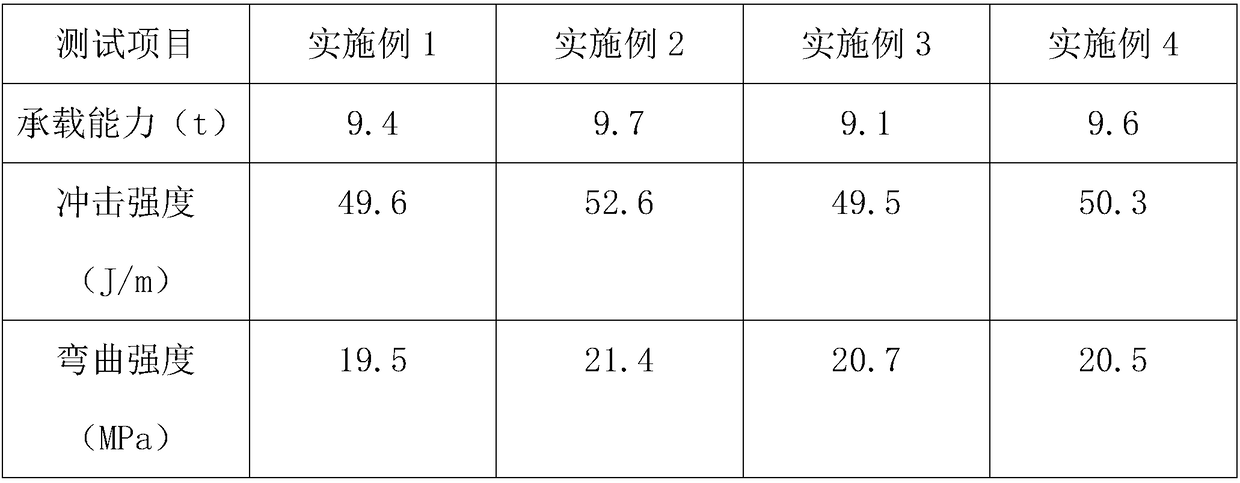

Examples

Embodiment 1

[0019] A high-strength wood-plastic tray prepared from the following parts by weight of raw materials: 60 parts of modified cotton stalk powder, 70 parts of polypropylene recycled materials, 1 part of maleic anhydride grafted polypropylene, 2 parts of phthalic acid, and stearin 1 part of zinc acid, 2 parts of polypropylene wax, 0.2 part of diphenylamine, 1 part of antioxidant 1010, 0.5 part of azodicarboxylate, 7 parts of muscovite, 1 part of nano calcium carbonate, 8 parts of glass fiber, 2 parts of carbon fiber .

Embodiment 2

[0021] A high-strength wood-plastic tray prepared from the following parts by weight of raw materials: 80 parts of modified cotton stalk powder, 50 parts of polypropylene recycled materials, 5 parts of maleic anhydride grafted polypropylene, 0.5 parts of phthalic acid, and stearin 2 parts of zinc acid, 1 part of polypropylene wax, 1 part of diphenylamine, 0.2 parts of antioxidant 1010, 1 part of azodicarboxylate, 3 parts of muscovite, 10 parts of nano calcium carbonate, 2 parts of glass fiber, 8 parts of carbon fiber .

Embodiment 3

[0023] A high-strength wood-plastic tray prepared from the following parts by weight of raw materials: 60 parts of modified cotton stalk powder, 70 parts of polypropylene recycled materials, 1 part of maleic anhydride grafted polypropylene, 2 parts of phthalic acid, and stearin 1 part of zinc acid, 2 parts of polypropylene wax, 0.2 part of diphenylamine, 1 part of antioxidant 1010, 0.5 part of azodicarboxylate, 7 parts of muscovite, 1 part of nano calcium carbonate, 8 parts of glass fiber, 2 parts of carbon fiber .

[0024] The preparation method of the modified cotton stalk powder is as follows: dry the cotton stalks and pulverize them, pass a 20-mesh sieve to obtain cotton stalk powder, and then spray the composite enzyme preparation evenly on the cotton stalk powder, and control the temperature at 55°C. Enzymatic hydrolysis for 35 hours, and then drying at 105°C until the moisture content is less than 3% to obtain modified cotton stalk powder; the composite enzyme preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com