Patents

Literature

101results about How to "Easy visual inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

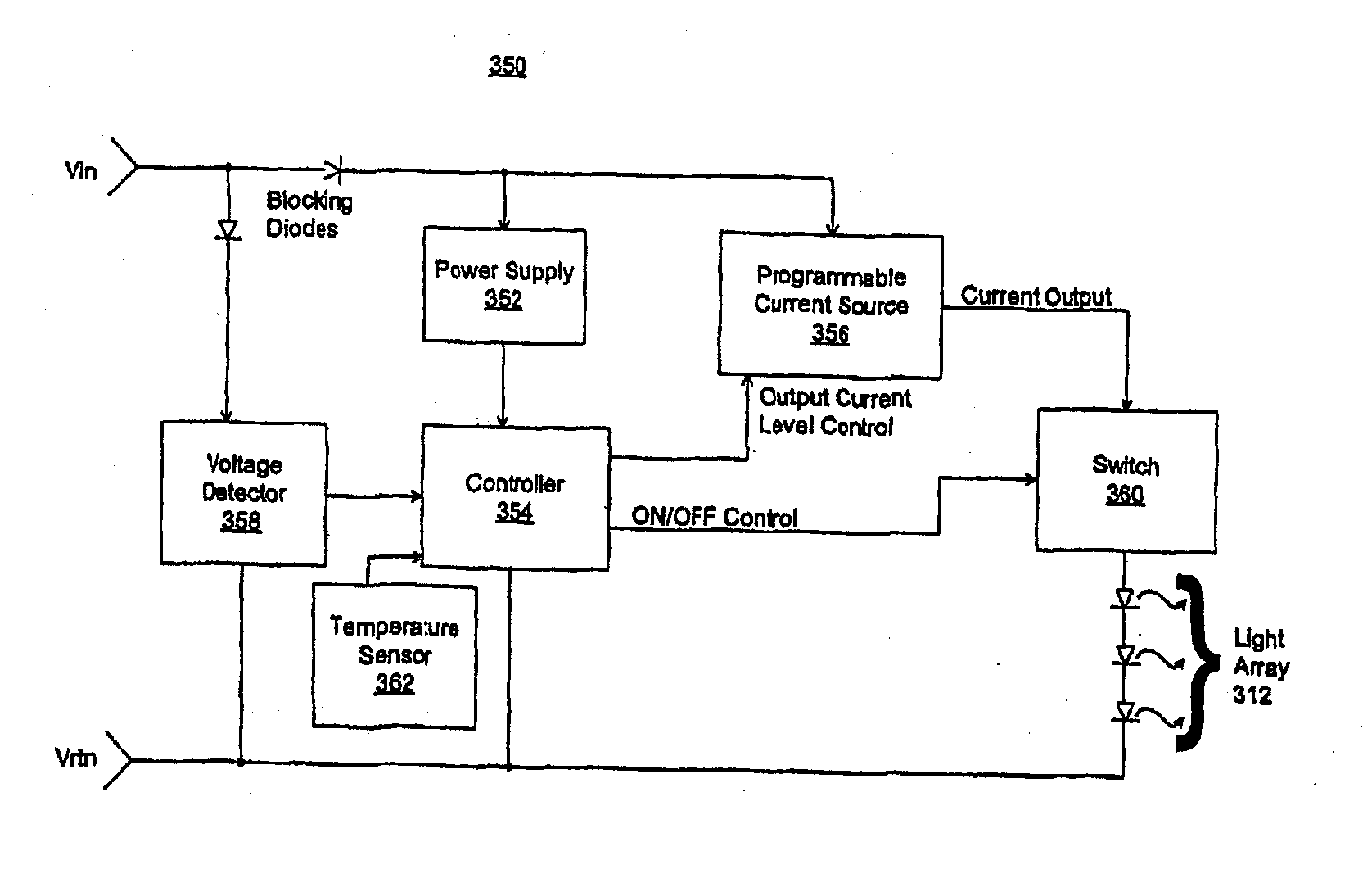

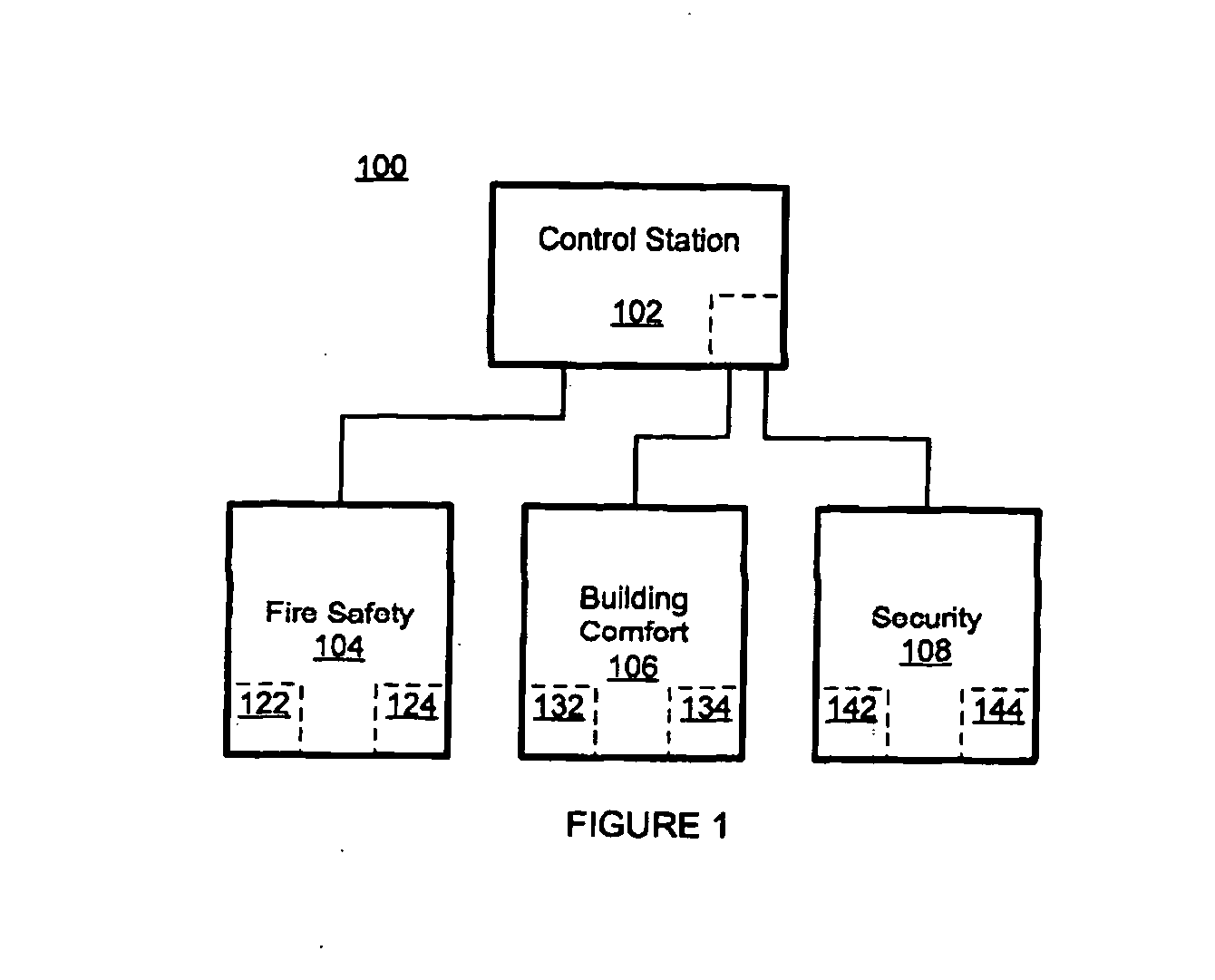

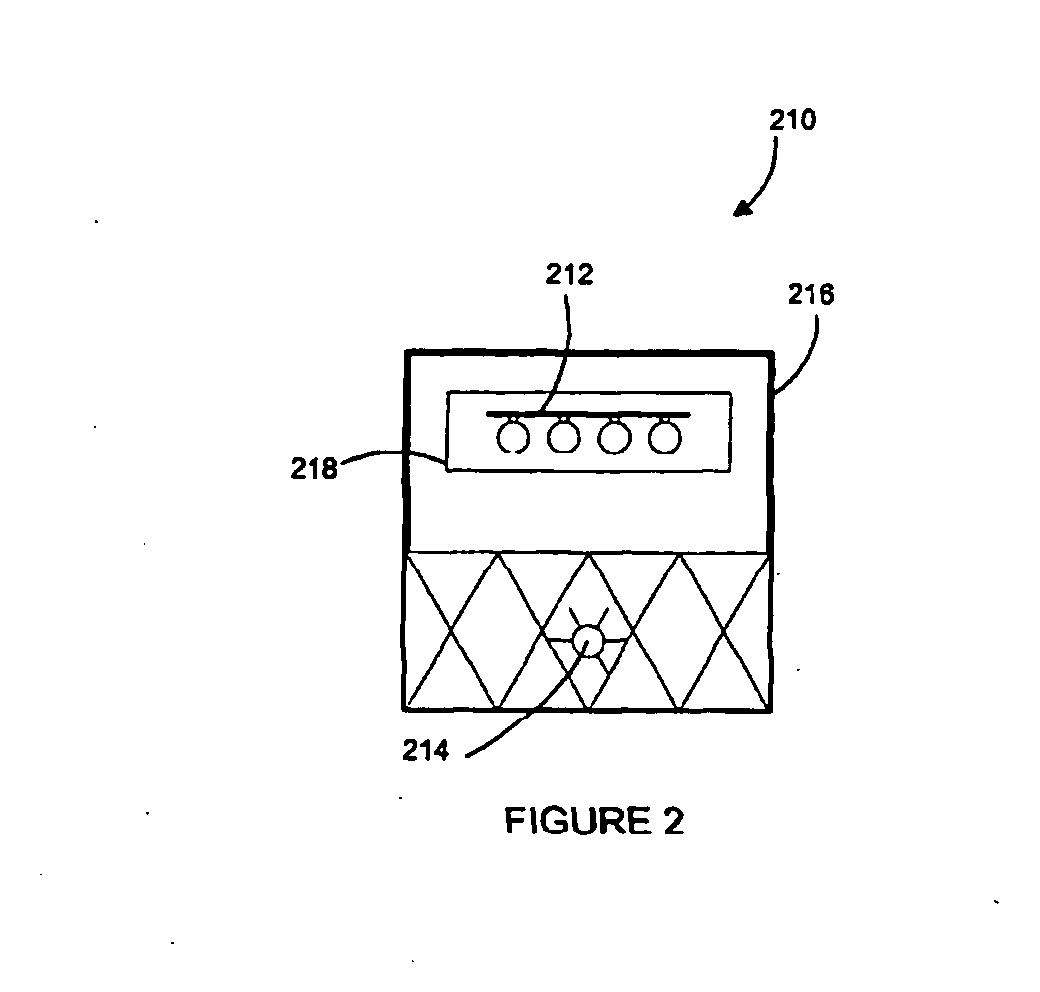

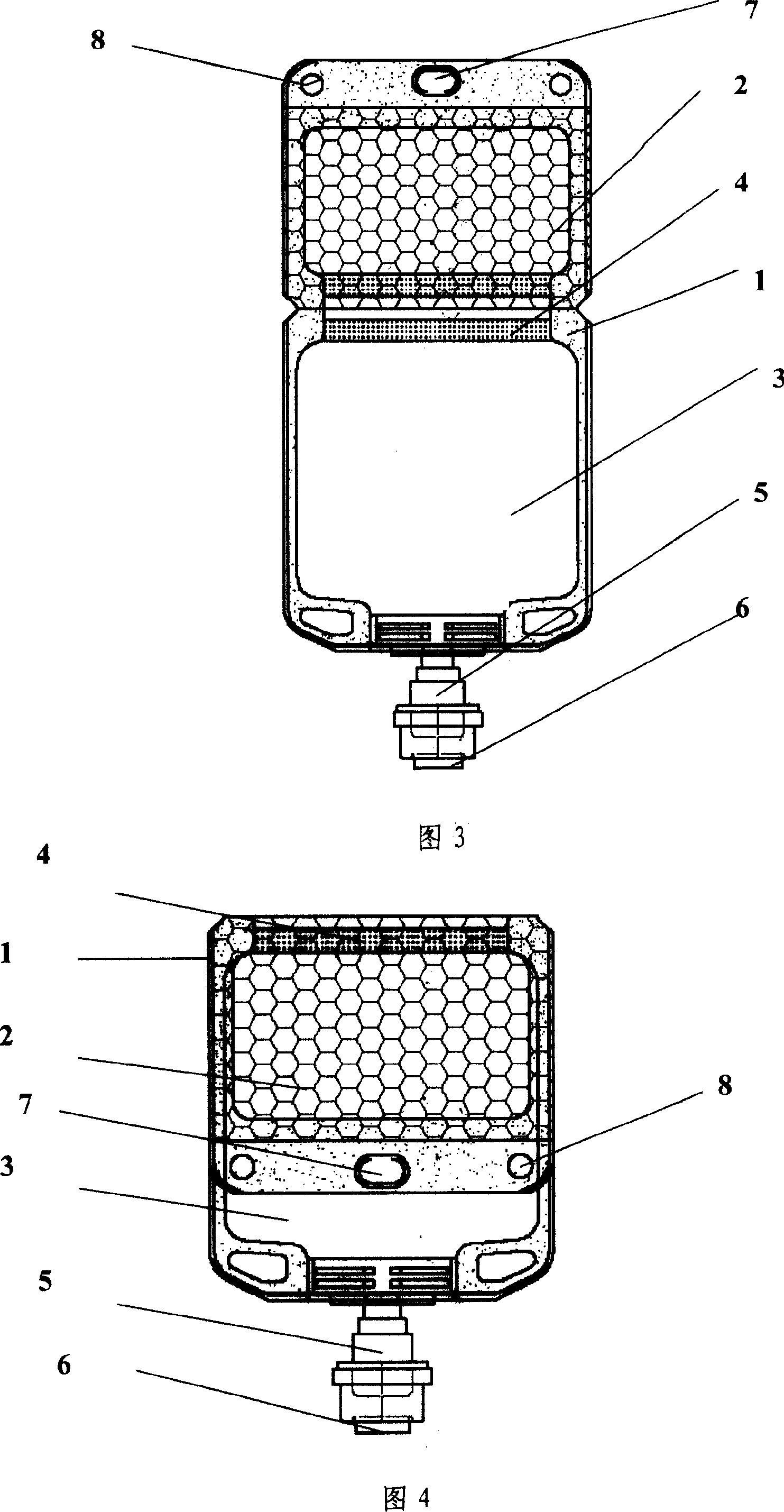

LED strobe for hazard protection systems

InactiveUS20070035255A1Preventing over-drivingEasy visual inspectionElectrical apparatusElectric light circuit arrangementEngineeringProtection system

A light-emitting diode (“LED”) based strobe may be used in automated system to provide a visual alert to occupants and / or building personnel if an emergency condition exists. A LED based strobe provides an even distribution of light having a sharp, bright pulse of light desired for emergency evacuation using lower power consumption.

Owner:SIEMENS IND INC

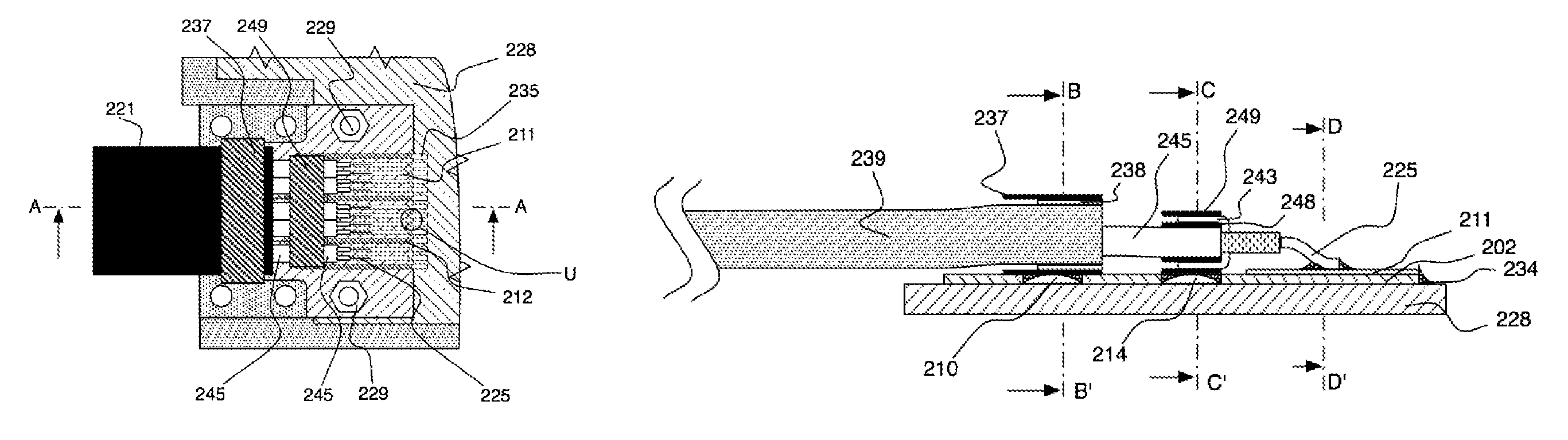

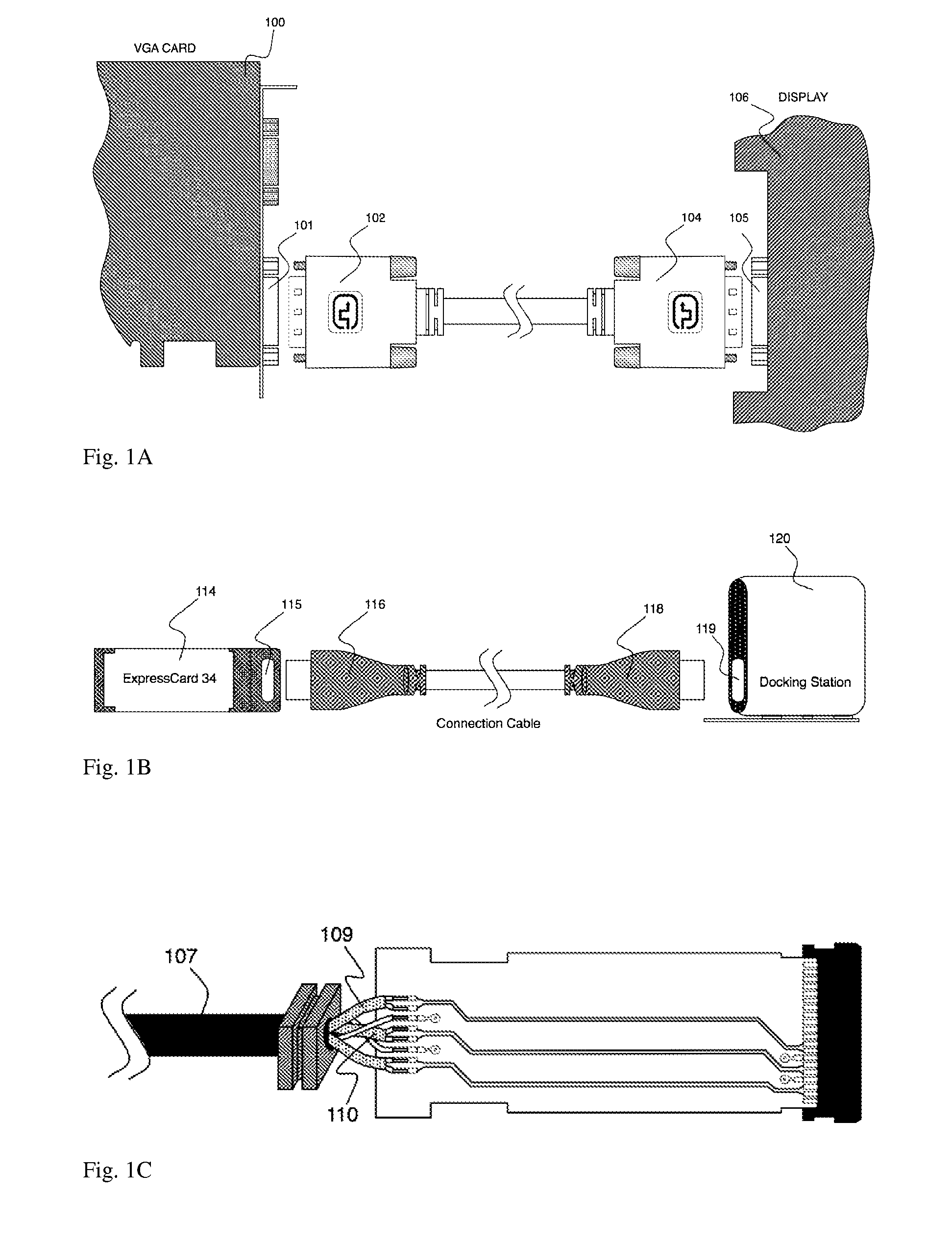

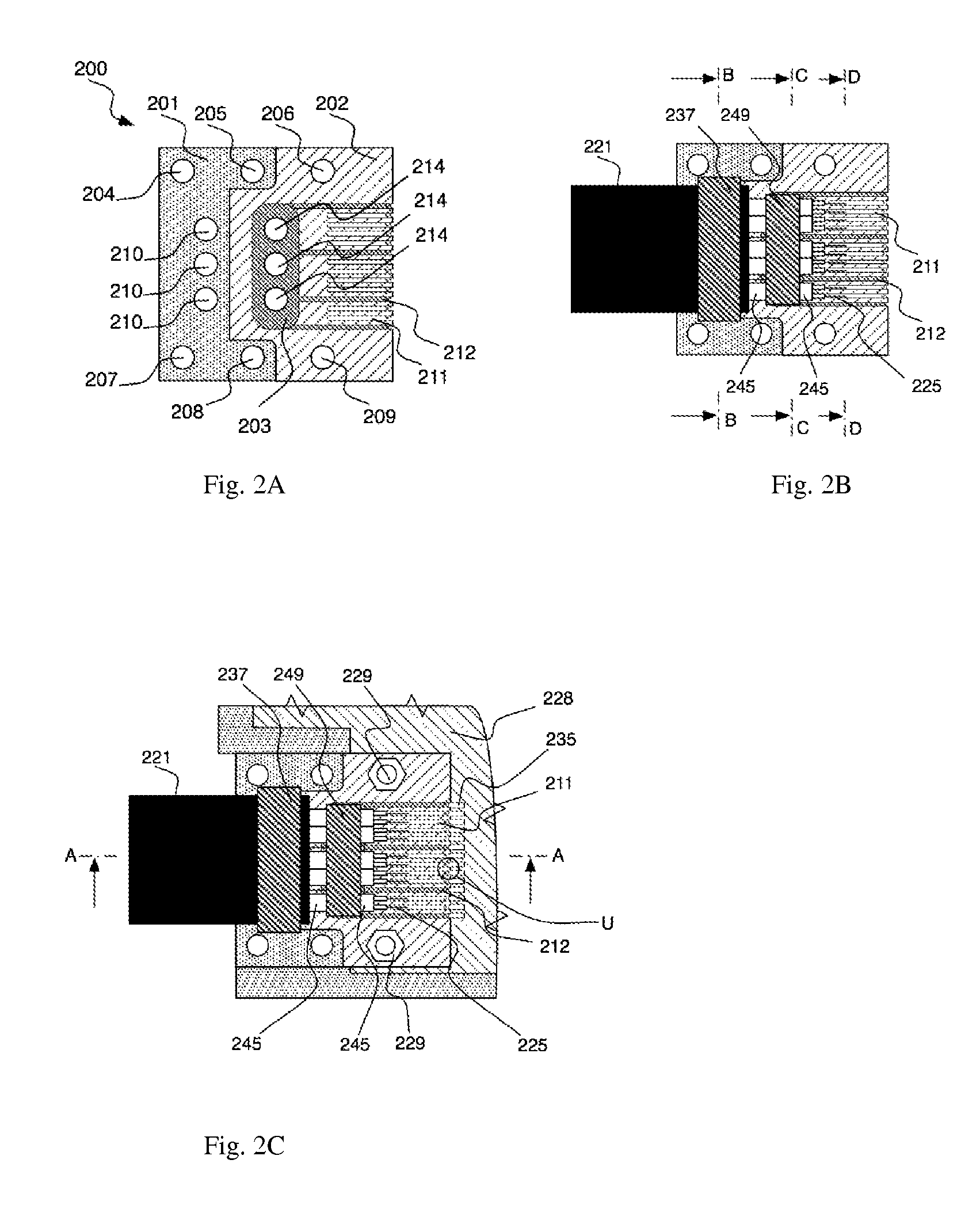

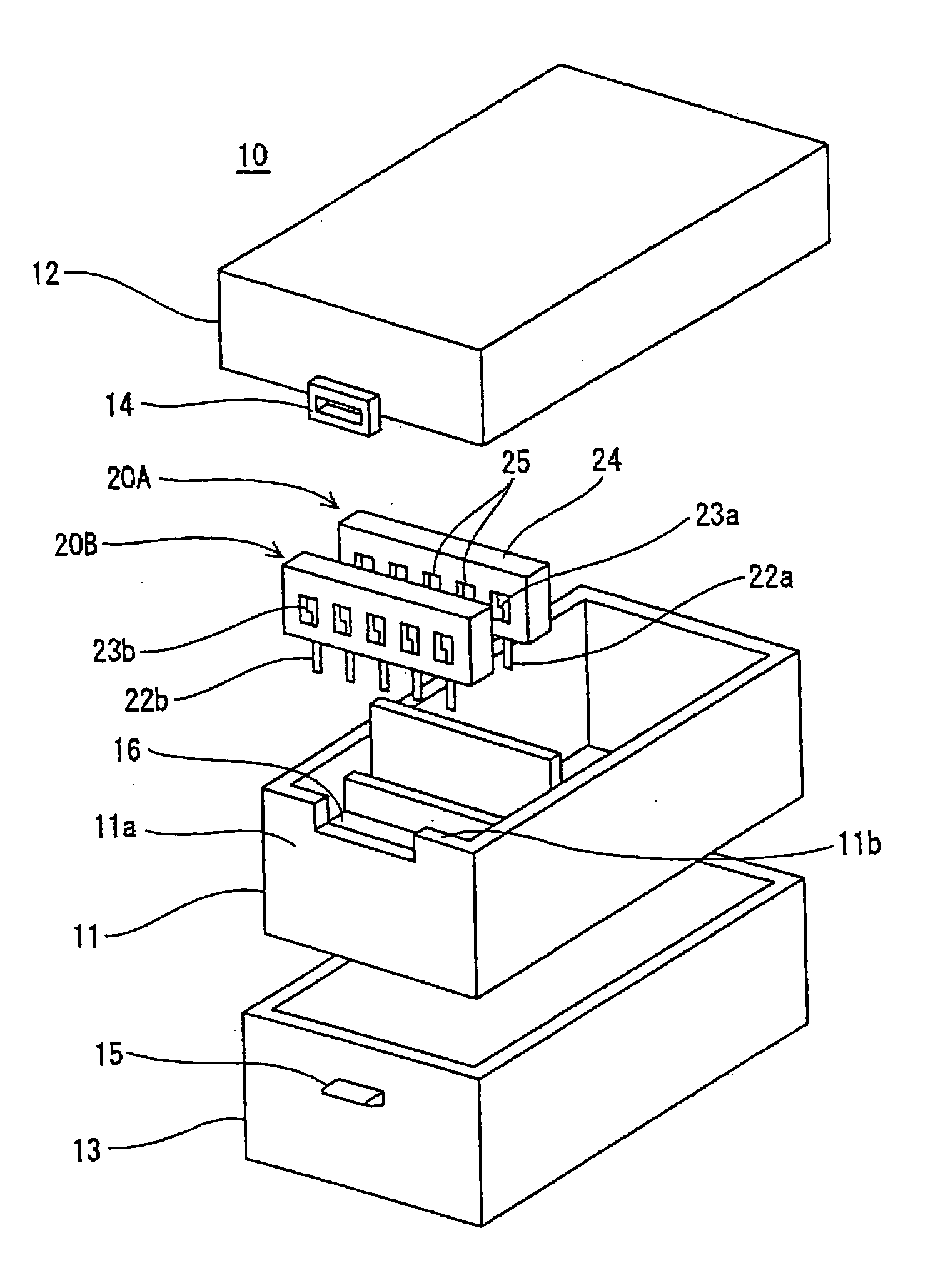

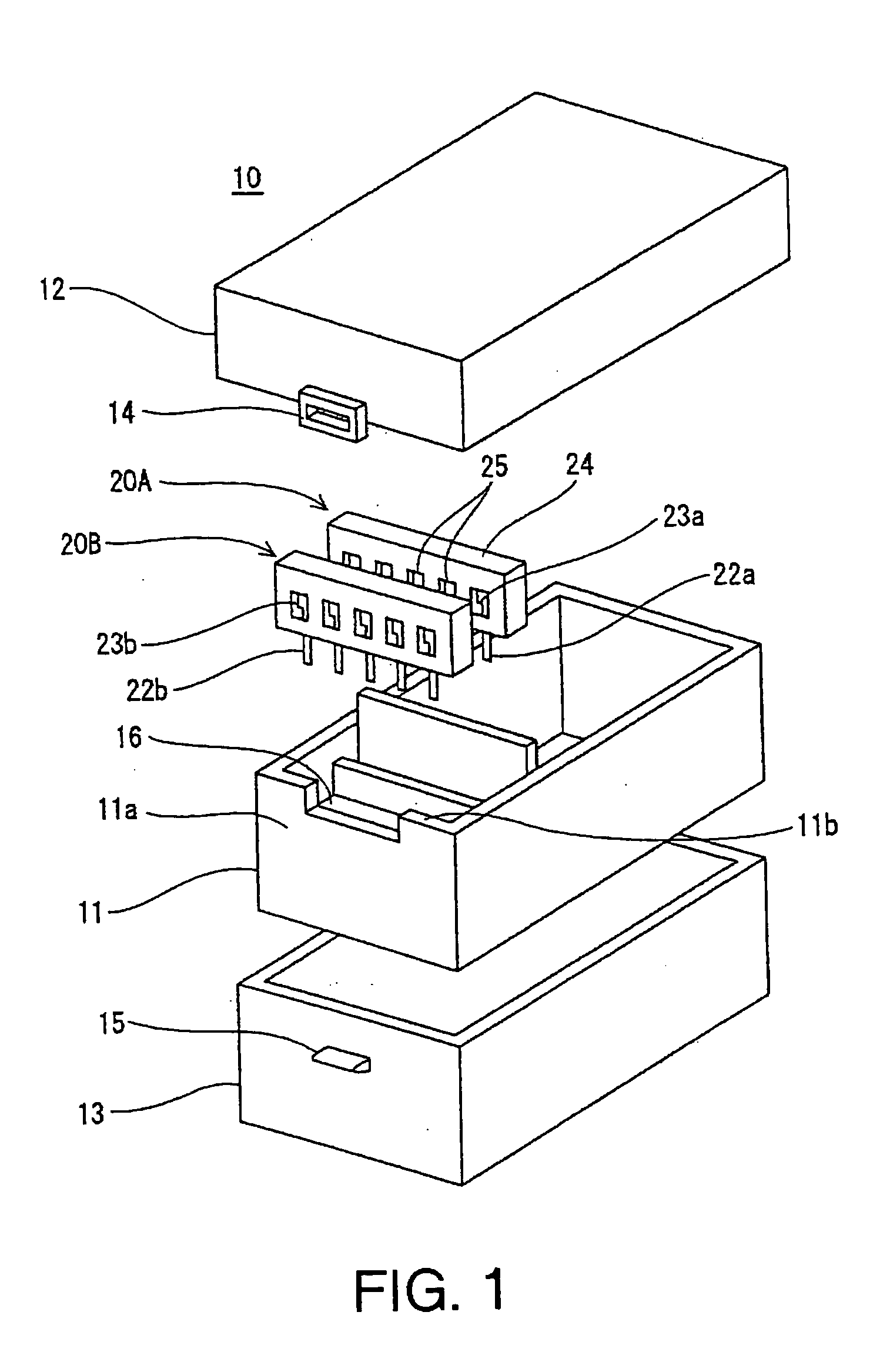

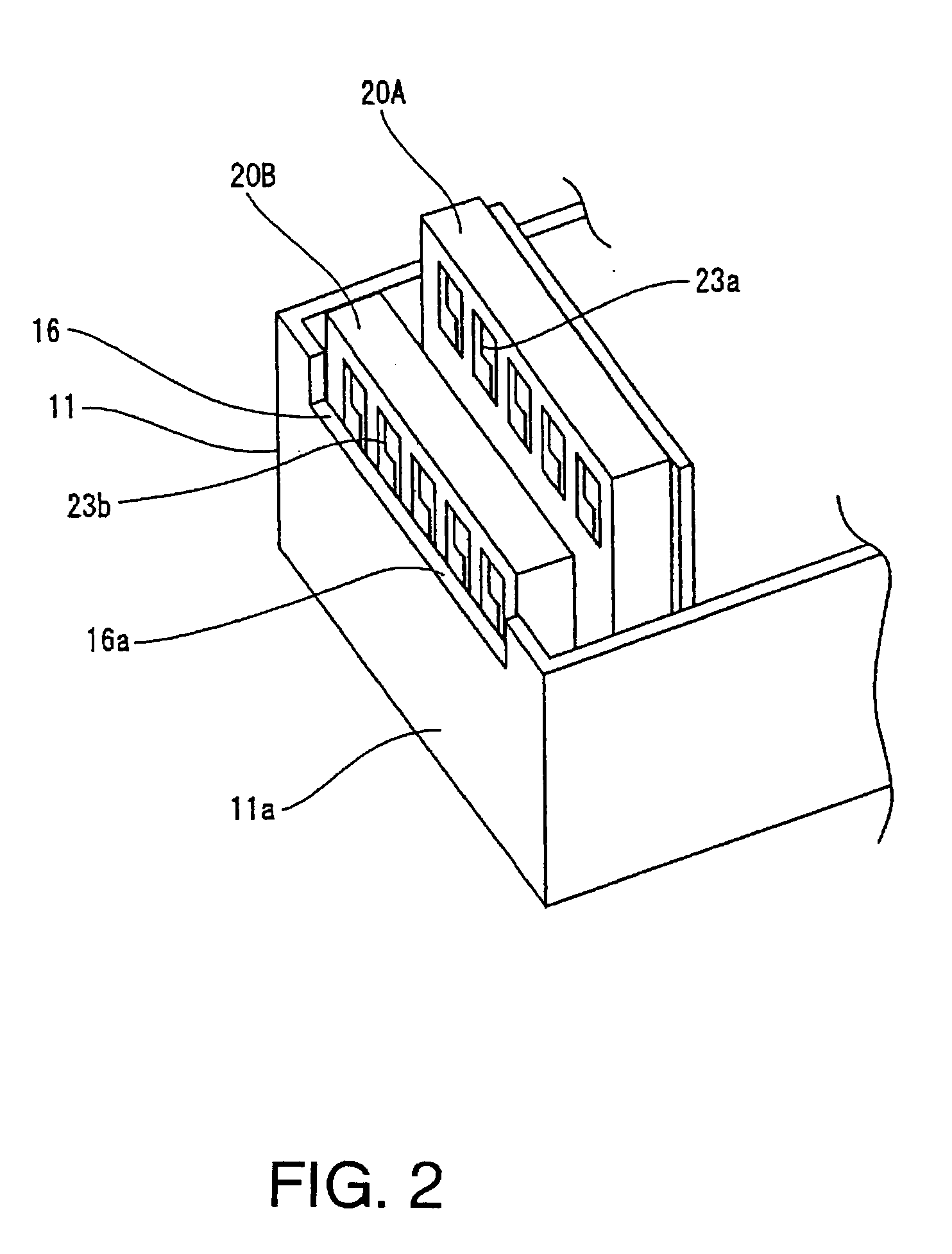

Electrical connection between cable and printed circuit board for high data speed and high signal frequency

InactiveUS7690930B2Low costEasy visual inspectionLine/current collector detailsElectrically conductive connectionsData connectionElectrical connection

A direct galvanic connection between a cable, having a preferred flat cross-section, and an electronic Printed Circuit Board (“Target PCB”) (228) by means of an intermediate PCB (“Interconnection PCB”) (200) allowing an impedance matched and length balanced electrical connection is described, thus offering ideal conditions for high speed and high frequency data connections. At the same time, the connection allows to keep the flexibility of a modular production and assembly workflow, typical of the use of well known connectors.

Owner:CHEN HUBERT +1

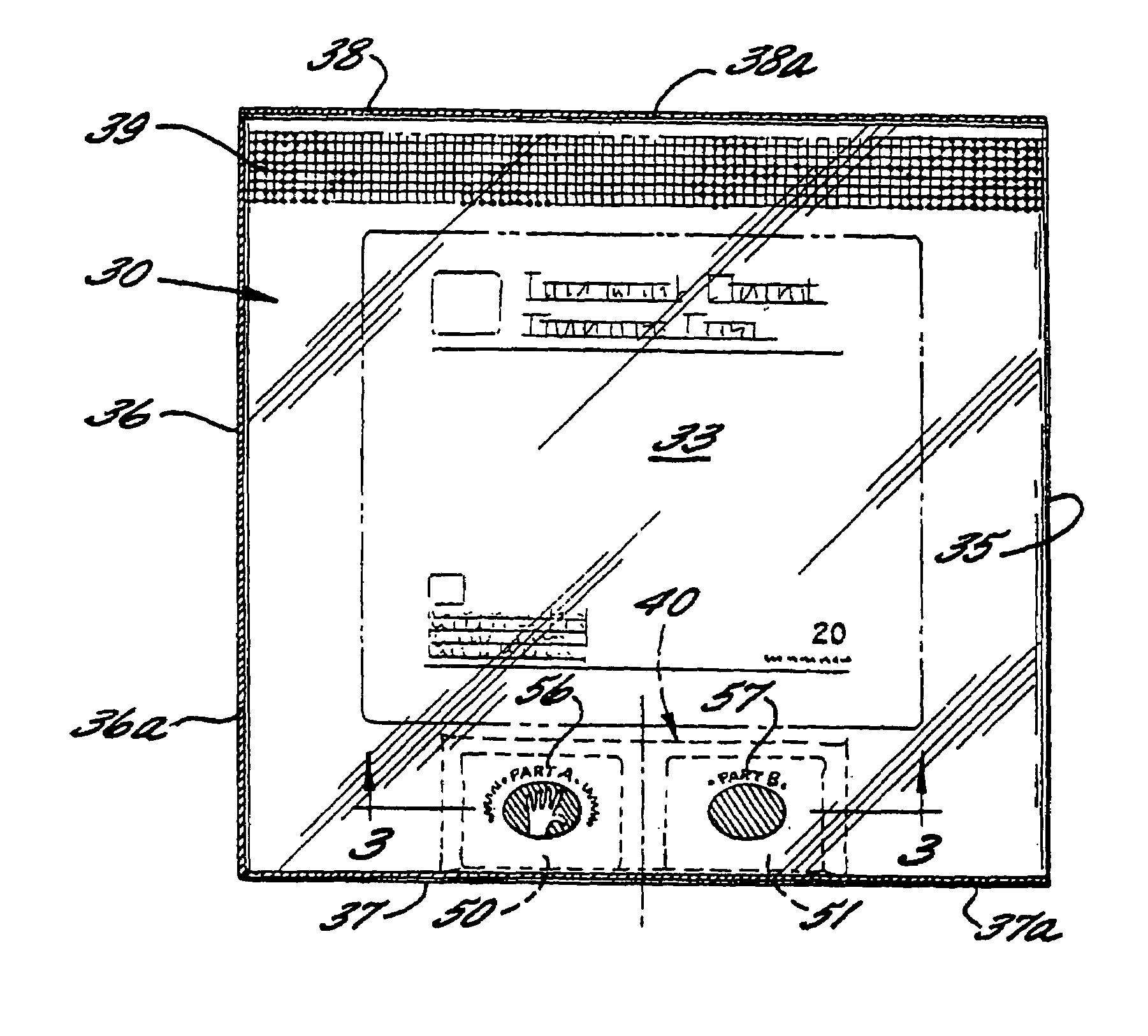

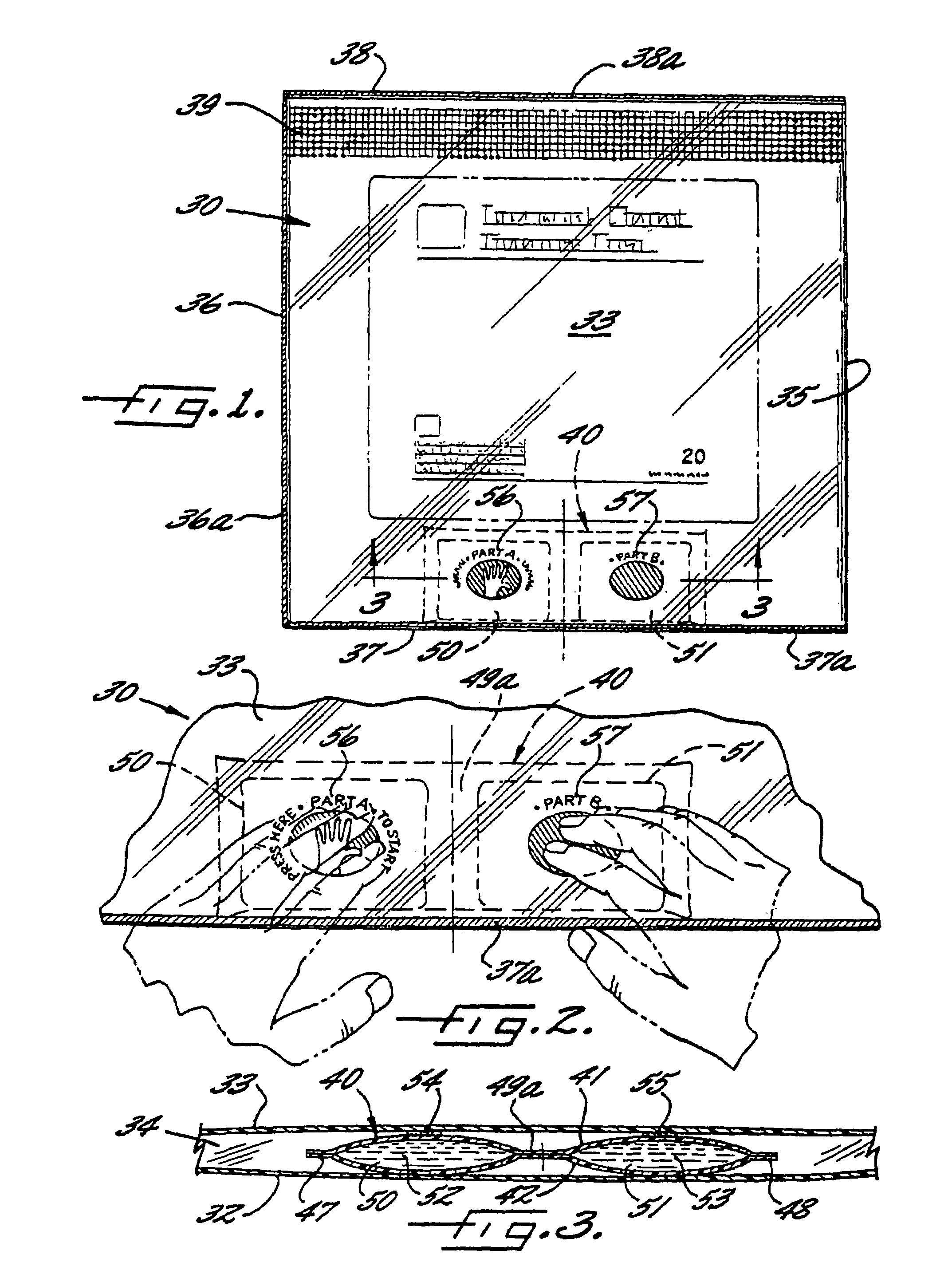

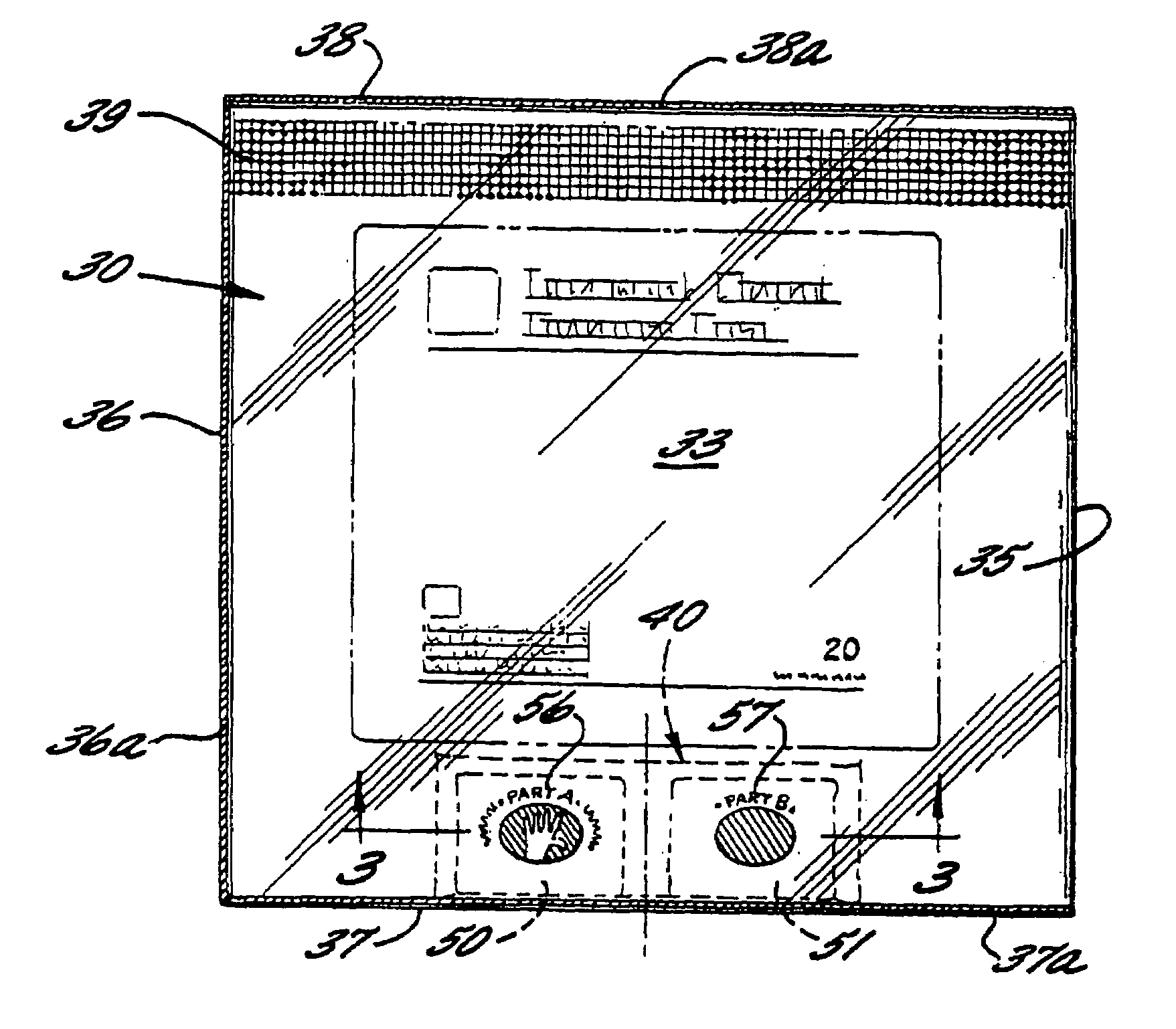

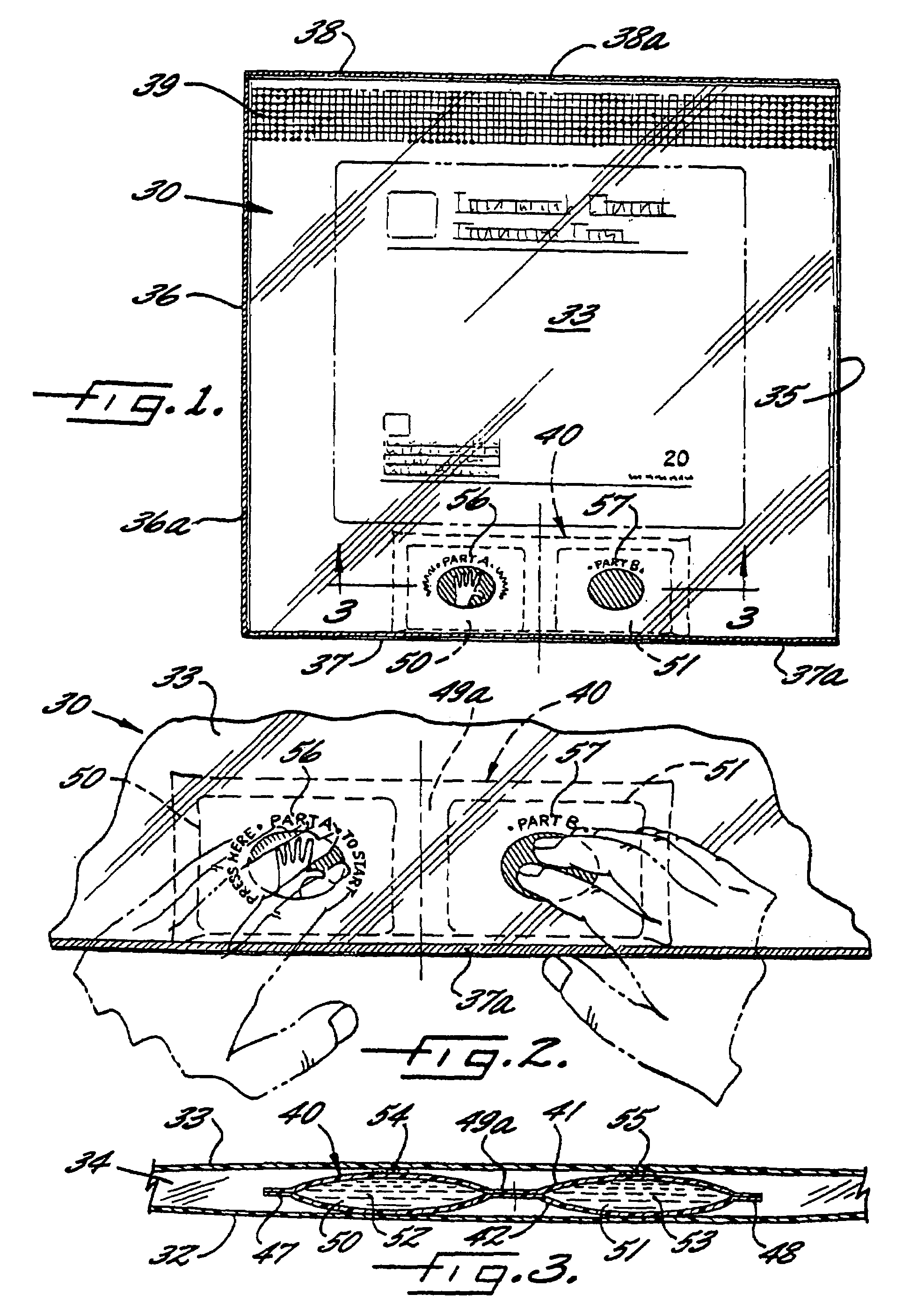

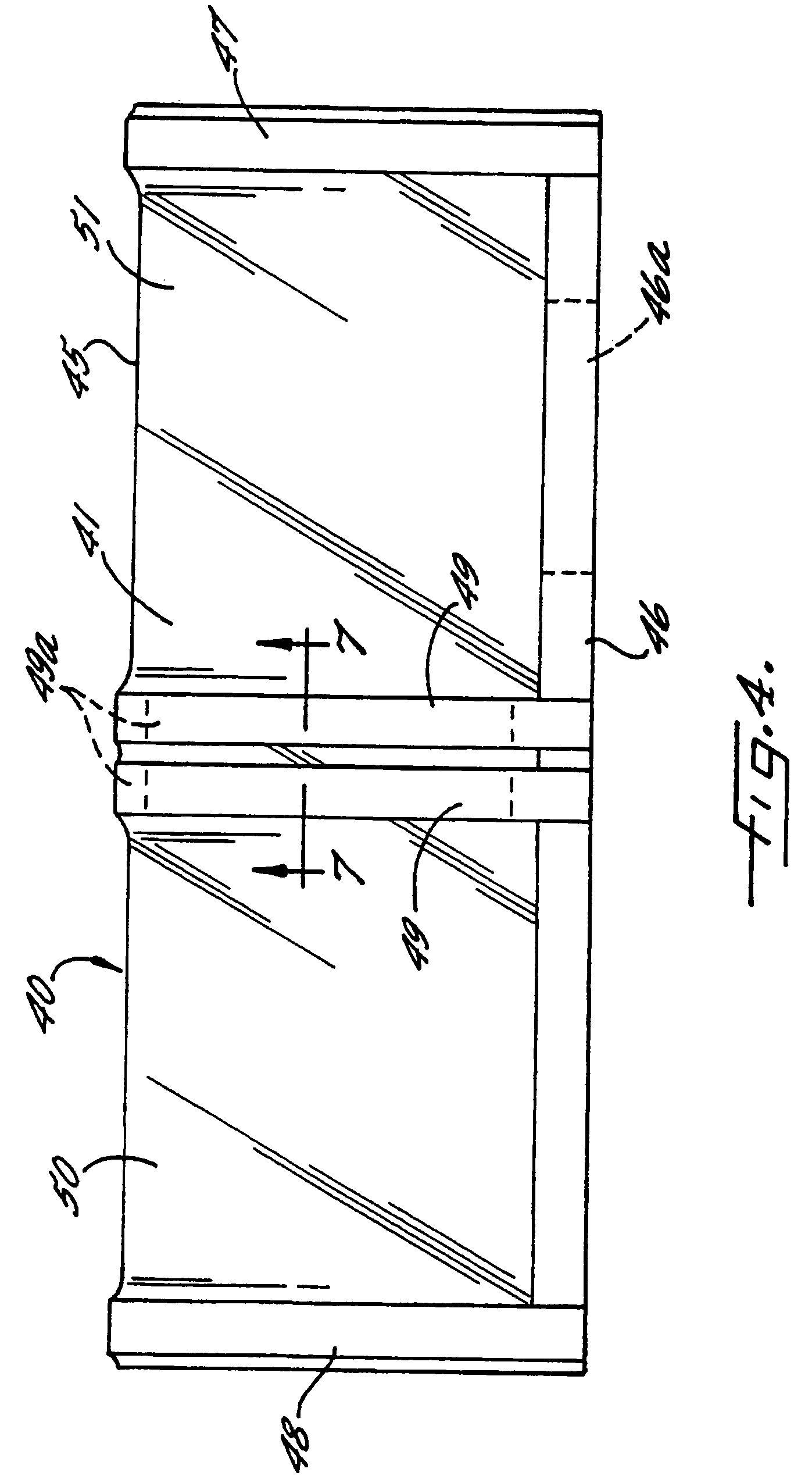

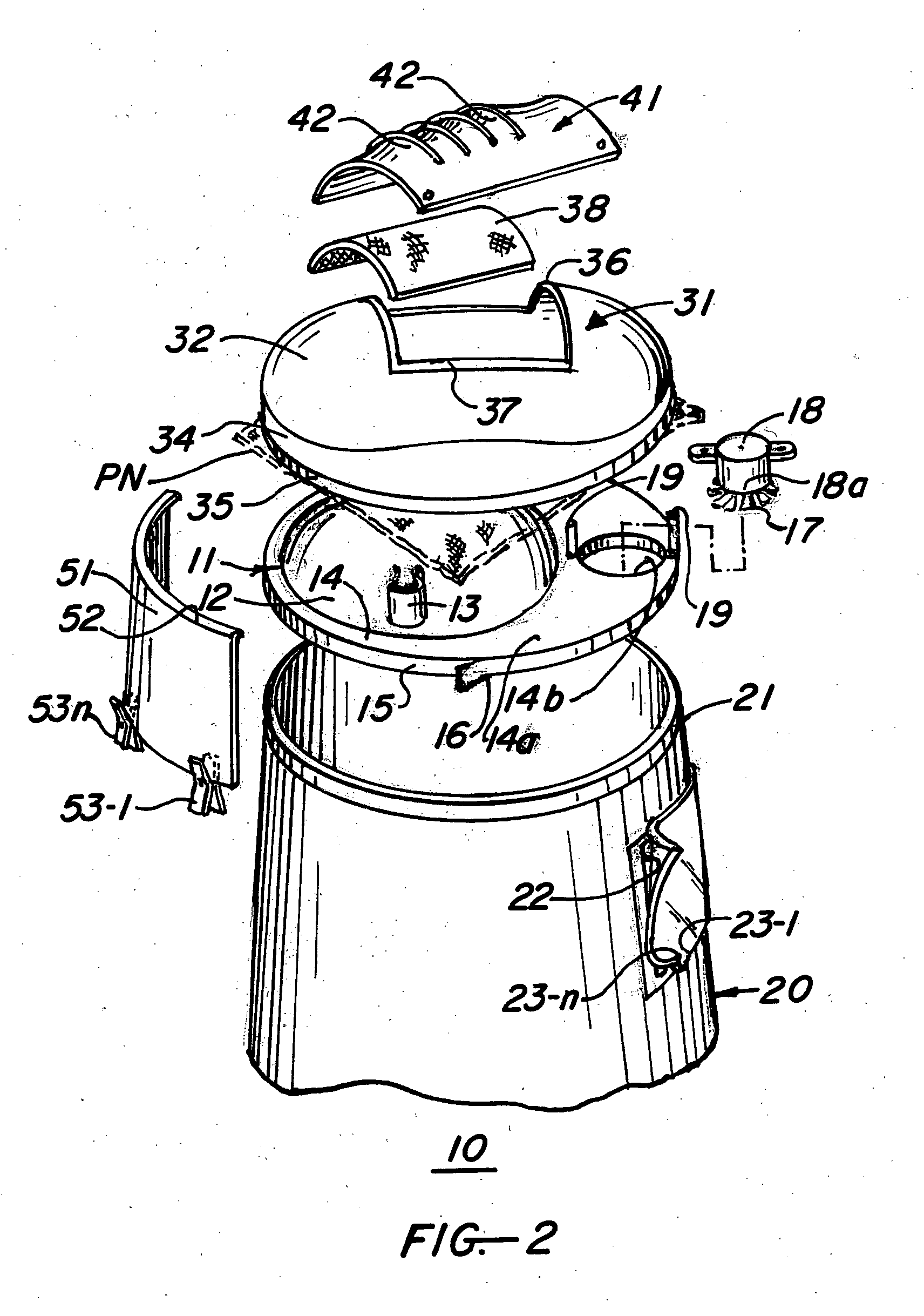

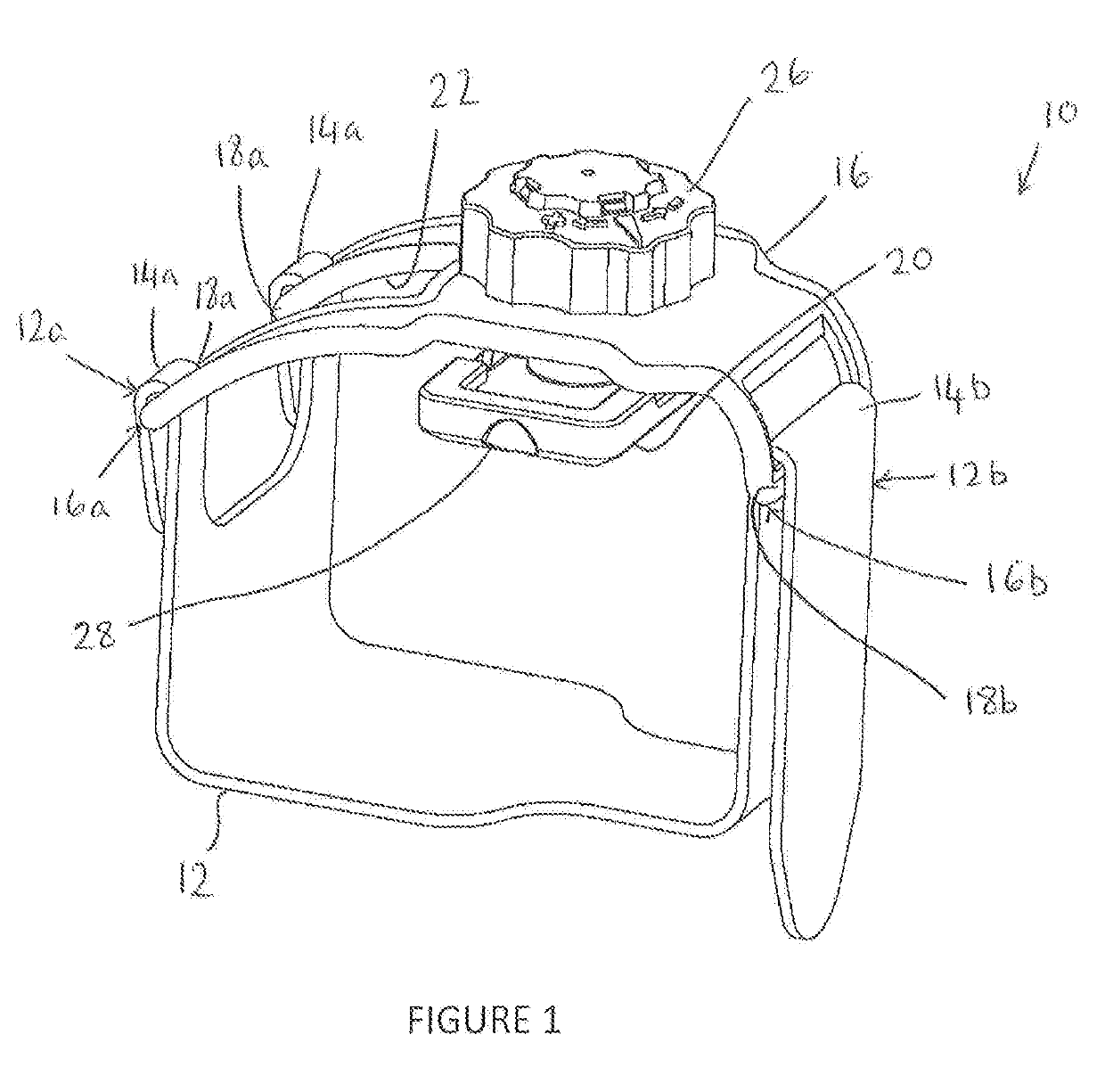

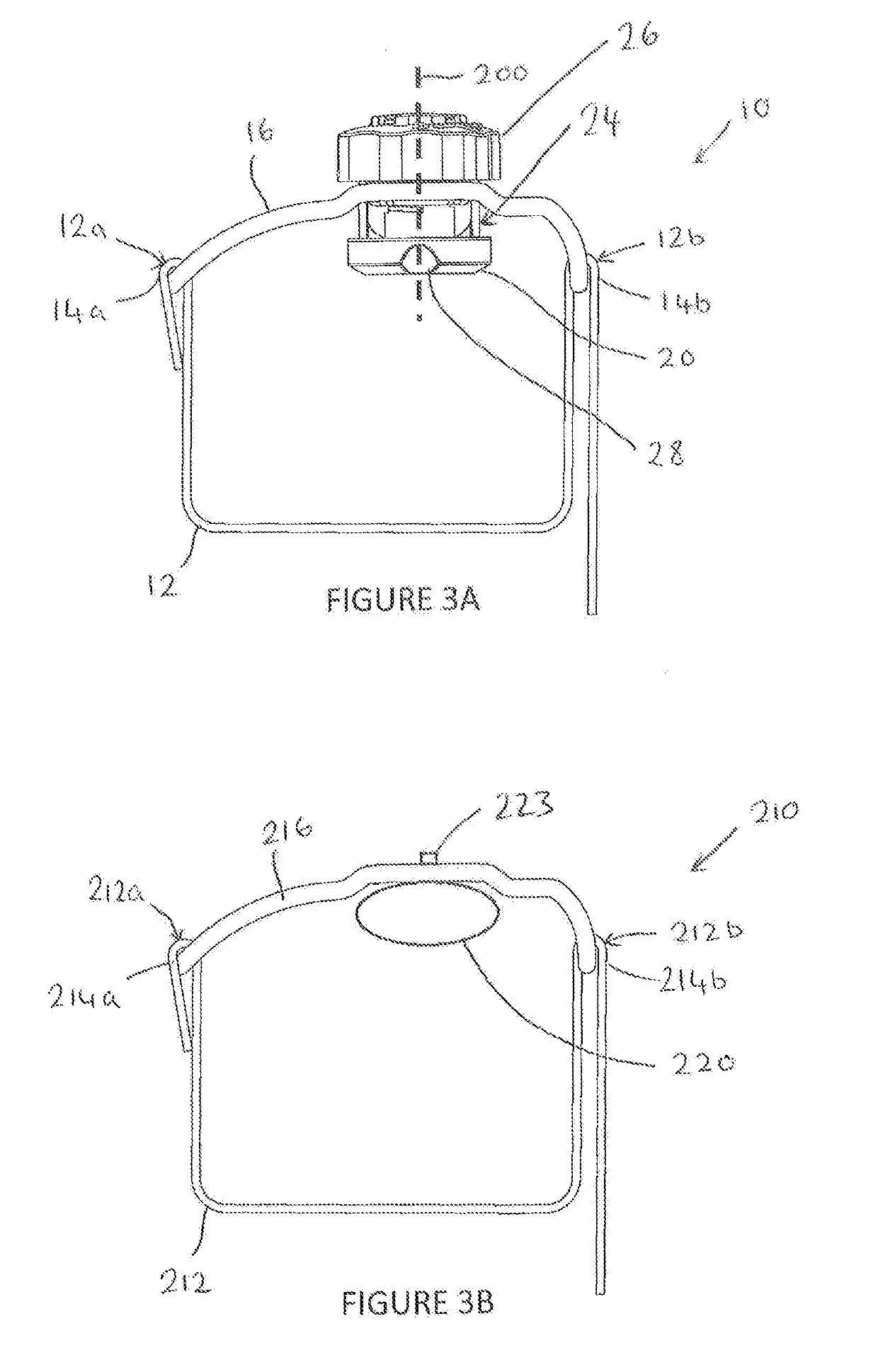

Foam in bag packaging system and method for producing the same

InactiveUS6983839B2Improve adhesionEasy visual inspectionContainers to prevent mechanical damageThin material handlingEngineeringPlastic film

A packaging system for producing a foam-in-bag cushion upon demand includes a bag of flexible plastic film and defining therein an enclosed space which is vented to the outside of the bag, a foam precursor packet positioned at a predetermined location within the enclosed space in the bag and being formed of a barrier material. The packet includes first and second compartments with a first frangible seal separating the first and second compartments which when ruptured will permit the contents of the compartments to be mixed to form a foam cushion and a second frangible seal between one of the compartments and the enclosed space in the bag. A first foam precursor component is contained in the first compartment of the packet and a second foam precursor component is contained in the second compartment of the packet. The frangible seals have a peel strength of at least about one pound per inch and less than about twelve pounds per inch and more particularly a peel strength of about one pound per inch to about seven pounds per inch. The frangible seals are formed by providing bands of printed area on the facing surfaces of the material forming the packet which is arranged in a matrix of printed and unprinted areas. The printed areas prevent the surfaces from being joined by heat sealing and the matrix is such that a frangible seal of the desired peel strength is formed.

Owner:SEALED AIR CORP

Fastener

Owner:ILLINOIS TOOL WORKS INC

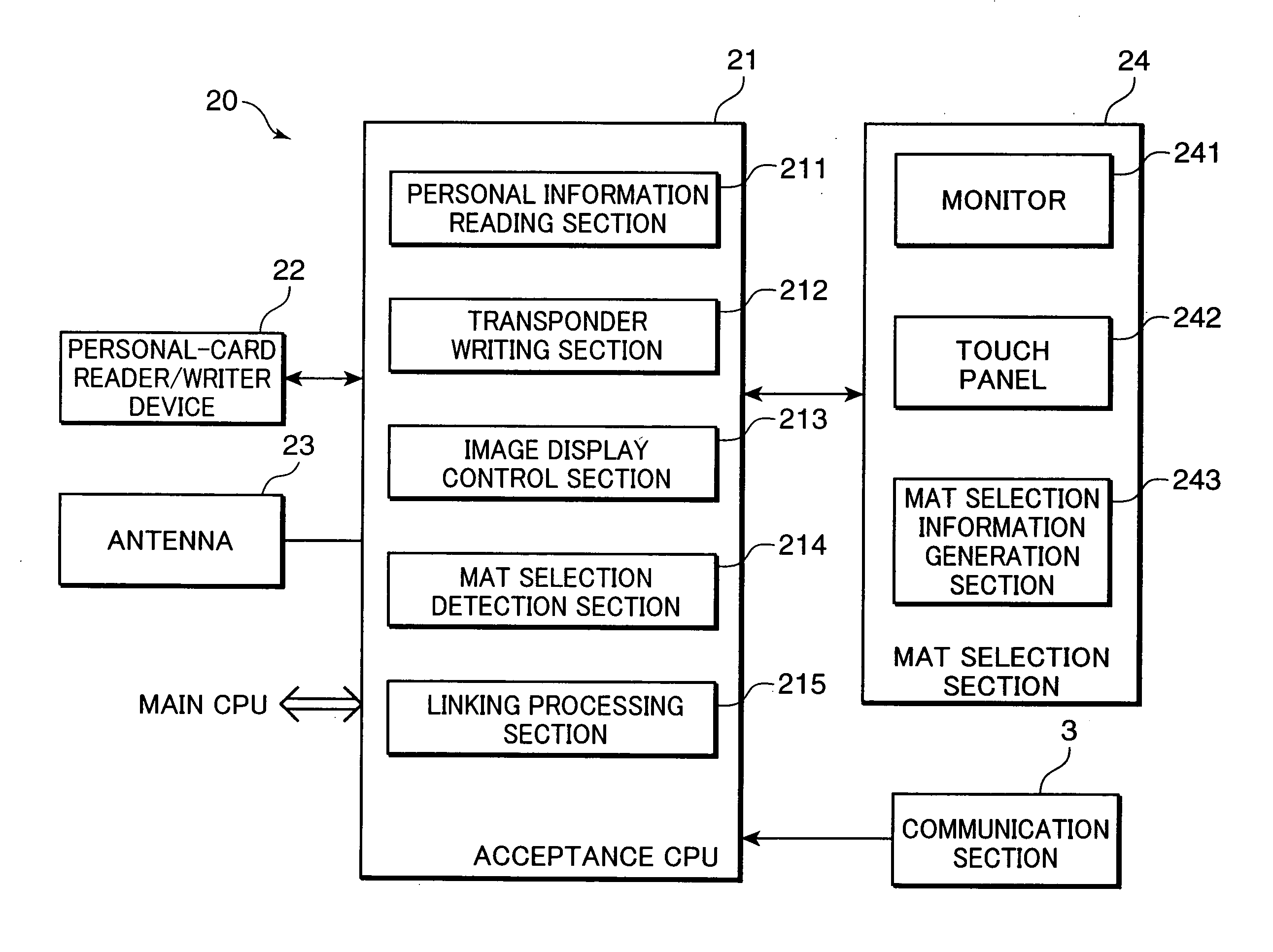

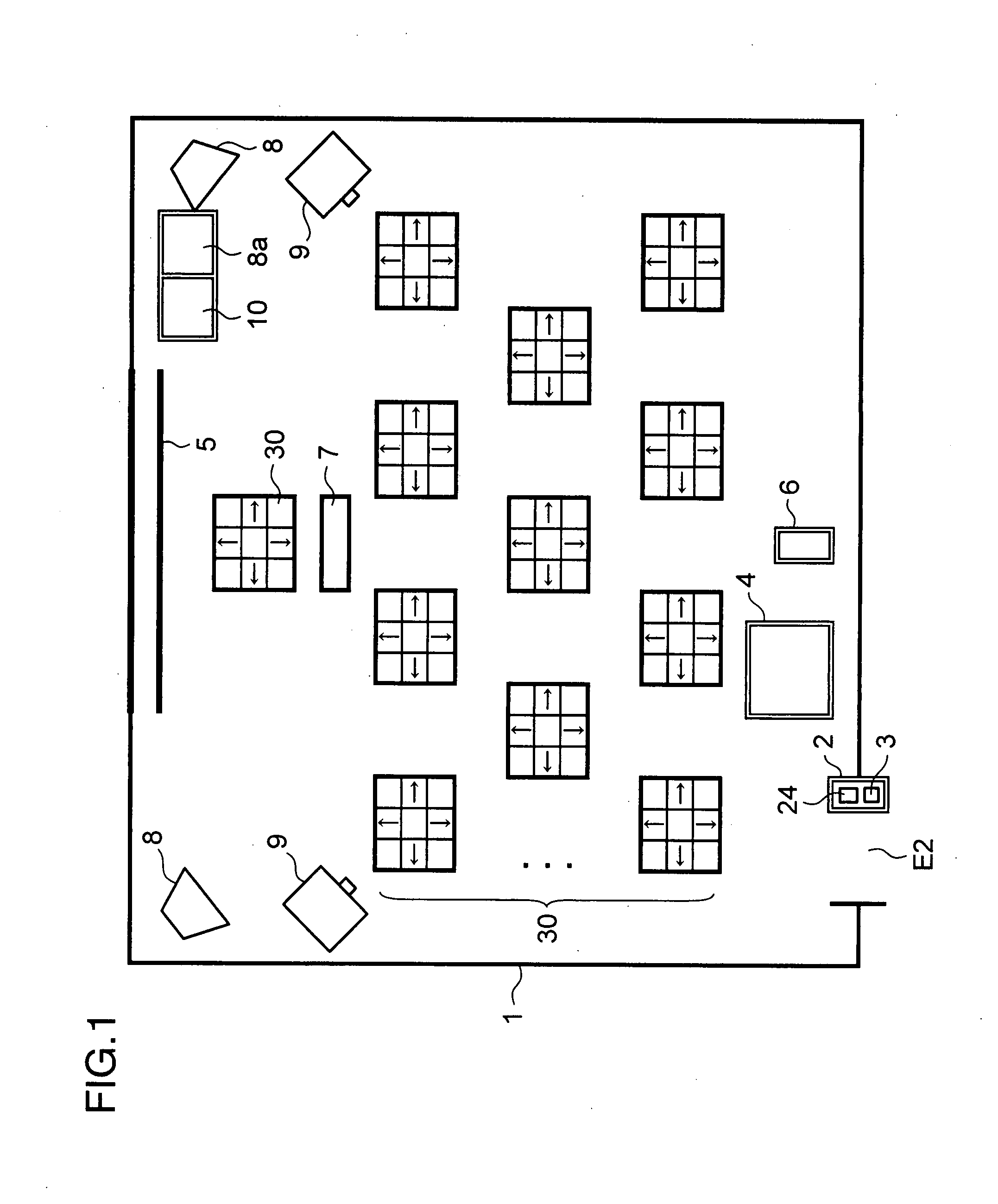

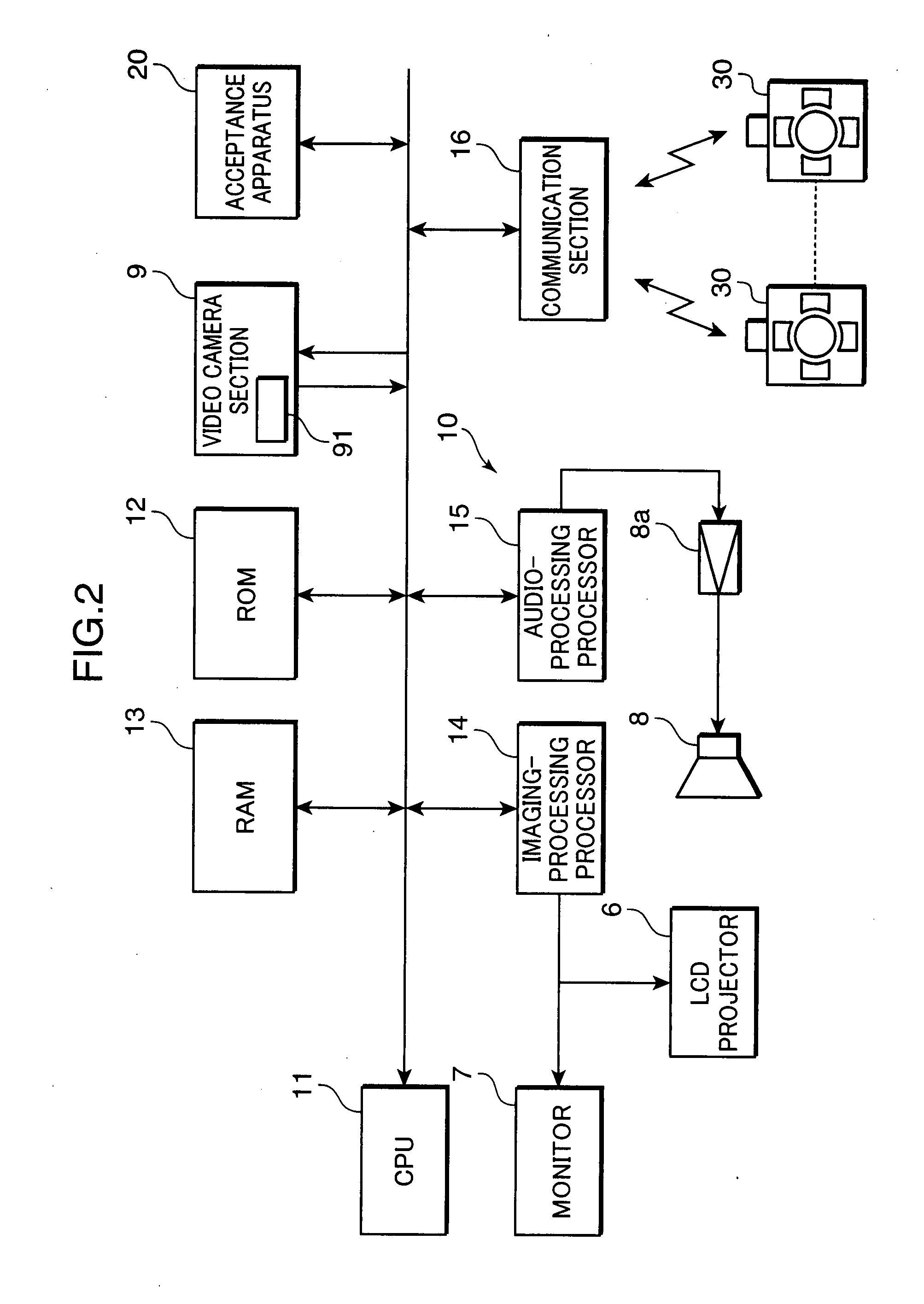

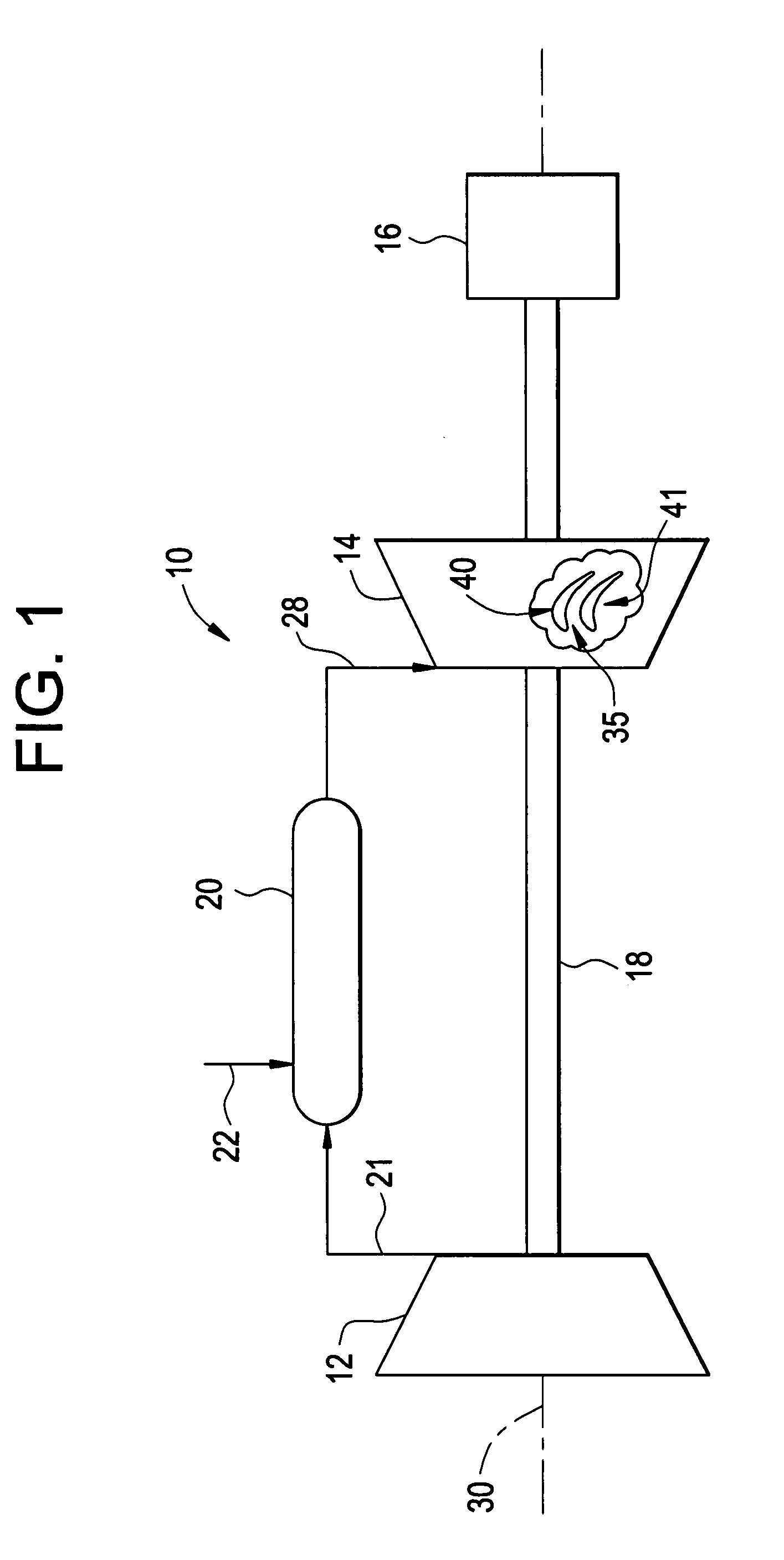

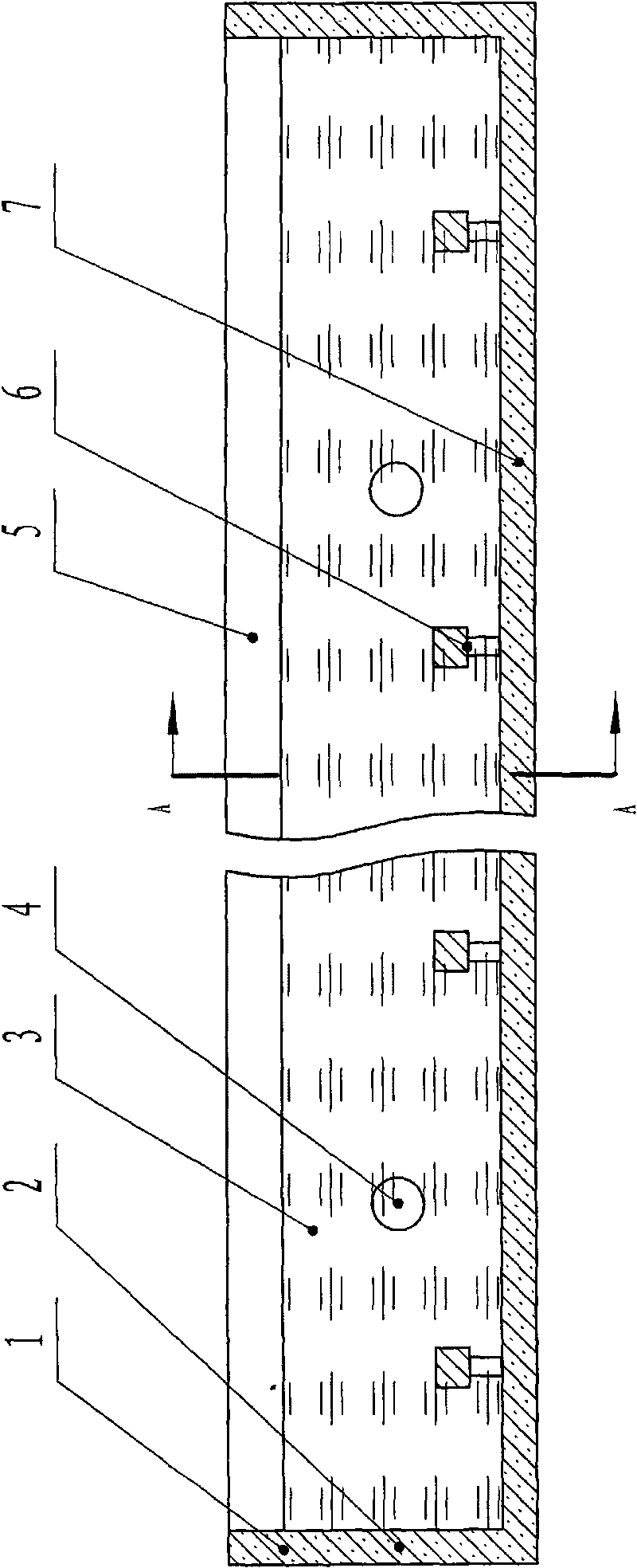

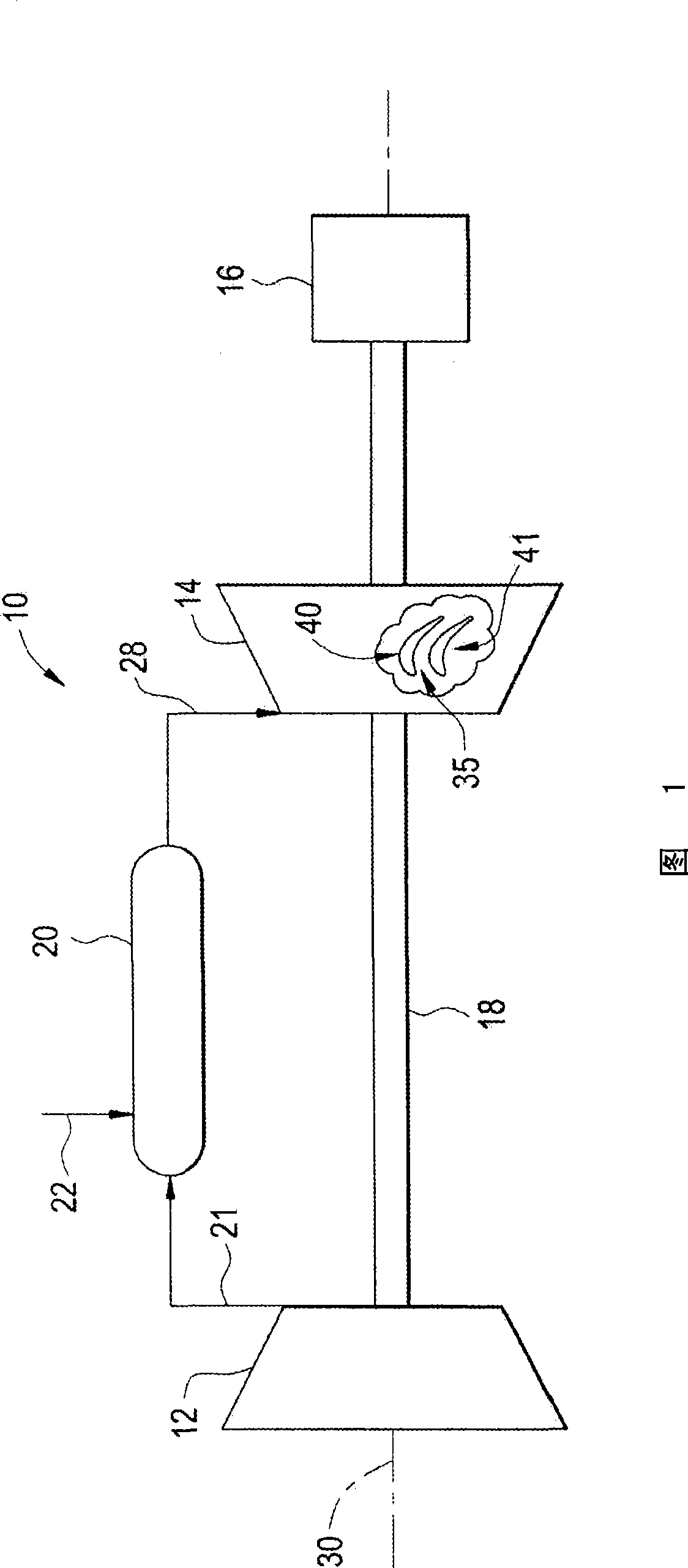

Movement Information Processing System

InactiveUS20080146329A1Increase awarenessEasy visual inspectionVideo gamesSpecial data processing applicationsInformation processingComputer science

The movement information processing system of the present invention includes a screen 5 which displays via a projector 6 guide images GG which induces stepping movements of the feet of players on mats 30 and mats for players where each of the mats 30 detects the stepping position and the stepping movement of each player with respect to the guide images GG. The detected results are evaluated by an evaluation means 116, 120 via a communication section 16 and the evaluation results are displayed on the screen with an image presentation processing control section 112. The system provides exercise guide images that induce players a variety of movements in a highly recognizable manner regardless of the number of players.

Owner:KONAMI SPORTS & LIFE

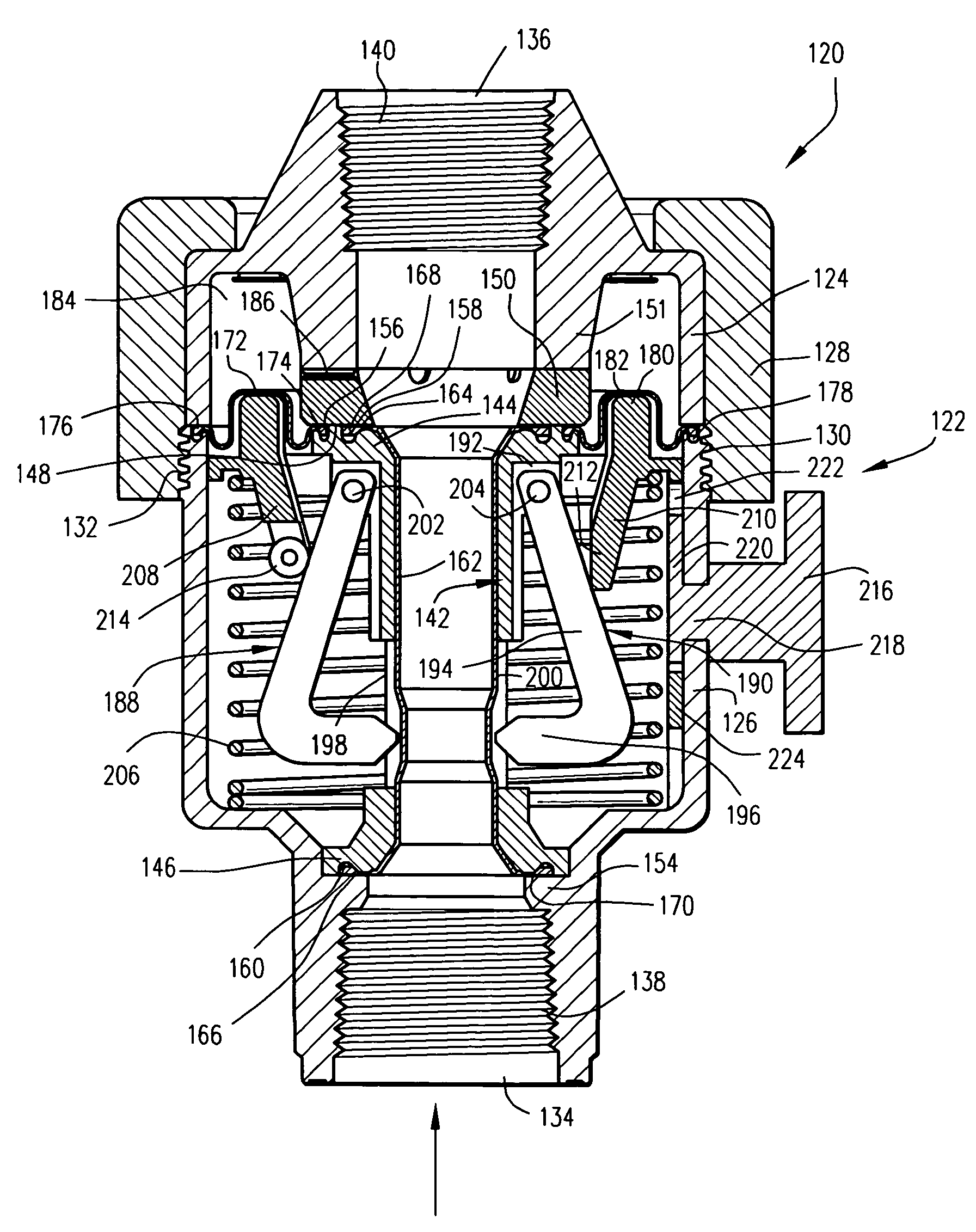

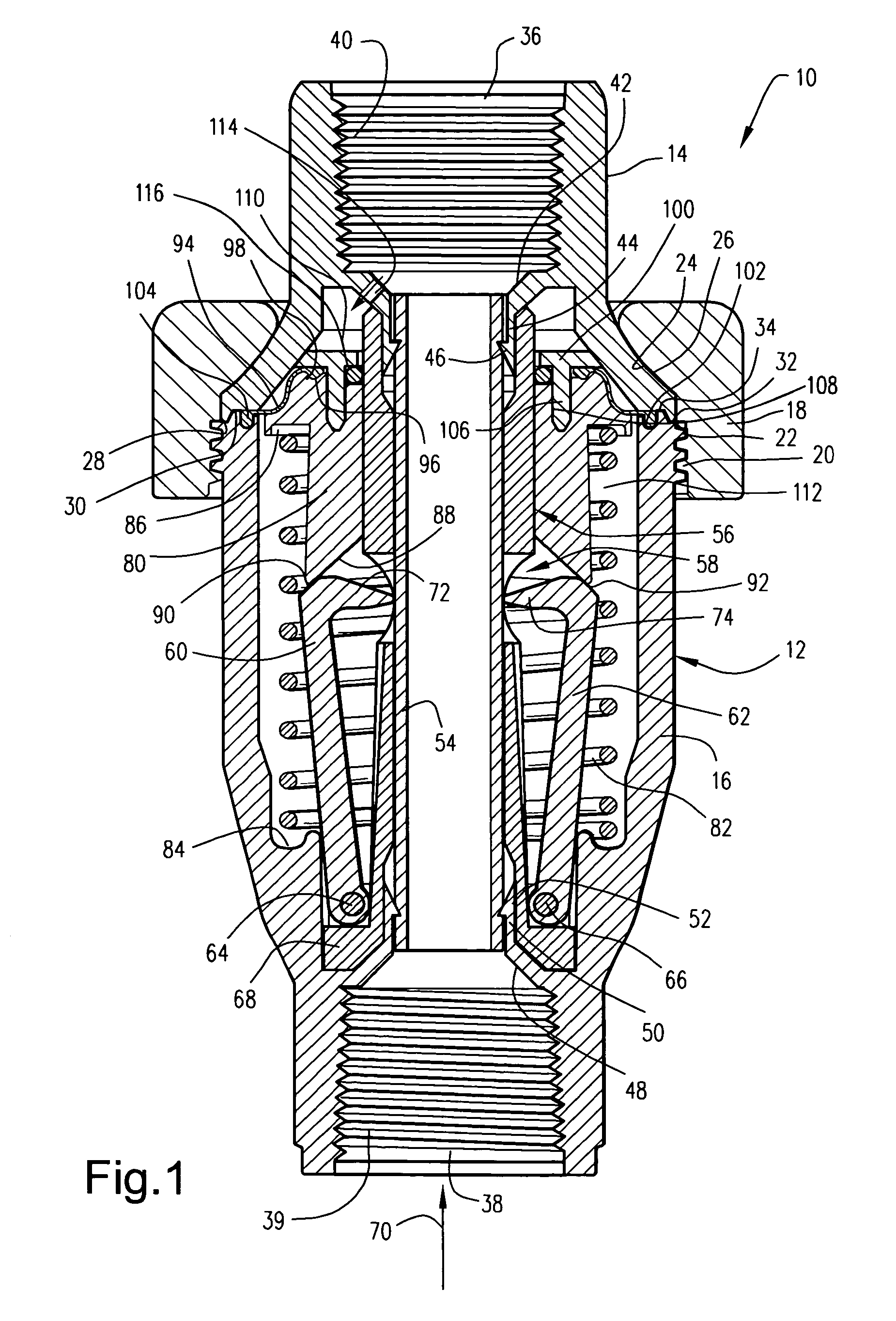

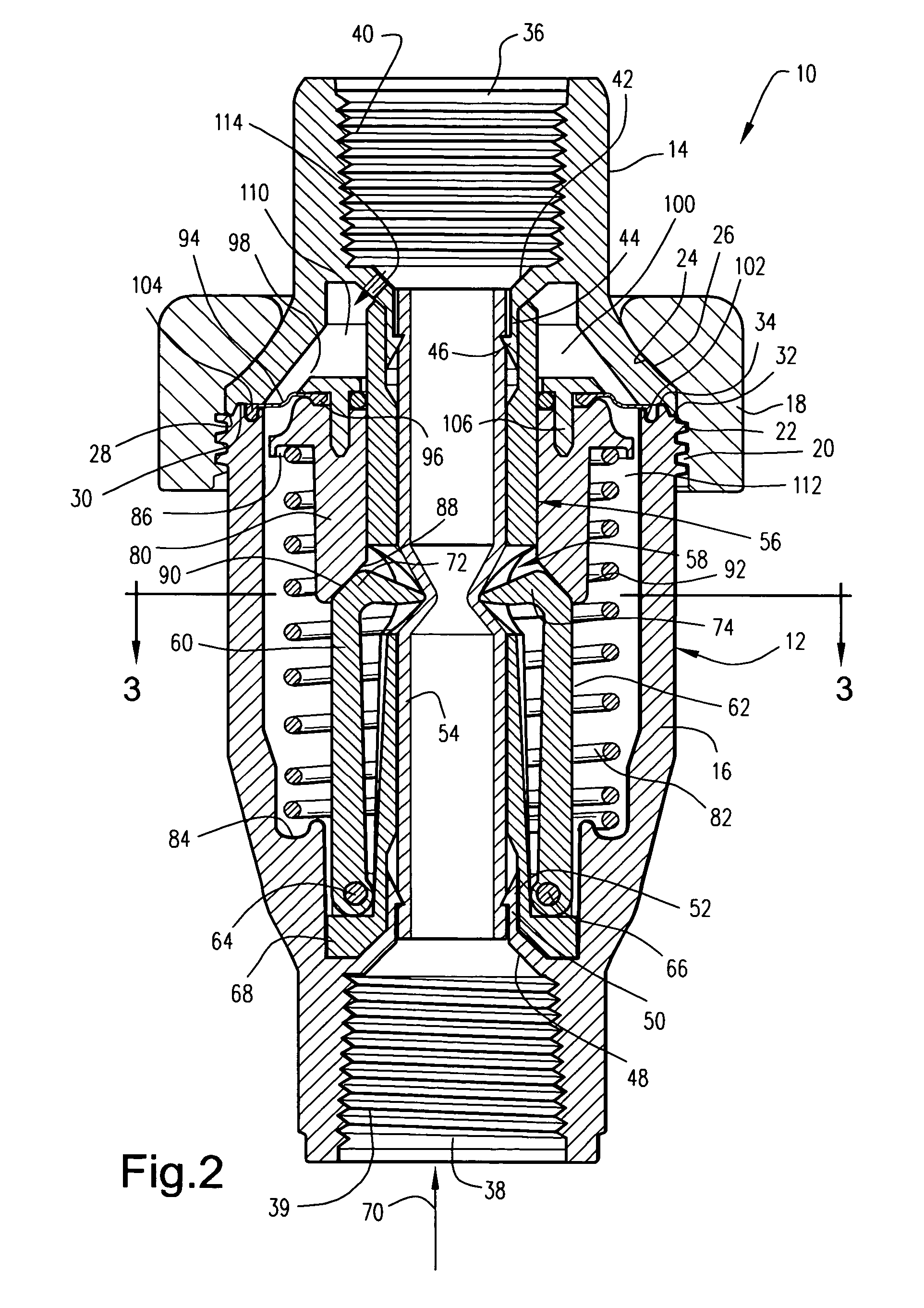

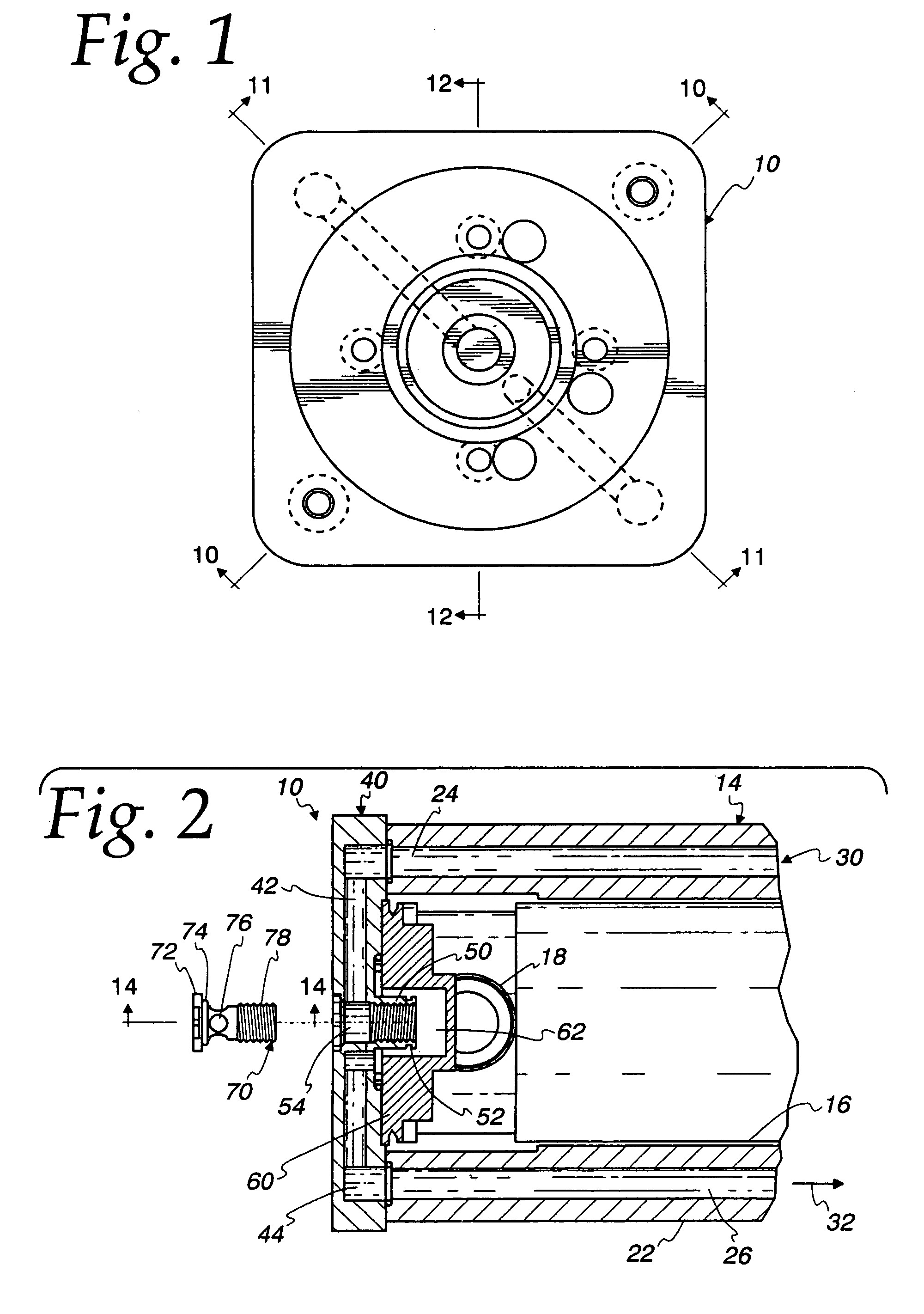

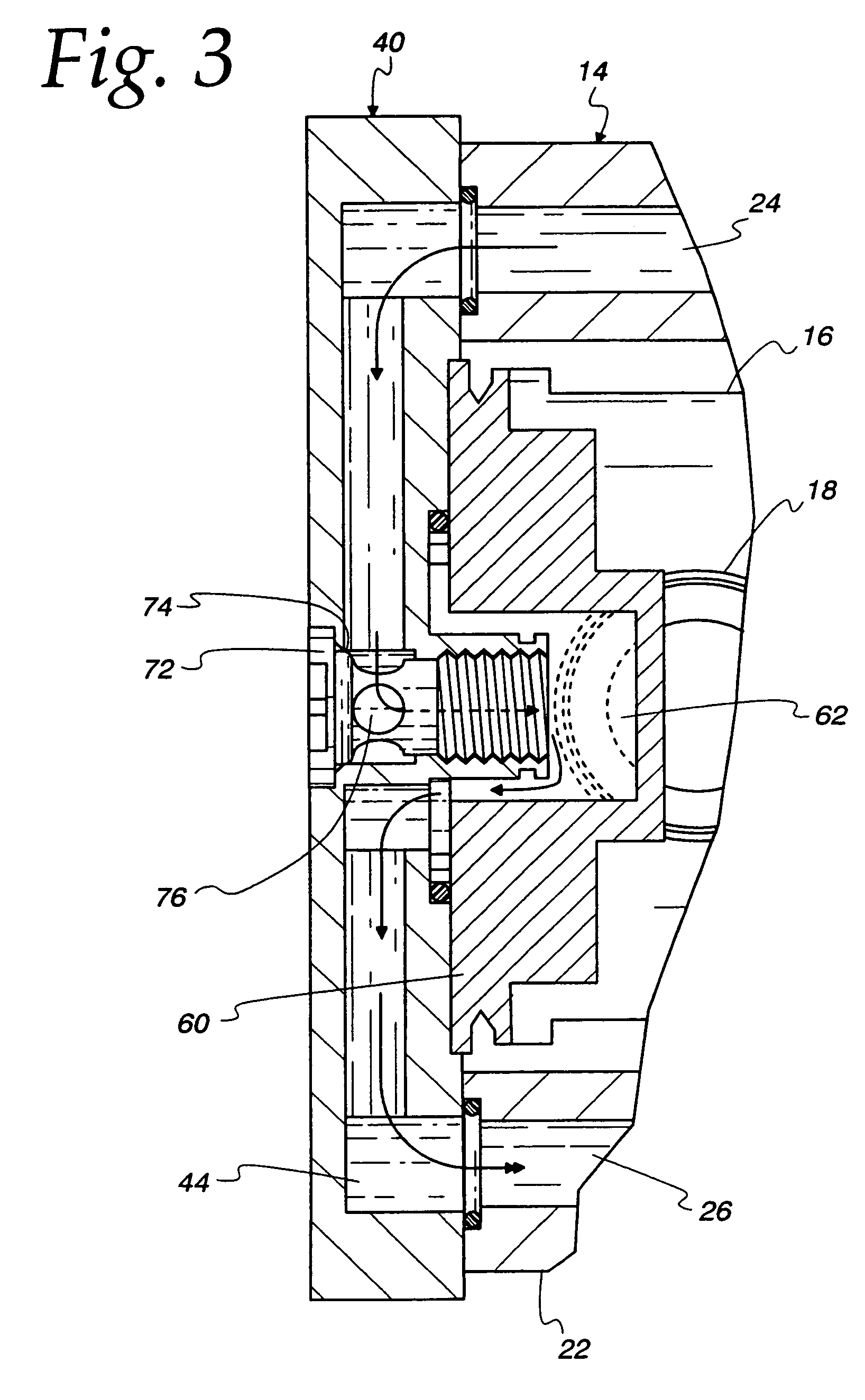

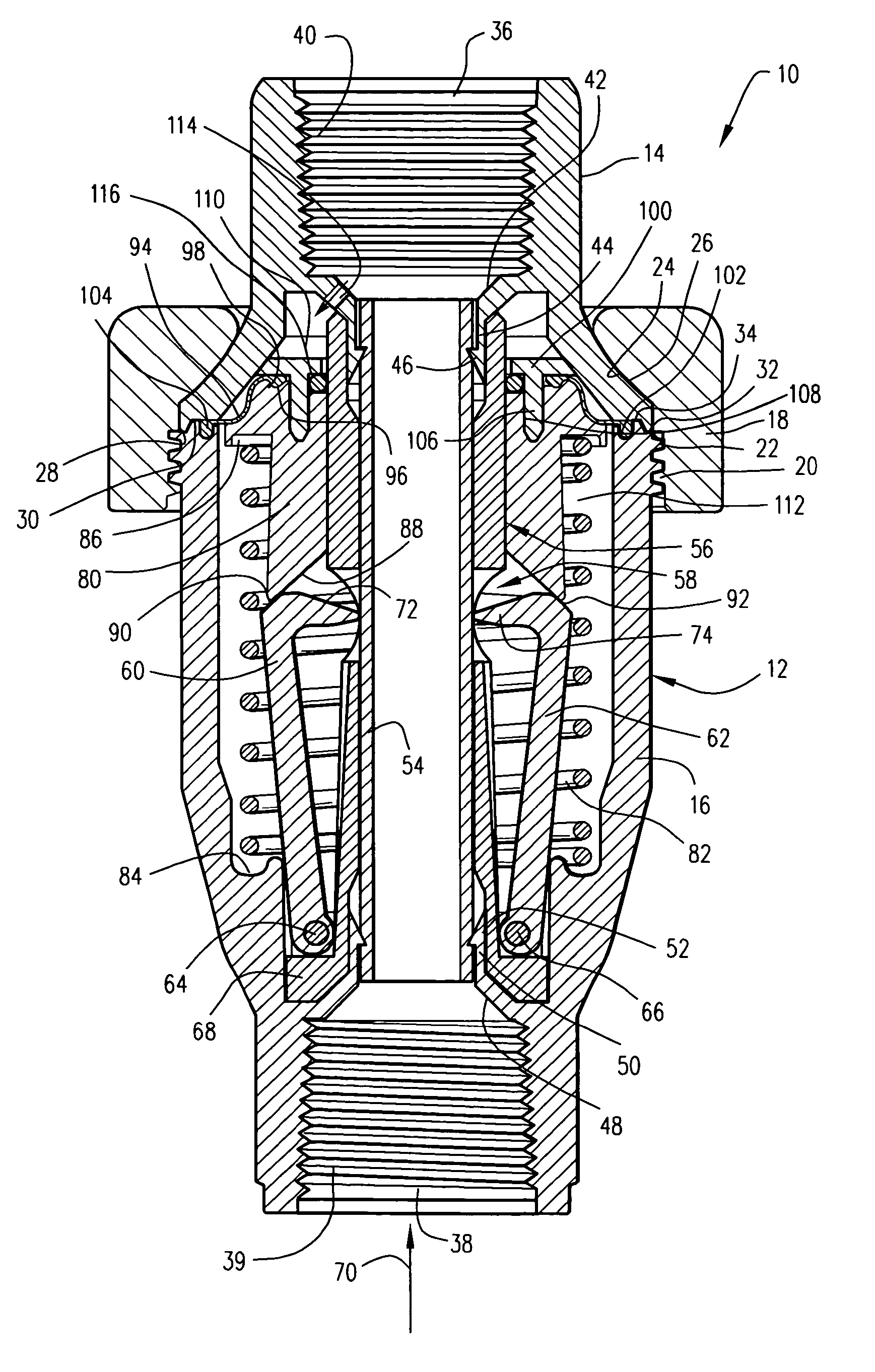

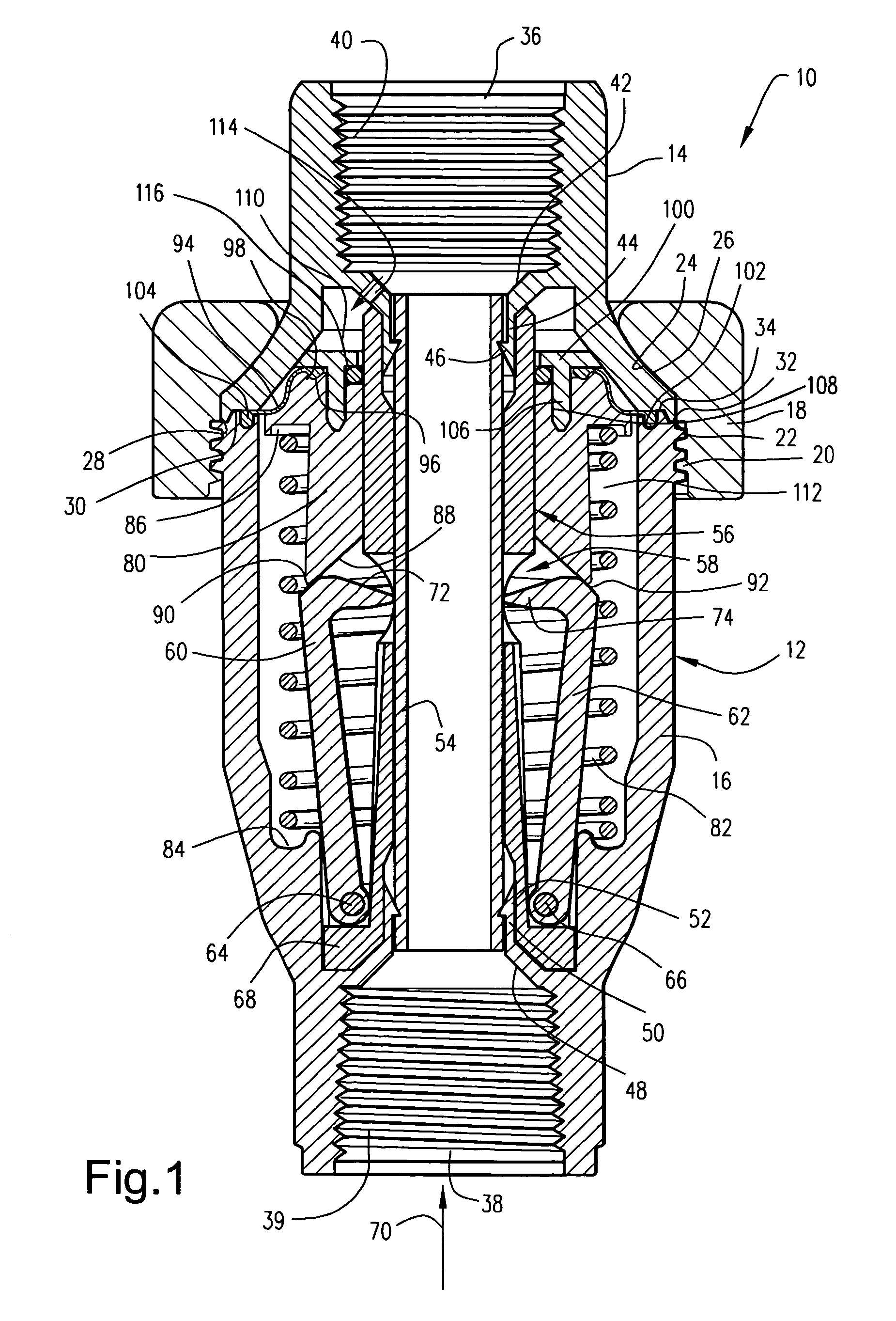

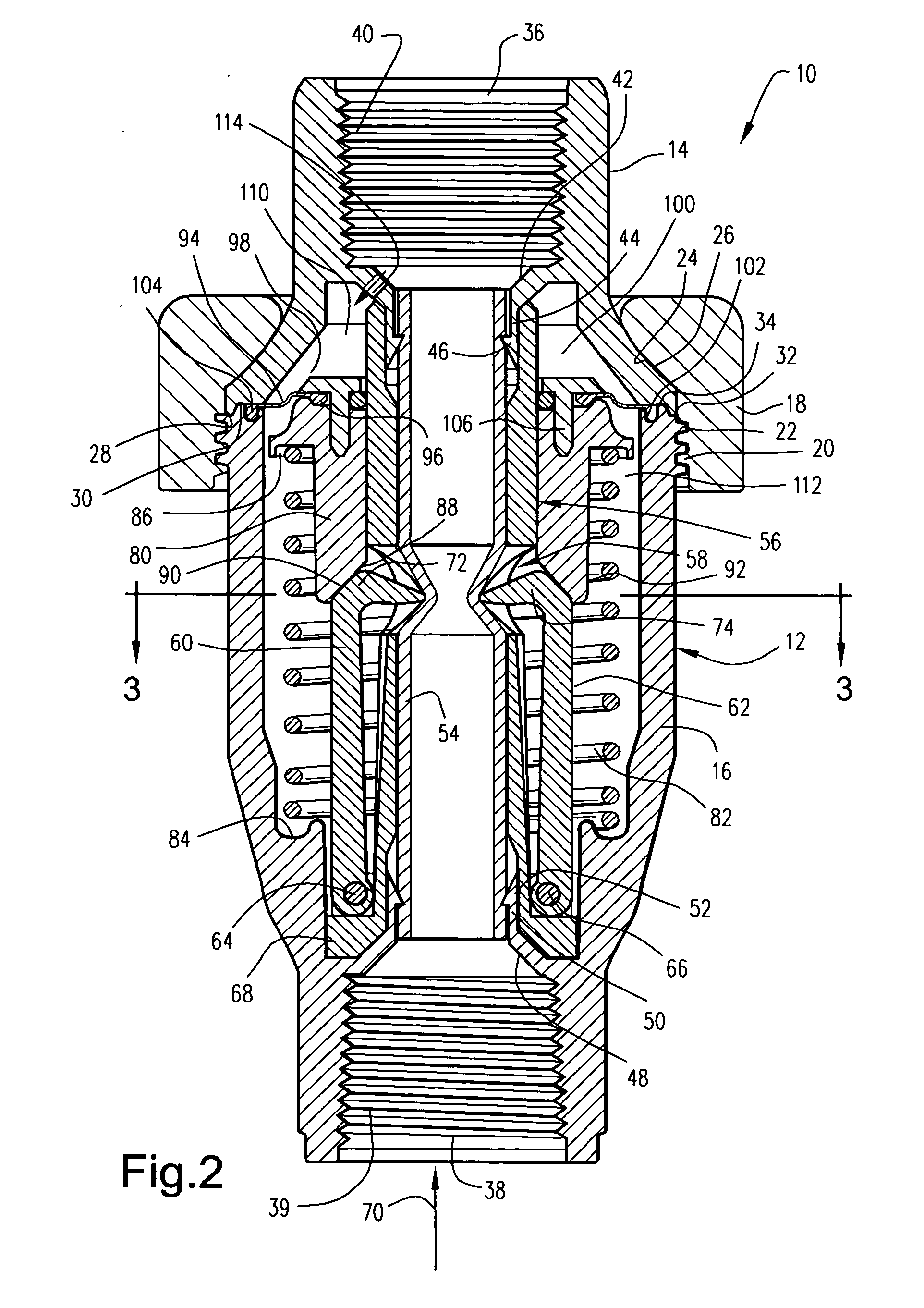

Flow through pressure regulator with pinch valve

ActiveUS7168444B2Avoid easy cloggingEasy visual inspectionDiaphragm valvesOperating means/releasing devices for valvesPinch valveEngineering

A fluid pressure regulator includes a regulator housing having an inlet end and an outlet end; a flexible flow tube extending between the inlet end and the outlet end; a hollow piston located at a downstream location relative to a mid-portion of the flow tube in a direction of flow of fluid through the regulator housing; a first chamber above the piston and a second chamber below the piston; a passage establishing fluid communication between the outlet end and the first chamber; and at least one pinch arm pivotally mounted at one end within the regulator housing and movable in response to movement of the piston by an increase in fluid pressure in the first chamber so that an opposite end of the at least one pinch arm will pinch a portion of the flow tube and thereby restrict flow through the flow tube.

Owner:NELSON IRRIGATION CORP

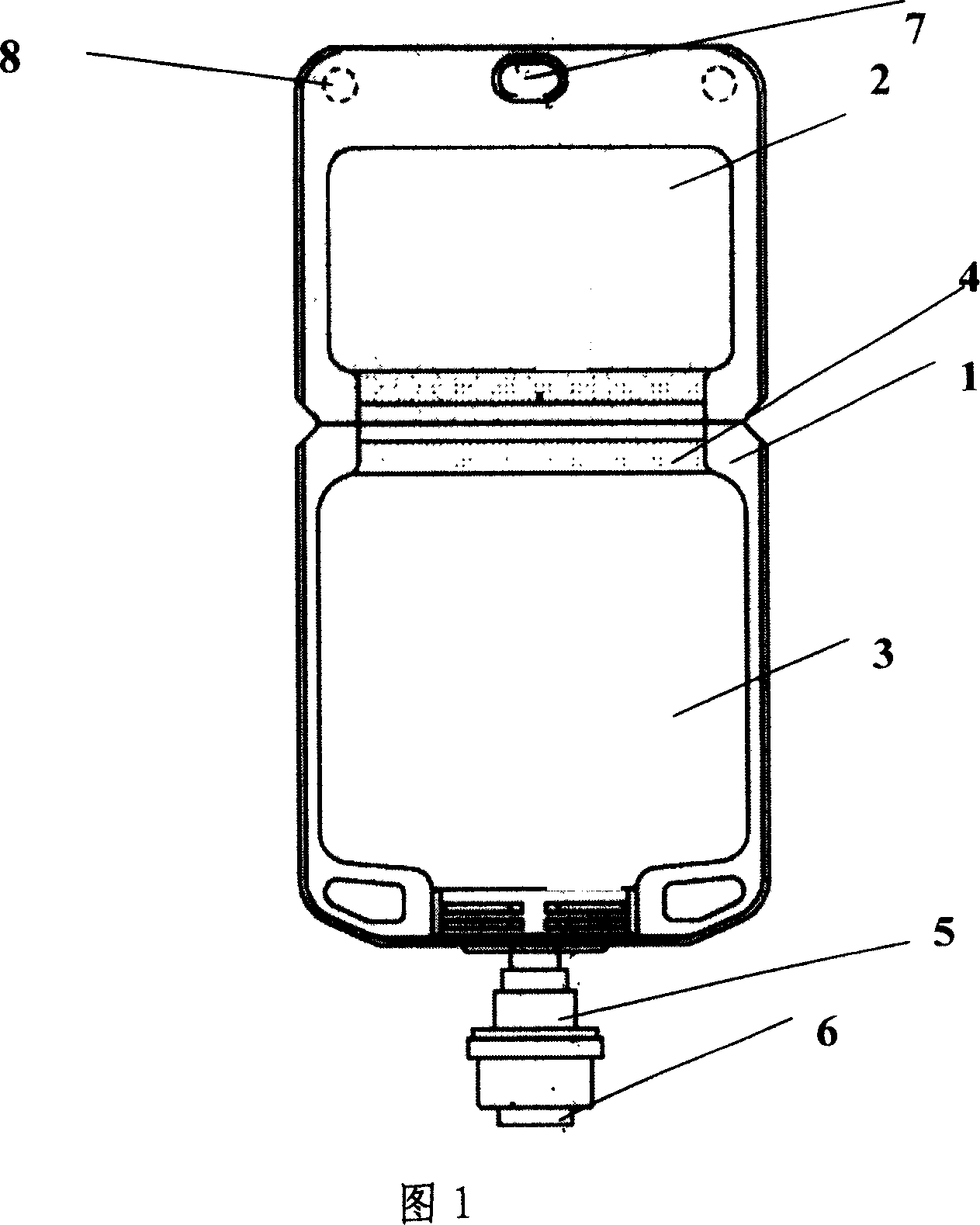

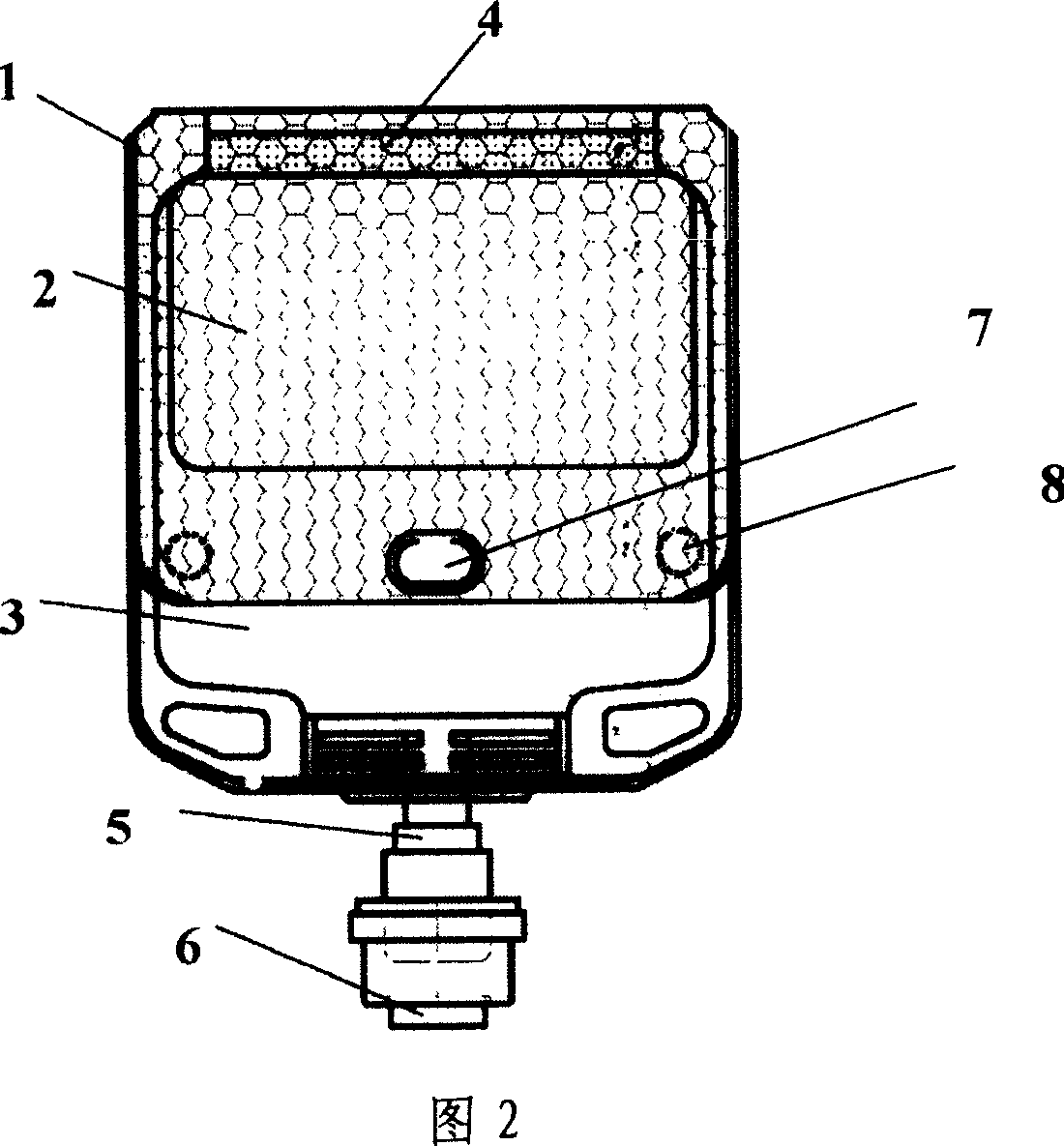

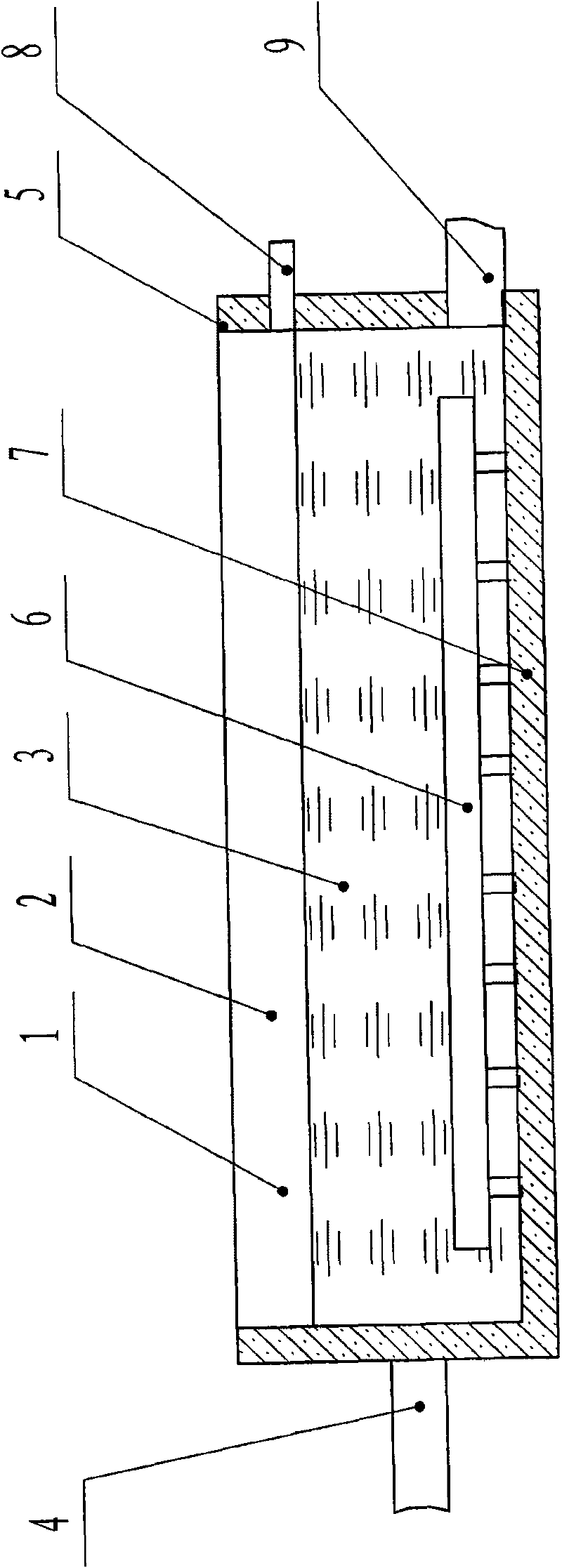

Powder and liquid bag and preparation method thereof

The invention discloses a powder-liquid container and manufacturing method, which is composed of sealed bag with two bag film on the periphery, wherein the bag possesses at least one powder chamber with antibiotics and liquid chamber with aseptic solution, which is separated by separating part, the separating part is connected by bag film through strippable welding structure, two external sides of bag film of powder chamber possesses a layer of baffle film.

Owner:SHANGHAI WUBIN PACKAGING PRODS

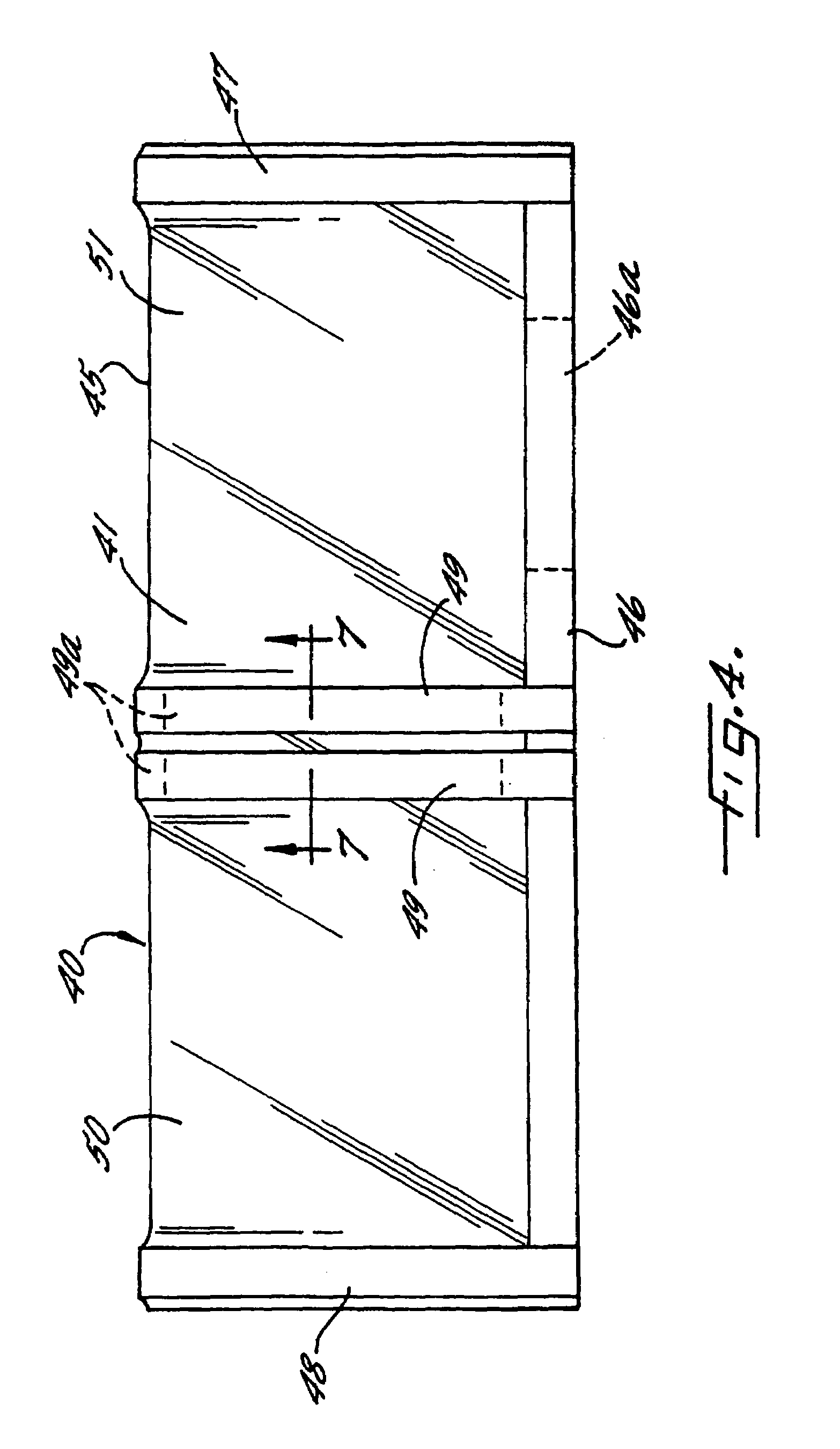

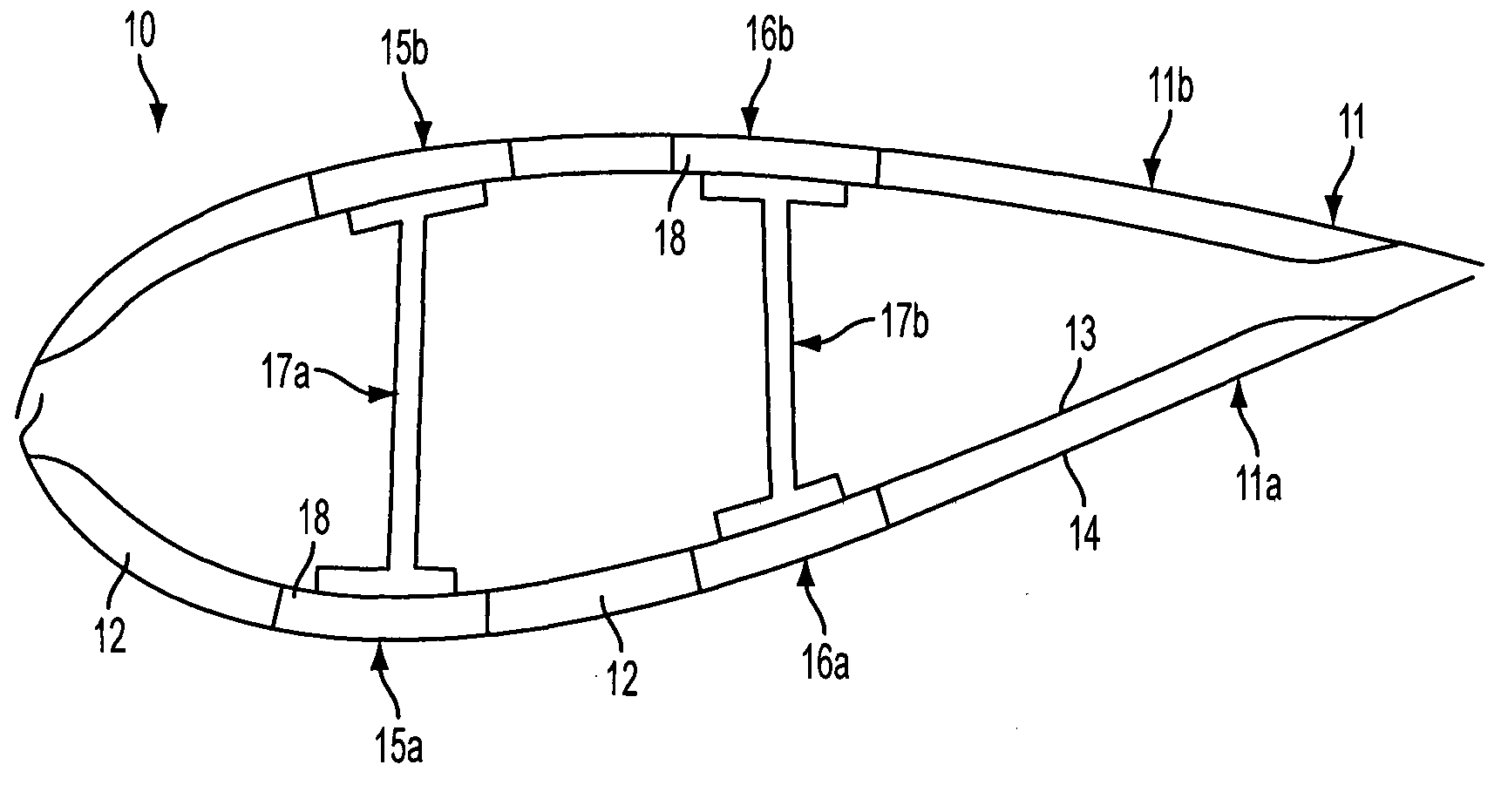

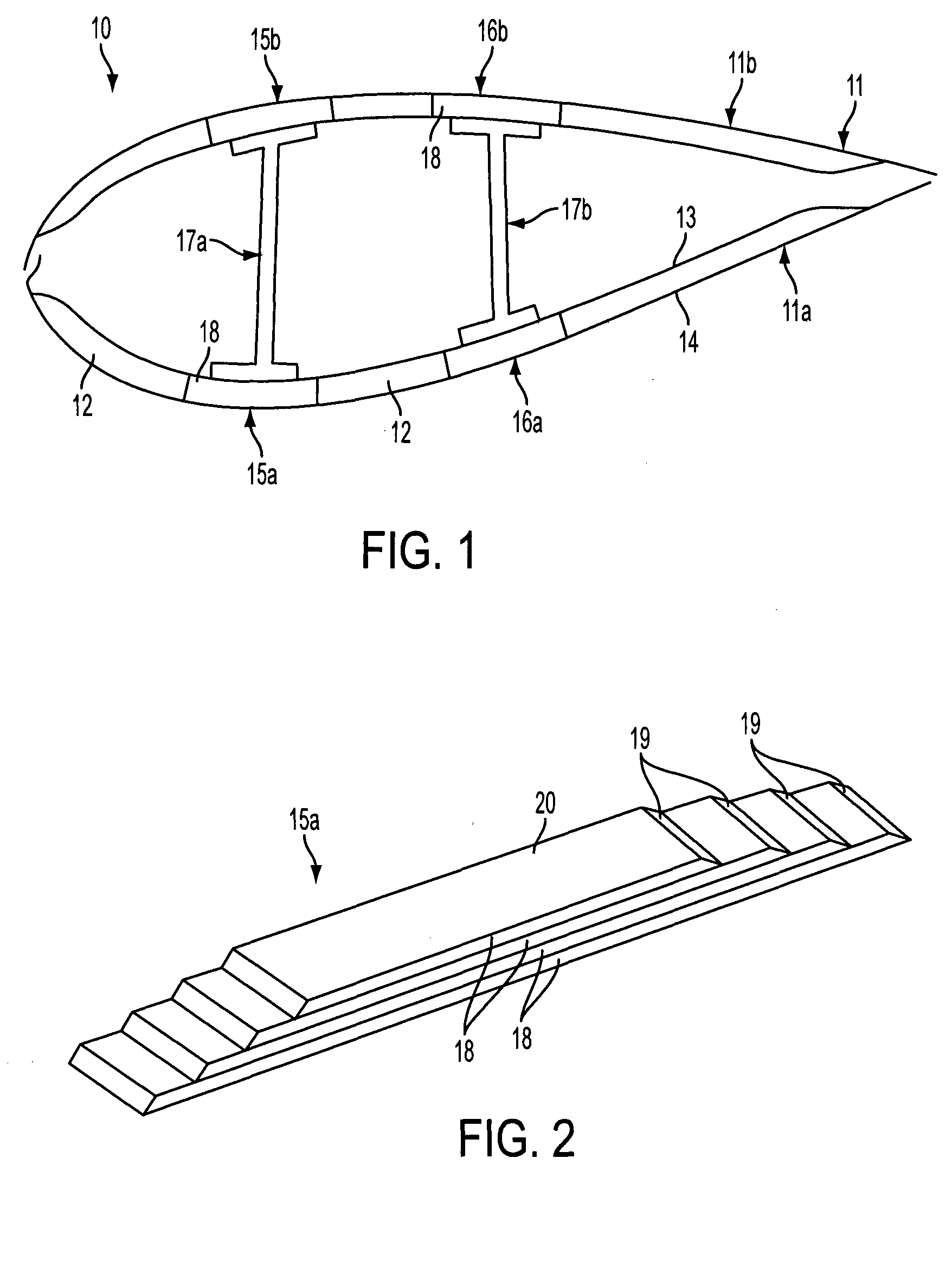

Reinforcing strip for a wind turbine blade

InactiveUS20160273516A1Easy visual inspectionRelatively time consuming.Engine manufactureLayered productsTurbine bladeWind force

A strip of fibre-reinforced polymeric material for a longitudinal reinforcing structure of a wind turbine blade, the strip having substantially flat upper and lower surfaces and extending longitudinally between first and second transverse edges, wherein an end region of the strip tapers in thickness towards the first transverse edge, and wherein one or more slots are defined in the tapered end region, the or each slot extending longitudinally from the first transverse edge of the strip into the tapered end region.

Owner:VESTAS WIND SYST AS

Foam in bag packaging system and method for producing the same

InactiveUS6974025B2Improve adhesionPrecise applicationSynthetic resin layered productsContainers to prevent mechanical damageEngineeringPlastic film

A packaging system for producing a foam-in-bag cushion upon demand includes a bag of flexible plastic film and defining therein an enclosed space which is vented to the outside of the bag, a foam precursor packet positioned at a predetermined location within the enclosed space in the bag and being formed of a barrier material. The packet includes first and second compartments with a first frangible seal separating the first and second compartments which when ruptured will permit the contents of the compartments to be mixed to form a foam cushion and a second frangible seal between one of the compartments and the enclosed space in the bag. A first foam precursor component is contained in the first compartment of the packet and a second foam precursor component is contained in the second compartment of the packet. The frangible seals have a peel strength of at least about one pound per inch and less than about twelve pounds per inch and more particularly a peel strength of about one pound per inch to about seven pounds per inch. The frangible seals are formed by providing bands of printed area on the facing surfaces of the material forming the packet which is arranged in a matrix of printed and unprinted areas. The printed areas prevent the surfaces from being joined by heat sealing and the matrix is such that a frangible seal of the desired peel strength is formed.

Owner:SEALED AIR U S

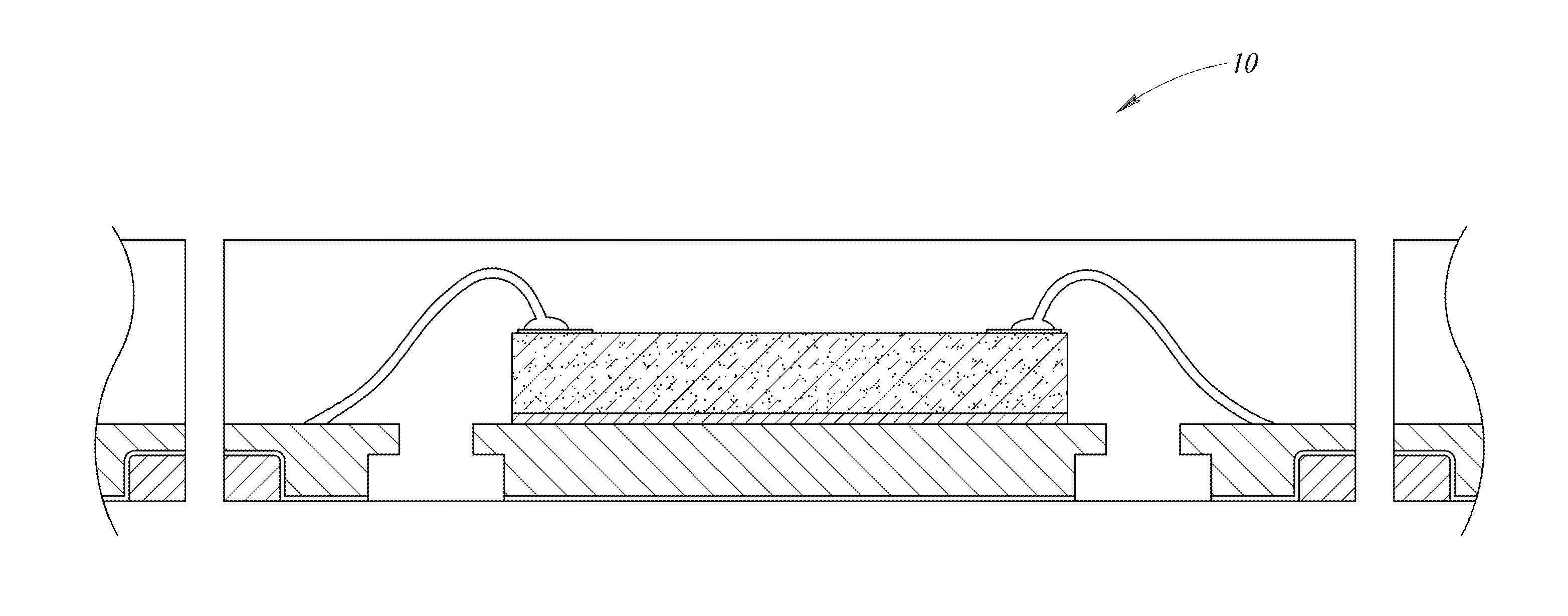

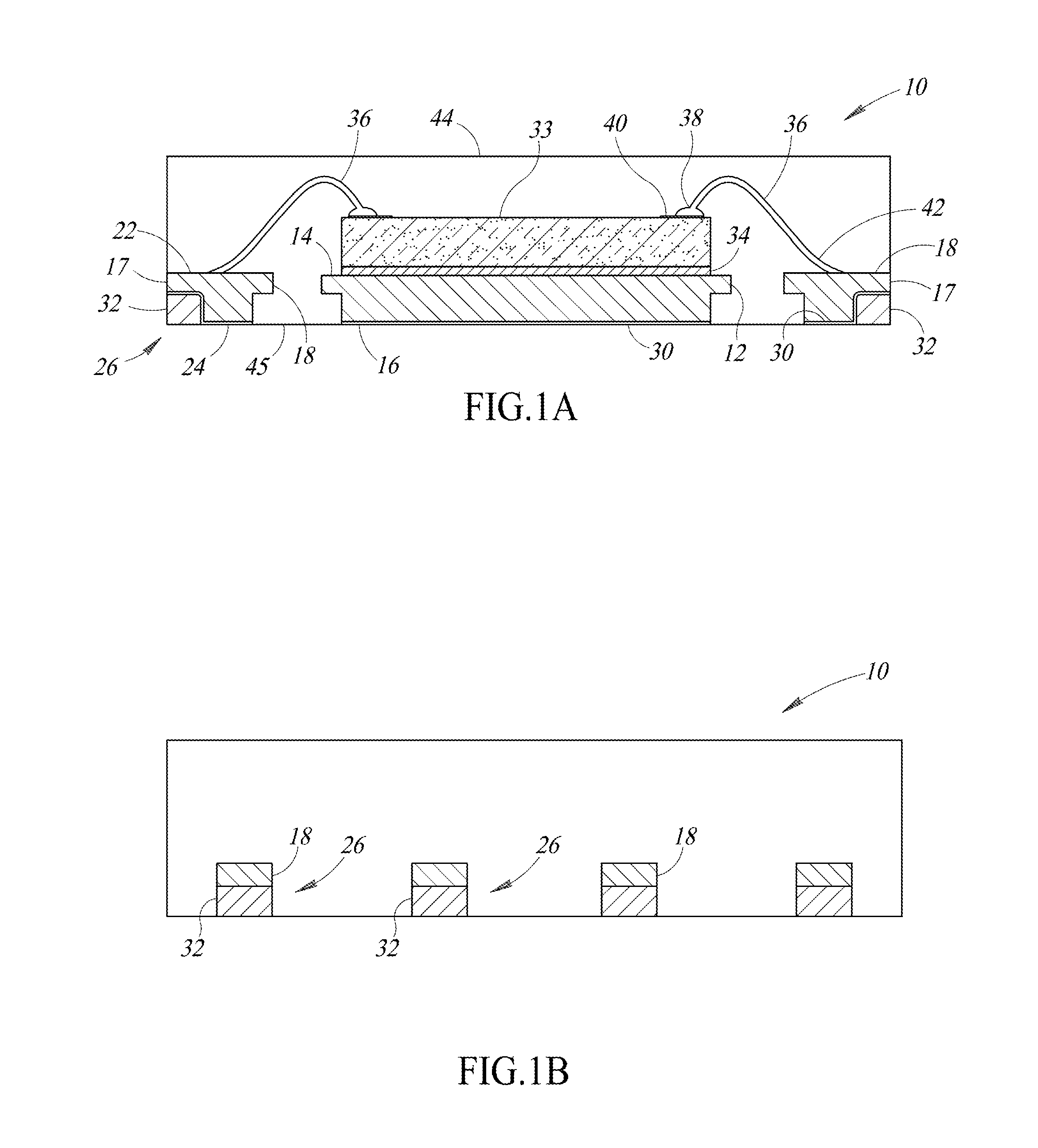

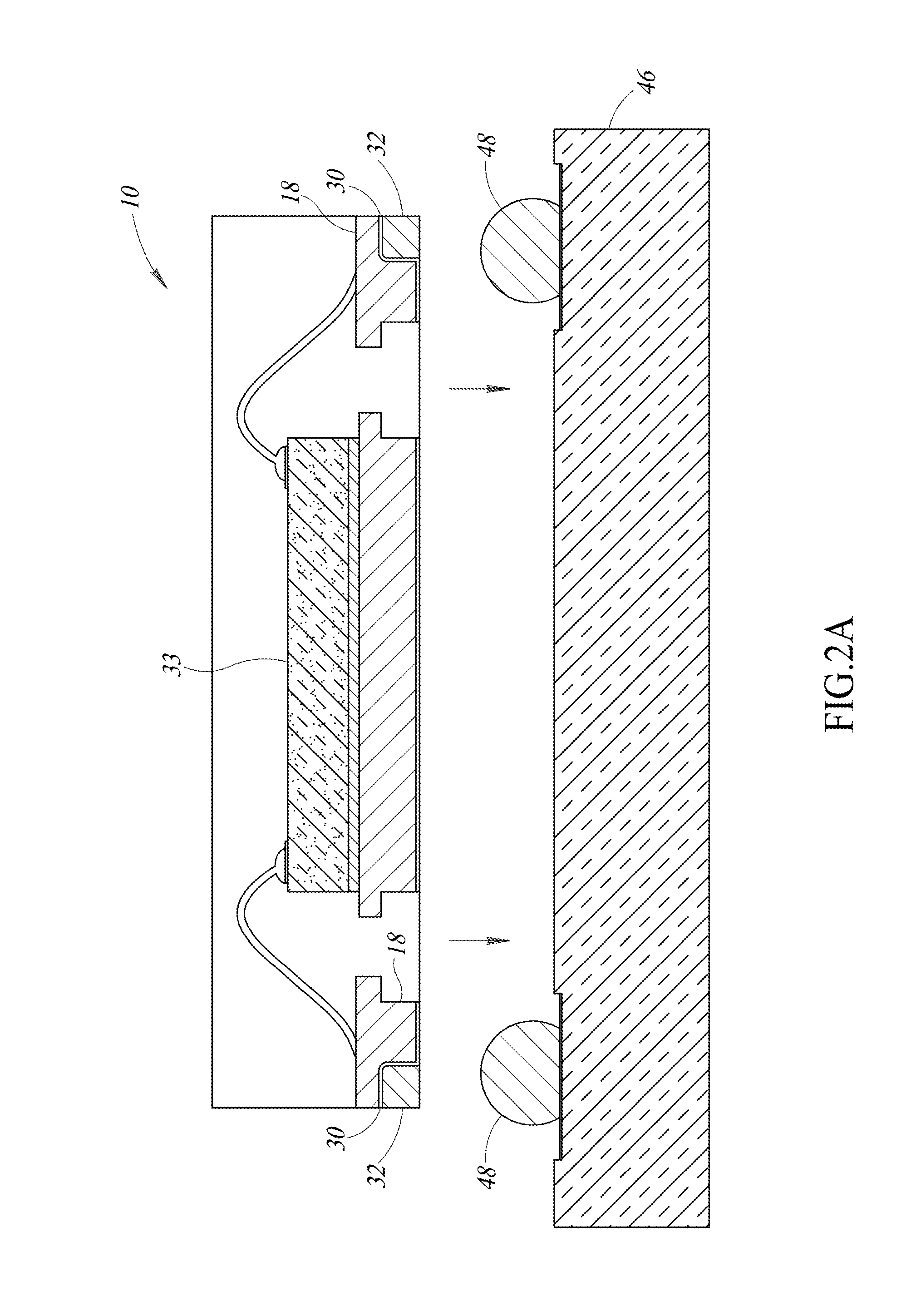

Leadframe package with pre-applied filler material

ActiveUS20160183369A1Easy visual inspectionSemiconductor/solid-state device detailsPrinted circuit aspectsFilling materialsVisual inspection

Embodiments of the present disclosure are directed to a leadframe package with recesses formed in outer surface of the leads. The recesses are filled with a filler material, such as solder. The filler material in the recesses provides a wetable surface for filler material, such as solder, to adhere to during mounting of the package to another device, such as a printed circuit board (PCB). This enables strong solder joints between the leads of the package and the PCB. It also enables improved visual inspection of the solder joints after the package has been mounted.

Owner:STMICROELECTRONICS SRL

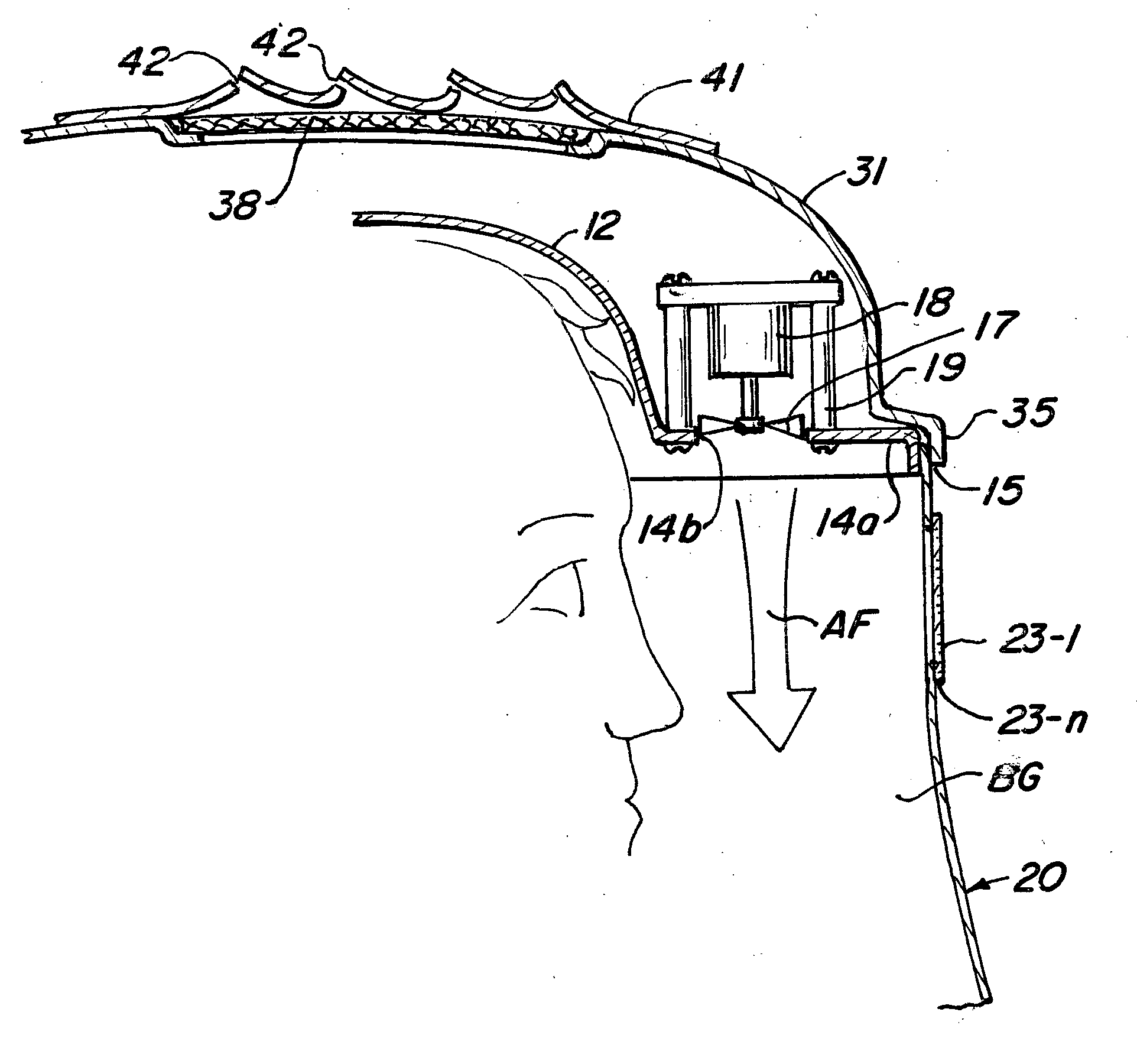

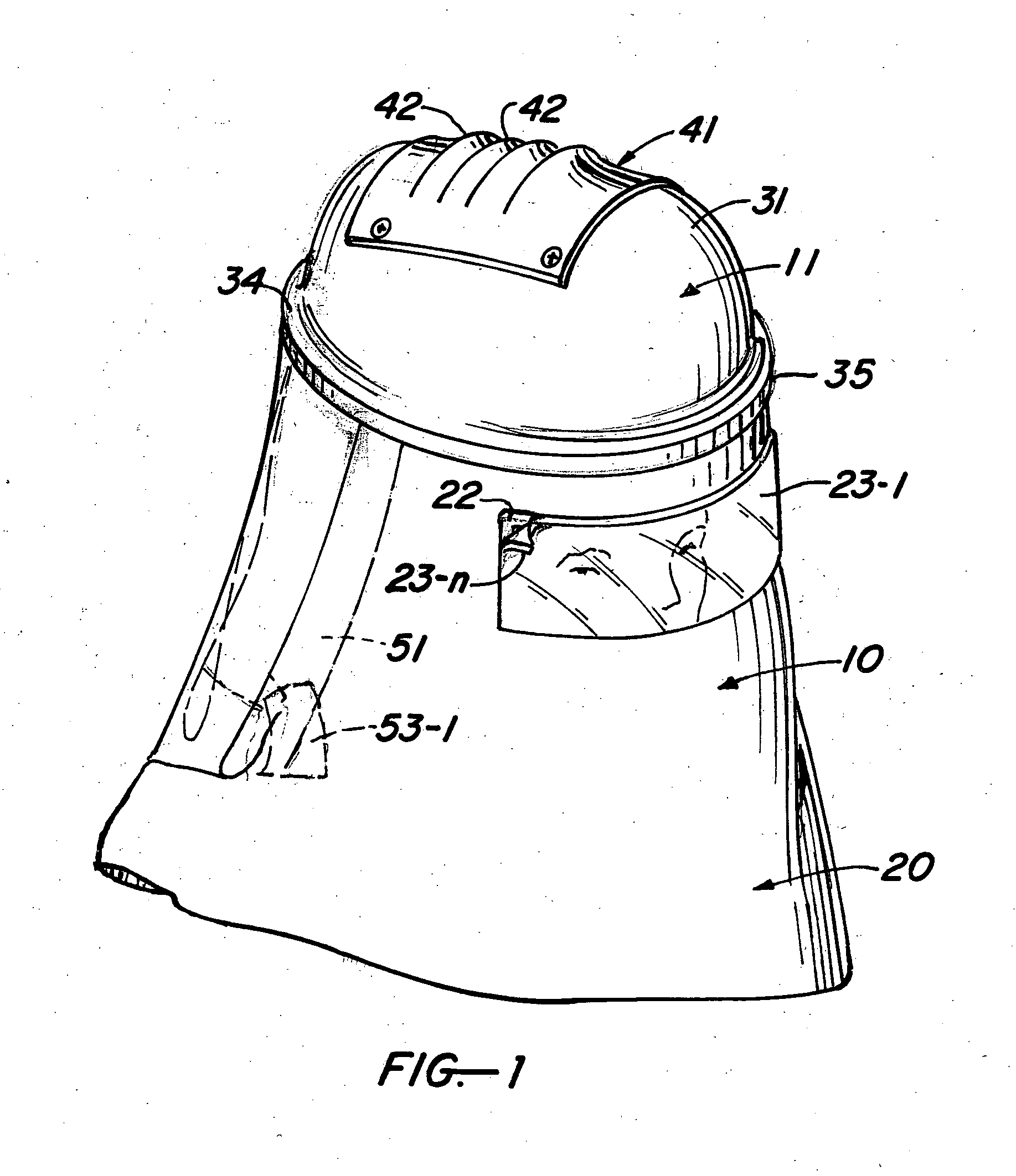

Respiration hood useful in biological, radiological and chemical emergencies

InactiveUS20070221214A1Function increaseUse polarizedChemical protectionHeat protectionElectricityHOOD assembly

A respiration hood assembly is effected from a thin-walled headpiece nested within the periphery of a mating exterior housing that includes a filtered aperture. The nested engagement between the headpiece and the housing is also useful in capturing one edge of a plastic membrane skirt that is thus suspended to drape over the person wearing the headpiece. A battery powered electric fan is deployed within the housing to draw ambient air through the vent aperture into the space shrouded by the skirt. The nested headpiece arrangement is useful in retaining other fibrous towels or tissue to extend the usefulness of the assembly and a parallel connection is provided to a motor vehicle battery to extend the period of electrical excitation.

Owner:BROCKMAN ROBERT

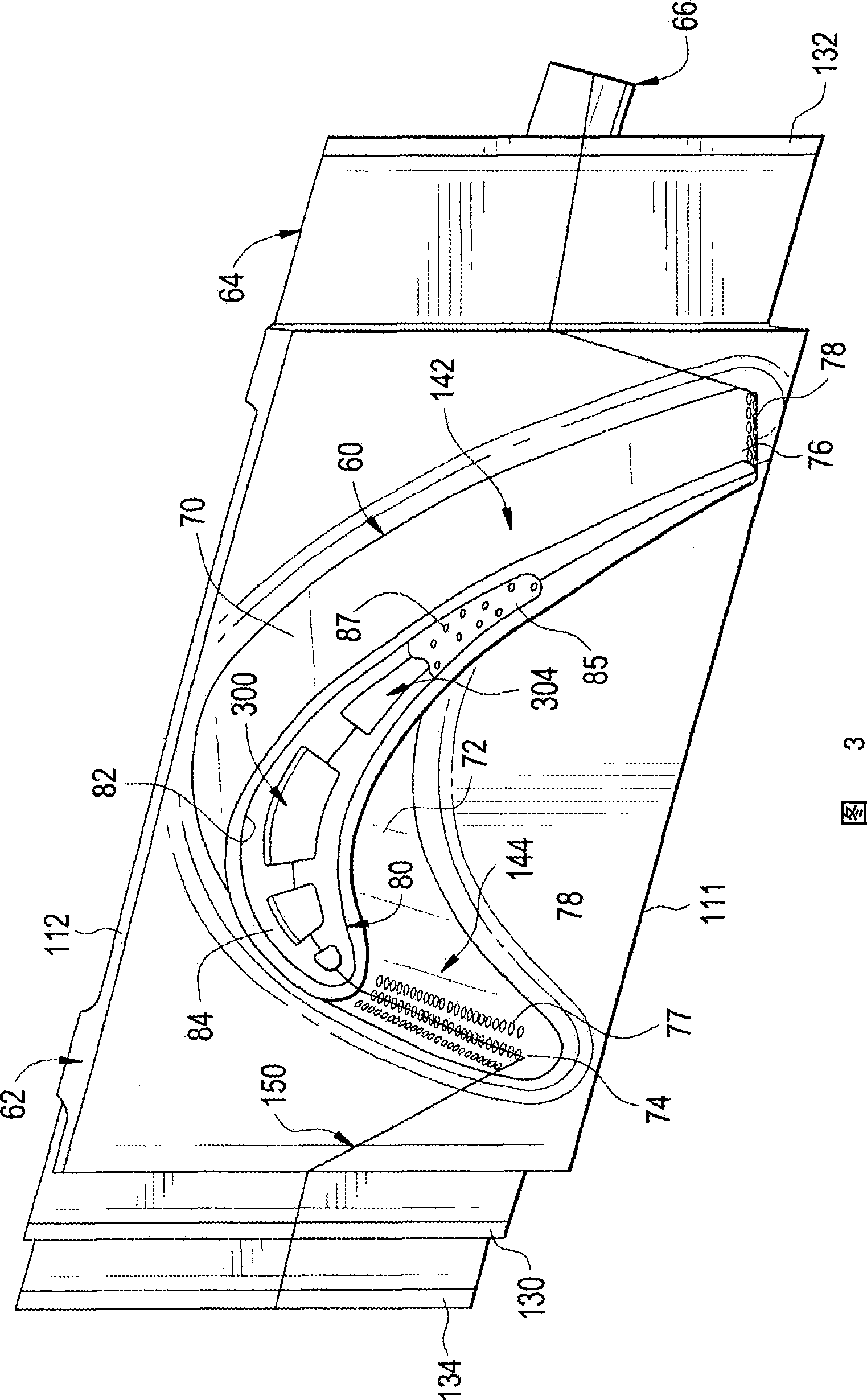

Multi-part cast turbine engine component having an internal cooling channel and method of forming a multi-part cast turbine engine component

InactiveUS20090060714A1Well formedEasy visual inspectionPump componentsBlade accessoriesCooling channelTurbine

A multi-part cast component for a turbine engine includes a first component section having a main body portion including at least one cooling flow passage section, and a second component section having a main body including at least one cooling flow passage section. The first and second component sections are joined along a parting line to form a turbine engine component with the at least one cooling flow passage section of the first component section aligning with the at least one cooling flow passage of the second component section to form a cooling flow channel.

Owner:GENERAL ELECTRIC CO

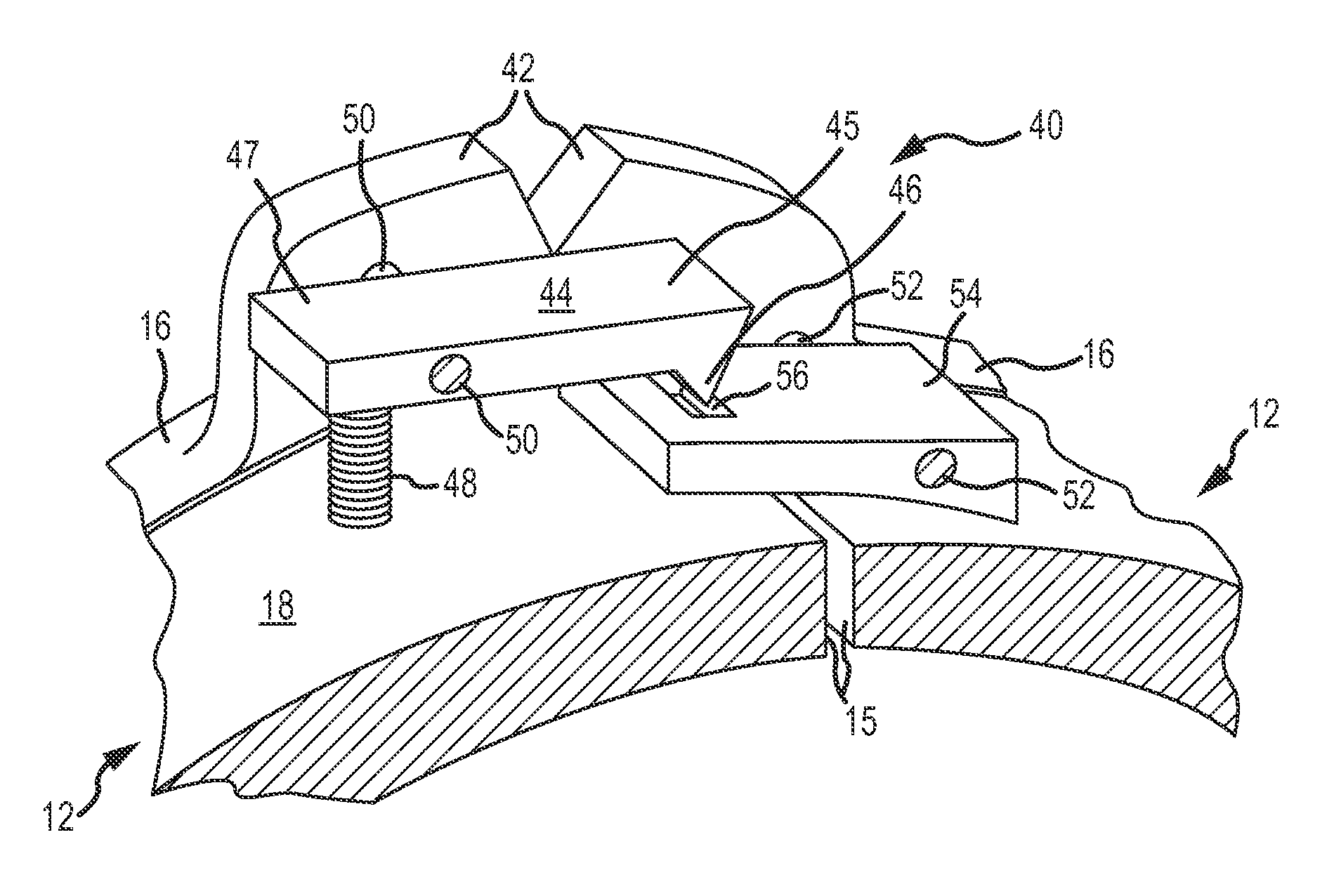

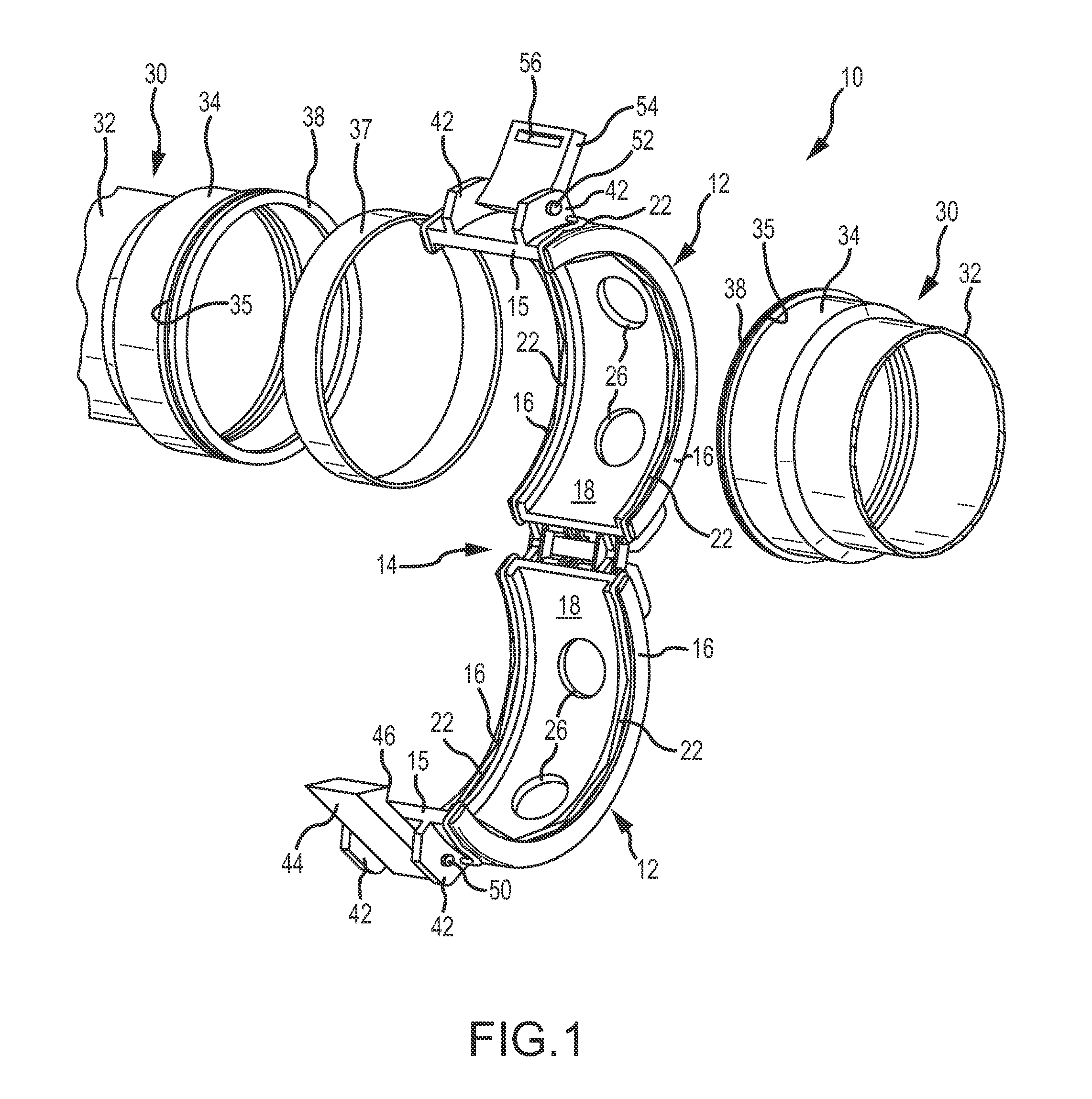

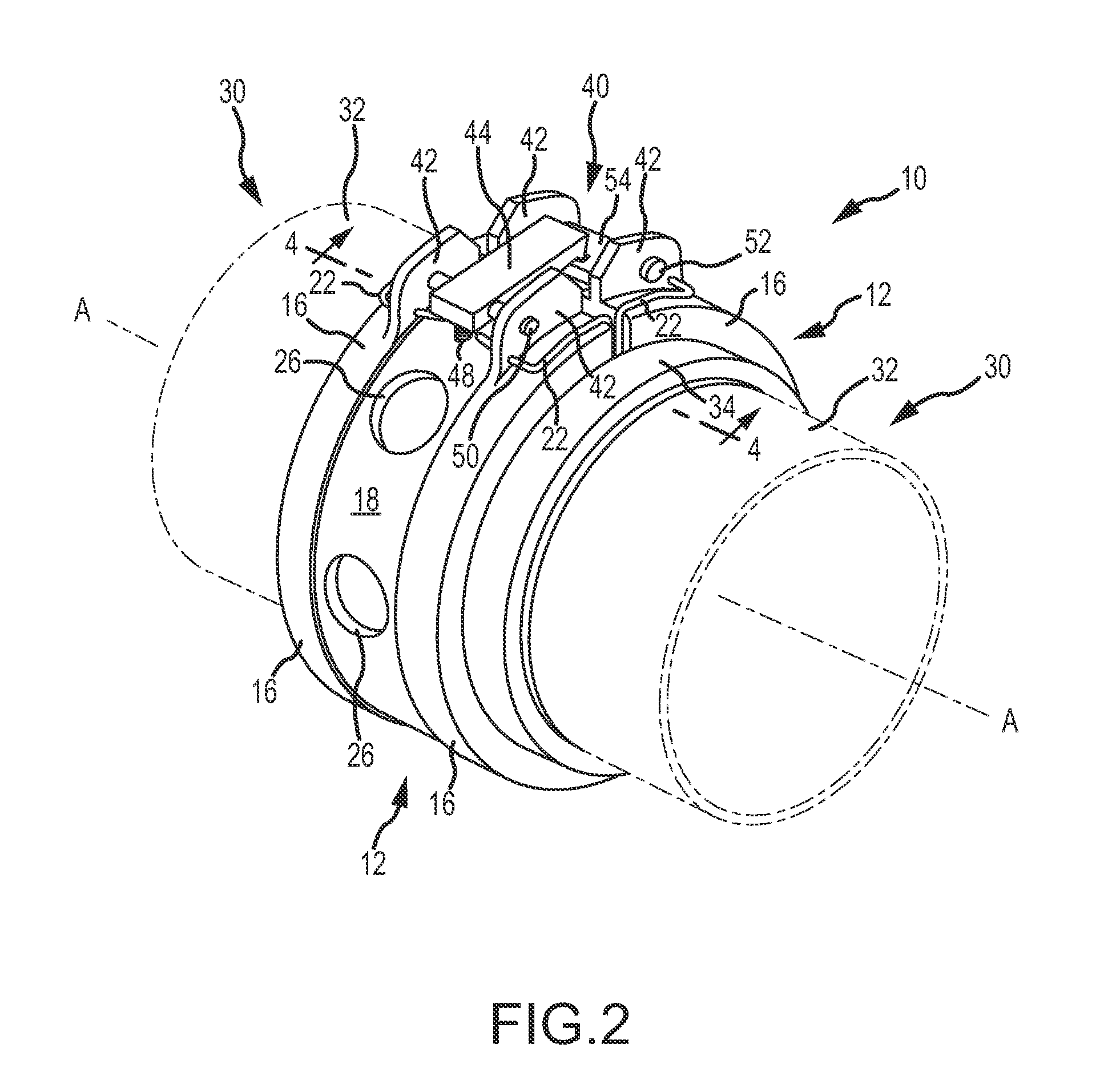

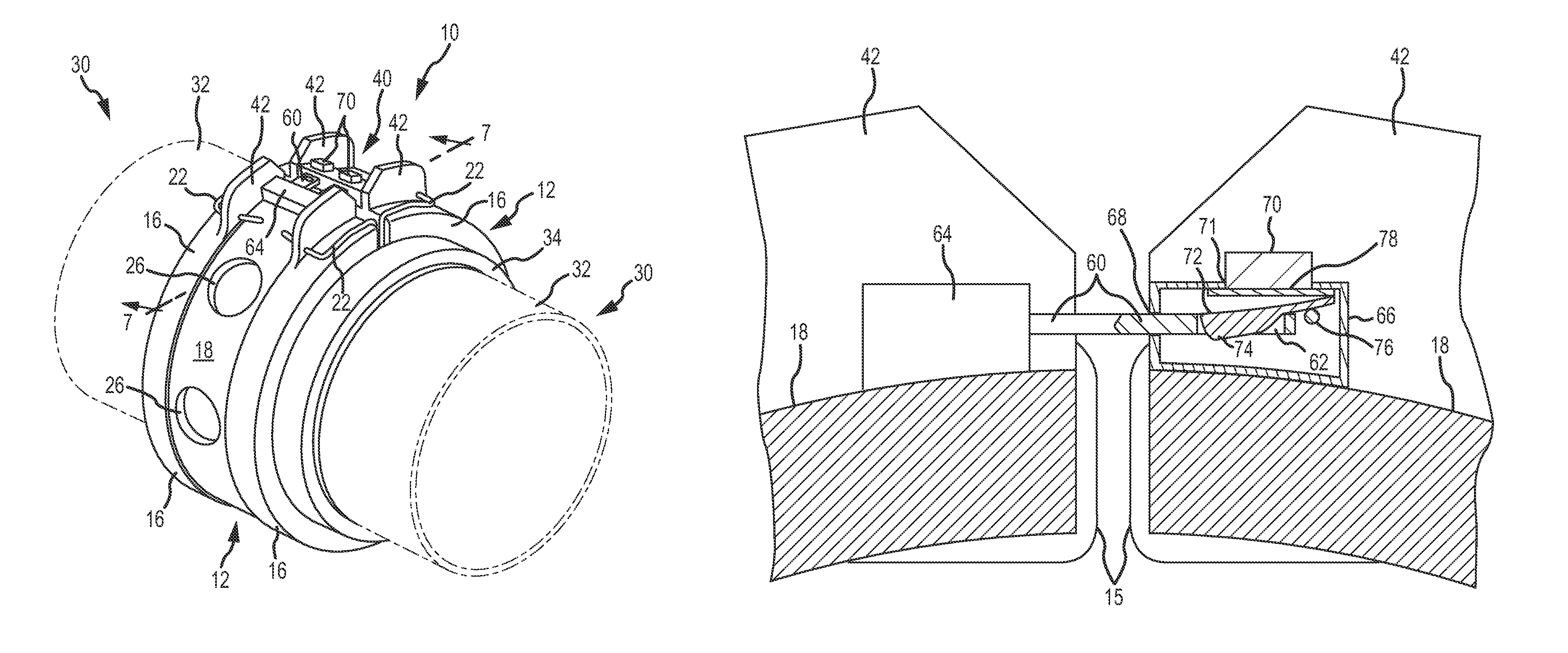

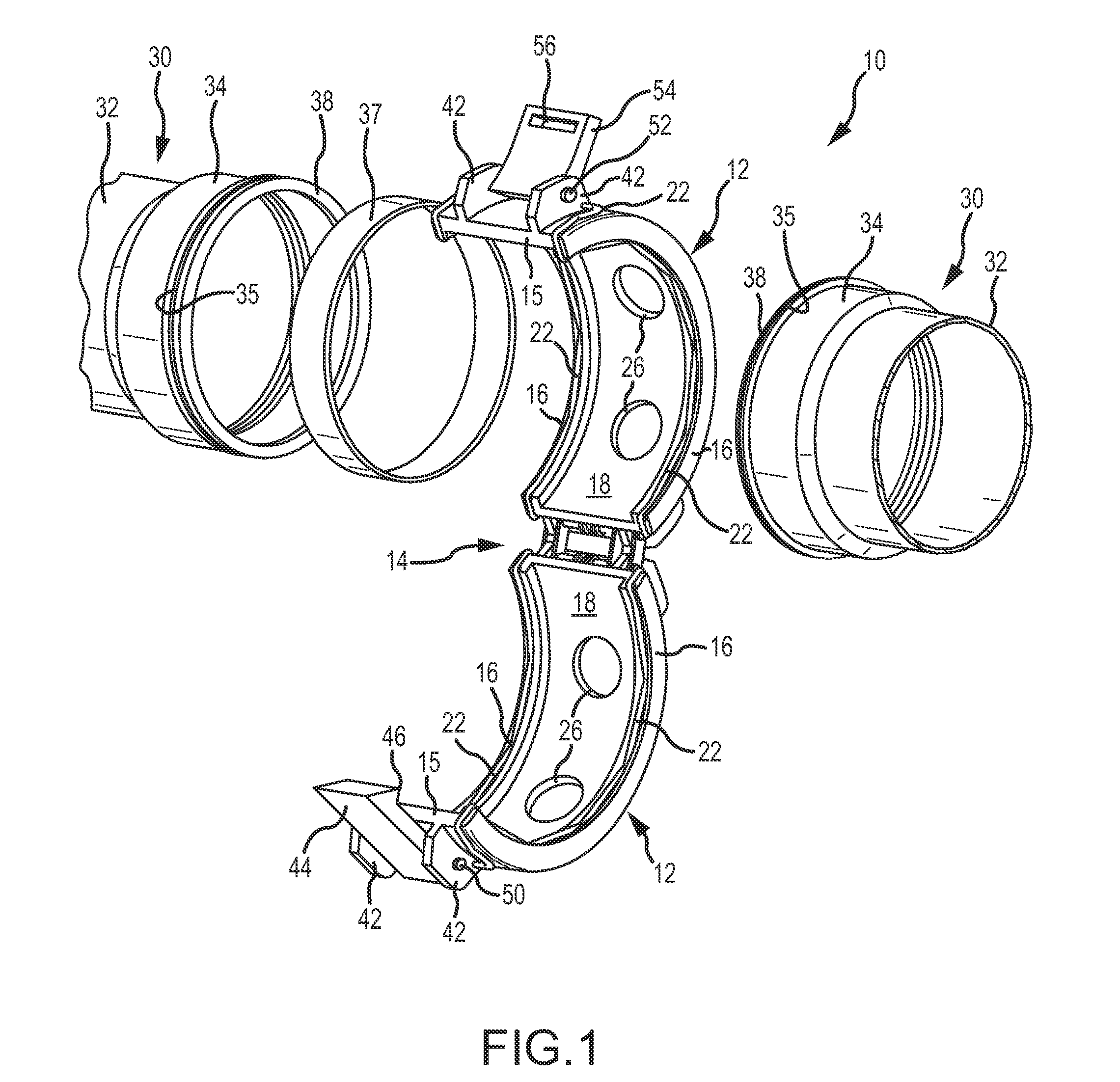

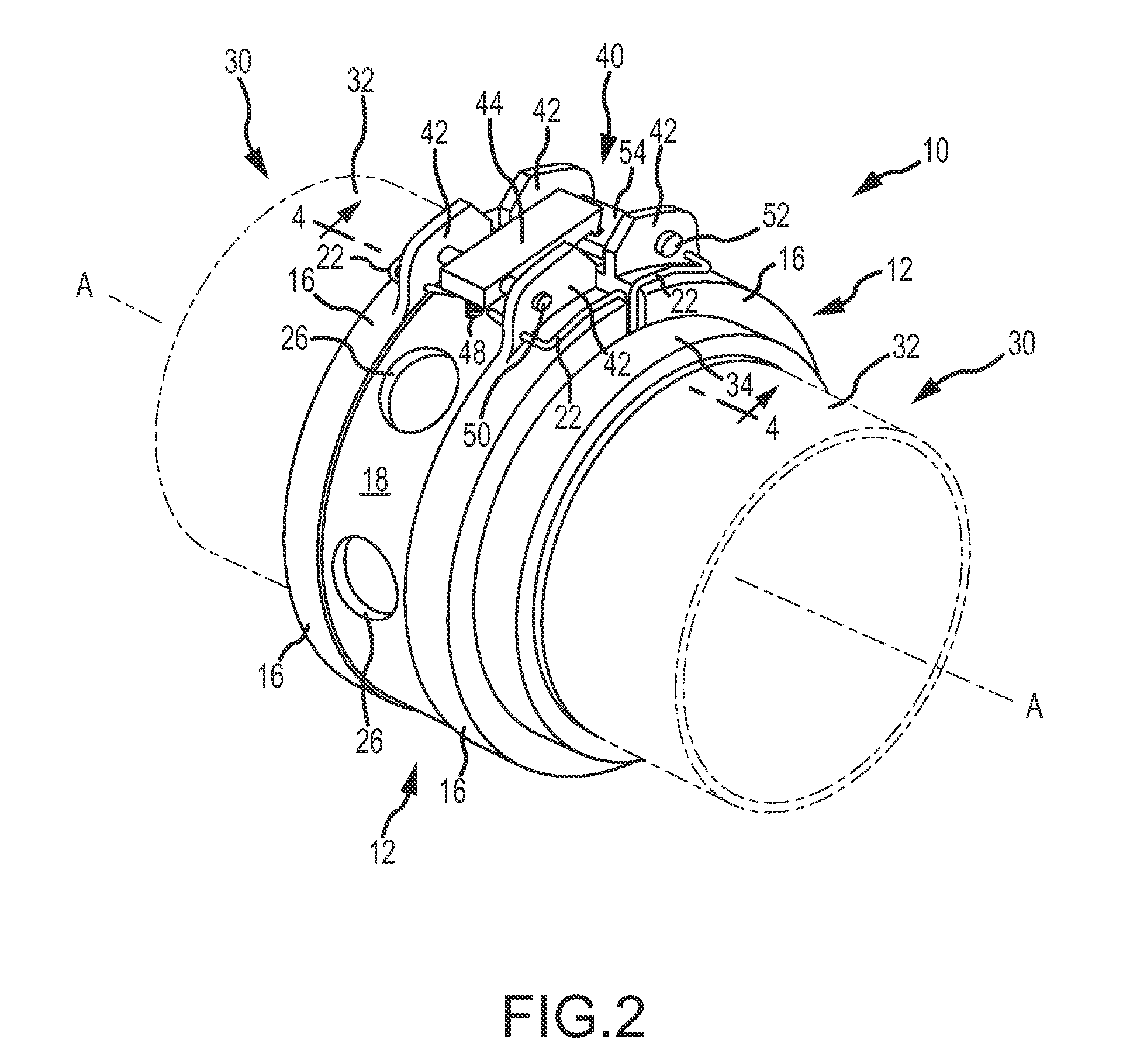

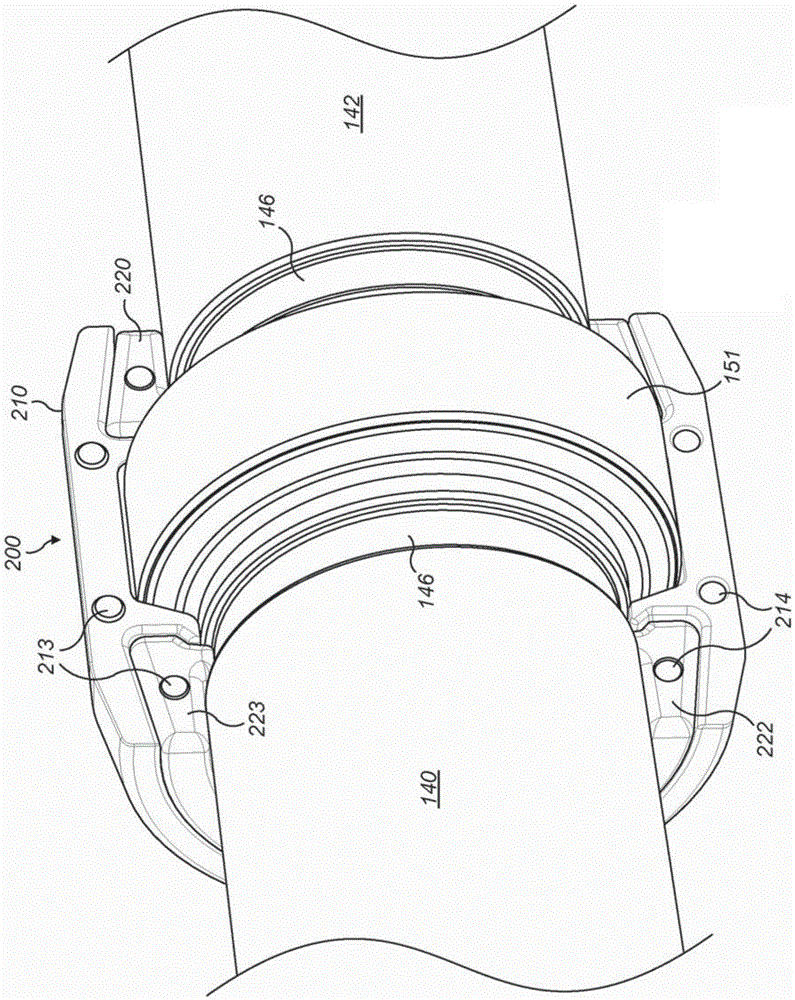

Latching mechanisms for clamshell type couplers

ActiveUS20150102600A1Sufficient electrical conductivityPrevent static buildupFlanged jointsPipe couplingsCouplingEngineering

Latching mechanisms in multiple embodiments connect clamshell type couplers comprising a pair of arcuate coupling halves joined at a hinge. One embodiment includes a biased catch lever that engages a corresponding latch plate. Another embodiment includes a plurality of latching extensions that engage an opposing latching housing, along with biased locking buttons for selectively locking the mechanism. Another embodiment includes dual rotatable latching arms for interconnecting the coupling halves, each arm having a latching cam for selectively locking the mechanism. Another embodiment includes a rotatable latching arm and a receiving bracket for receiving the latching arm for selectively locking the mechanism. Another embodiment includes an over center hinge mechanism including three cooperating and rotatable latch plates. Another embodiment includes cooperating cassette mechanisms, each having connector extensions for connecting the cassette mechanisms to one another for selectively locking the mechanism. Methods are also disclosed for selectively locking the latching mechanisms

Owner:EATON INTELLIGENT POWER LTD

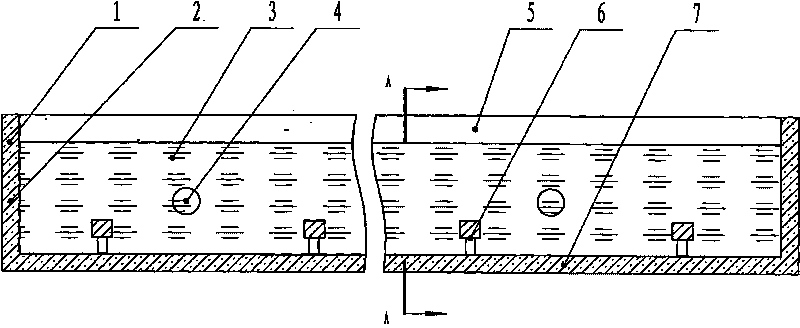

Method of processing chromium-nickel austenite stainless steel continuous casting slab

The invention relates to a method of processing chromium-nickel austenite stainless steel continuous casting billet, comprising the following steps in sequence: (1) placing cut chromium-nickel austenite stainless steel continuous casting slab into a circulating water tank and removing the slag crusts adhered to the surface of the chromium-nickel austenite stainless steel continuous casting slab; (2) lifting the chromium-nickel austenite stainless steel continuous casting slab out of the circulating water tank and cooling the same; and (3) visually detecting the chromium-nickel austenite stainless steel continuous casting slab to decide whether the chromium-nickel austenite stainless steel continuous casting slab needs to be polished. If having smaller and less oscillation marks on the surface, the chromium-nickel austenite stainless steel continuous casting slab does not need to be polished; if having obvious oscillation marks on the surface, the defected chromium-nickel austenite stainless steel continuous casting slab needs to be artificially polished; and if having deep oscillation marks, scabs on the surface or the like on the surface, the defected chromium-nickel austenite stainless steel continuous casting slab needs to be integrally polished with a polishing machine until the oscillation marks, the scabs or the like on the surface can not be seen visually. The method of processing chromium-nickel austenite stainless steel continuous casting billet uses water to remove all the protective slag crusts adhered to the surface of the chromium-nickel austenite stainless steel continuous casting slab, thus the visual detection of chromium-nickel austenite stainless steel continuous casting slab can be detected, the polishing workload can be greatly reduced, the yield can be increased and the processing efficiency can be improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Latching mechanisms for clamshell type couplers

Latching mechanisms in multiple embodiments connect clamshell type couplers comprising a pair of arcuate coupling halves joined at a hinge. One embodiment includes a biased catch lever that engages a corresponding latch plate. Another embodiment includes a plurality of latching extensions that engage an opposing latching housing, along with biased locking buttons for selectively locking the mechanism. Another embodiment includes dual rotatable latching arms for interconnecting the coupling halves, each arm having a latching cam for selectively locking the mechanism. Another embodiment includes a rotatable latching arm and a receiving bracket for receiving the latching arm for selectively locking the mechanism. Another embodiment includes an over center hinge mechanism including three cooperating and rotatable latch plates. Another embodiment includes cooperating cassette mechanisms, each having connector extensions for connecting the cassette mechanisms to one another for selectively locking the mechanism. Methods are also disclosed for selectively locking the latching mechanisms.

Owner:EATON INTELLIGENT POWER LTD

Multi-part cast turbine engine component having an internal cooling channel and method of forming the same

A multi-part cast component for a turbine engine includes a first component section having a main body portion including at least one cooling flow passage section, and a second component section having a main body including at least one cooling flow passage section. The first and second component sections are joined along a parting line to form a turbine engine component with the at least one cooling flow passage section of the first component section aligning with the at least one cooling flow passage of the second component section to form a cooling flow channel.

Owner:GENERAL ELECTRIC CO

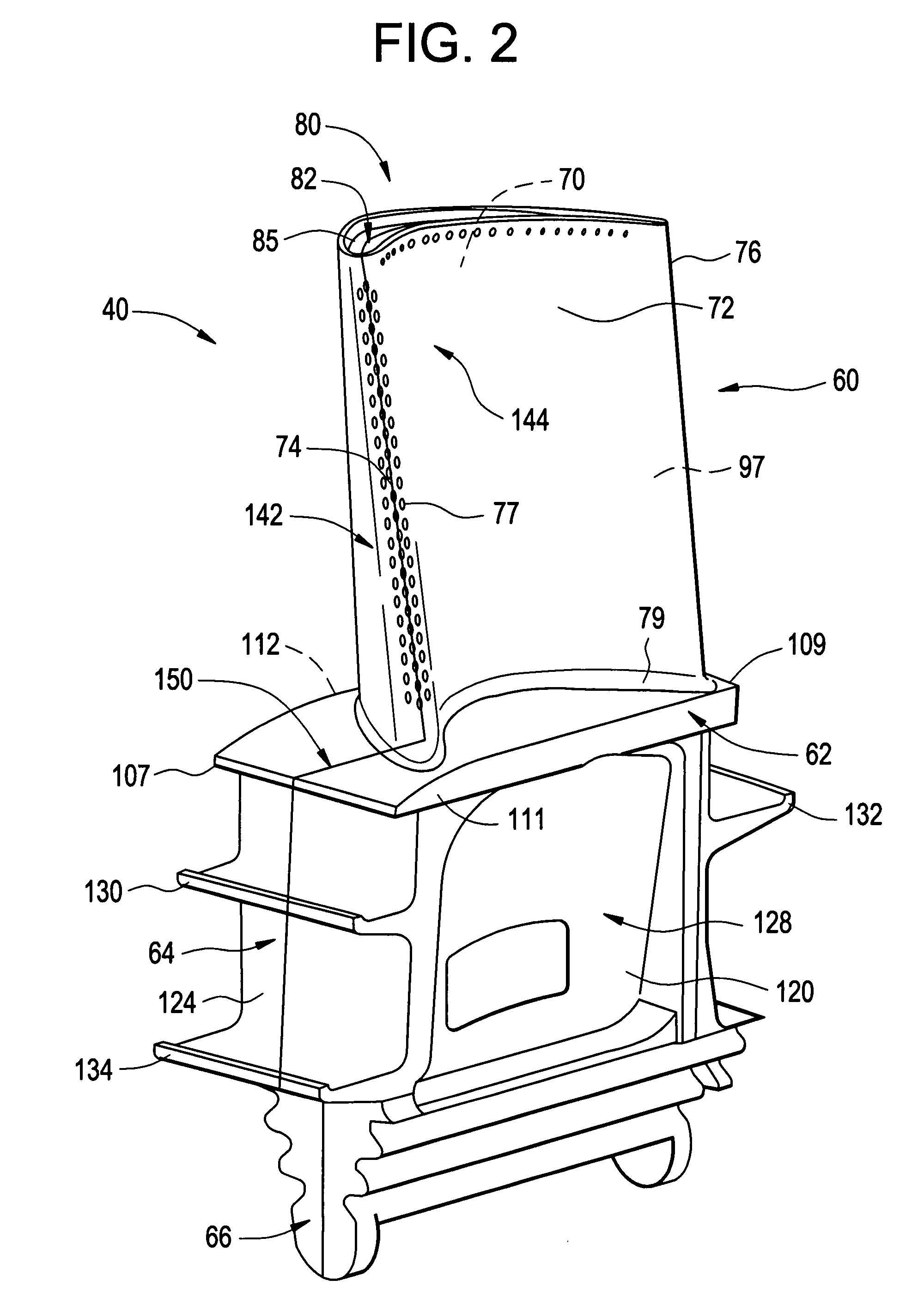

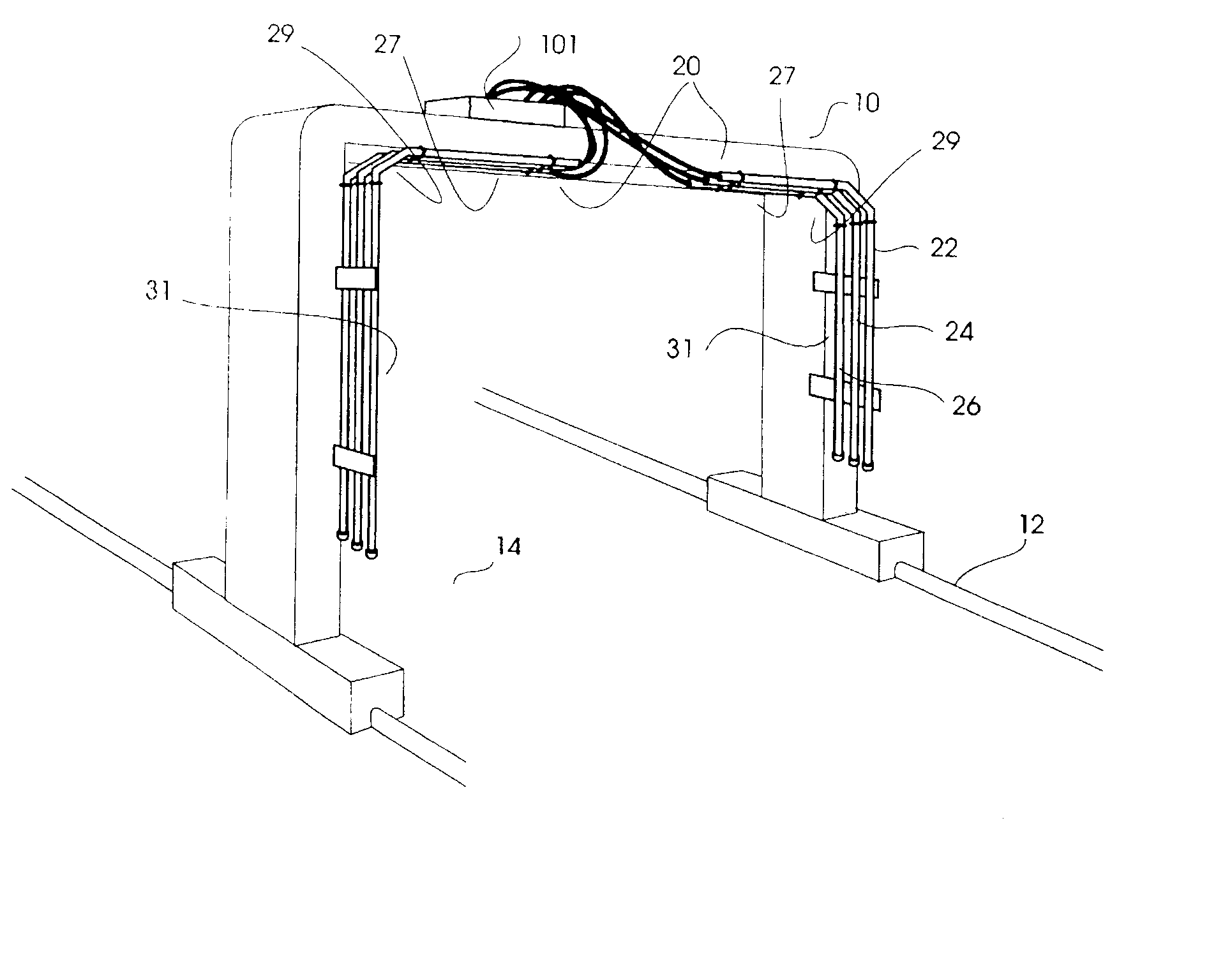

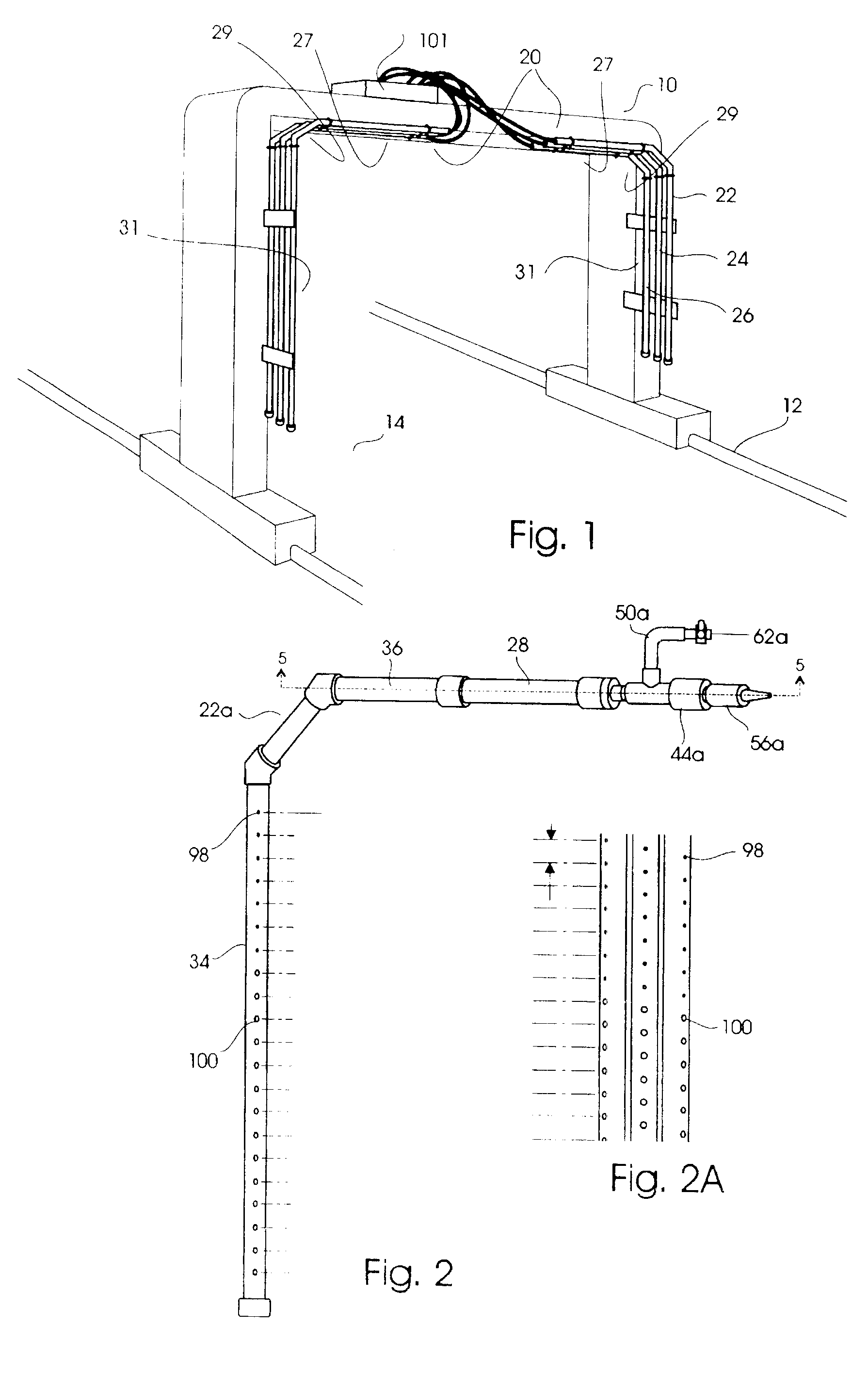

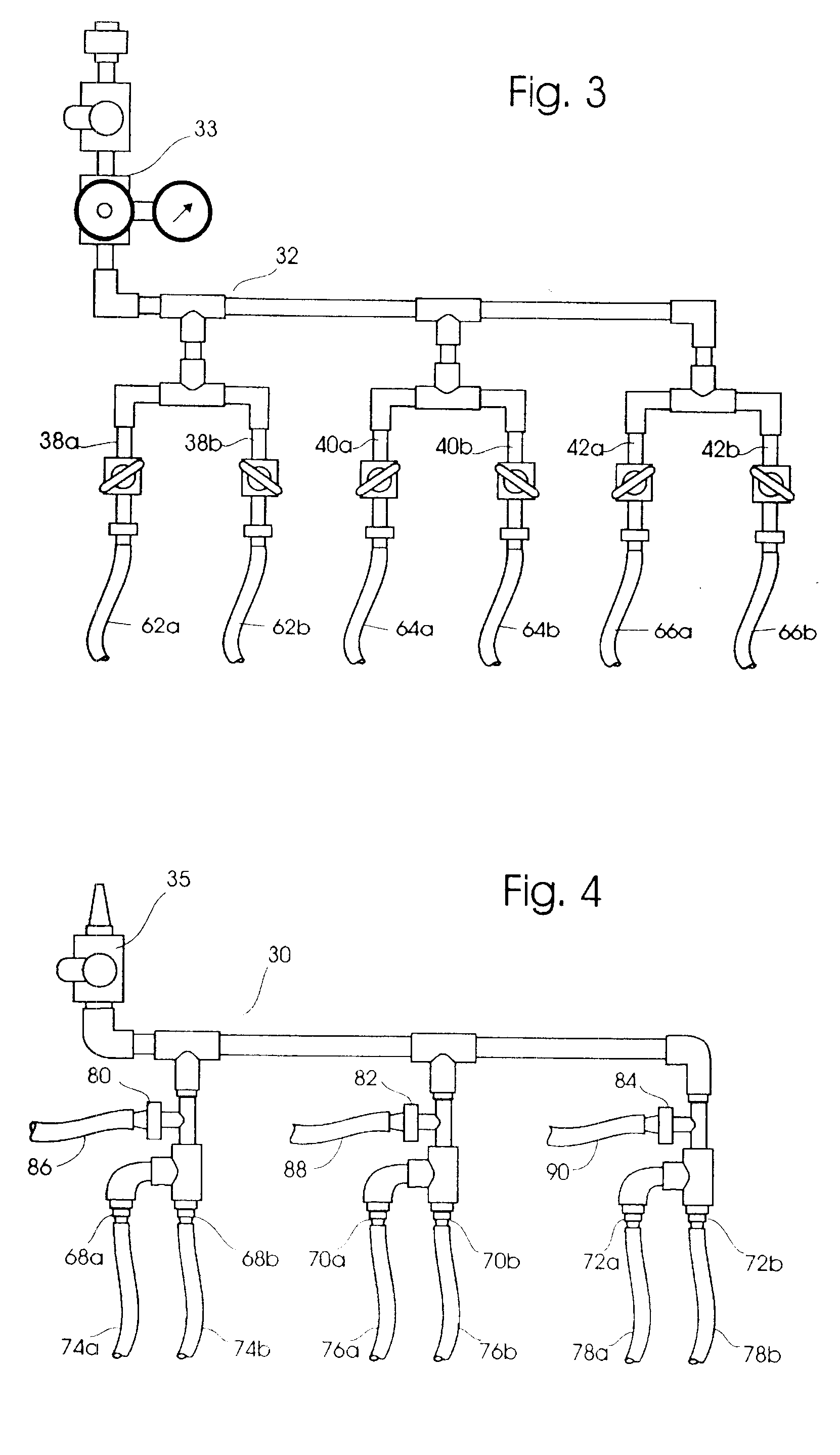

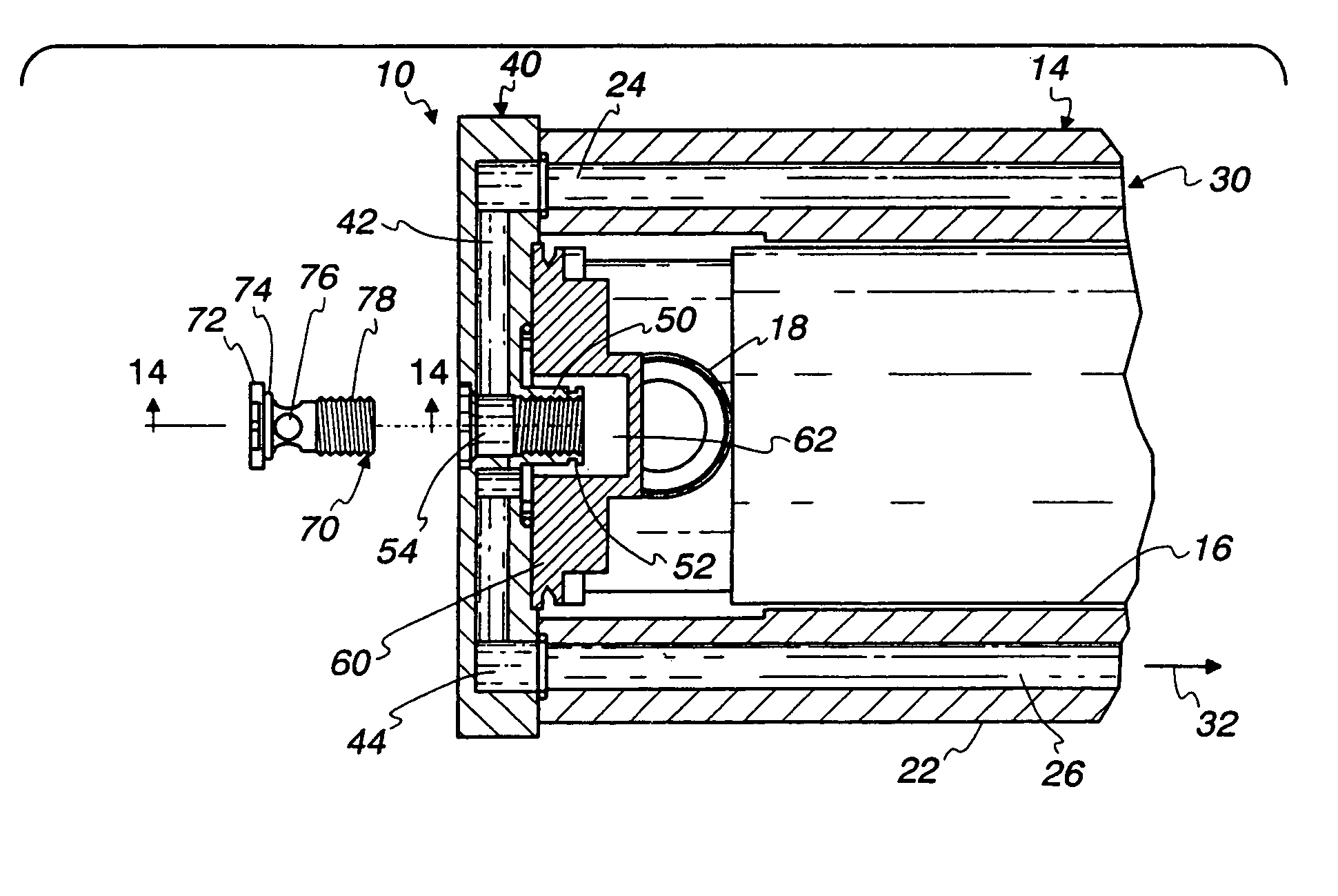

Foam apparatus for use with roll-over and/or automatic type car wash

InactiveUSRE37830E1Maximize solution coverageEasy visual inspectionLiquid surface applicatorsMovable spraying apparatusEngineeringBuffer zone

The present invention is directed to a manifold which includes a foam generating zone having means for receiving a foamable solution and air therethrough to produce a foam, a streaming discharge zone wherein the streaming discharge zone includes a first plurality of aperture surfaces of a first diameter and a second plurality of aperture surfaces of a second diameter larger than said first diameter and a buffer zone operably communicably associated with the foam generating zone and streaming discharge zone with means for impeding flow of the foam therebetween.

Owner:CHASE STEVEN ANDREW

Removable filter holder and method

ActiveUS7203282B2Easily reattachedSimple and clear operationX-ray tube electrodesMembrane filtersHigh energyX-ray

A cooling system is provided for high energy emitting devices such as employed in X-ray diffraction testing equipment. The cooling system includes a removable filter holder that carries a filter for being disposed in a cooling path formed in the X-ray head assembly with the holder including a detachable connection to the head. The removable holder allows for servicing of the filter without requiring significant disassembly operations on the X-ray head assembly. In the preferred form, the holder has a screw-type configuration and the detachable connection is a threaded connection to a cooling head portion of the X-ray head assembly.

Owner:PROTO MANUFACTURING LTD

Electrical connection box

InactiveUS20050020106A1Delay in inspectionEasy to operatePrinted circuitsEmergency protective devicesElectrical connectionJunction box

An electrical connection box has a configuration in which fuse sections of bus bars integrated with fusible links housed in parallel alignment can be visually inspected with ease. The bus bars are positioned with space therebetween so that a bus bar closest to a peripheral wall of the case is placed at a lowest position and that the inner bus bars are placed at higher positions. A cut-out section is provided on an upper edge of a peripheral wall of the case so that the position of the cut-out section opposes the fuse sections of the bus bar at the lowest position.

Owner:SUMITOMO WIRING SYST LTD

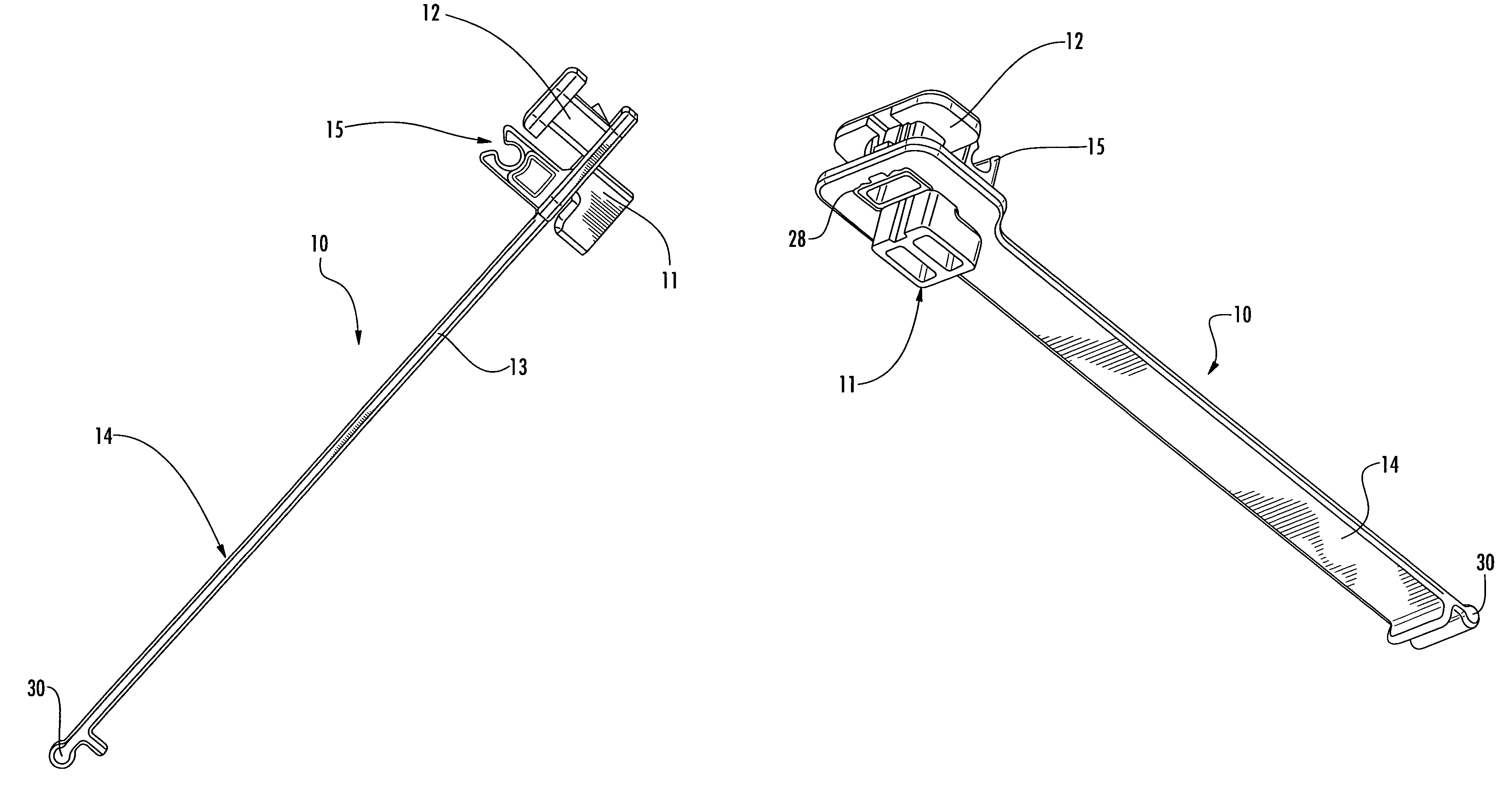

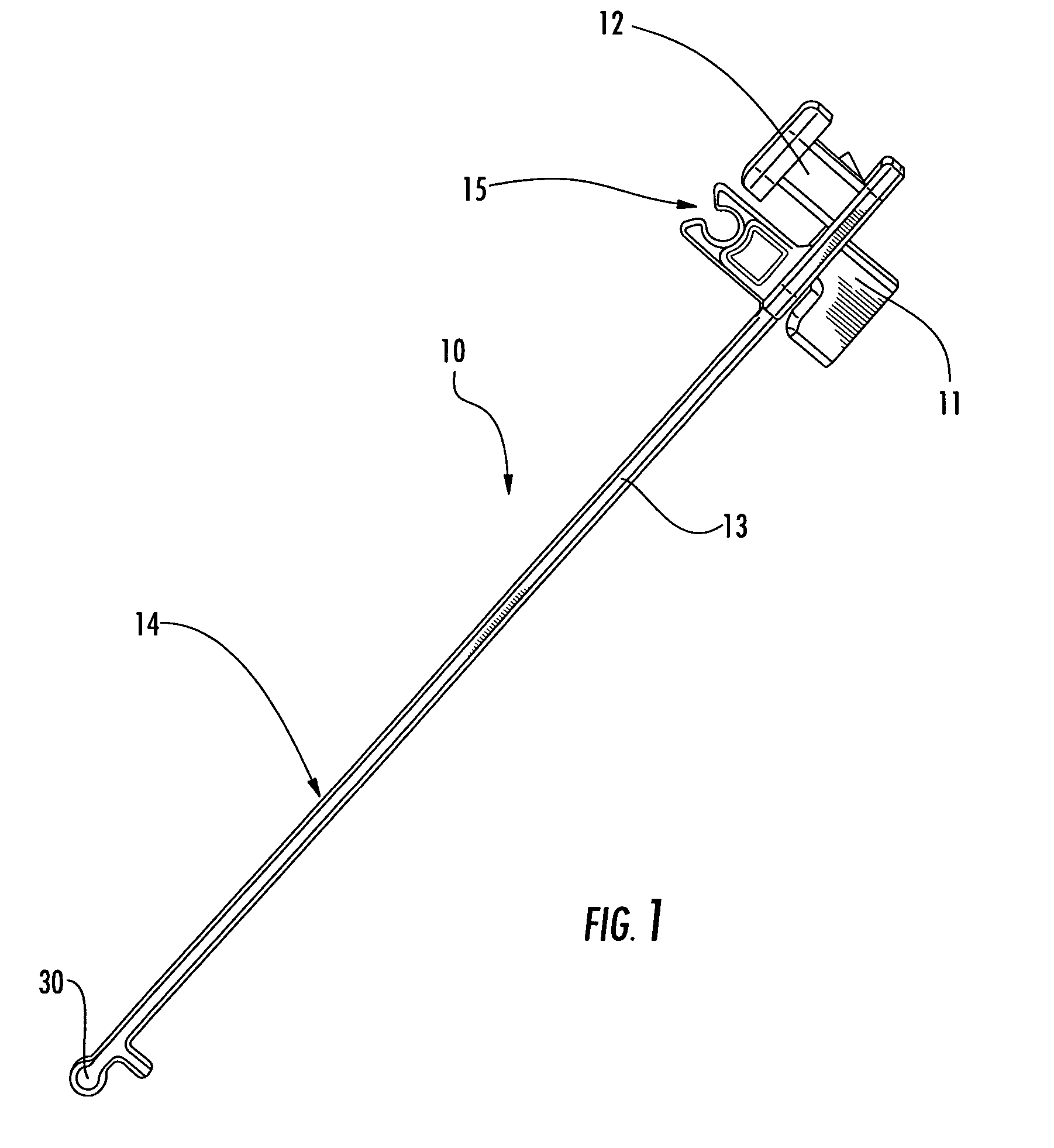

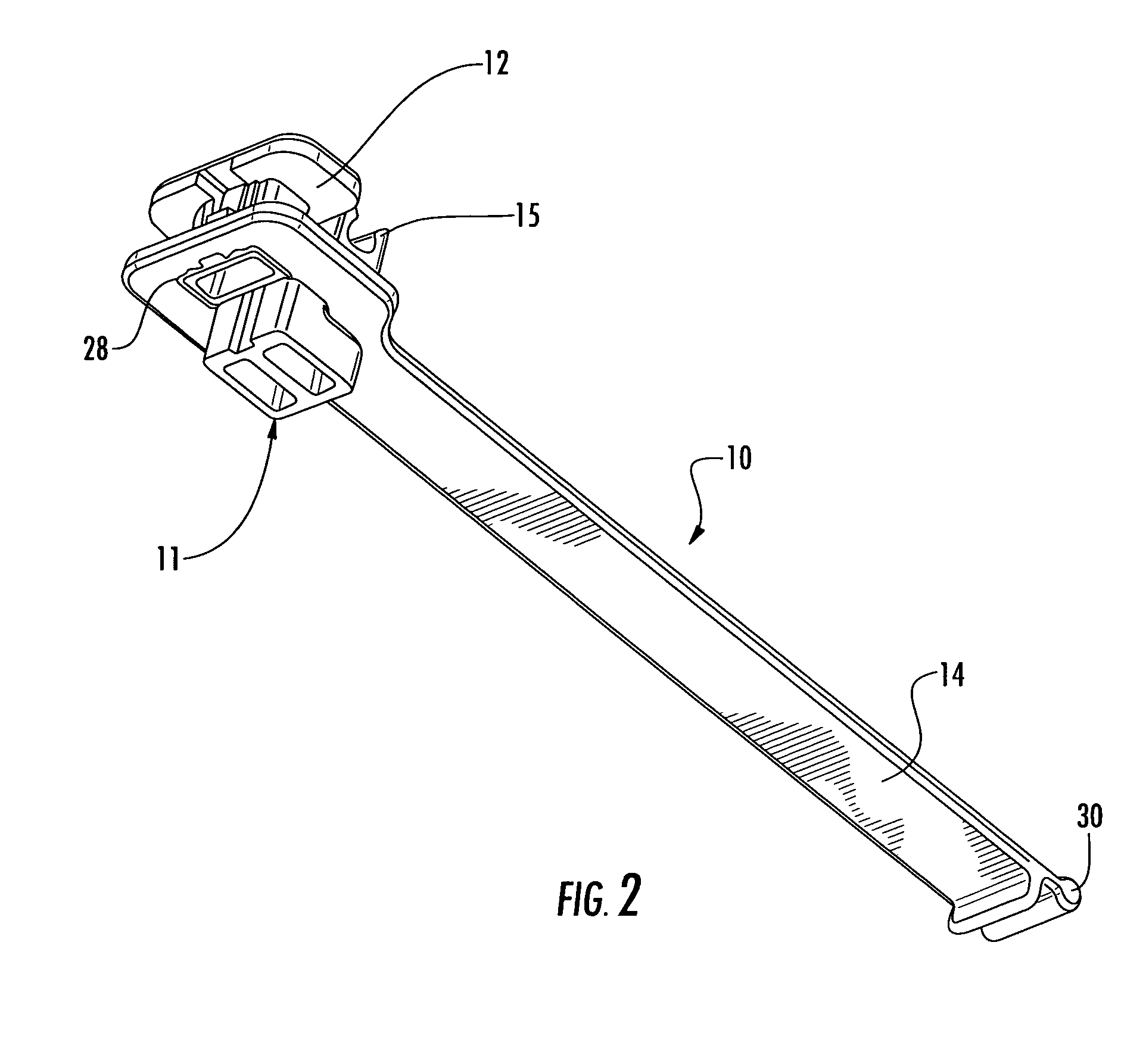

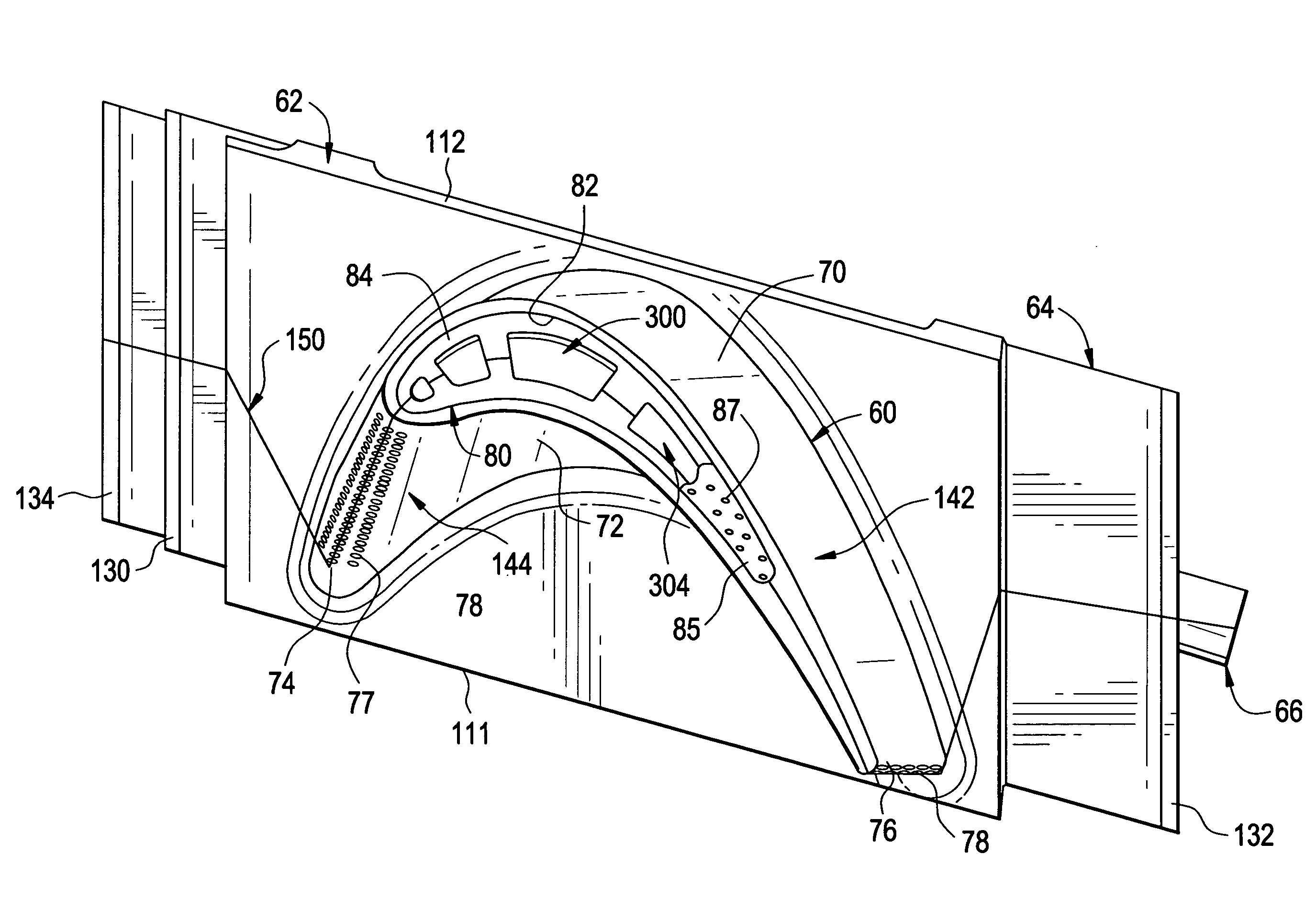

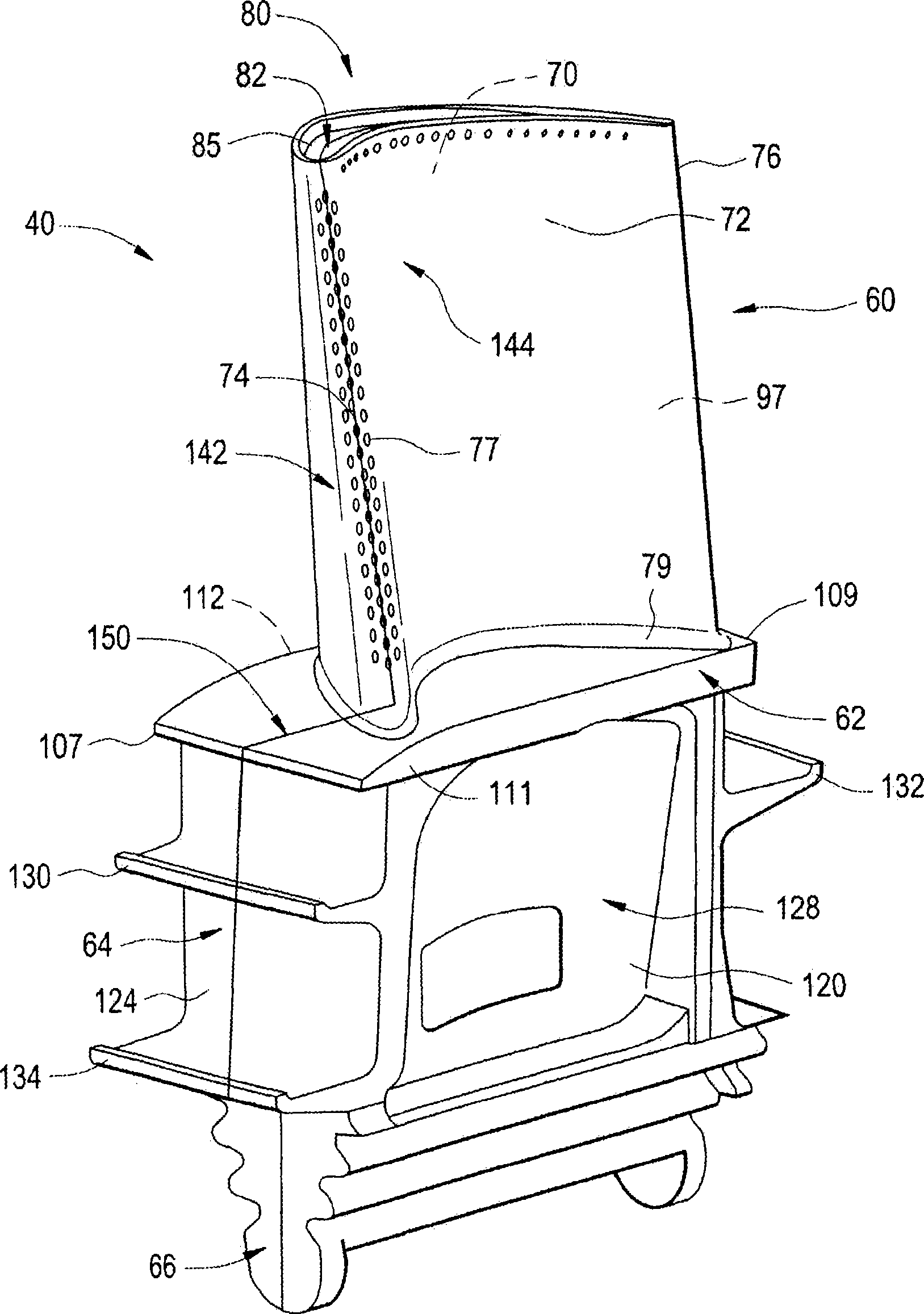

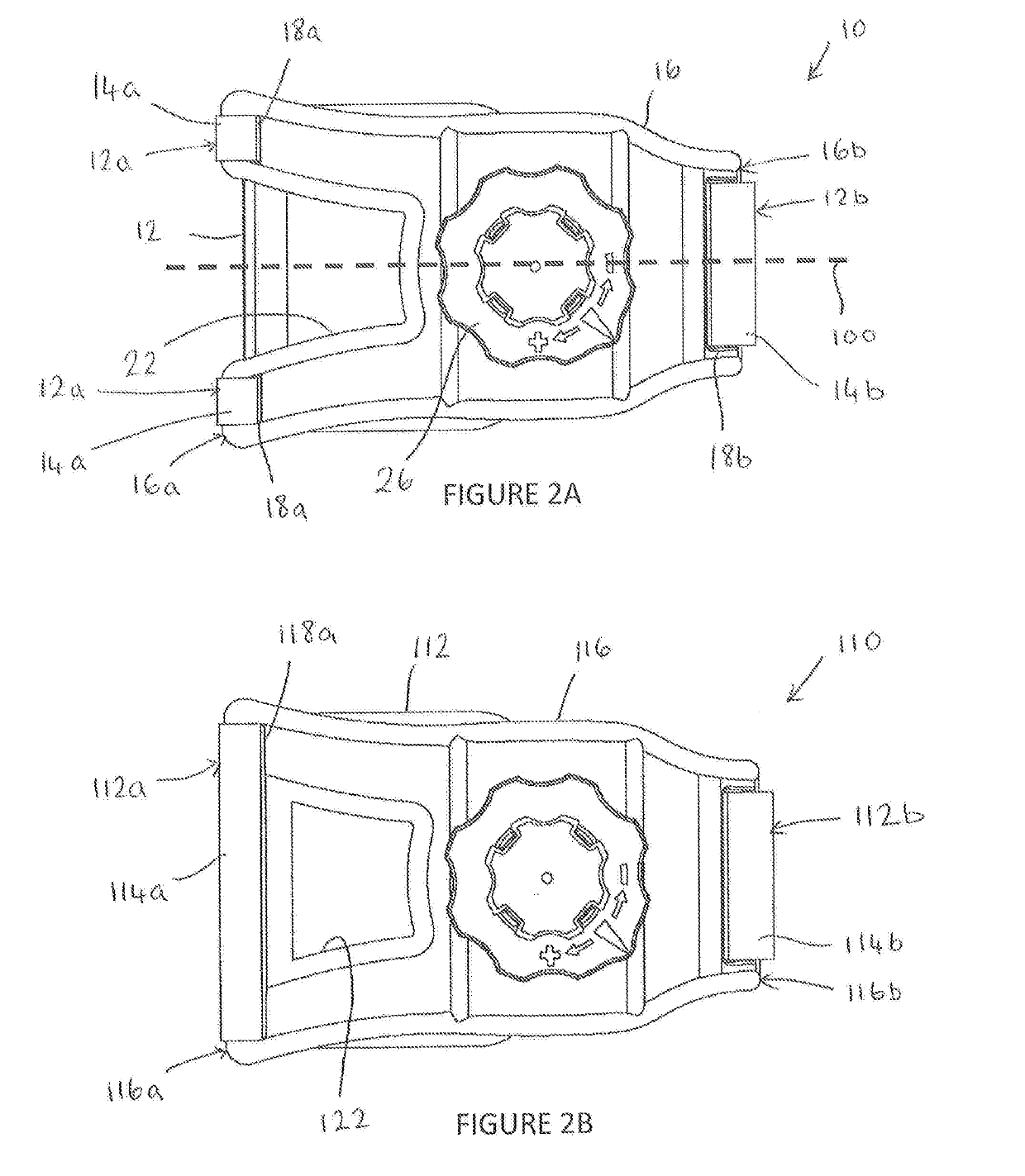

Arterial compression device and methods of using the same

ActiveUS20190090886A1Easy visual inspectionEase of evaluationCatheterDiagnostic recording/measuringWristCompression device

Owner:CORMED LTD

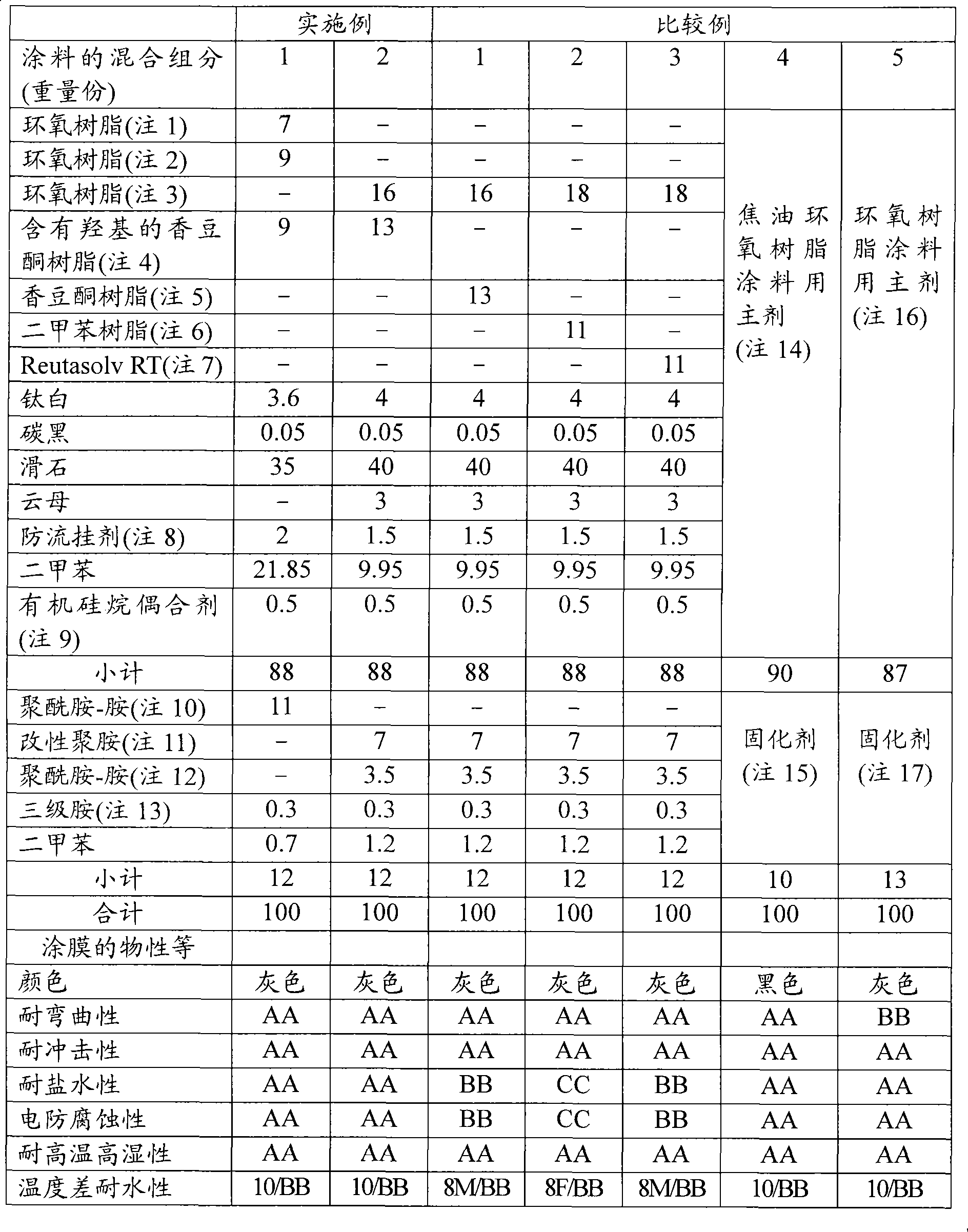

Anticorrosive coating composition

InactiveCN101443425AGood compatibilityImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyTar

An anticorrosive coating composition comprising (A) an epoxy resin, (B) an amine-type curing agent, and (C) a hydroxyl-containing coumarone resin, characterized in that the coumarone resin (C) is contained in an amount of 1 to 500 parts by weight per 100 parts by weight of the epoxy resin (A). The coumarone resin (C) is preferably one which contains hydroxyl in an amount of 1 to 5% in one molecule and has a softening point of 200 DEG C or below. The coating composition can give coating films in which the plural resin components are homogeneously mixed and which are excellent in anticorrosion property, water resistance, and adhesion. Further, since the composition is free from tar unlike conventional anticorrosive coating compositions, it can give light-colored cured coating films free from bleed-out of any component and is clear of the problems of safety and hygiene in application.

Owner:CHUGOKU MARINE PAINTS

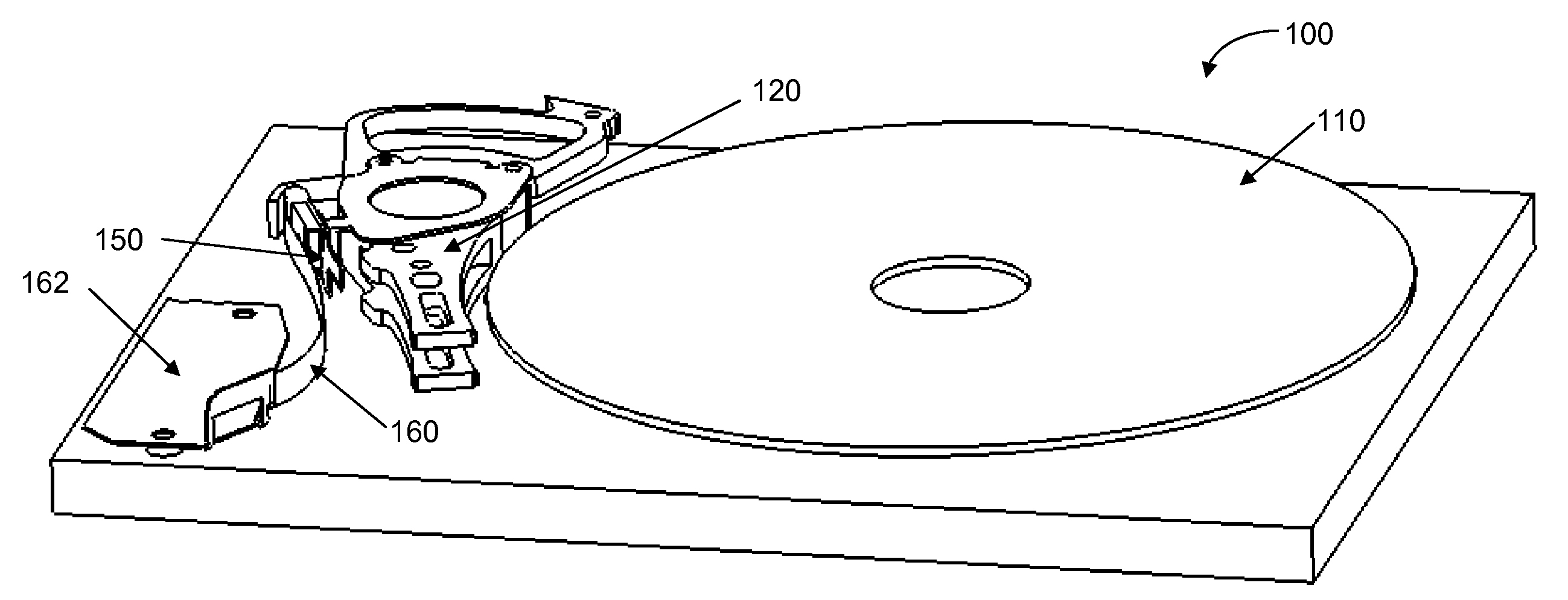

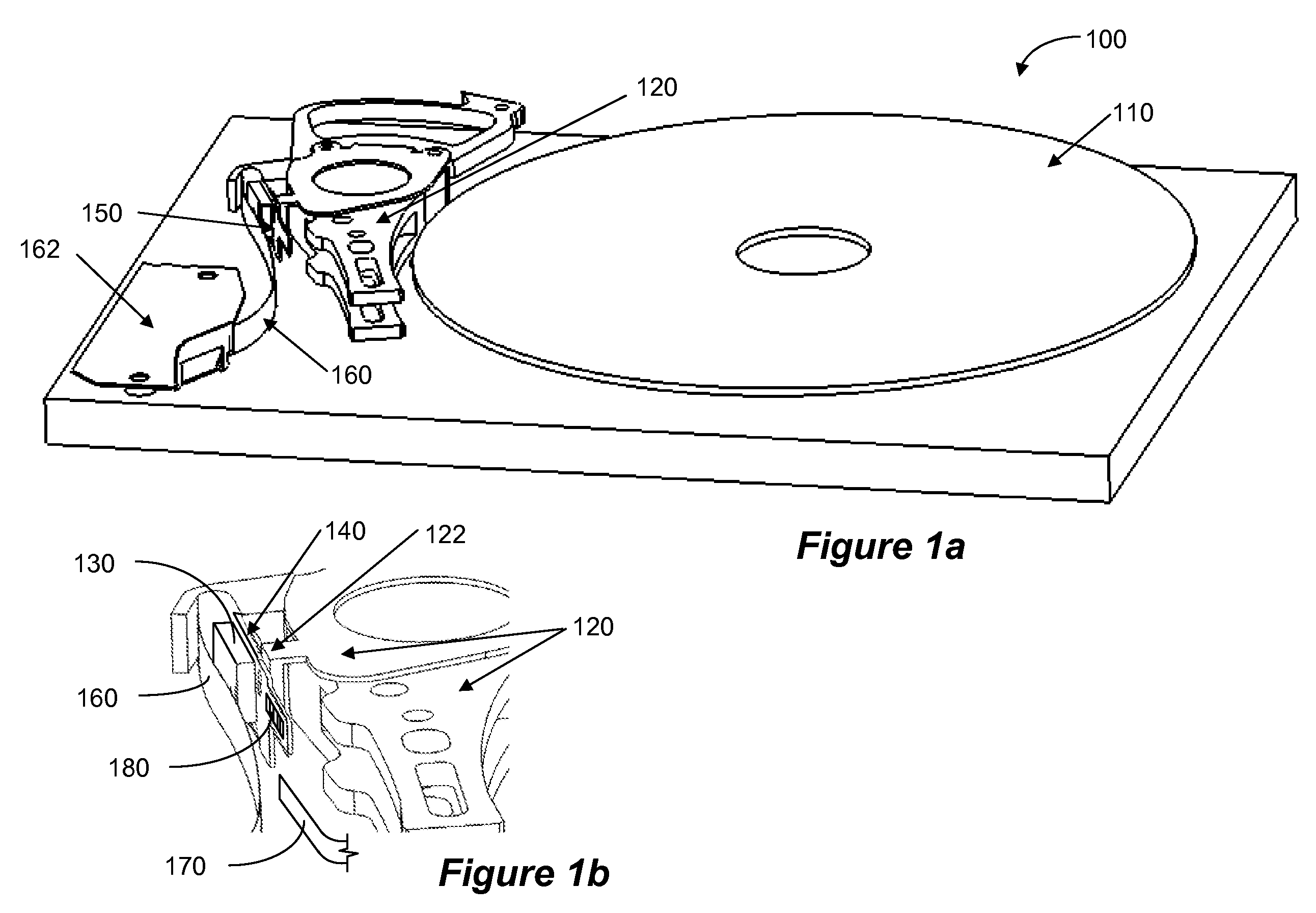

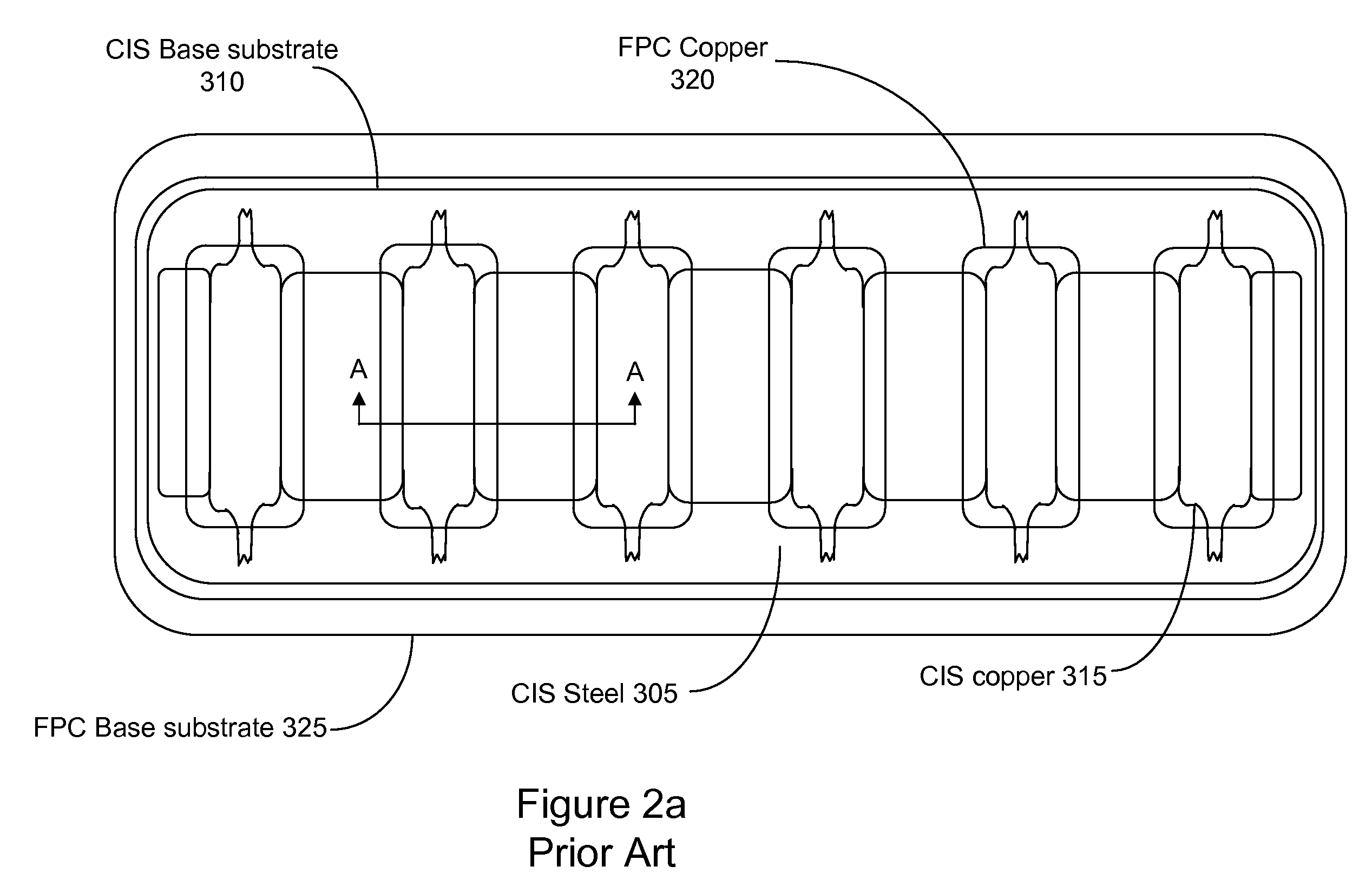

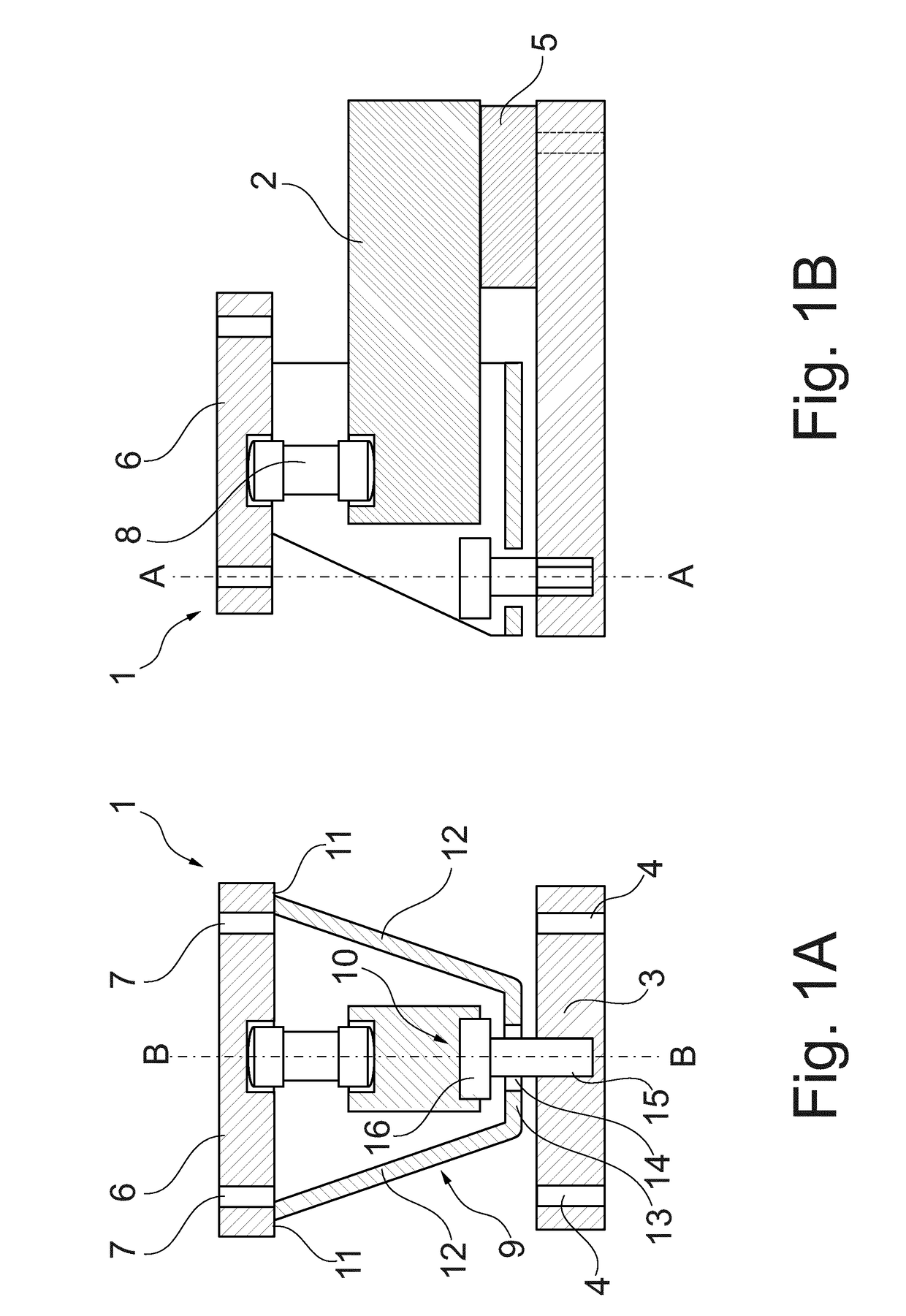

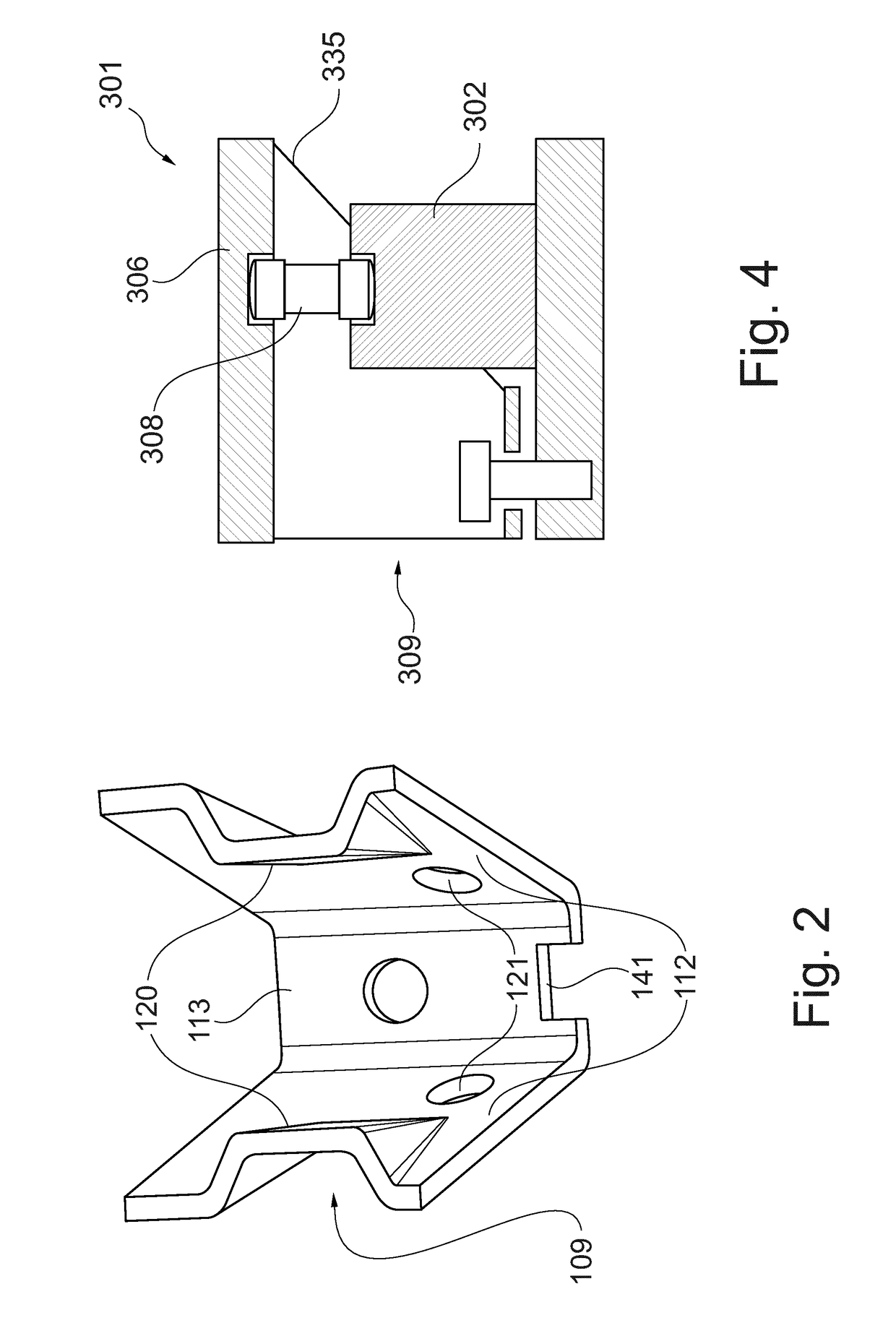

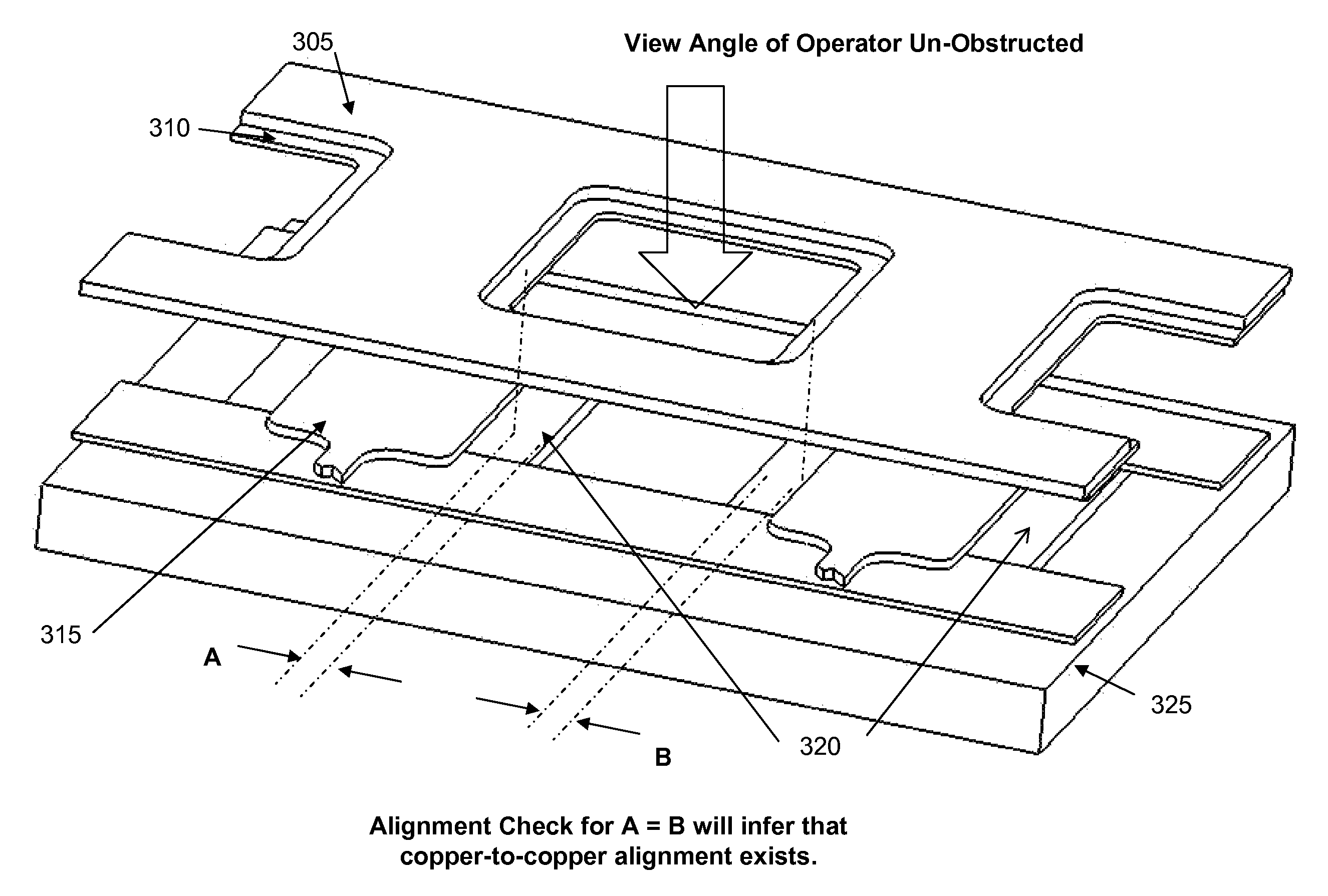

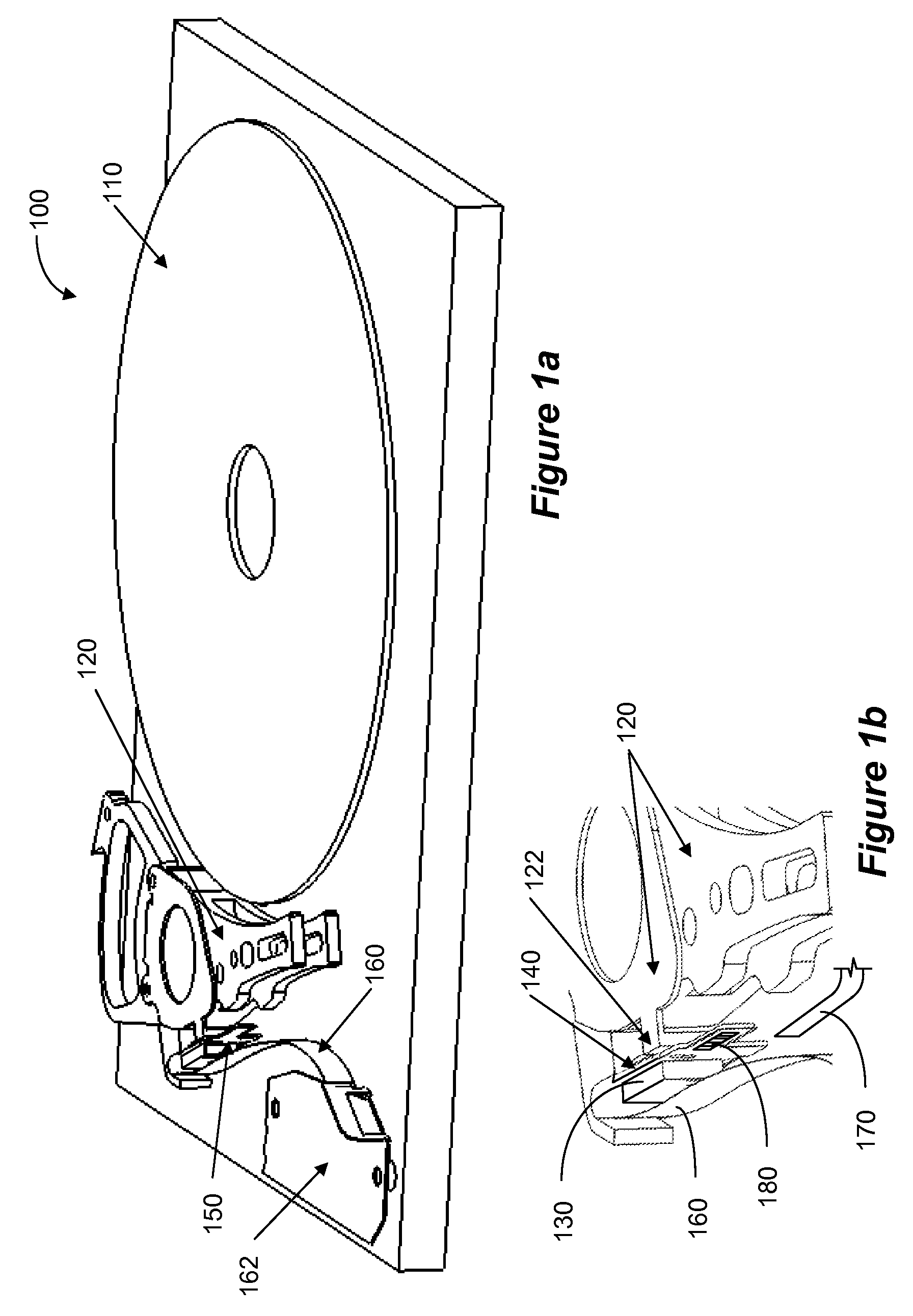

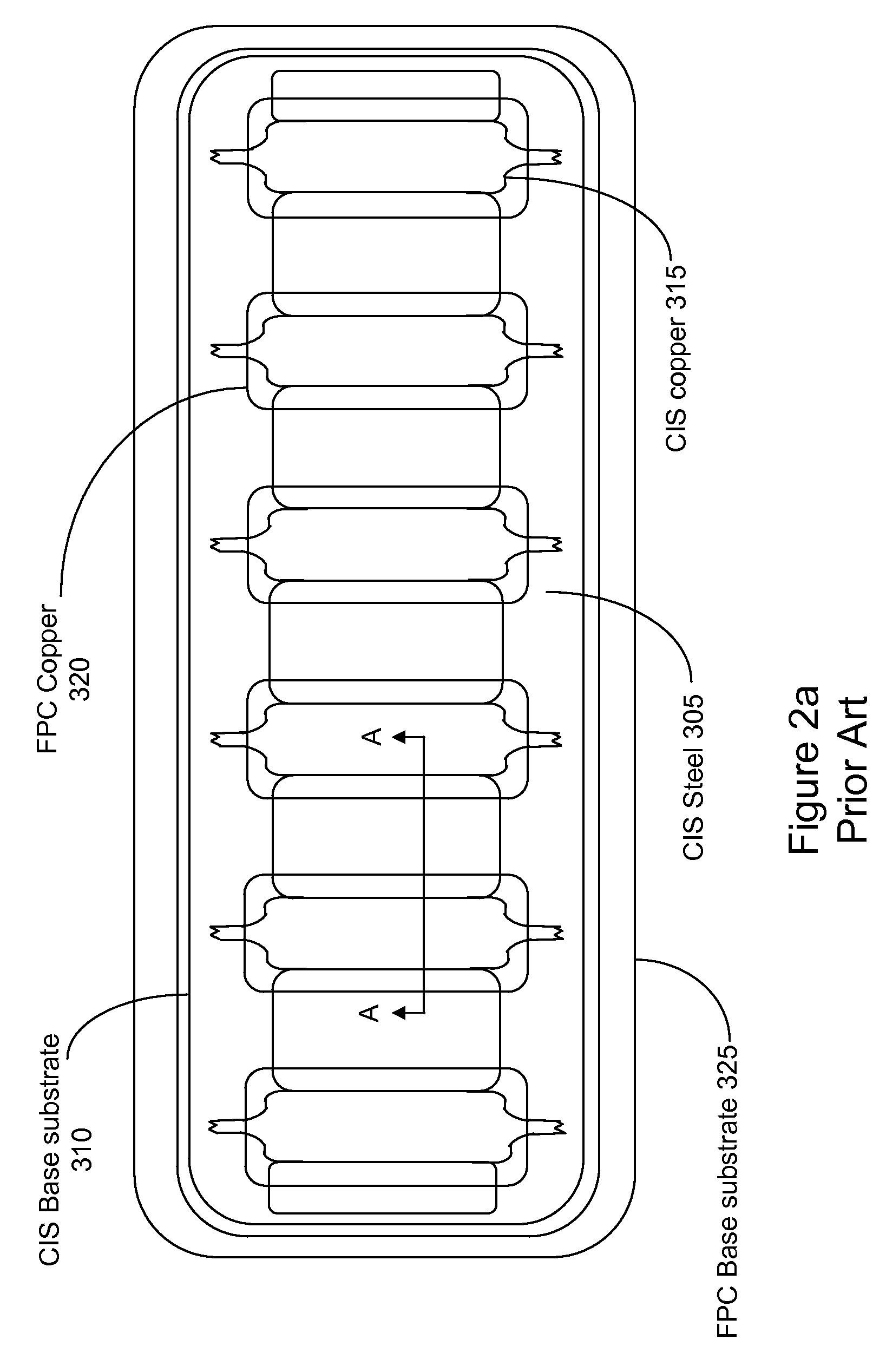

Method for mating flexure to flex-print circuit and flexure therefor

ActiveUS20080099236A1Easy visual inspectionEasy to checkContact member assembly/disassemblyIncorrect coupling preventionHard disc driveVisual inspection

Inspection windows are cut or formed into the tail section of the flexure circuit tail in a hard disk drive Head Gimbal Assembly (HGA), or CIS, to enable visual inspection of the alignment of the CIS to the head preamp circuit, or FPC. The holes are made in the steel backing and base polyimide, and are positioned between adjacent conductive pads. In addition to facilitating visual inspection, the windows also enable rework of solder. Additionally, solder wicking holes may also be provided in the conductive pads and / or the polyimide and steel backing.

Owner:NITTO DENKO CORP

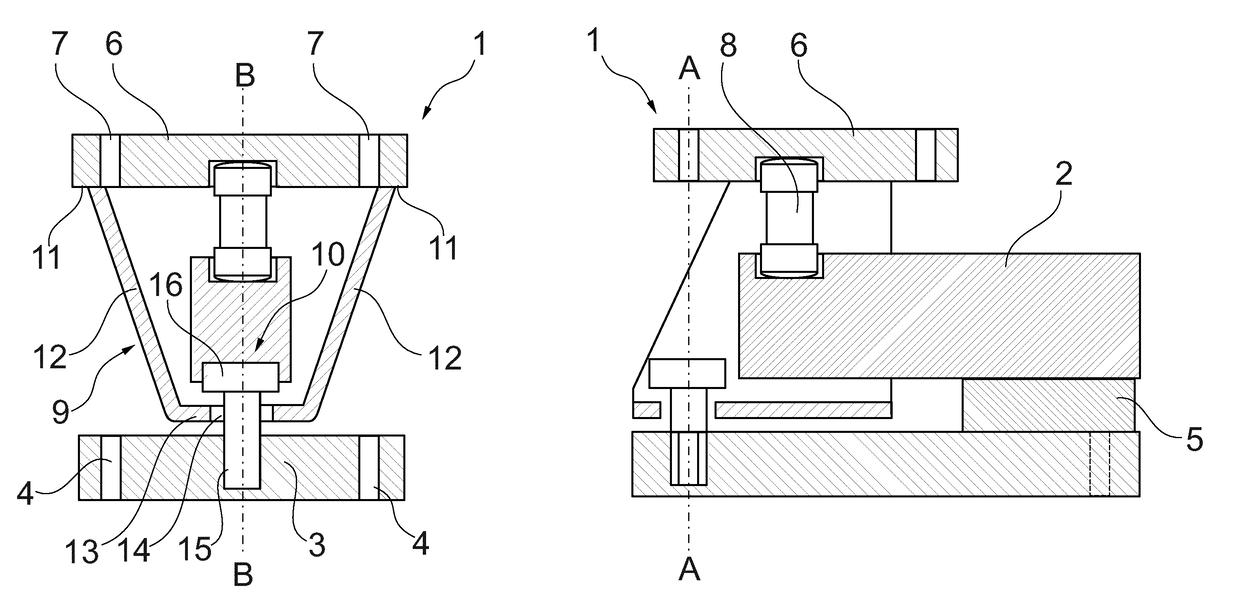

Load cell weigh module hat limits horizontal floating movement of the top plate

ActiveUS9612150B2Easy visual inspectionReduce accumulationWeighing relieving/arrestment mechanismsEngineeringLoad cell

A weigh module (1) includes a load cell (2), a base plate (3), a top plate (6), a force-transmitting member (8) serving to transmit the weighing force from the top plate (6) to the load cell (2), and movement-restricting means (9, 10) which serve to limit the horizontal floating movement of the top plate (6) relative to the base plate (3) within a confined range of free play and to transmit lateral force components directly from the top plate (6) to the base plate (3). One part of the movement-restricting means (9, 10) has the form of a channel whose top edges (11) are rigidly connected to the top plate (6) and whose flat bottom extends parallel to the base plate (3) at a clear distance from the latter. The other part of the movement-restricting means (9, 10) is a bolt whose shaft (15) is anchored in the base plate (3) and passes with all-around clearance through a passage (14) in the channel bottom (13), and whose head (16) is larger than the passage (14) and arranged above the channel bottom (13) with a vertical clearance gap from the latter.

Owner:METTLER TOLEDO GMBH

Method for mating flexure to flex-print circuit and flexure therefor

ActiveUS8173909B2Easy visual inspectionFacilitate visual inspection and reworkContact member assembly/disassemblyPrinted circuit aspectsHard disc driveAudio power amplifier

Owner:NITTO DENKO CORP

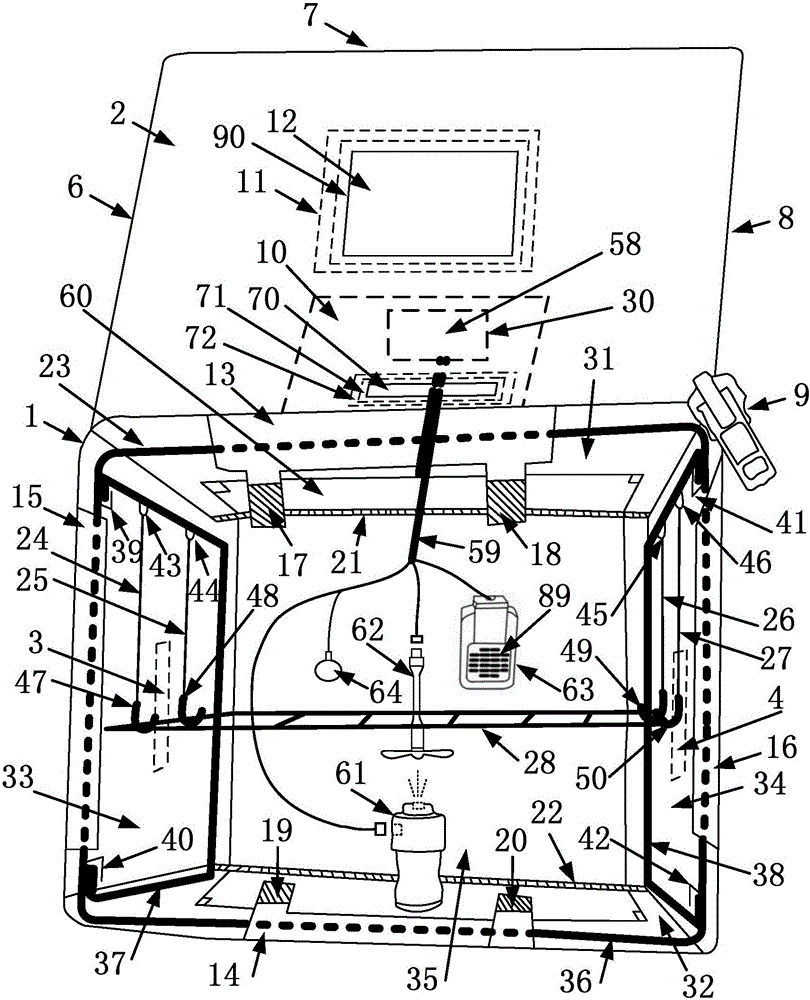

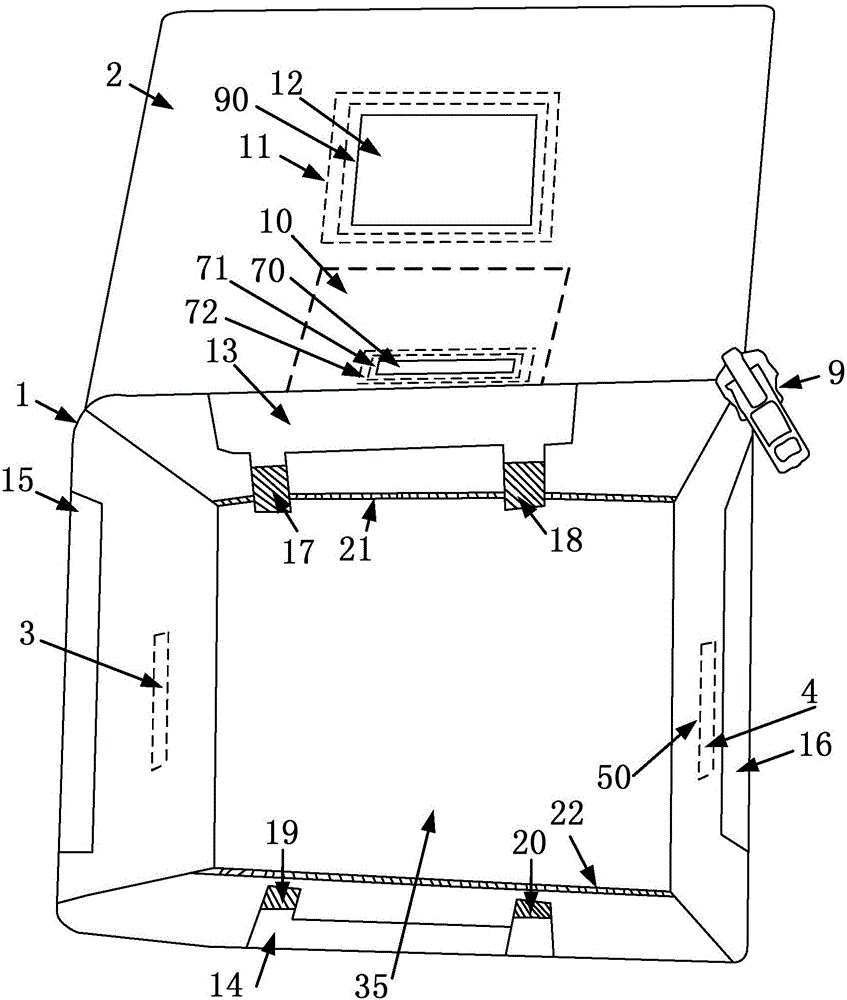

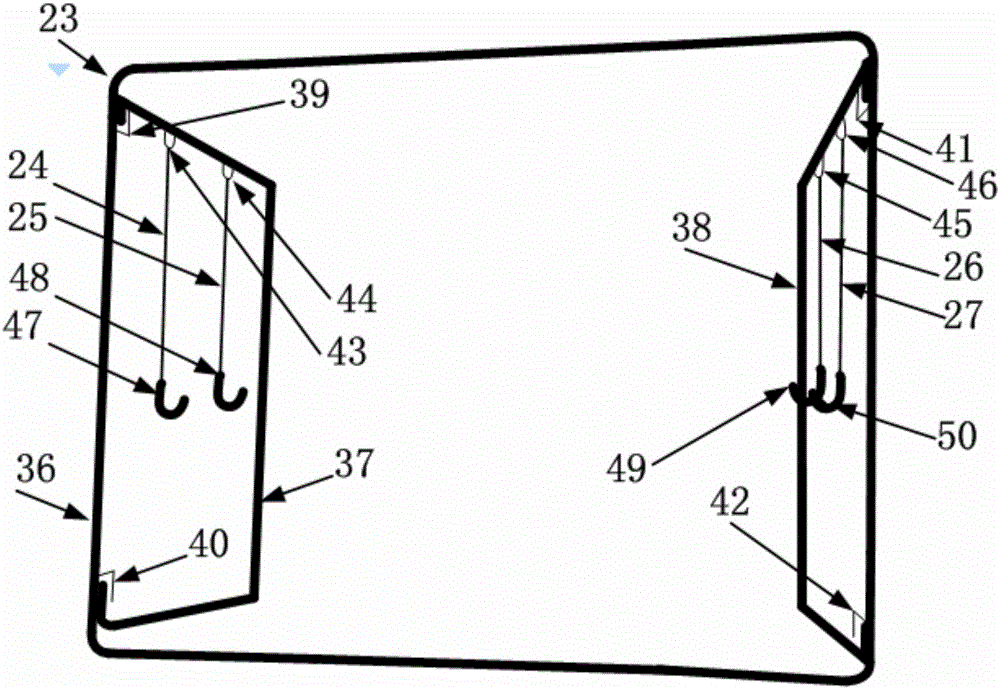

Multifunctional household bread fermentation tank

InactiveCN105660763AReal temperatureReal humidityBread-toastersProversNetwork communicationEngineering

The invention discloses a multifunctional domestic bread fermentation box, which comprises a box body, a box cover, a fixed through pipe, a support frame, a hook, a compartment frame, a fixed ribbon and a control assembly, and the control assembly is controlled by an input power supply, a device, output connection harness, heating device, humidifier, fan, temperature and humidity probe, and lighting lamp. The control assembly is self-contained and can be separated from the box and stored separately. The bread fermentation box provided by the present invention has a built-in Ultrasonic humidifier, fan, large-area heating device and temperature and humidity probe make the temperature and humidity distribution in the box more uniform, and make the temperature and humidity data detected by the controller more real in the box. The bread fermentation box has network communication, Foldable, easy to assemble and disassemble, easy to maintain, evenly heated and humidified, light in weight, easy to observe and economical and practical.

Owner:马发财

Flow through pressure regulator with pinch valve

ActiveUS20050263188A1Control flowAvoid easy cloggingDiaphragm valvesOperating means/releasing devices for valvesPinch valvePiston

A fluid pressure regulator includes a regulator housing having an inlet end and an outlet end; a flexible flow tube extending between the inlet end and the outlet end; a hollow piston located at a downstream location relative to a mid-portion of the flow tube in a direction of flow of fluid through the regulator housing; a first chamber above the piston and a second chamber below the piston; a passage establishing fluid communication between the outlet end and the first chamber; and at least one pinch arm pivotally mounted at one end within the regulator housing and movable in response to movement of the piston by an increase in fluid pressure in the first chamber so that an opposite end of the at least one pinch arm will pinch a portion of the flow tube and thereby restrict flow through the flow tube.

Owner:NELSON IRRIGATION

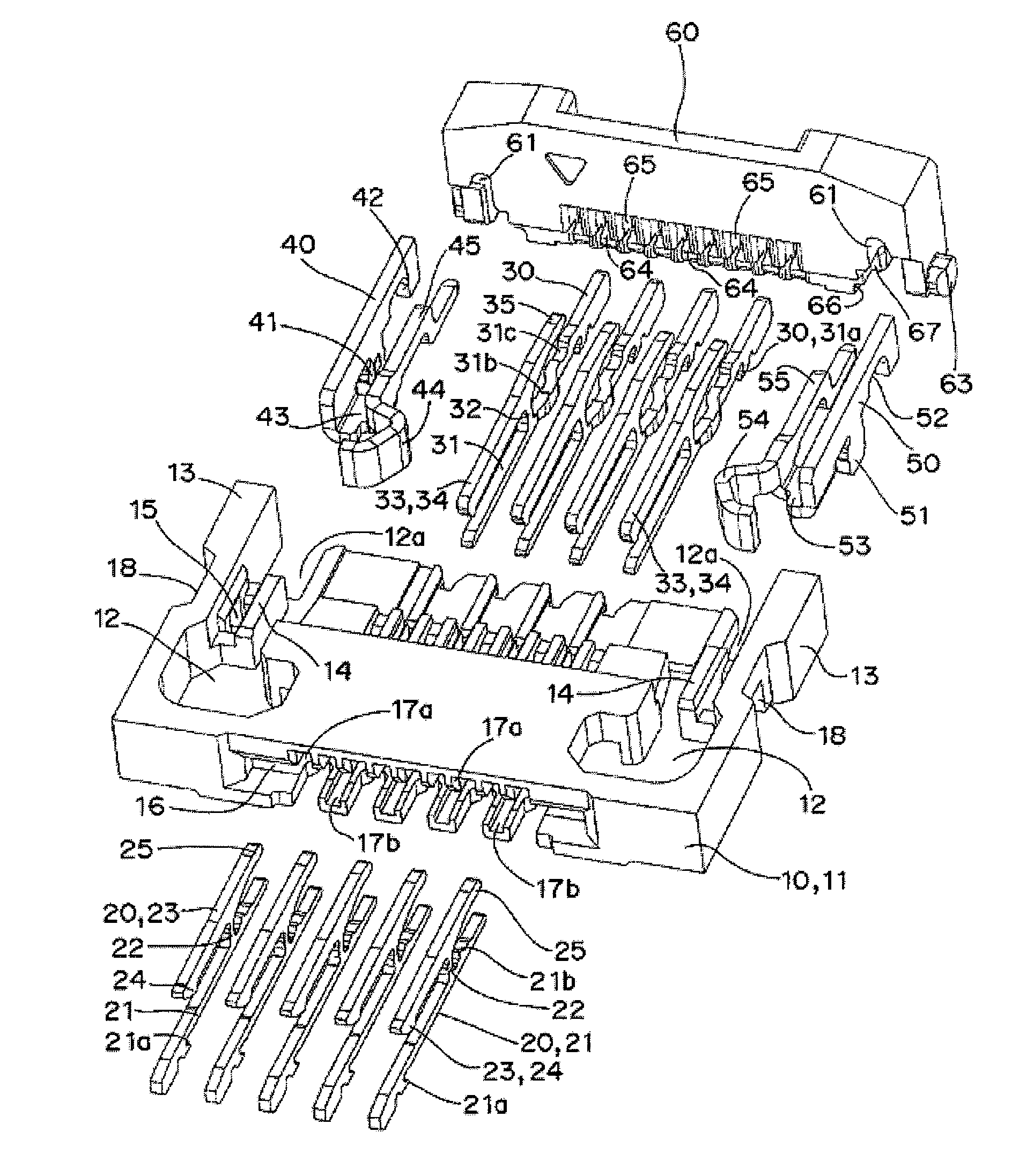

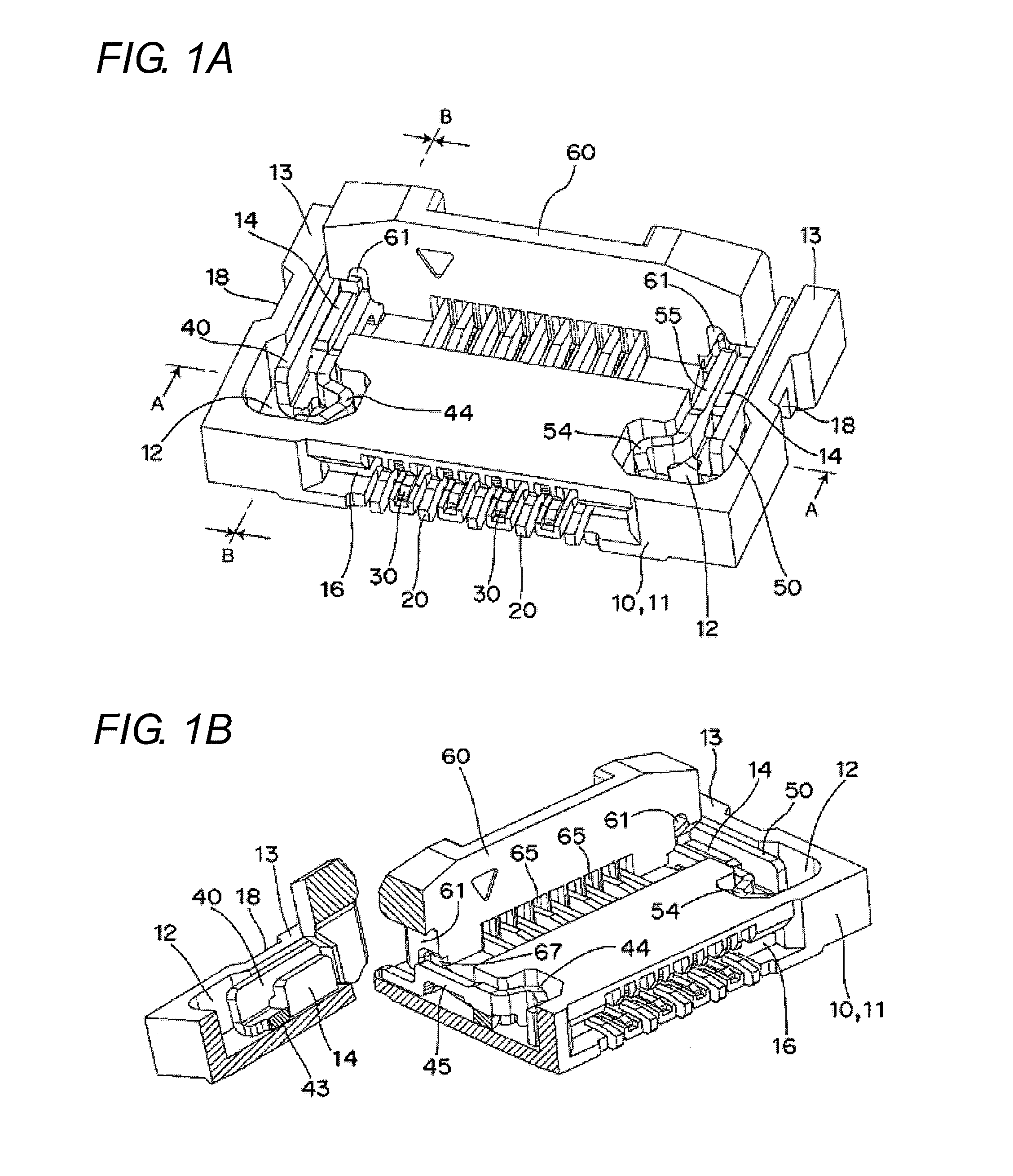

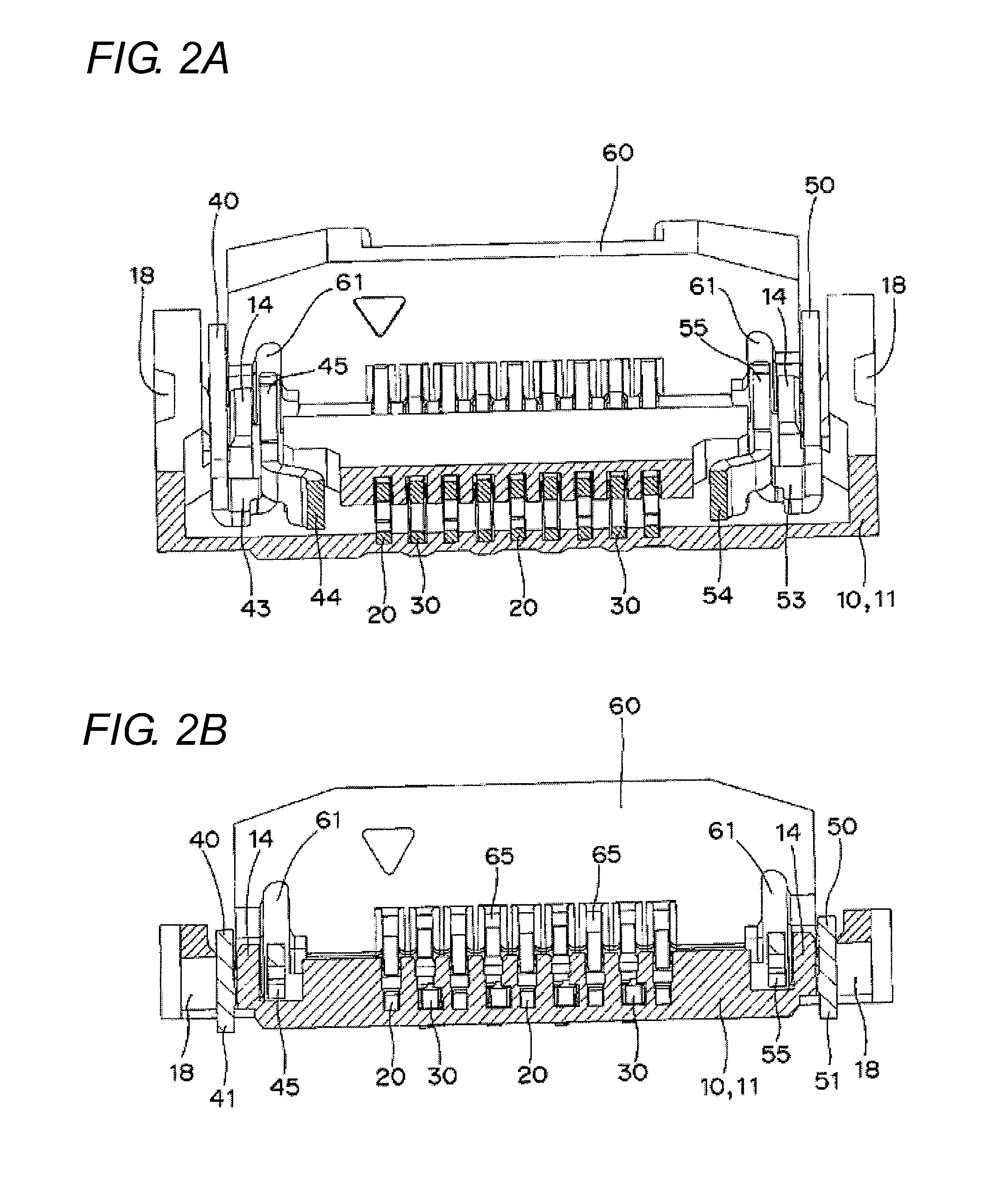

Connector

ActiveUS20110312202A1Easy to checkReliably preventing false connectionEngagement/disengagement of coupling partsCoupling contact membersEngineeringMechanical engineering

Owner:ORMON CORP

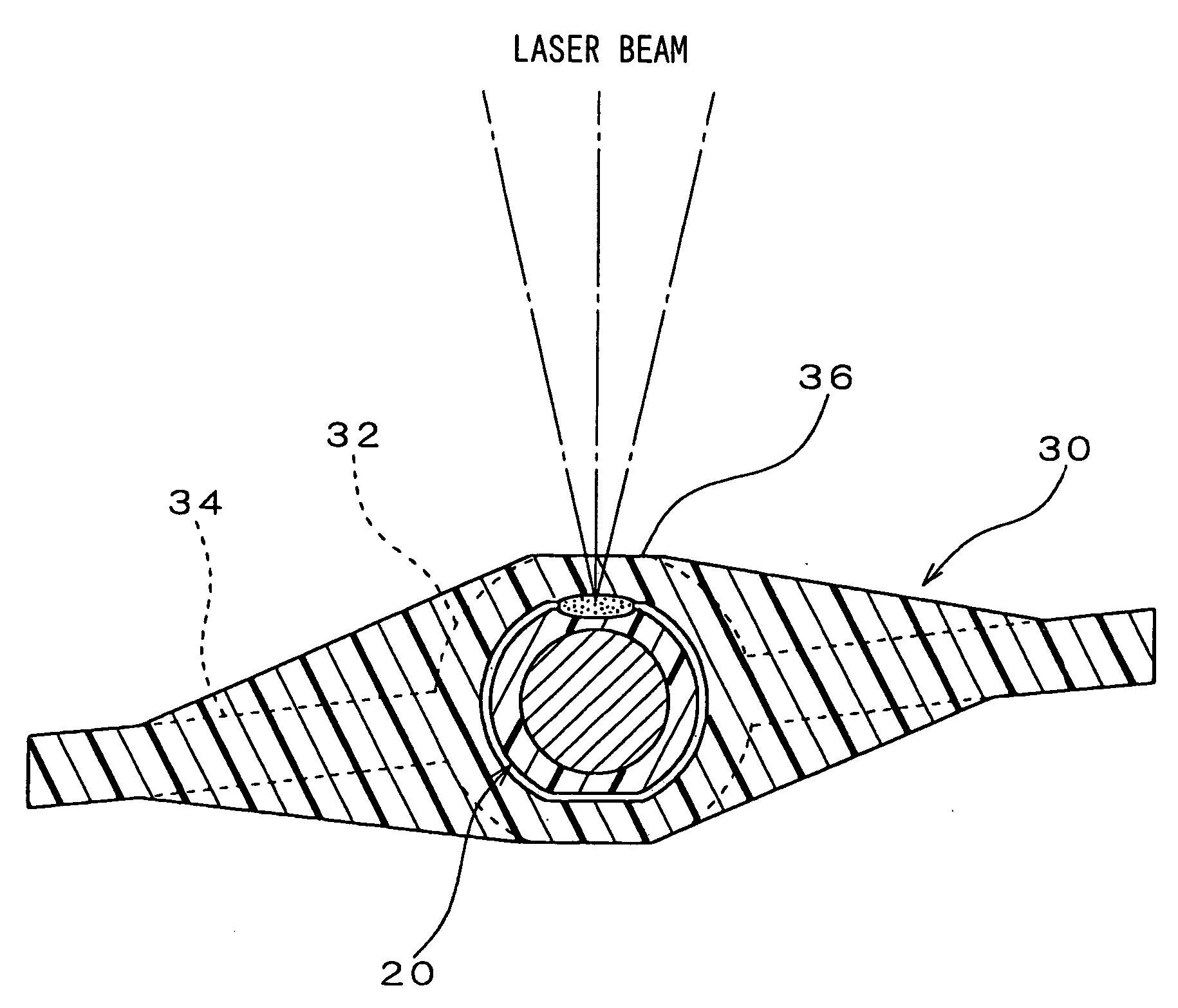

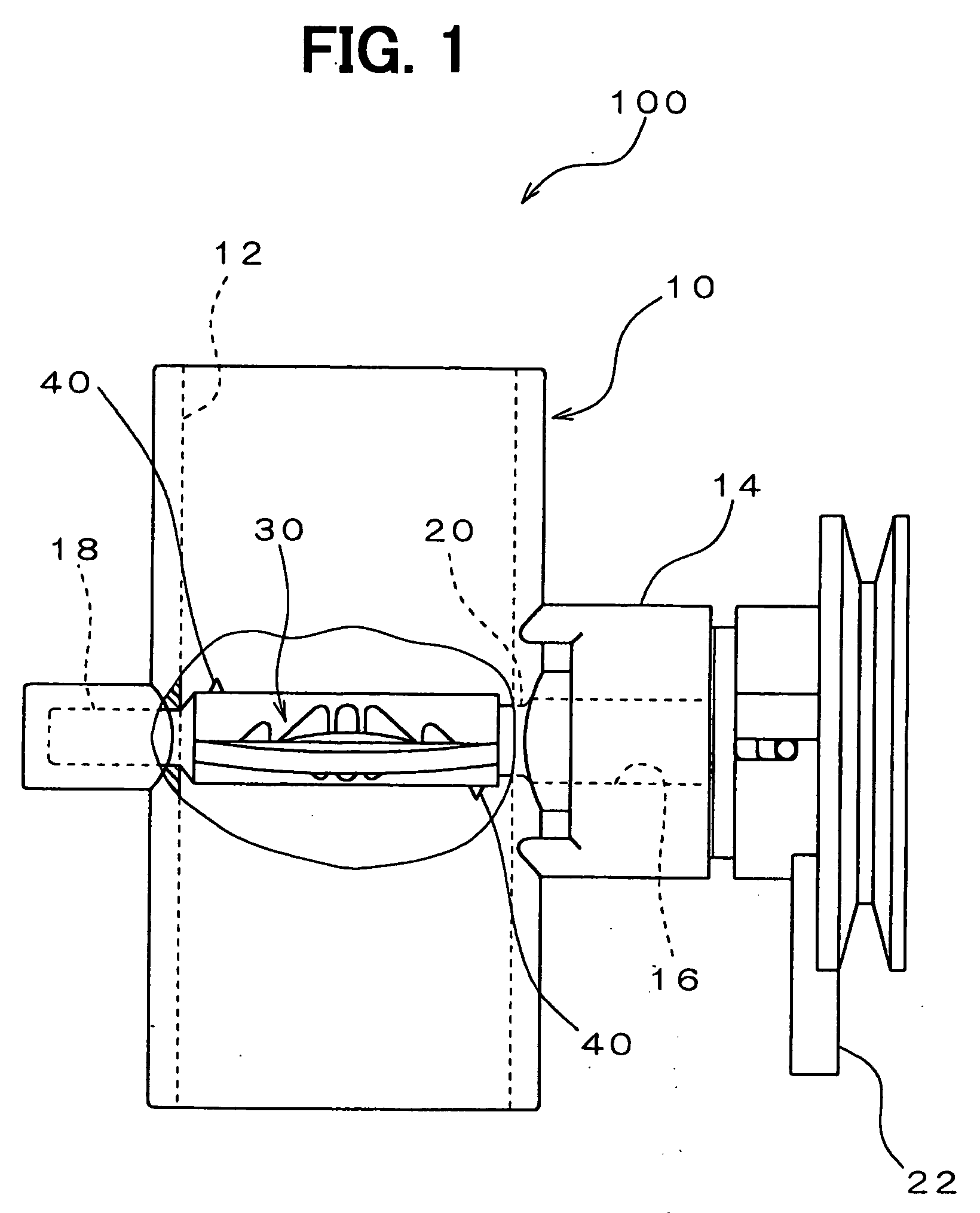

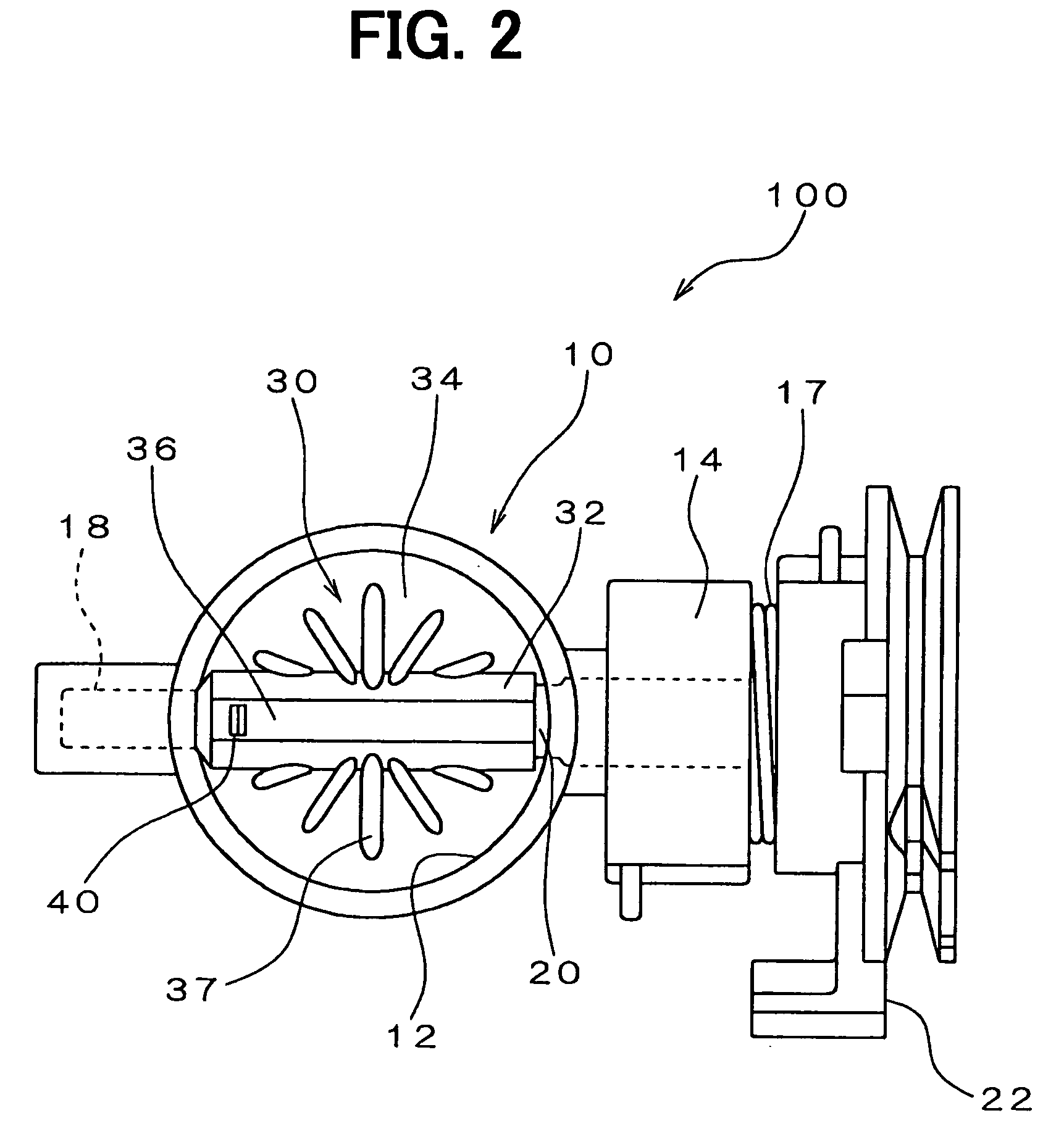

Laser welding method, laser welding structure, and throttle valve device

InactiveUS20050109971A1Increase temperatureReduce heating capacityEngine controllersMachines/enginesEngineeringLaser beams

A throttle valve and a throttle shaft are welded to each other. Here, the throttle valve is made of resin material having a transmission property for a laser beam and includes a convex portion on a surface thereof irradiated by the laser beam. By contrast, the throttle shaft is made of resin material having a absorption property for a laser beam. The throttle valve and the throttle shaft are disposed so that their mutual portions to be welded face each other. Laser beams are radiated from the surface of the throttle valve to the mutual portions to be welded so that the convex portion is included in a part of an irradiated region.

Owner:DENSO CORP

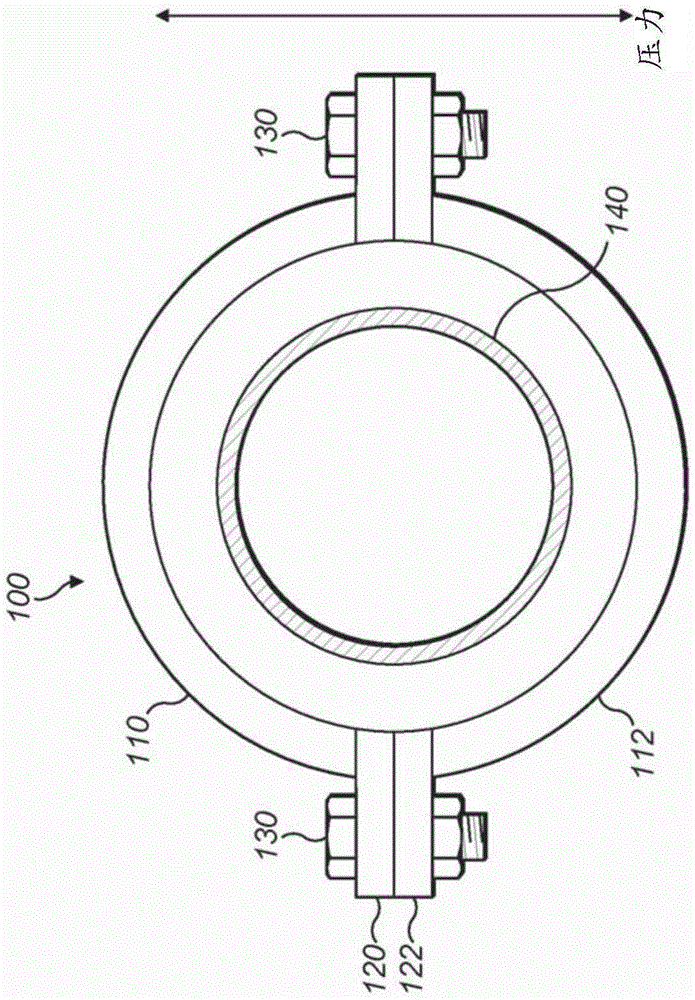

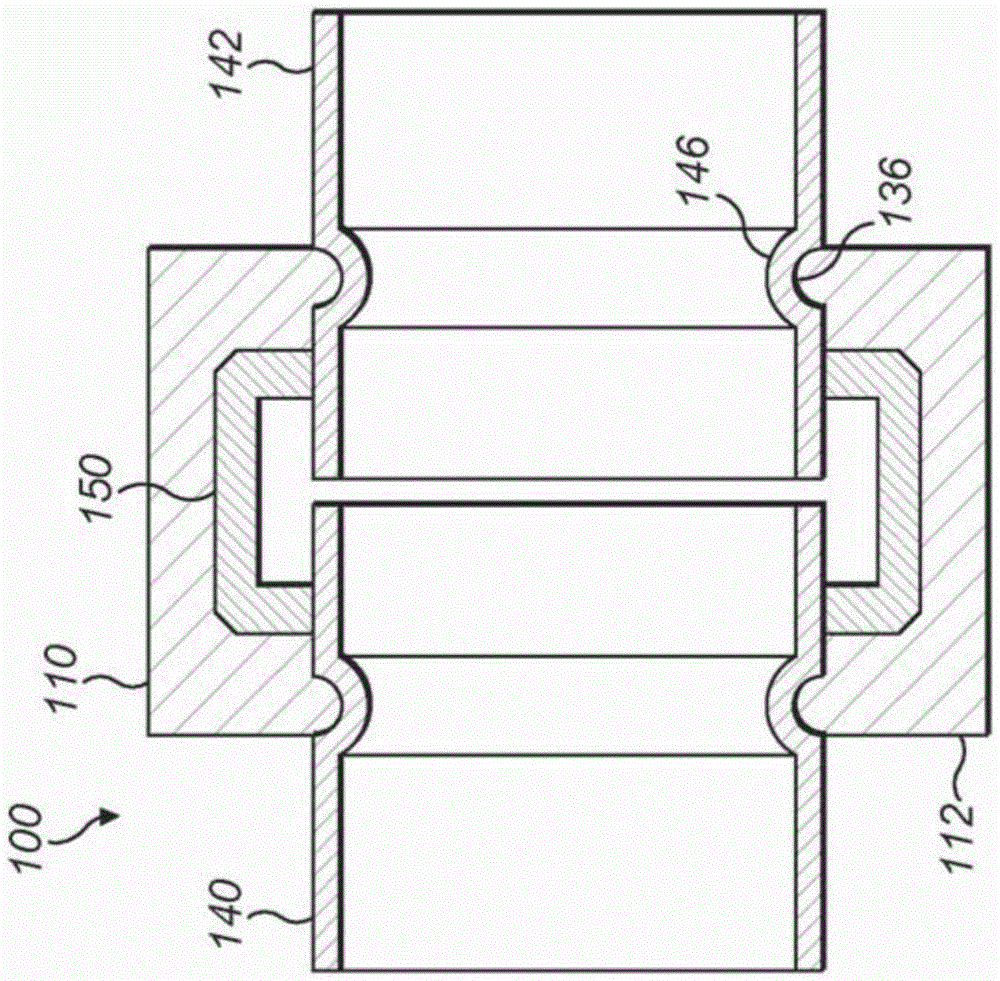

Improvements in and relating to pipe coupling

InactiveCN105431666AEasy visual inspectionSleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

Disclosed is a pipe coupling for connecting the ends of two tubular conduits, comprising: a pair of casing elements (200), each comprising an outer part (210) and a pair of inner parts (220), the inner and outer parts being rotatable relative to each other, wherein in a first configuration, the pair of casing elements (200) are separate and positionable to surround the ends of the tubular conduits and, in a second configuration, they are locked together, wherein the locking together is achieved by relative rotation of the respective inner (220) and outer (210) parts such that the inner parts (210) of one casing element (200) at least partially engage with the outer part (210) of the other casing element (200).

Owner:JCCO331

Pressure-sensitive adhesive sheet

InactiveUS20140037911A1Improve scratch resistanceResistant to increase in adhesive strengthLayered productsAcid polymer adhesivesWater dispersibleEmulsion

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com